Patents

Literature

37results about How to "Good antimagnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

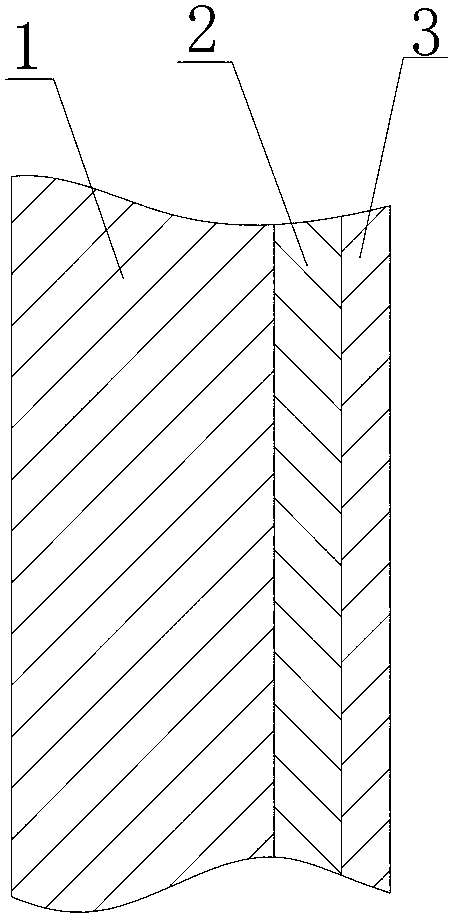

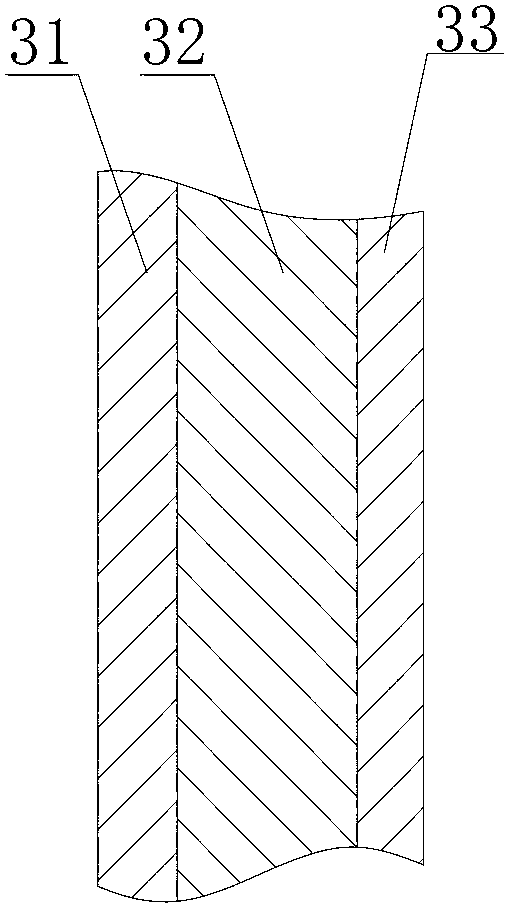

Bearing bush and process thereof for spraying MoS2 on alloy layer

ActiveCN103122937AGood bite resistanceReduce coefficient of frictionPretreated surfacesBearing componentsEnvironmental resistanceParylene

The invention provides a bearing bush and a process thereof for spraying MoS2 on an alloy layer for solving the problem that the alloy layer or the plated layer of the bearing bush peels off frequently. The bearing bush comprises a steel backing layer and the alloy layer fixedly arranged. The alloy layer is provided with a spraying layer fixed with the alloy layer. The alloy layer is one of an aluminum alloy layer or a copper-lead alloy. The spraying layer comprises a PI (Polyimide) resin layer, a MoS2 layer and a PAR (Parylene) lubricating coating sequentially arranged. The PI resin layer is contacted with the alloy layer. The bearing bush can effectively improve the dry grinding resistance, the anti-occlusion performance, the corrosion resistance and the wear resistance through the MoS2 layer by arranging the spraying layer on the alloy layer, the problem that the inner surface of the bearing bush in the installation and use process is scratched is solved, and the service lives of the bearing bush and lubricating oil in the bearing bush are prolonged. The bearing bush is good in practicality, and the whole manufacturing process of the bearing bush is safe and environment-friendly, so that the environmental pollution can be reduced.

Owner:YANTAI CHUNSHENG SLIDING BEARING

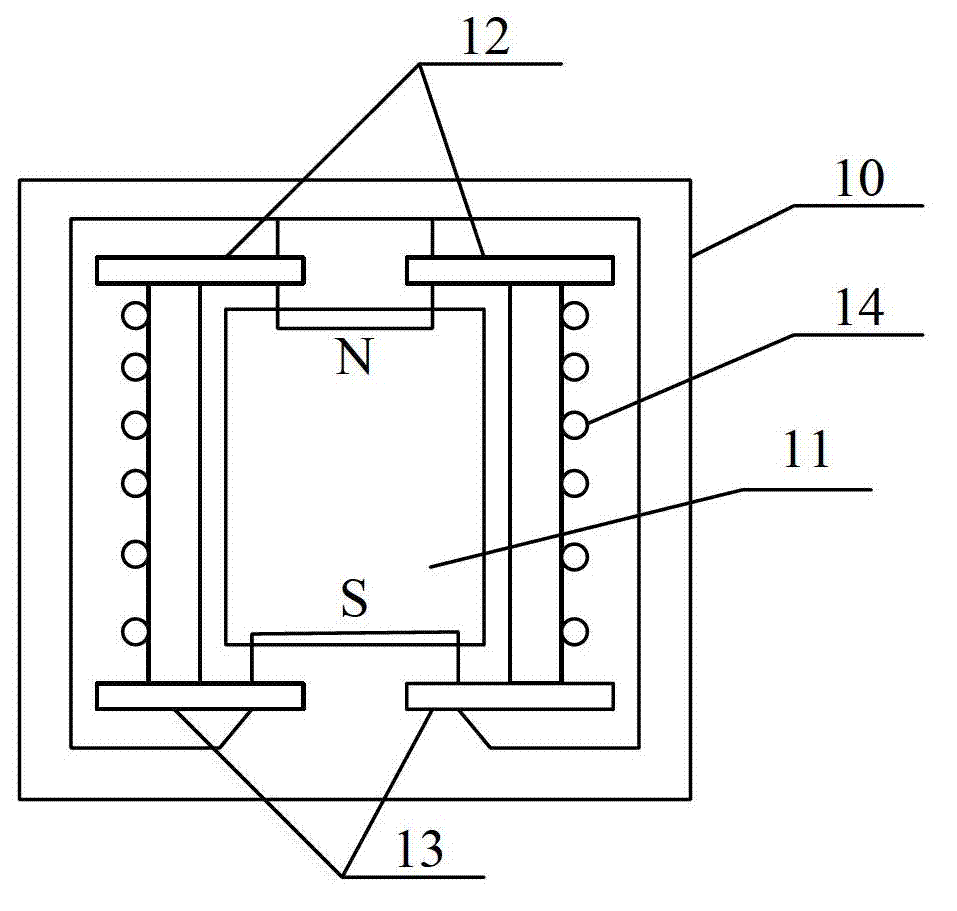

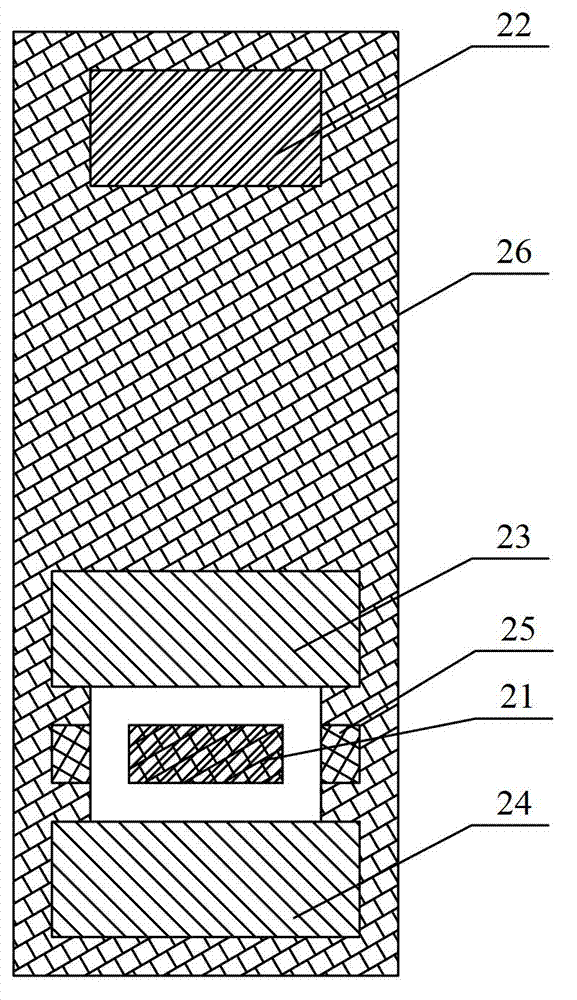

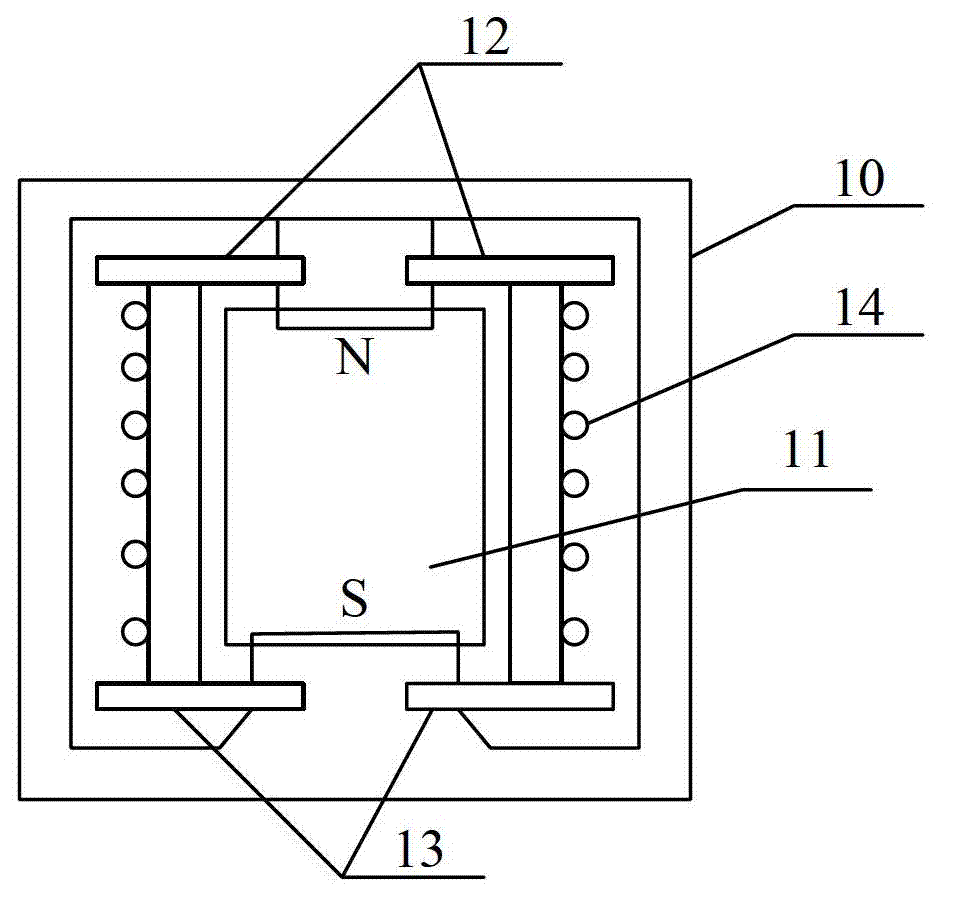

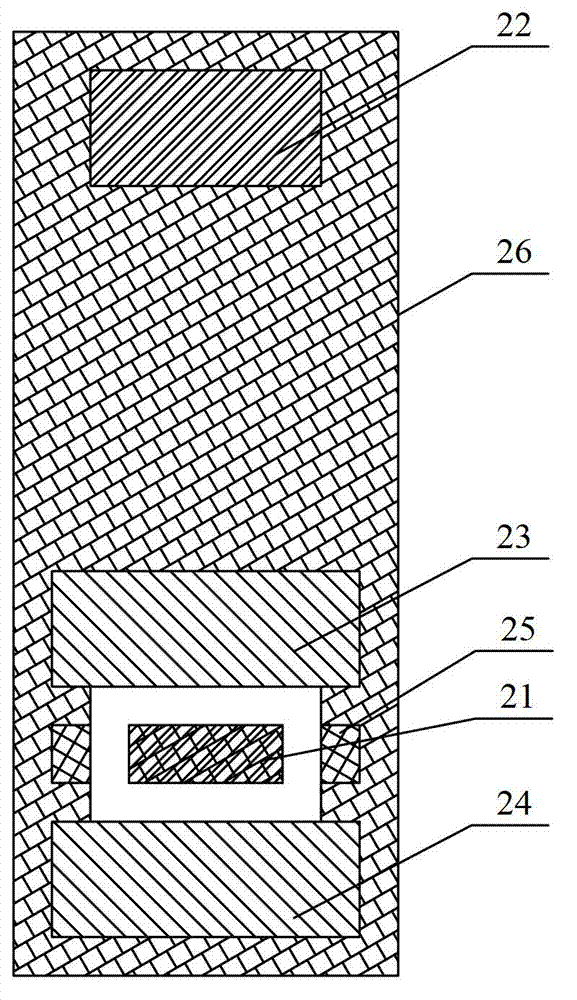

Magnetic-suspension wave detector

ActiveCN103048683AFast and accurate regressionHigh monitoring sensitivitySeismic signal receiversStable stateMagnetic poles

The invention provides a magnetic-suspension wave detector. The magnetic-suspension wave detector comprises a shell, a fixed permanent magnet, a first diamagnetic body, a coil, a second diamagnetic body and a suspension permanent magnet, wherein the fixed permanent magnet, the first diamagnetic body, the coil and the second diamagnetic body are sequentially arranged at the inner part of the shell from top to bottom, the suspension permanent magnet is positioned in the coil, and the magnetic pole magnetisms of the fixed permanent magnet and the suspension permanent magnet facing each other are different. According to the magnetic-suspension wave detector provided by the invention, the gravity born by the suspension permanent magnet can be offset through an attraction force from the fixed permanent magnet to the suspension permanent magnet, and the suspension permanent magnet is guaranteed to be in a stable state through the diamagnetic bodies which are positioned at the upper part and the lower part of the suspension permanent magnet; and when the suspension permanent magnet shifts to optional one direction, a component force of a horizontal direction or a vertical direction of a resulting force born by the suspension permanent magnet is opposite to a shifting direction, thus the suspension permanent magnet can be quickly and accurately attracted to return to a balance position, and the sensitivity and the accuracy of monitoring are increased.

Owner:丹东大东线圈工程有限公司

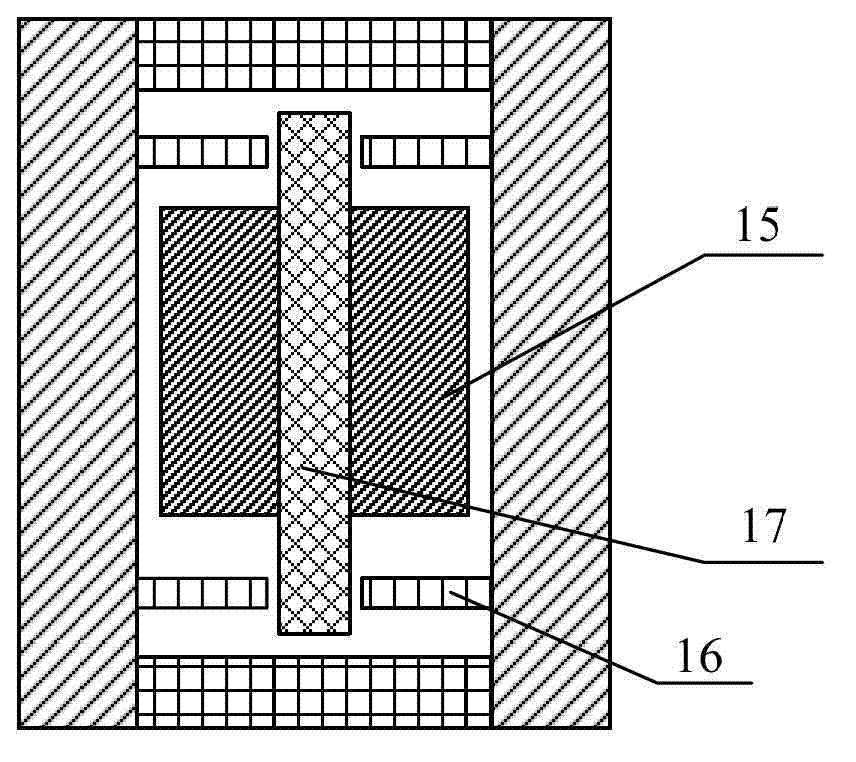

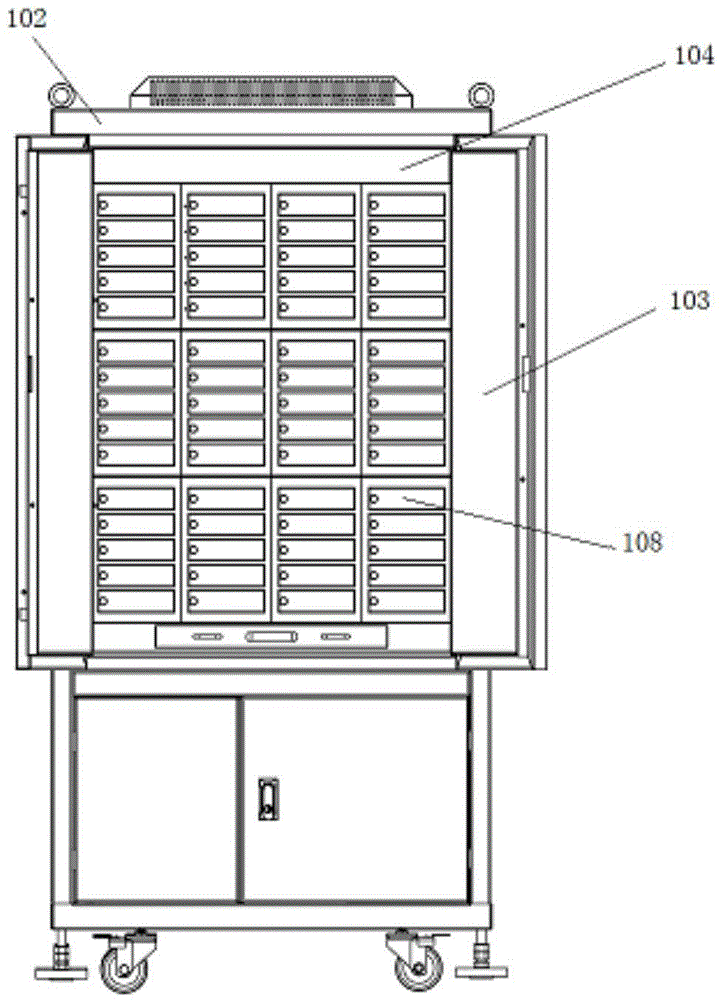

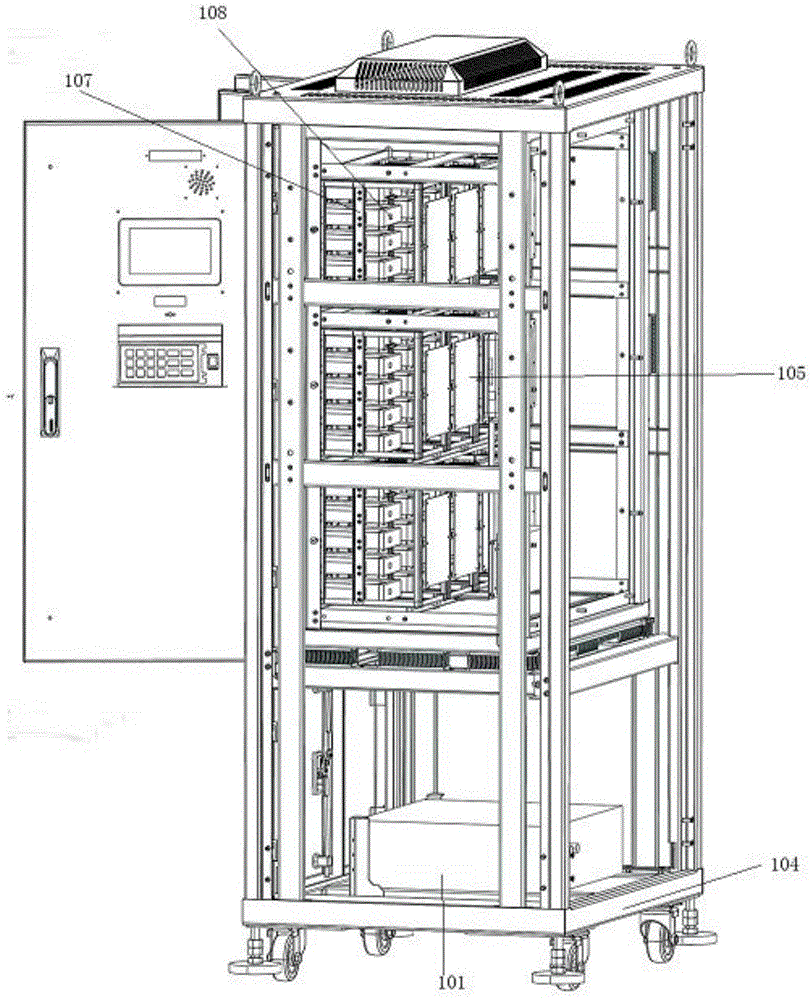

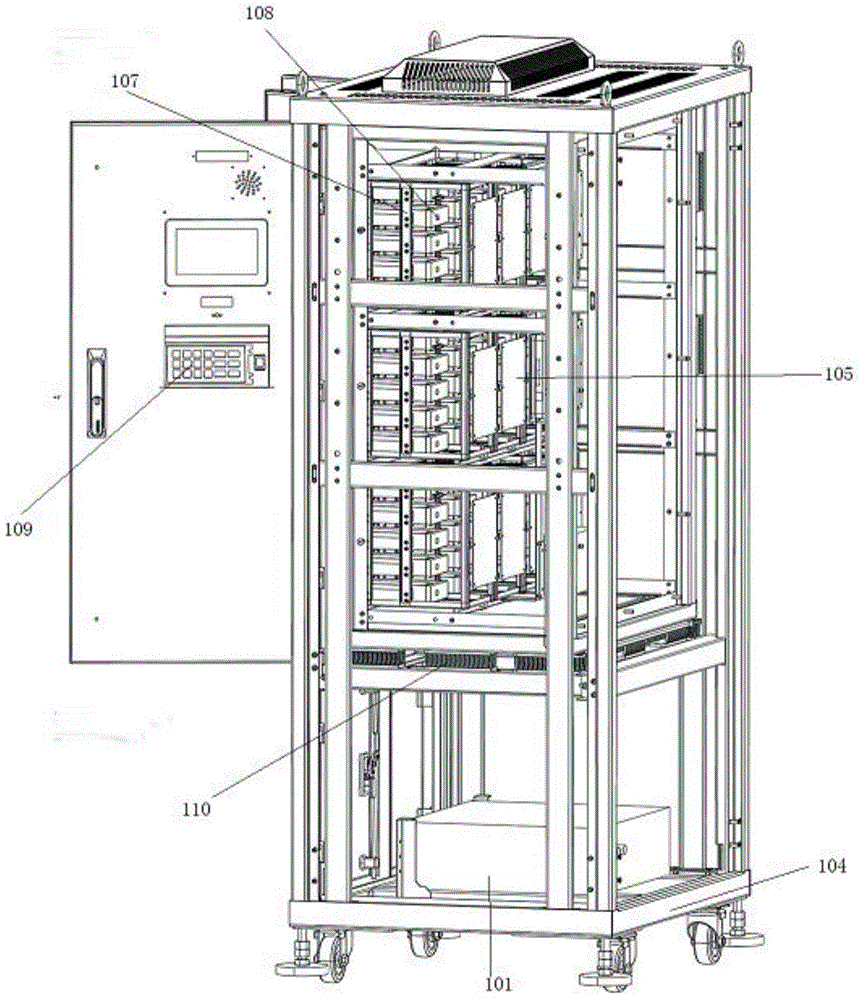

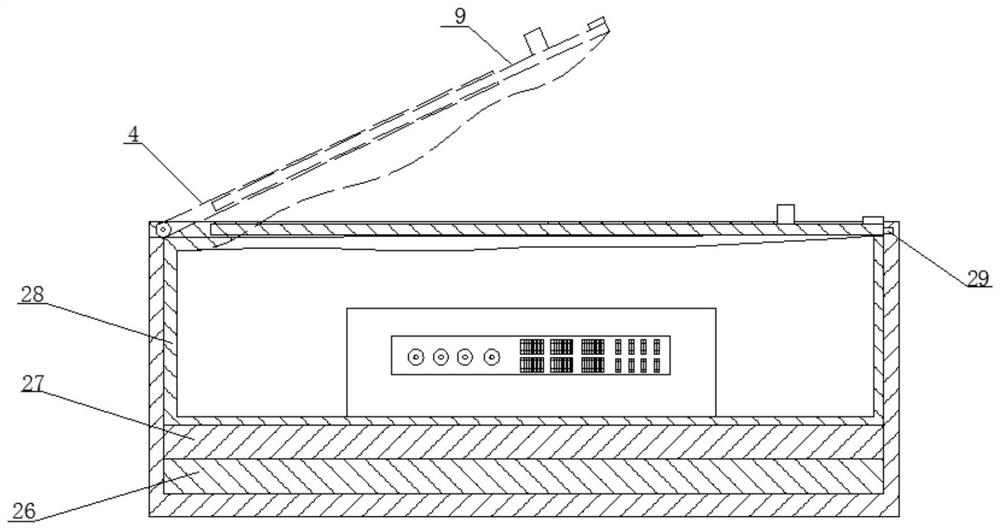

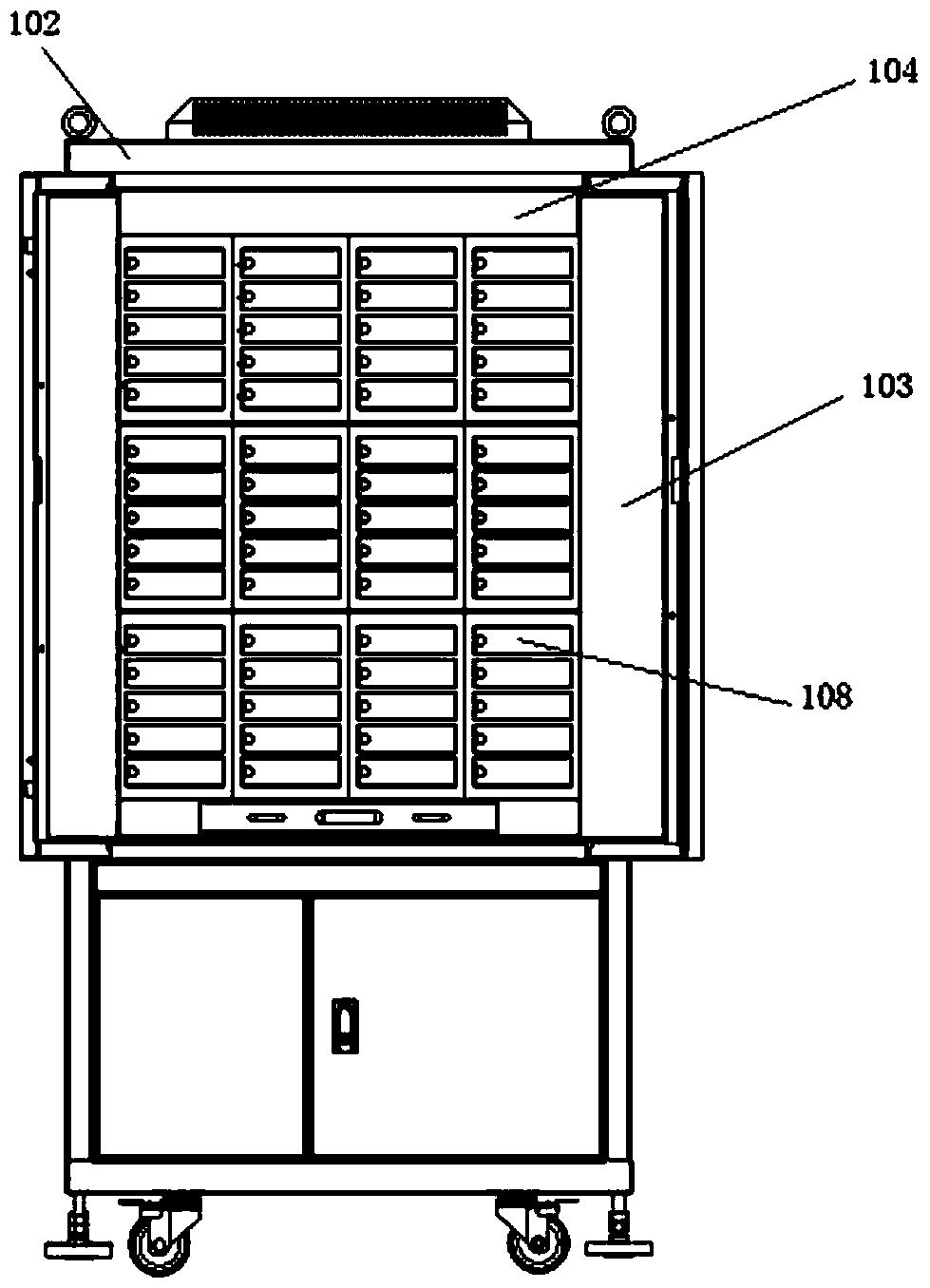

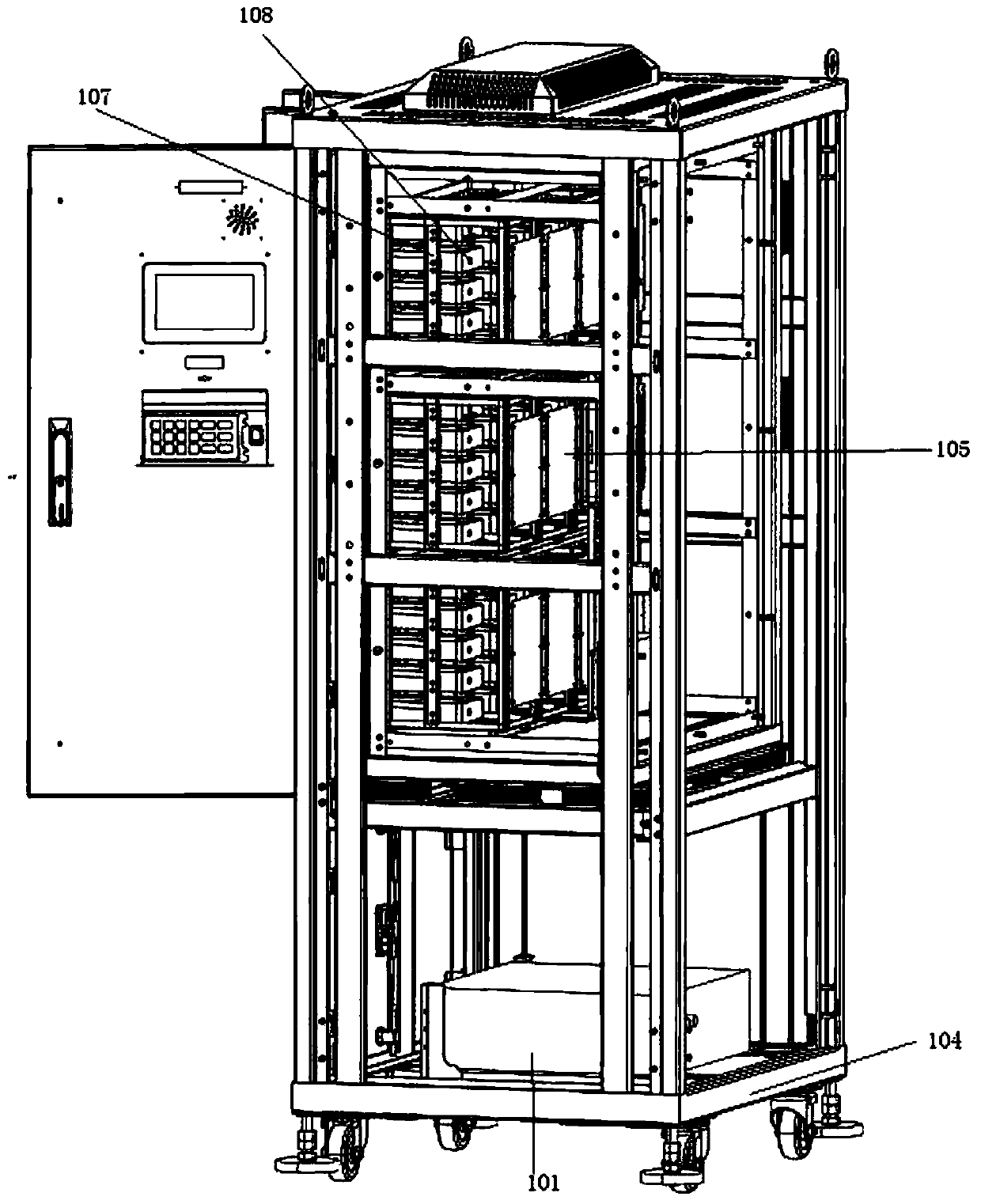

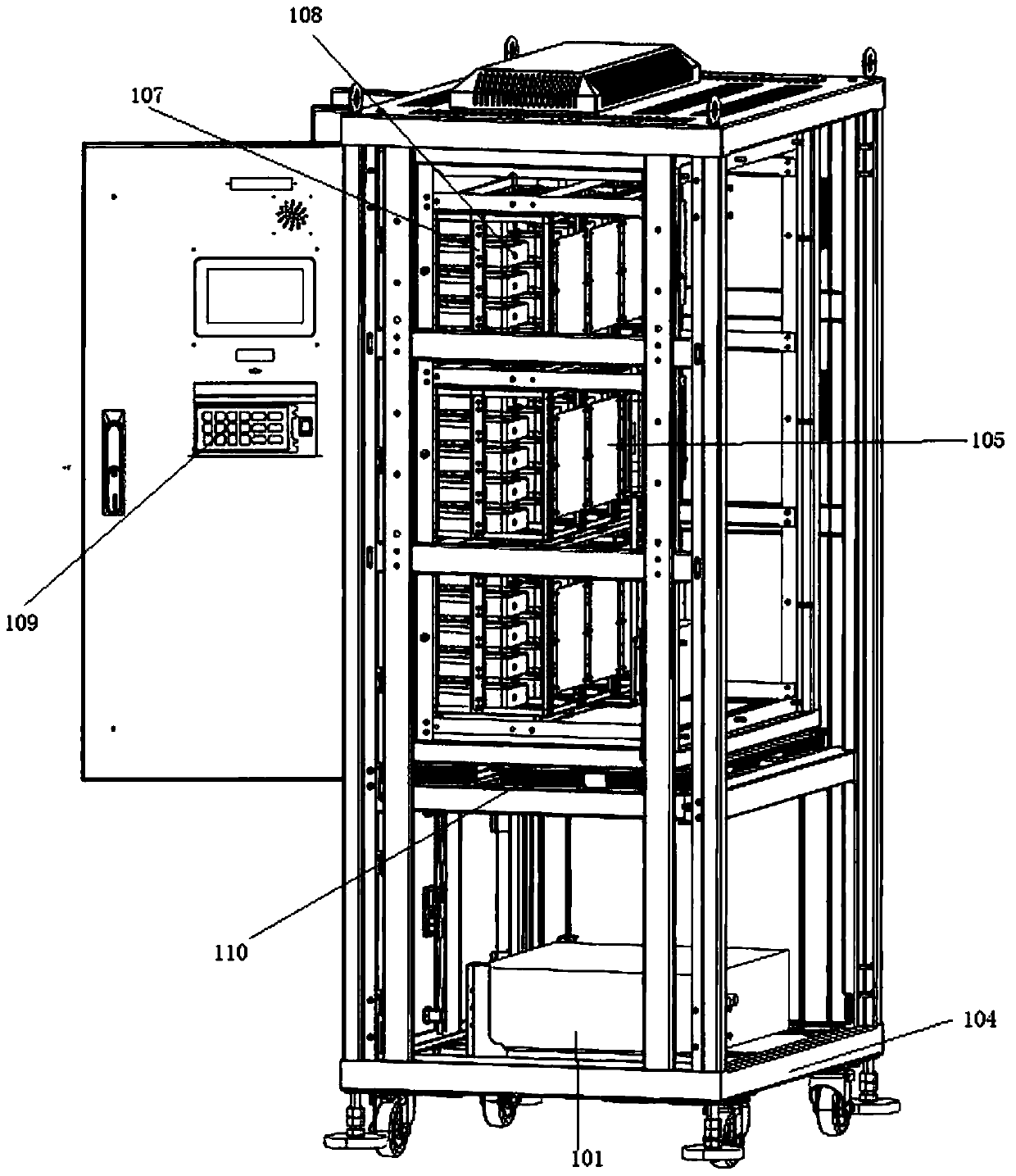

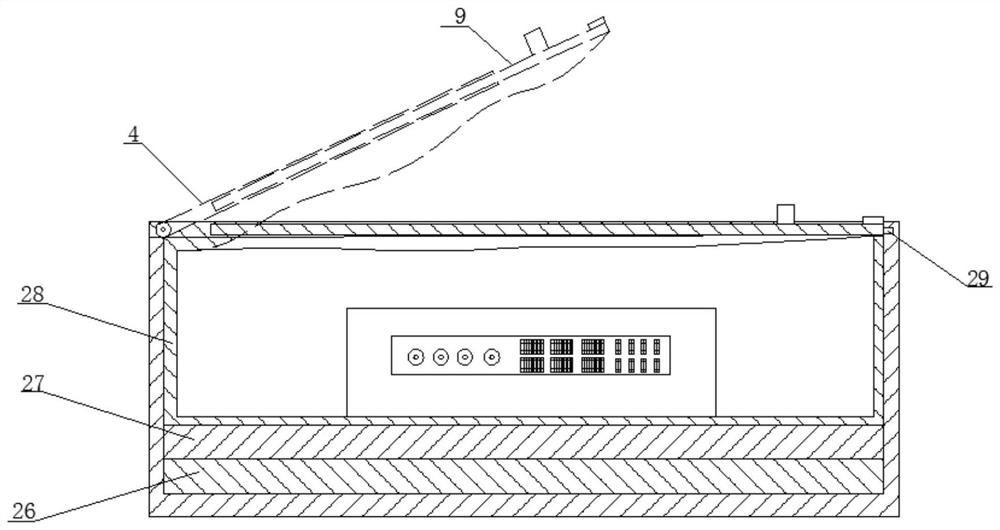

Hard disk storage cabinet

ActiveCN104134451AGood antimagneticEasy to prevent dustInput/output to record carriersRecord information storageData managementControl circuit

The invention discloses a hard disk storage cabinet, and relates to the technical field of storage devices. The hard disk storage cabinet solves the problem that a user cannot conveniently manage massive data resources in the prior art. According to the technical scheme, the hard disk storage cabinet comprises a power source, a machine cabinet body, a sealing door, an inner box body, a control circuit board, hard disk interfaces, one or more hard disk racks and a plurality of hard disk cartridges. The sealing door is arranged on the front side of the machine cabinet body. The inner box body is arranged inside the machine cabinet body. An interval exists between the inner box body and the machine cabinet body. The control circuit board is located inside the interval or arranged inside the inner box body. The hard disk racks are arranged inside the inner box body. The hard disk cartridges are arranged inside the hard disk racks. The hard disk interfaces are arranged on the rear sides of the hard disk cartridges and connected with the control circuit board. The control circuit board and the hard disk interfaces are powered by the power source. The hard disk storage cabinet can be applied to the field of data management.

Owner:BEIJING HANLONG SIQI DIGITAL TECH

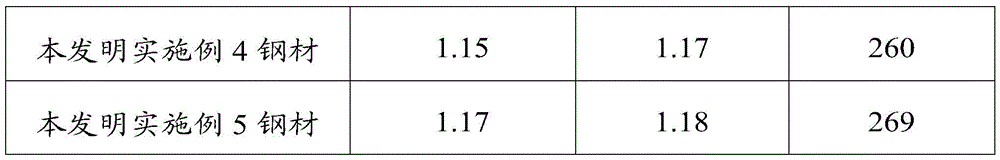

Non-magnetic ventilation box iron material for nuclear power/hydropower station and preparing method of non-magnetic ventilation box iron material

The invention belongs to the field of stainless steel material molding, in particular to a non-magnetic ventilation box iron material for a nuclear power / hydropower station and a preparing method of the non-magnetic ventilation box iron material. Ventilation box iron 0Cr18Ni9 comprises chemical components including 18%-19% of Cr, not larger than 4.0% of Mn, 8%-9% of Ni, not larger than 0.04% of C,not larger than 1.0% of Si, not larger than 0.035% of P, not larger than 0.020% of S, 2%-3% of Cu, 0.18%-0.22% of N and the balance Fe and inevitable impurities. The ventilation box iron 0Cr18Ni9 isobtained through technologies of burdening, electric-arc furnace smelting, AOD furnace refining, electroslag remelting, continuous mill operation, solution treatment, wire winding, acid pickling, drying, drawing, solution treatment, roll forming, cutting, checking, packaging, storage and the like in sequence. The preparation technology is simple, and oxidation machining is not needed. The stainless steel material prepared through the method has the beneficial effect that the austenite structure is stable, the magnetic conductivity is reduced while the strength is guaranteed, the condition thatthe magnetic conductivity mu is smaller than or equal to 1.1(H=15924 A / m), the beneficial effects of high ductility, good resistance to oxidation, good diamagnetism, resistance to intergranular corrosion and the like are achieved, and traditional 0Cr18Ni9 austenitic stainless steel can be replaced.

Owner:大连环新新材料科技有限公司

Alloy material for automobile brake pump piston and preparation method of alloy material

The invention provides an alloy material for an automobile brake pump piston. The alloy material comprises 0.04%-0.10% of C, 0.8%-2.0% of Mn, 0.03%-0.04% of P, 0.03%-0.04% of S, 1.0%-2.0% of Si, 17.0%-20.0% of Cr, 8.0%-11.0% of Ni, 0.45%-0.70% of Ti, 0.7%-1.2% of Cu, 0.2%-0.5% of Ta, 0.20%-0.50% of Nb and the balance of Fe; the metal raw materials are sintered under the conditions of vacuum and 850-880 DEG C; subsequently, tempering is carried out at 600 DEG C, followed by cooling, and in such a manner, the alloy material having excellent properties of magnetic resistance, corrosion resistance, pressure resistance and not easy deformation is obtained.

Owner:HANGZHOU POLYTECHNIC

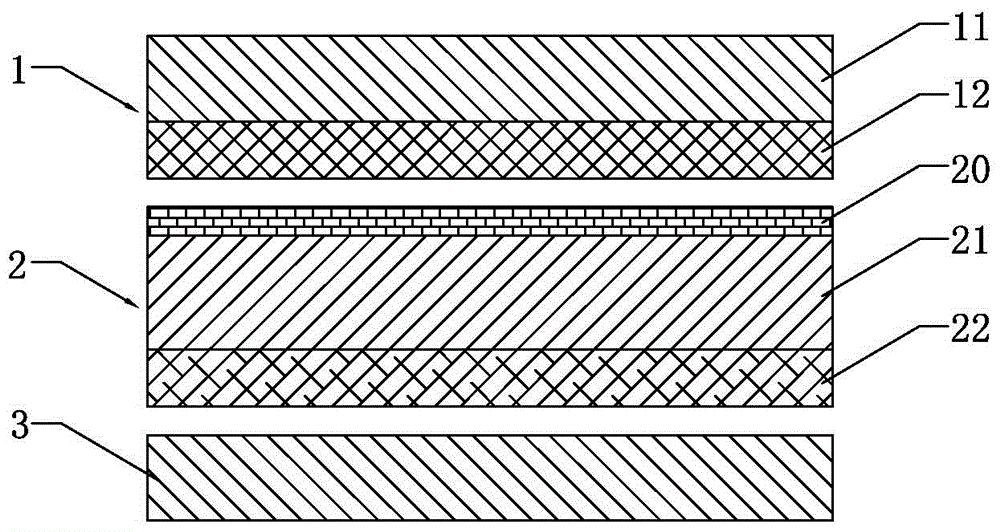

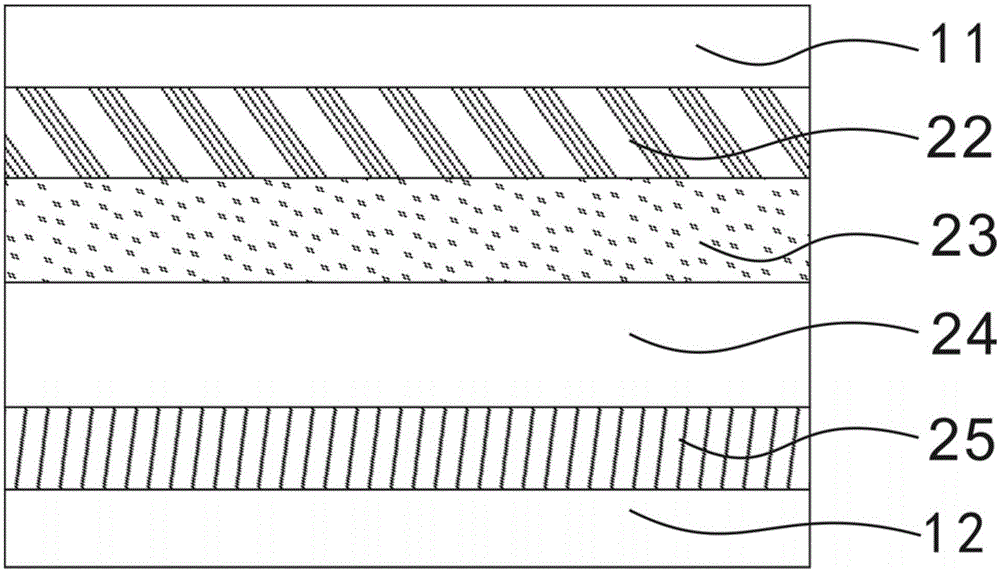

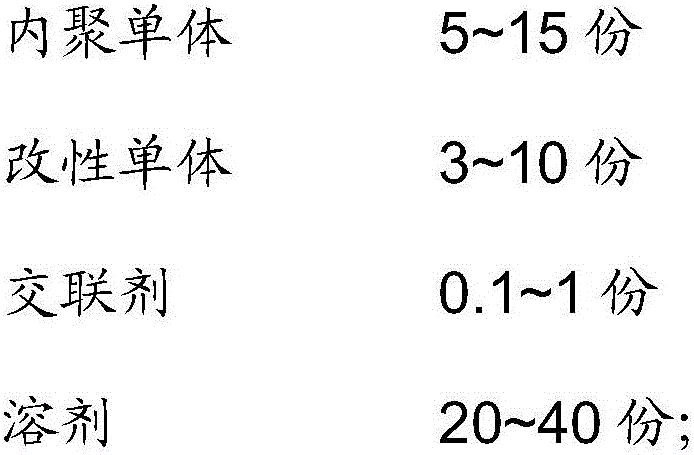

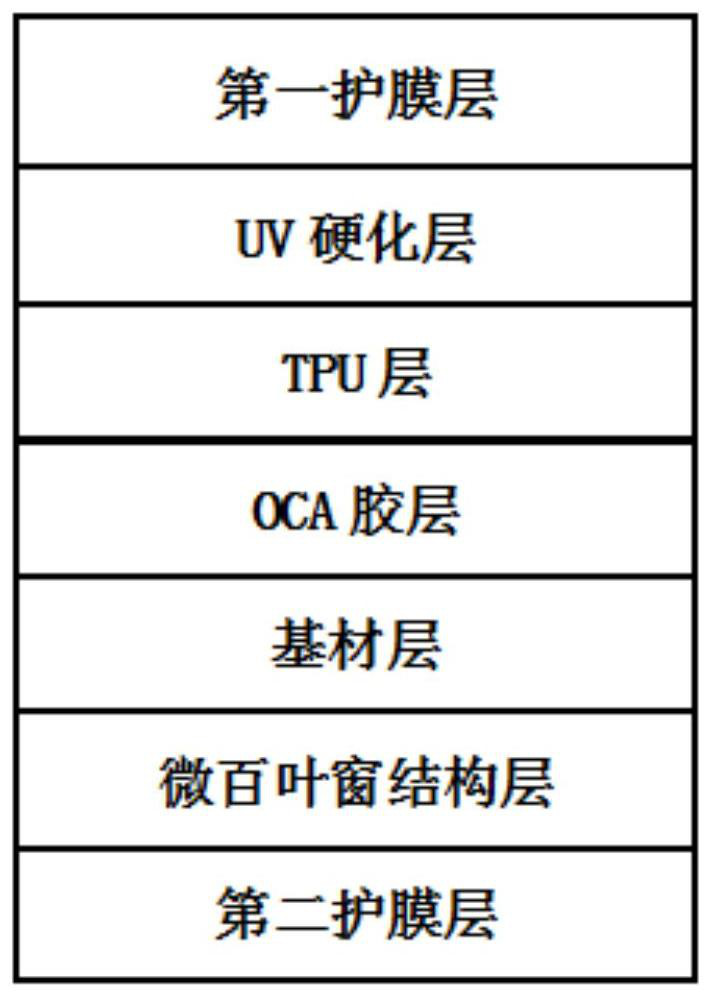

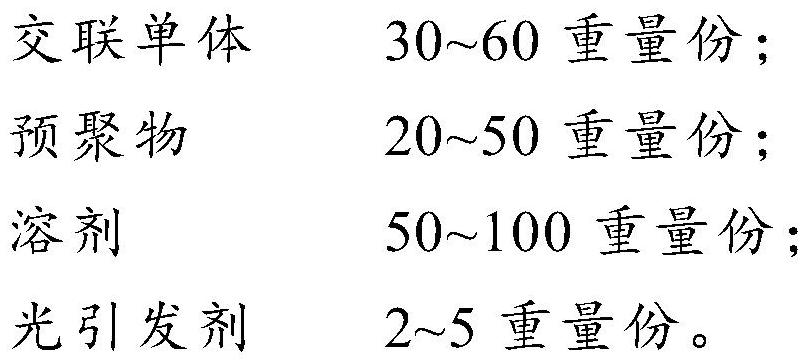

Peep-proof printable magnetic-resistant film and preparation method thereof

ActiveCN107142036AAvoid scratchesWith anti-magnetic effectFilm/foil adhesivesOrganic non-macromolecular adhesiveMagnetic effectConfidentiality

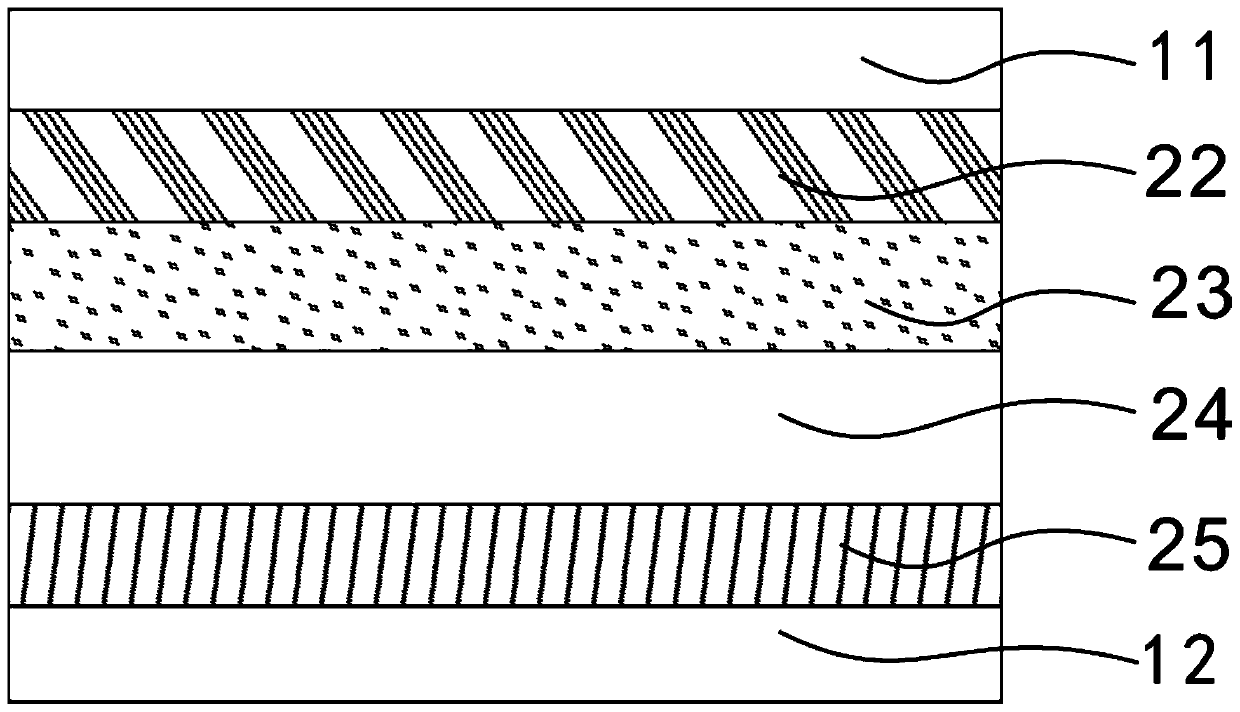

The invention provides a peep-proof printable magnetic-resistant film. The peep-proof printable magnetic-resistant film comprises a first protective film layer, an UV hardened layer composited to the first protective layer, a TPU layer composited on the UV hardened layer, an OCA adhesive layer composited on the TPU layer, a substrate layer combined on the OCA adhesive layer, a micro louver structure layer composited on the substrate layer and a second protective layer combined to the micro louver structure layer. The UV hardened layer is made of metal and oxide thereof, carbon conductive material and UV varnish glue. The UV hardened layer has an anti-magnetic effect and a printable function, the UV-hardened layer cooperates with the other layers to obtain the peep-proof printable magnetic-resistant film which has display confidentiality, the peep-proof layer is effectively prevented from being scratched, and the film has good printability and magnetic resistance and can meet customer's personal pursuit.

Owner:NALI OPTICAL MATERIAL DONGGUAN

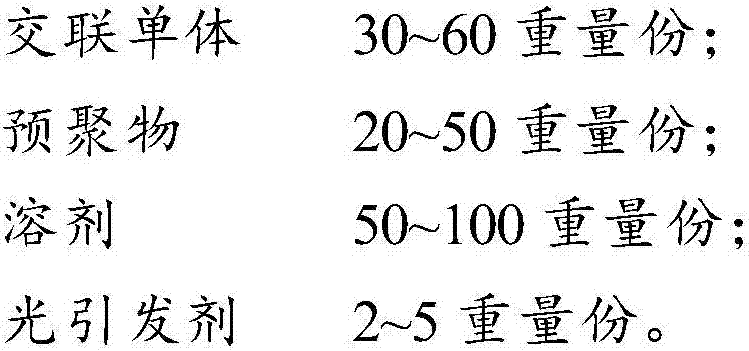

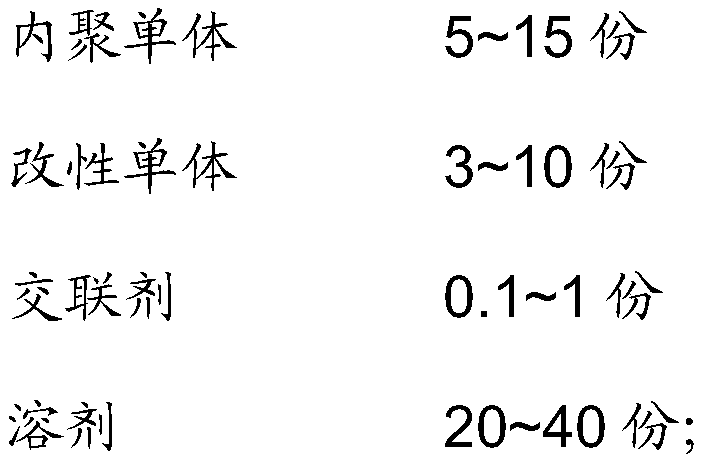

Anti-electromagnetic protective membrane and preparation method thereof

InactiveCN105969234AGood anti-electromagnetic effectGood antimagnetic propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryStripping membrane

The invention relates to the technical field of protective membranes, in particular to an anti-electromagnetic protective membrane and a preparation method thereof. The anti-electromagnetic protective membrane comprises a protective membrane layer, a use membrane layer and a stripping membrane which are sequentially attached from top to bottom. The protective membrane layer comprises a protective membrane body and a stripping adhesive layer attached to the lower surface of the protective membrane body. The use membrane layer comprises a base material attached to the lower surface of the stripping adhesive layer and an anti-magnetic adhesive layer attached to the lower surface of the base material, and the lower surface of the anti-magnetic adhesive layer and the upper surface of the stripping membrane are attached. By means of the anti-magnetic adhesive layer, the anti-electromagnetic protective membrane is good in anti-magnetic performance, simple in structure, stable in performance and good in compatibility between materials.

Owner:胡银坤

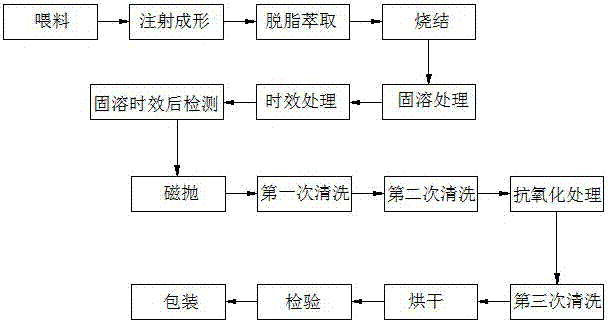

Copper alloy injection forming technology

The invention discloses a copper alloy injection molding process, which sequentially forms copper alloy products with complex structures through feeding, injection molding, degreasing extraction, sintering and post-treatment processes. Through the above method, the copper alloy products formed by the copper alloy injection molding process of the present invention meet the requirements of high strength and high thermal conductivity at the same time, and the whole process is simple, the production cycle is shortened, the surface finish is high, the corrosion resistance is good, and it has excellent corrosion resistance. Magnetic properties.

Owner:CHANGZHOU GIAN TECH

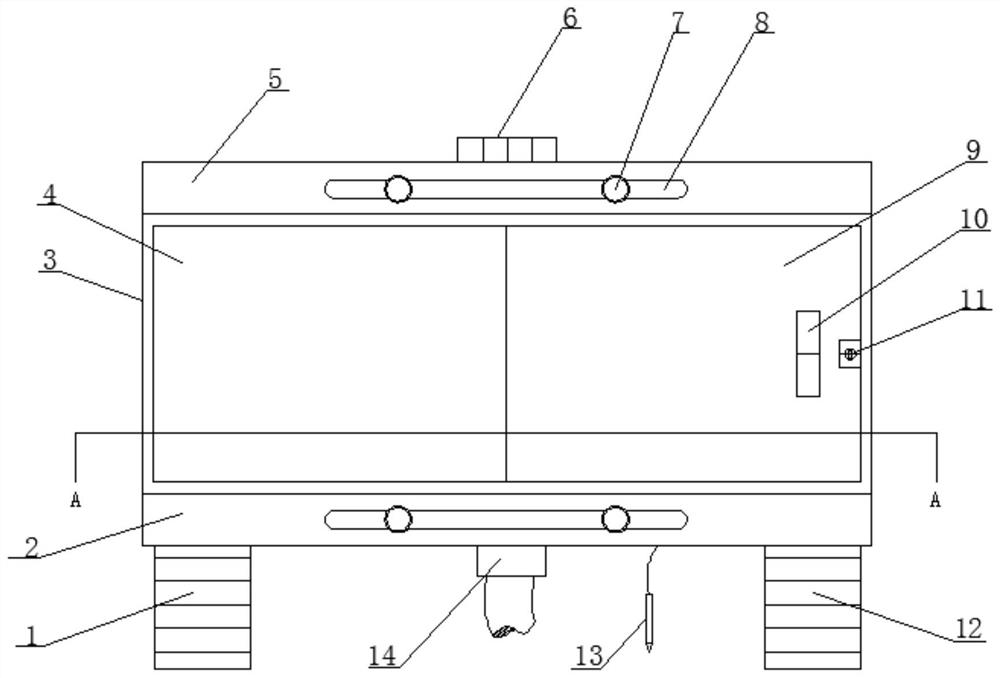

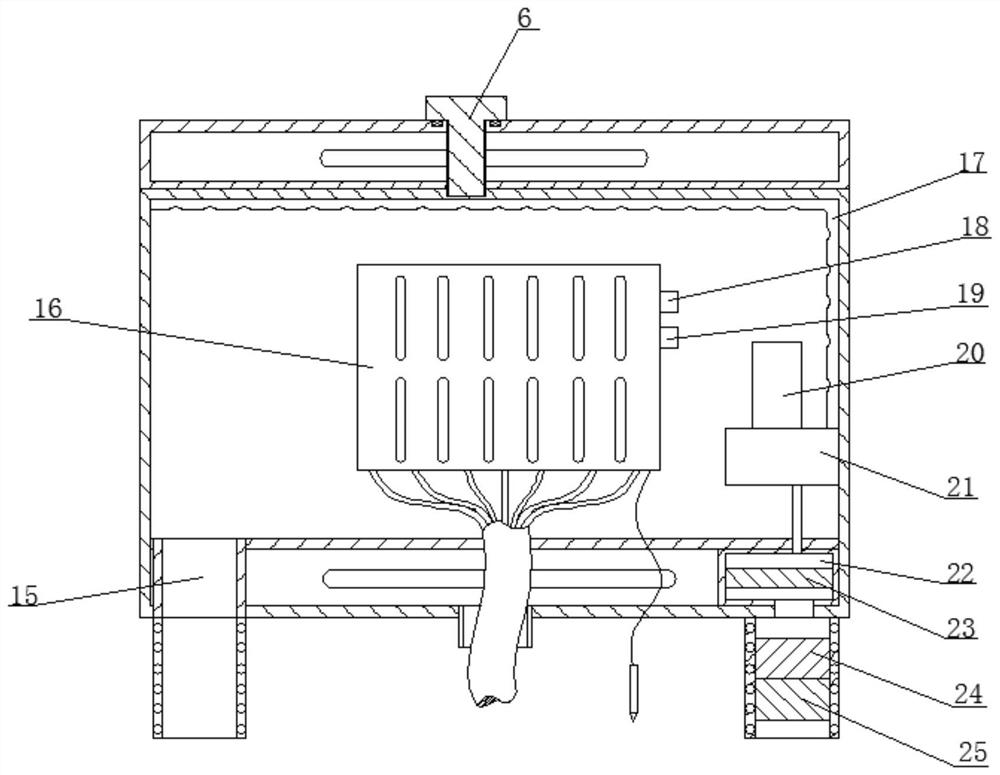

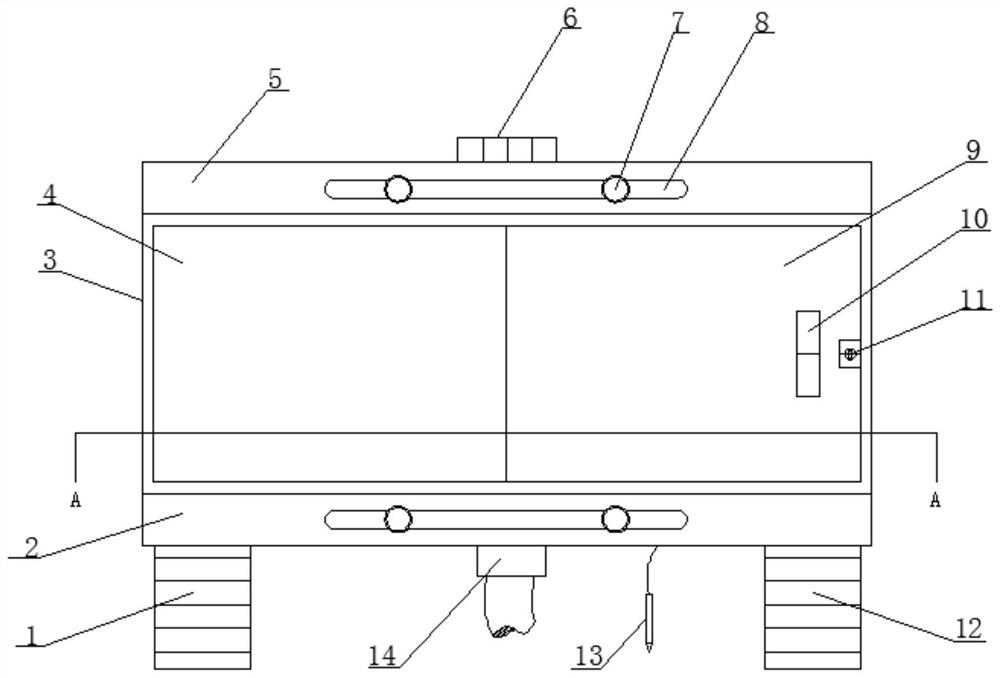

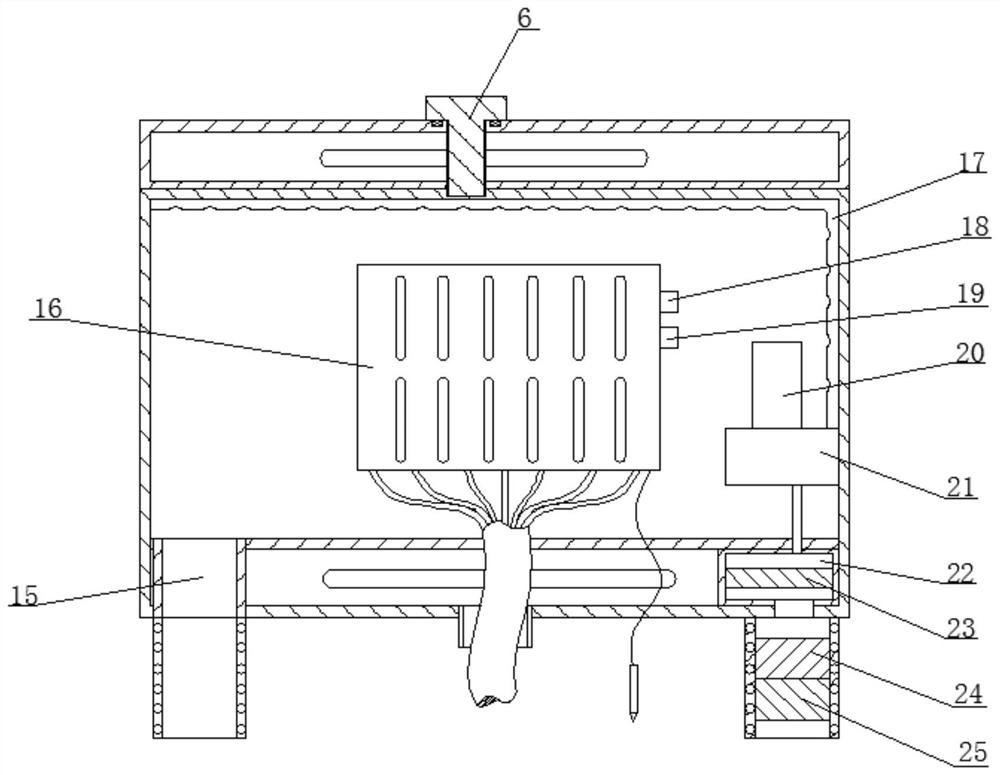

Electric power communication equipment based on electric power internet of things

ActiveCN111800962AEasy to fixEasy to useData switching detailsClosed casingsMechanical engineeringElectric power

The invention discloses electric power communication equipment based on an electric power internet of things. The equipment comprises a main box body (3) and an upper box body (5) and the lower box body (2) connected to the upper end and the lower end of the main box body (3) respectively. A power communication equipment main body (16) is arranged in the main box body (3), transverse port grooves(8) are formed in the front ends and the rear ends of the upper box body (5) and the lower box body (2), and connecting assemblies are arranged in the upper box body (5) and the lower box body. According to the invention, through designing the connecting assembly, three installation modes of adsorption fixation, compression fixation and wall hanging fixation can be realized at the same time, and single use or mixed use can be selected according to needs, thereby facilitating the installation and fixation of the power communication equipment, enabling the power communication equipment to be fixed firmly, being very good in stability, and facilitating the use of the power communication equipment.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LAIYANG POWER SUPPLY CO

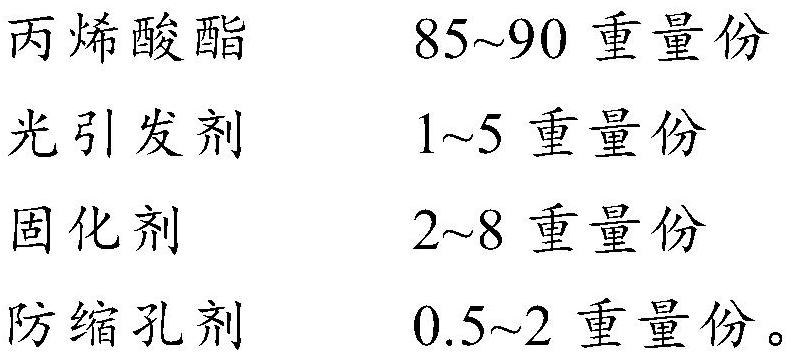

An anti-blue-light antimagnetic film and a preparing method thereof

ActiveCN106566430AFree from harmGood antimagneticFilm/foil adhesivesOrganic non-macromolecular adhesiveProtecting eyeElectromagnetic interference

An anti-blue-light antimagnetic film and a preparing method thereof are disclosed. The film has a good antimagnetic property and good anti-blue-light effects, thus playing a role of protecting glasses of persons and protecting electronic elements. The film includes, from top to bottom, an upper release film, an anti-blue-light layer, an antimagnetic metal layer, an insulating substrate, an acrylic adhesive layer and a lower release film. The thickness of the anti-blue-light layer is 50-100 [mu]m. The thickness of the antimagnetic metal layer is 50-100 [mu]. The thickness of the carrier insulating substrate is 50-150 [mu]. Anti-blue-light and antimagnetic functions are combined, and therefore the anti-blue-light antimagnetic film not only protects eyes of persons from being damaged by blue light, but also protects electronic products from electromagnetic interferences.

Owner:NALI OPTICAL MATERIAL DONGGUAN

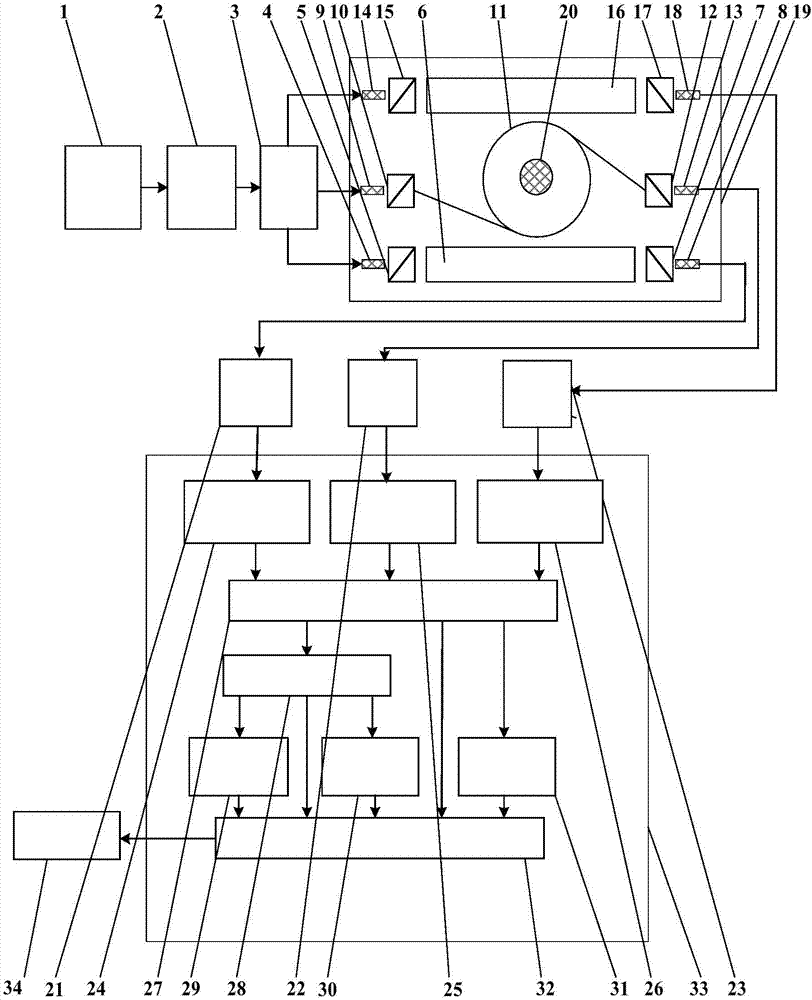

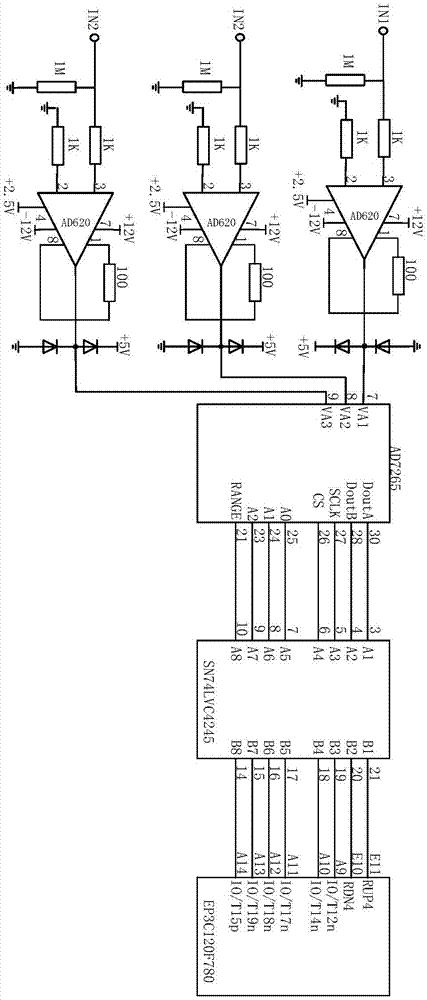

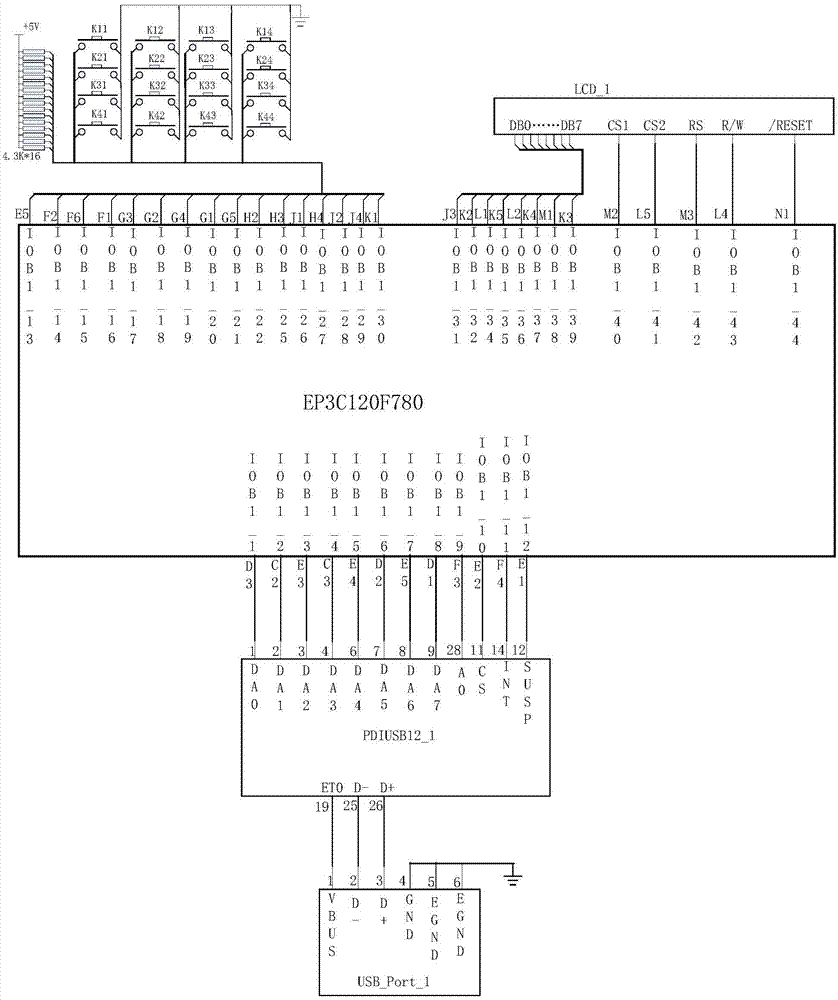

Double magnetic circuit composite optic current transformer and its signal processing method

PendingCN107144718AStrong anti-magnetic interference abilityImprove steady-state accuracy and transient accuracyVoltage/current isolationPhysicsPolarizer

The invention belongs to the current measurement technology field and more particularly, to a double magnetic circuit composite optic current transformer and its signal processing method, comprising the following elements connected in succession: a laser diode driver, a tail fiber equipped laser diode, a light splitter, a double magnetic circuit composite magnetic light sensing unit and photoelectric detectors wherein the double magnetic circuit composite magnetic light sensing unit comprises three parallel light path channels with each light path channel comprising the following elements connected in succession: an input collimator, a polarizer, magnetic light sensing materials, a polarization detector, and an output collimator, wherein the first magnetic light sensing material and the third magnetic light sensing material are both bar-shaped magnetic light sensing glass and are arranged in parallel and in symmetry at two sides of a powered conductor. The light penetration direction is vertical to the tested current flowing direction of the powered conductor; and the second magnetic light sensing material is a magnetic light sensing fiber that is wrapped on the powered conductor uniformly. The ends of the three light path channels are connected with three different photoelectric detectors respectively. The invention solves the problems with temperature sensitivity and electromagnetic interference.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Spraying mos2 process of a bearing bush and its alloy layer

ActiveCN103122937BGood bite resistanceReduce coefficient of frictionPretreated surfacesBearing componentsParyleneAlloy

The invention provides a bearing bush and a process thereof for spraying MoS2 on an alloy layer for solving the problem that the alloy layer or the plated layer of the bearing bush peels off frequently. The bearing bush comprises a steel backing layer and the alloy layer fixedly arranged. The alloy layer is provided with a spraying layer fixed with the alloy layer. The alloy layer is one of an aluminum alloy layer or a copper-lead alloy. The spraying layer comprises a PI (Polyimide) resin layer, a MoS2 layer and a PAR (Parylene) lubricating coating sequentially arranged. The PI resin layer is contacted with the alloy layer. The bearing bush can effectively improve the dry grinding resistance, the anti-occlusion performance, the corrosion resistance and the wear resistance through the MoS2 layer by arranging the spraying layer on the alloy layer, the problem that the inner surface of the bearing bush in the installation and use process is scratched is solved, and the service lives of the bearing bush and lubricating oil in the bearing bush are prolonged. The bearing bush is good in practicality, and the whole manufacturing process of the bearing bush is safe and environment-friendly, so that the environmental pollution can be reduced.

Owner:YANTAI CHUNSHENG SLIDING BEARING

Hard disk storage apparatus

InactiveCN105511567ASimple structureGood antimagneticDigital processing power distributionHeat sinkControl circuit

The invention discloses a hard disk storage apparatus. A housing is in a hollow hexagonal structure. Hard disk trays are distributed on the internal edge of the housing at equal intervals; the housing opposite to the hard disk trays is provided with heat radiating seams and heat radiating sheets; each hard disk joint is arranged on the back side of the housing; each hard disk joint is connected with a control circuit board; damping sheets are mounted under the hard disk trays; each damping sheet is arranged between each two hard disk trays; each damping sheet is made from six-dimensionality rubber; one end of the side arm of the housing is movably connected with two sides of the housing via bolts; the front end of the housing is provided with a front cover; and the front cover rotates with the side arm to a closed state to cover an opening and to be buckled with a framework, so the hard disk can be fixed in accommodating space. The hard disk storage apparatus is simply structured has great damping effect and air circulation; a plurality of hard disks can be accommodated; and the hard disk storage apparatus is antimagnetic and dustproof, thereby possessing wide adaptability.

Owner:QINGDAO ZHONGKE SOFTWARE

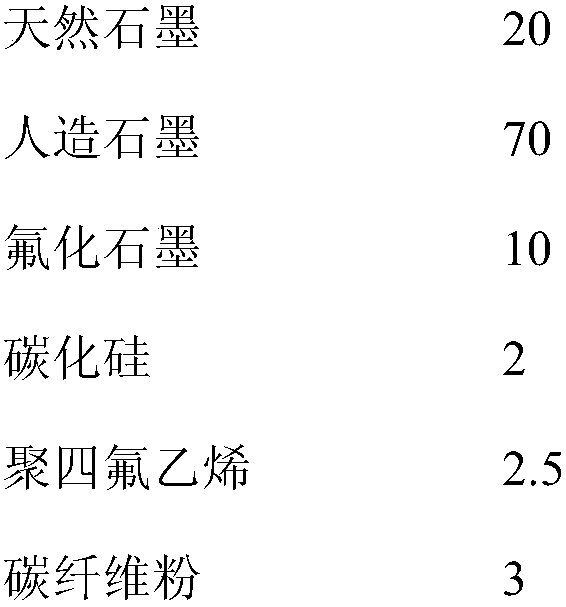

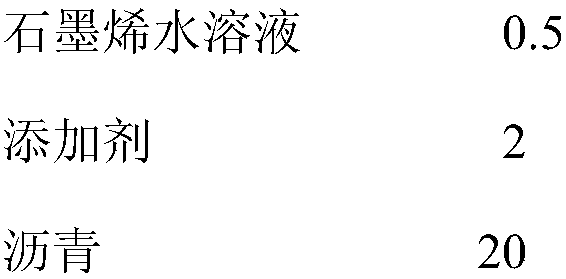

Brush material for manufacturing electric tool motor

InactiveCN107785746AModerate resistivityImprove wear resistanceRotary current collectorDynamoelectric machine connectorsFiberAngle grinder

The invention discloses a brush material for manufacturing an electric tool motor, relating to the field of materials. The brush comprises base powder and asphalt; in particular, the base powder comprises an aqueous solution of graphene; and the base powder further comprises graphite, silicon carbide and carbon fiber powder. The brush for the electric tool has moderate resistivity, low brush running spark grade, good commutation performance, good product stability, excellent abrasion resistance and electromagnetic interference resistance, and is especially suitable for medium and low power angle grinder motors.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

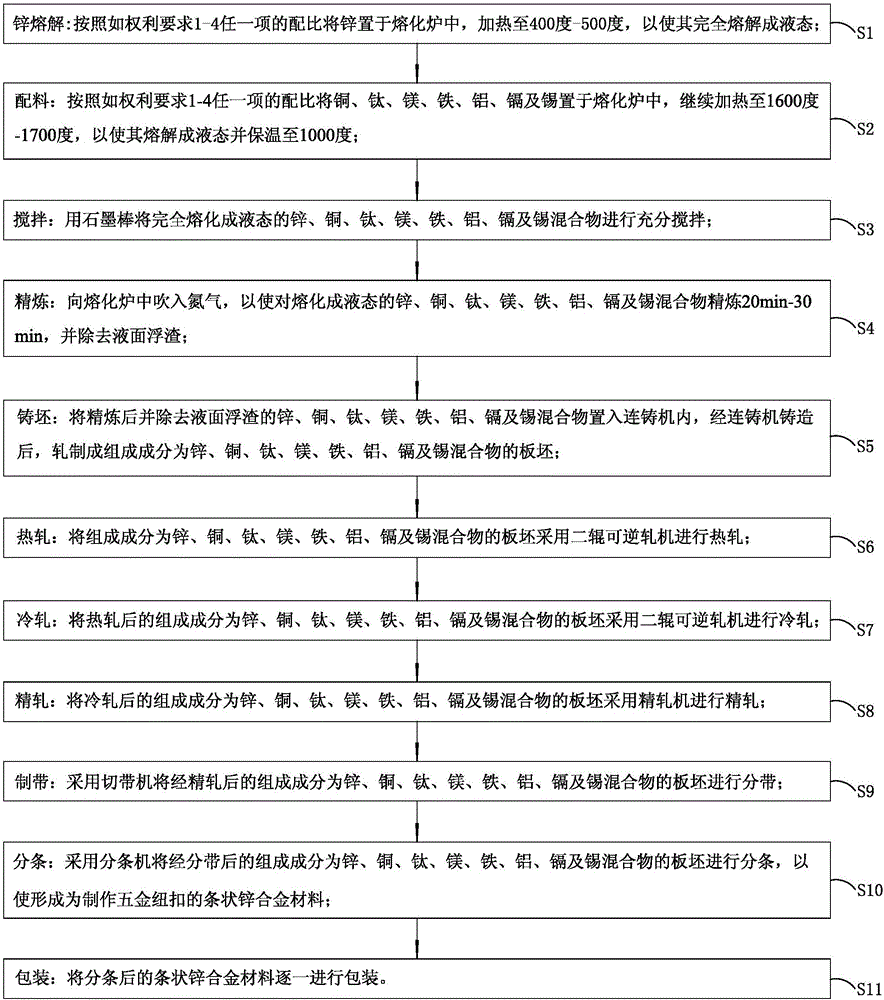

Novel material for hardware button and processing technique thereof

The invention discloses a novel material for a hardware button. The novel material comprises, by weight, 0.55-1.5% of copper, 0.1-0.19% of titanium, 0.04-0.07% of magnesium, 0-0.06% of iron, 0-0.02% of aluminum, 0-0.002% of cadmium, 0-0.001% of tin and the balance zinc. The novel material for the hardware button has the effects that the weight percentage of zinc is large, so that the corresponding hardware button made from the novel material for the hardware button is made to have very good diamagnetism; the weight percentage of copper is small, so that the corresponding hardware button made from the novel material for the hardware button is made light in texture, and low in manufacturing cost and production cost; the proportion of magnesium enables the corresponding hardware button made from the novel material for the hardware button to have certain malleability and heat dissipation capability; the proportion of titanium enables to the corresponding hardware button made from the novel material for the hardware button to have certain metallic luster and strength; and the whole novel material for the hardware button is prepared by matching zinc, copper, titanium, magnesium, iron, aluminum, cadmium and tin, the corresponding hardware button made from the novel material for the hardware button is made to still have very high rigidity, and therefore, the novel material for the hardware button is excellent in performance.

Owner:深圳华腾云谷科技有限公司

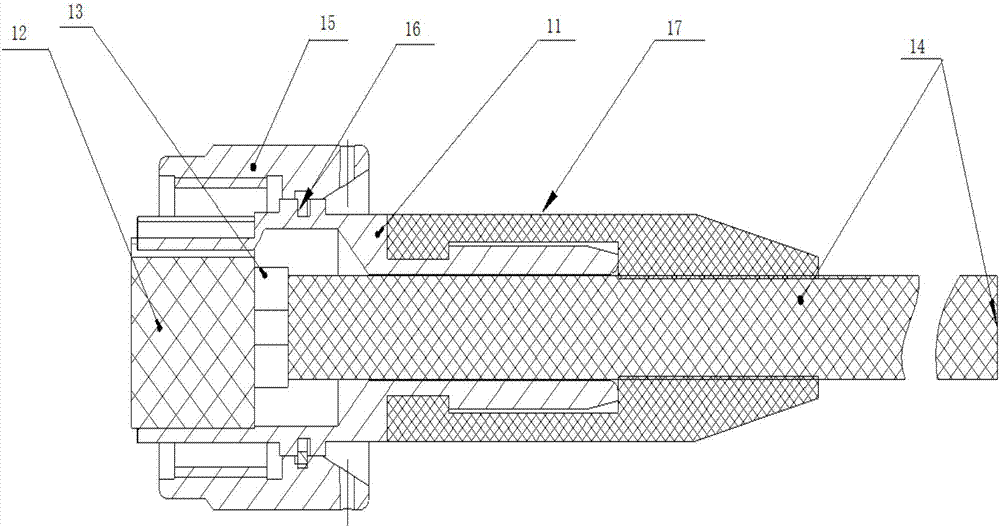

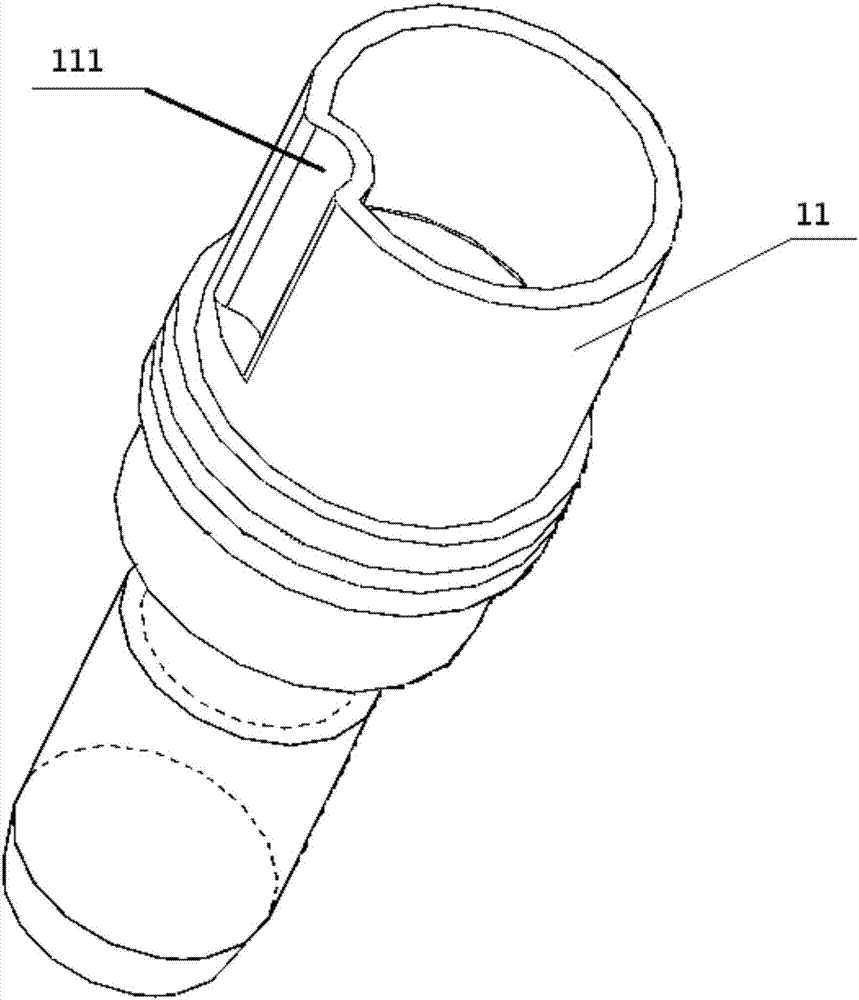

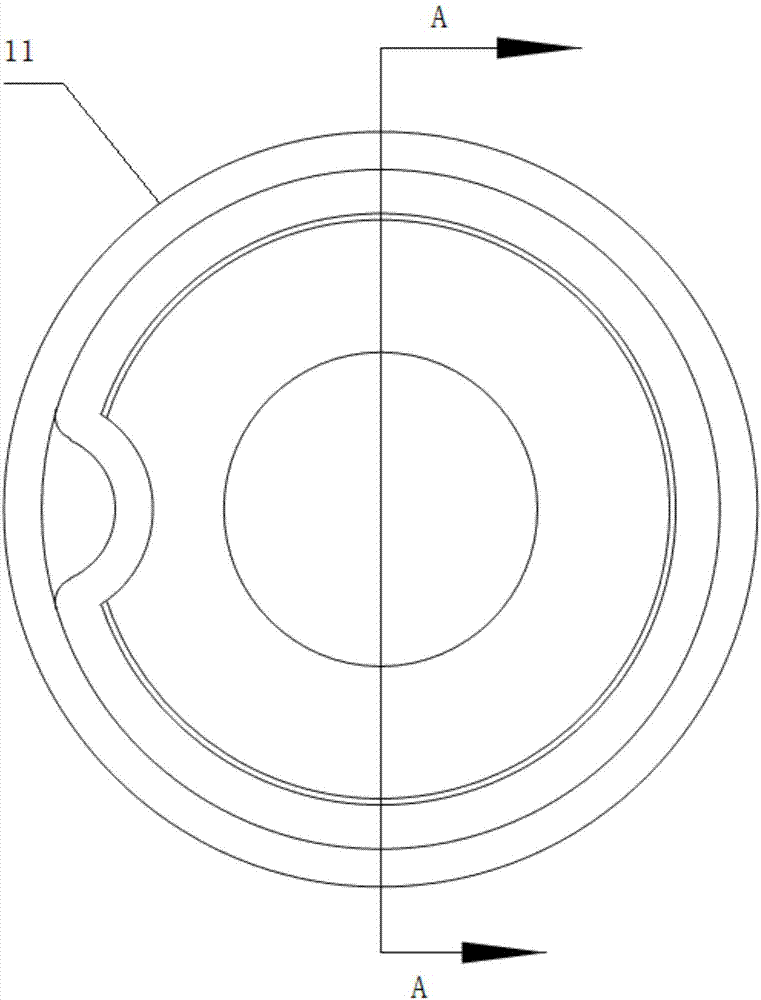

Mini round four-core electric connector and assembly method thereof

PendingCN107994372ASimple structureCompact structureContact member assembly/disassemblyCoupling contact membersElectricityAviation

The invention discloses a mini round four-core electric connector. The mini round four-core electric connector comprises a plug component and a socket component. The plug component comprises a plug shell. A jack base, a jack and a first cable are mounted in the plug shell. A connection ring and a plug bushing sleeve the plug shell. A clamp ring is arranged at the joint between the connection ringand the plug shell. The socket component comprises a socket shell. A pin base is mounted in the socket shell. A pin is fixed to the pin base. A second cable is connected with the pin. An O-ring is arranged on a waist pad of the socket shell. Locking nuts are mounted on two sides of the socket shell. The mini round four-core electric connector shares the features of high contact density and small size with round connectors, has the advantages of high density, lightweight and microminiaturization, can be applied to severe environments with high vibration and impact, is applicable to occasions with special requirements on space and equipment lightweight, and can be widely applied to aviation and spaceflight fields and environments with large environment temperature change.

Owner:MIANYANG CITY JINHUA WESTERN ELECTRIC MFG

Hard disk storage cabinet

ActiveCN104134451BGood antimagneticEasy to prevent dustInput/output to record carriersRecord information storageControl powerData management

Owner:BEIJING HANLONG SIQI DIGITAL TECH

Wear-resisting electromagnetic shielding modified polyformaldehyde material

The invention discloses a wear-resisting electromagnetic shielding modified polyformaldehyde material which is prepared from the following ingredients in parts by weight: 70 to 90 parts of polyformaldehyde, 10 to 20 parts of molybdenum disulfide, 5 to 10 parts of conductive carbon black, 0.5 to 5 parts of liquid dispersing agent, 0.2 to 0.8 part of metal passivator, 0.2 to 0.8 part of heat stabilizer and 0.2 to 0.5 part of antioxidant. The modified polyformaldehyde material disclosed by the invention is suitable for special environments related to weather resistance, long-acting lubrication, electromagnetic shielding and the like of communication base stations and the like.

Owner:SUZHOU WEIRUICHENG NEW MATERIAL

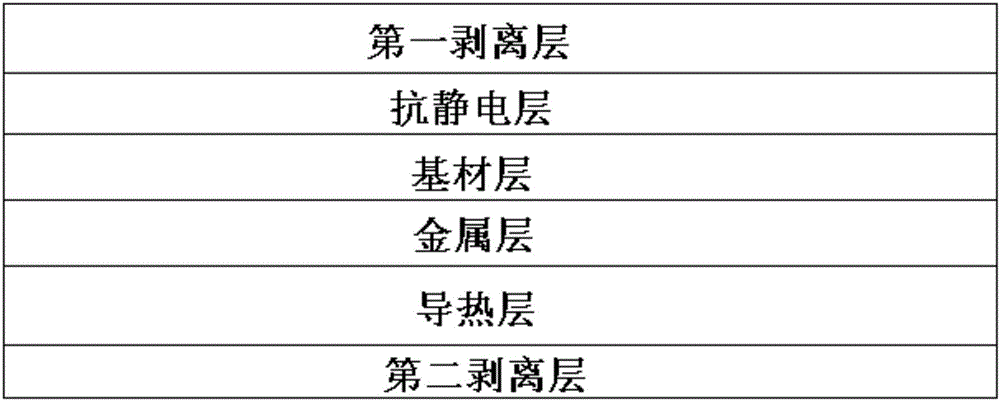

Anti-magnetic heat-conducting film and preparation method thereof

InactiveCN106113849AGood antimagneticSpread quicklySynthetic resin layered productsCoatingsHeat conductingBoron nitride

The invention provides an anti-magnetic heat-conducting film which comprises a first stripping layer, an antistatic layer compounded on the first stripping layer, a base material layer compounded on the antistatic layer, a metal layer compounded on the base material layer, a heat-conducting layer compounded on the metal layer, and a second stripping layer compounded on the heat-conducting layer, wherein heat-conducting particles are dispersed inside the heat-conducting layer, and comprise one or several of aluminum oxide particles, aluminum hydroxide particles, boron nitride particles and copper zinc alloy particles. According to the anti-magnetic heat-conducting film provided by the invention, the metal layer and the heat-conducting layer are simultaneously arranged, the heat-conducting particles are dispersed inside the heat-conducting layer, magnetism can be effectively resisted while matching with the metal layer, and heat generated on electronic components or electronic equipment can be rapidly transferred, so that an effect of protecting the electronic components and equipment is achieved. The invention also provides a method for preparing the anti-magnetic heat-conducting film.

Owner:胡银坤

Anti-peeping printable antimagnetic film and preparation method thereof

ActiveCN107142036BAvoid scratchesWith anti-magnetic effectSynthetic resin layered productsLaminationMagnetic effectAdhesive glue

The invention provides a peep-proof printable magnetic-resistant film. The peep-proof printable magnetic-resistant film comprises a first protective film layer, an UV hardened layer composited to the first protective layer, a TPU layer composited on the UV hardened layer, an OCA adhesive layer composited on the TPU layer, a substrate layer combined on the OCA adhesive layer, a micro louver structure layer composited on the substrate layer and a second protective layer combined to the micro louver structure layer. The UV hardened layer is made of metal and oxide thereof, carbon conductive material and UV varnish glue. The UV hardened layer has an anti-magnetic effect and a printable function, the UV-hardened layer cooperates with the other layers to obtain the peep-proof printable magnetic-resistant film which has display confidentiality, the peep-proof layer is effectively prevented from being scratched, and the film has good printability and magnetic resistance and can meet customer's personal pursuit.

Owner:NALI OPTICAL MATERIAL DONGGUAN

A kind of anti-blue light antimagnetic thin film and preparation method thereof

ActiveCN106566430BGood antimagneticImprove anti-blue light effectFilm/foil adhesivesOrganic non-macromolecular adhesiveProtecting eyeElectromagnetic interference

An anti-blue-light antimagnetic film and a preparing method thereof are disclosed. The film has a good antimagnetic property and good anti-blue-light effects, thus playing a role of protecting glasses of persons and protecting electronic elements. The film includes, from top to bottom, an upper release film, an anti-blue-light layer, an antimagnetic metal layer, an insulating substrate, an acrylic adhesive layer and a lower release film. The thickness of the anti-blue-light layer is 50-100 [mu]m. The thickness of the antimagnetic metal layer is 50-100 [mu]. The thickness of the carrier insulating substrate is 50-150 [mu]. Anti-blue-light and antimagnetic functions are combined, and therefore the anti-blue-light antimagnetic film not only protects eyes of persons from being damaged by blue light, but also protects electronic products from electromagnetic interferences.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Non-magnetic ventilation channel steel material for nuclear power/hydropower station and preparation method thereof

The invention belongs to the field of stainless steel material molding, in particular to a non-magnetic ventilation box iron material for a nuclear power / hydropower station and a preparing method of the non-magnetic ventilation box iron material. Ventilation box iron 0Cr18Ni9 comprises chemical components including 18%-19% of Cr, not larger than 4.0% of Mn, 8%-9% of Ni, not larger than 0.04% of C,not larger than 1.0% of Si, not larger than 0.035% of P, not larger than 0.020% of S, 2%-3% of Cu, 0.18%-0.22% of N and the balance Fe and inevitable impurities. The ventilation box iron 0Cr18Ni9 isobtained through technologies of burdening, electric-arc furnace smelting, AOD furnace refining, electroslag remelting, continuous mill operation, solution treatment, wire winding, acid pickling, drying, drawing, solution treatment, roll forming, cutting, checking, packaging, storage and the like in sequence. The preparation technology is simple, and oxidation machining is not needed. The stainless steel material prepared through the method has the beneficial effect that the austenite structure is stable, the magnetic conductivity is reduced while the strength is guaranteed, the condition thatthe magnetic conductivity mu is smaller than or equal to 1.1(H=15924 A / m), the beneficial effects of high ductility, good resistance to oxidation, good diamagnetism, resistance to intergranular corrosion and the like are achieved, and traditional 0Cr18Ni9 austenitic stainless steel can be replaced.

Owner:大连环新新材料科技有限公司

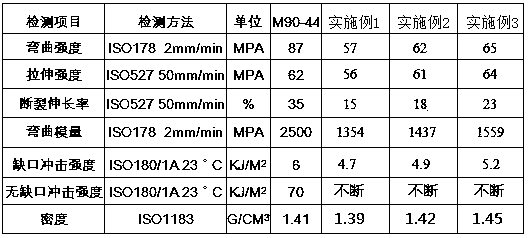

High-strength antimagnetic card case and preparation method thereof

InactiveCN106633306AGood antimagneticImprove mechanical propertiesGadolinium oxideMechanical property

The invention discloses a high-strength antimagnetic card case and a preparation method thereof. The preparation method of the high-strength antimagnetic card case comprises the following steps: 1) mixing polyethylene, an ethylene-vinyl alcohol copolymer, nano barium sulfate, nano gadolinium oxide, calcium sulfate whiskers, dibenzothiazyl disulfide, wollastonite powder, silicon nitride and choropropyltrimethoxysilane to obtain a mixture; and 2) mixing and molding pentaerythritol ester of rosin, potassium titanate whiskers, wheat bran, acrylic fiber copper complexed fibers, wood fibers and the mixture to prepare the high-strength antimagnetic card case. The high-strength antimagnetic card case prepared by the method has excellent antimagnetic and mechanical properties; and meanwhile, the preparation method has the properties of easiness of obtaining the raw materials, simple procedures and easiness of being popularized.

Owner:ANHUI DAER INTELLIGENT CONTROL SYST

A power communication device based on power internet of things

InactiveCN111800962BEasy to fixEasy to useData switching detailsClosed casingsMechanical engineeringCommunication device

The invention discloses electric power communication equipment based on an electric power internet of things. The equipment comprises a main box body (3) and an upper box body (5) and the lower box body (2) connected to the upper end and the lower end of the main box body (3) respectively. A power communication equipment main body (16) is arranged in the main box body (3), transverse port grooves(8) are formed in the front ends and the rear ends of the upper box body (5) and the lower box body (2), and connecting assemblies are arranged in the upper box body (5) and the lower box body. According to the invention, through designing the connecting assembly, three installation modes of adsorption fixation, compression fixation and wall hanging fixation can be realized at the same time, and single use or mixed use can be selected according to needs, thereby facilitating the installation and fixation of the power communication equipment, enabling the power communication equipment to be fixed firmly, being very good in stability, and facilitating the use of the power communication equipment.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LAIYANG POWER SUPPLY CO

Magnetic-suspension wave detector

ActiveCN103048683BFast and accurate regressionHigh monitoring sensitivitySeismic signal receiversStable stateMagnetic poles

The invention provides a magnetic-suspension wave detector. The magnetic-suspension wave detector comprises a shell, a fixed permanent magnet, a first diamagnetic body, a coil, a second diamagnetic body and a suspension permanent magnet, wherein the fixed permanent magnet, the first diamagnetic body, the coil and the second diamagnetic body are sequentially arranged at the inner part of the shell from top to bottom, the suspension permanent magnet is positioned in the coil, and the magnetic pole magnetisms of the fixed permanent magnet and the suspension permanent magnet facing each other are different. According to the magnetic-suspension wave detector provided by the invention, the gravity born by the suspension permanent magnet can be offset through an attraction force from the fixed permanent magnet to the suspension permanent magnet, and the suspension permanent magnet is guaranteed to be in a stable state through the diamagnetic bodies which are positioned at the upper part and the lower part of the suspension permanent magnet; and when the suspension permanent magnet shifts to optional one direction, a component force of a horizontal direction or a vertical direction of a resulting force born by the suspension permanent magnet is opposite to a shifting direction, thus the suspension permanent magnet can be quickly and accurately attracted to return to a balance position, and the sensitivity and the accuracy of monitoring are increased.

Owner:丹东大东线圈工程有限公司

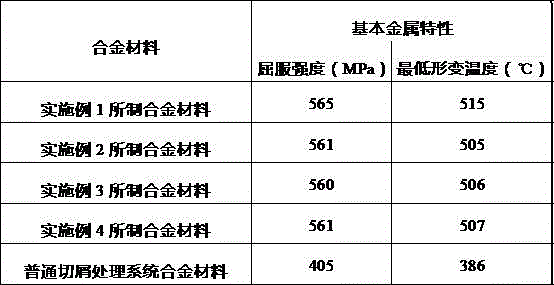

Alloy material for chip processing system of marine drilling platform and preparation method of alloy material

The invention provides an alloy material for a chip processing system of a marine drilling platform and a preparation method of the alloy material. The alloy material comprises components of raw materials as follows: C, Mn, Si, S, P, Cr, Ni, Mo, Cu, Ir, Mg, Al, V, W, Pb, Nb, Sn, Zn, Ho, Lu and the balance Fe. The preparation method comprises steps as follows: metal raw materials and nonmetal raw materials are sintered under the vacuum condition at the temperature of 950-1,000 DEG C, the sintered raw materials are cooled to 700 DEG C under the condition of inert gas pressurization for tempering, then are heated to 750 DEG C for annealing and are cooled finally, and a finished product of the material for the chip processing system of the marine drilling platform is obtained. The alloy material has antirust performance, antimagnetic performance, pressure resistance and seawater corrosion resistance and is not prone to deformation.

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

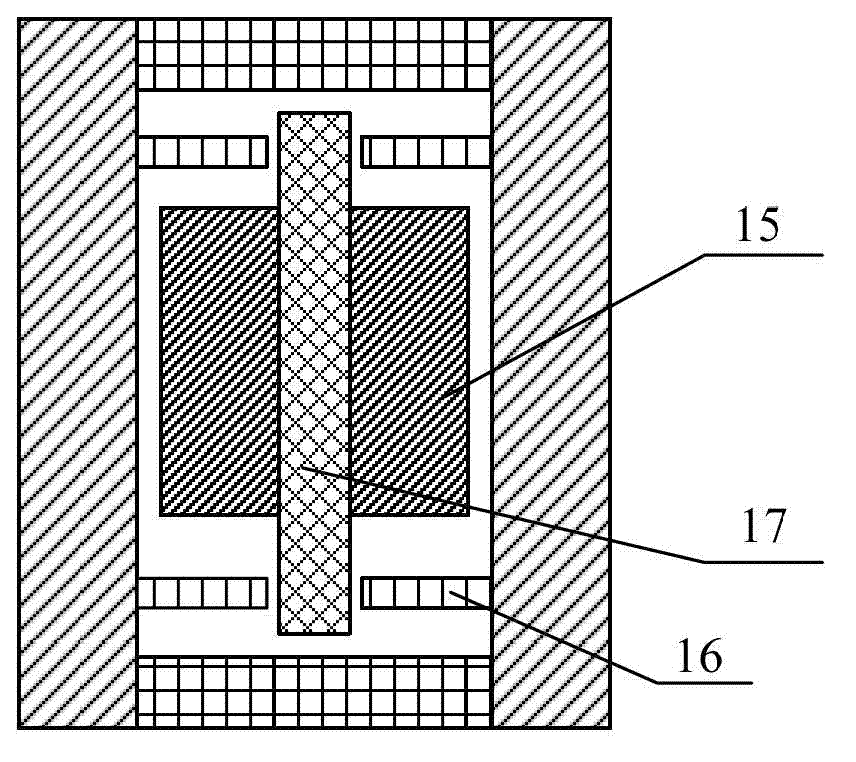

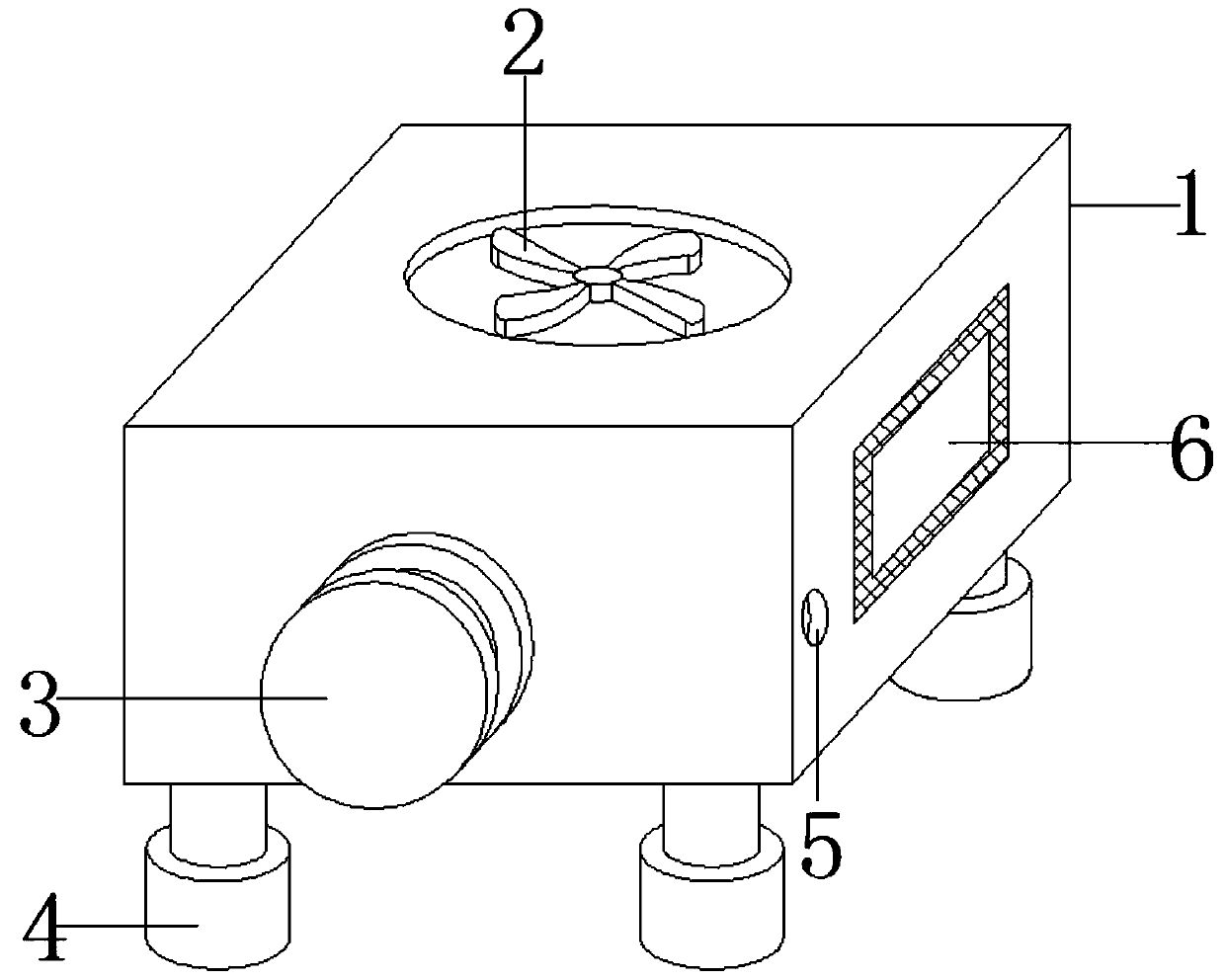

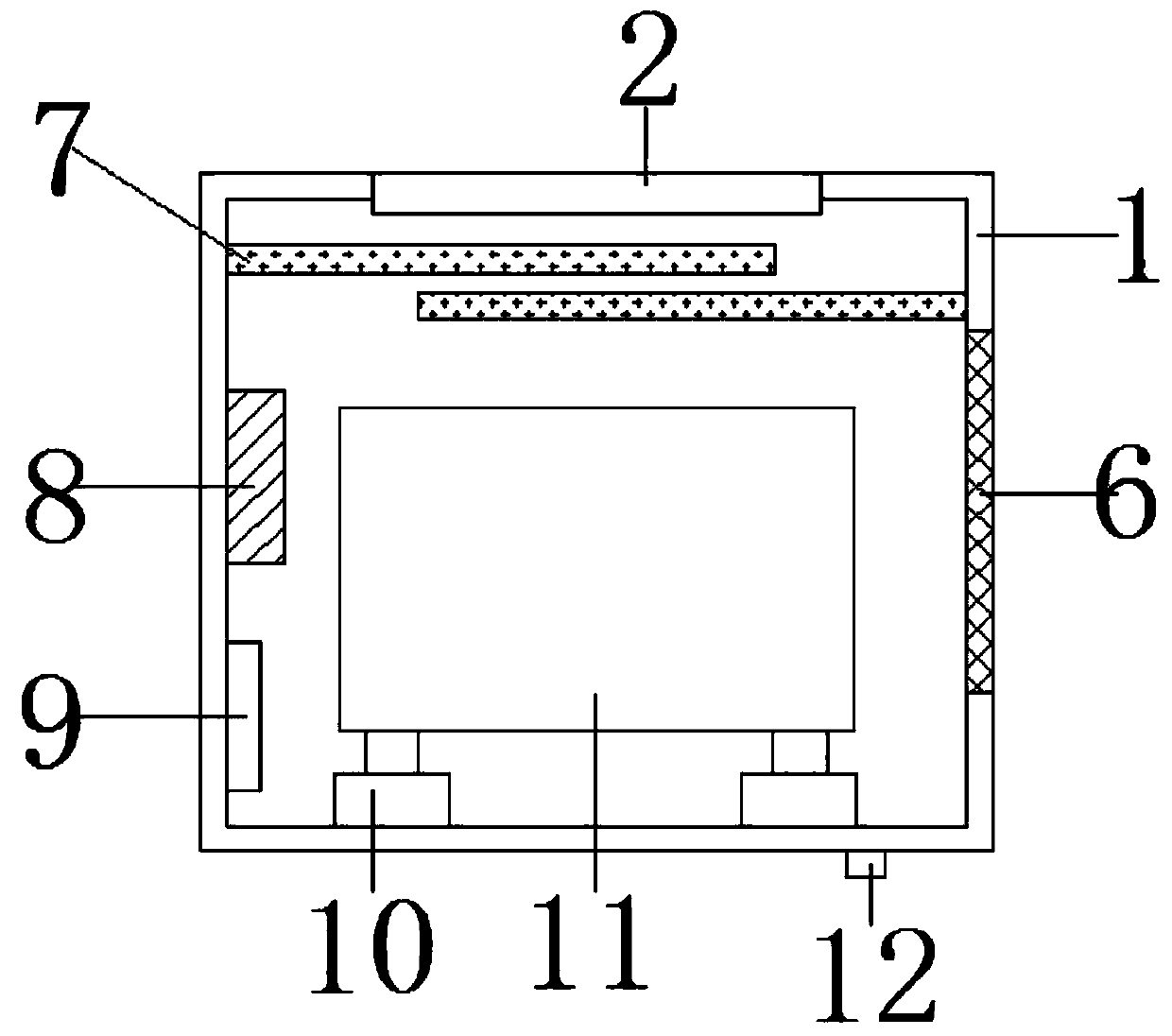

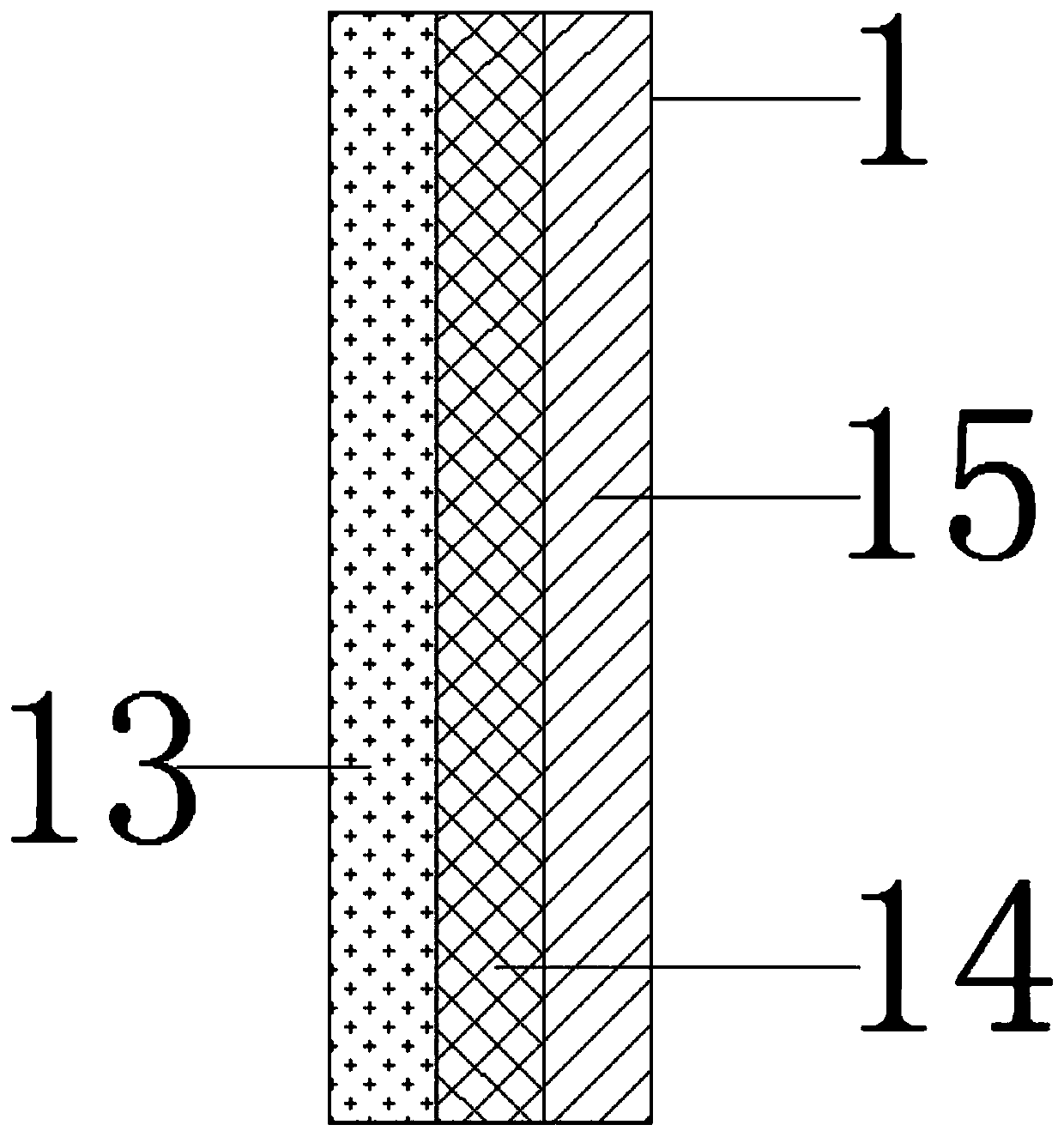

Magnetic disturbance generator, power generation method and device thereof

InactiveCN111509911AAvoid overall overheatingHigh outputCooling/ventillation arrangementSupports/enclosures/casingsMagnetic disturbanceDisplay device

The invention discloses a magnetic disturbance generator, a power generation method and device thereof, which comprises a shell. A fan is fixed in the middle of the top of the shell through screws; anopening is formed in the top of the shell corresponding to the fan; damping bases are fixed to the four corners of the bottom of the shell through screws; a grounding port is fixed on the bottom right side of the shell; a display is embedded in the middle of the right surface of the shell; a power outlet is arranged in the front of the display; the power outlet is embedded in the shell; two layers of isolation plates are arranged at the top of the inner side of the shell and arranged in a crossed mode, a generator is arranged below the isolation plates, damping supports are fixed to the fourcorners of the bottom of the generator through screws, a filter is arranged above the left side of the generator, a voltage detector is arranged below the filter, and the voltage detector and the filter are fixed to the inner wall of the shell through screws. The magnetic disturbance generator, the power generation method and the device have the advantages of multi-layer protection, electromagnetic filtering, voltage detection and multi-layer shock absorption.

Owner:重庆弘骊祥科技有限公司

High strength and long life check valve and manufacturing method thereof

The invention relates to a high strength and long life check valve and a manufacturing method thereof. The check valve comprises a check valve main body, an installation seat matched with the check valve main body, a sealing end arranged at the right end of the installation seat, and an oil inlet formed in the check valve main body; the check valve further comprises a spring fixed in the check valve main body, a spring seat, an arch feeding device arranged at the right end of the spring seat and a support column which is used for fixing the arch feeding device and arranged in the right end of the arch feeding device and can obtain a tapered forged flow line inclining to an inner hole in a centralized mode through square-to-circular hot extrusion and rotary forging ,. The check valve can achieve self-complementing of expansion under the high temperature and is high in safety.

Owner:NINGBO HUACHENG VALVE

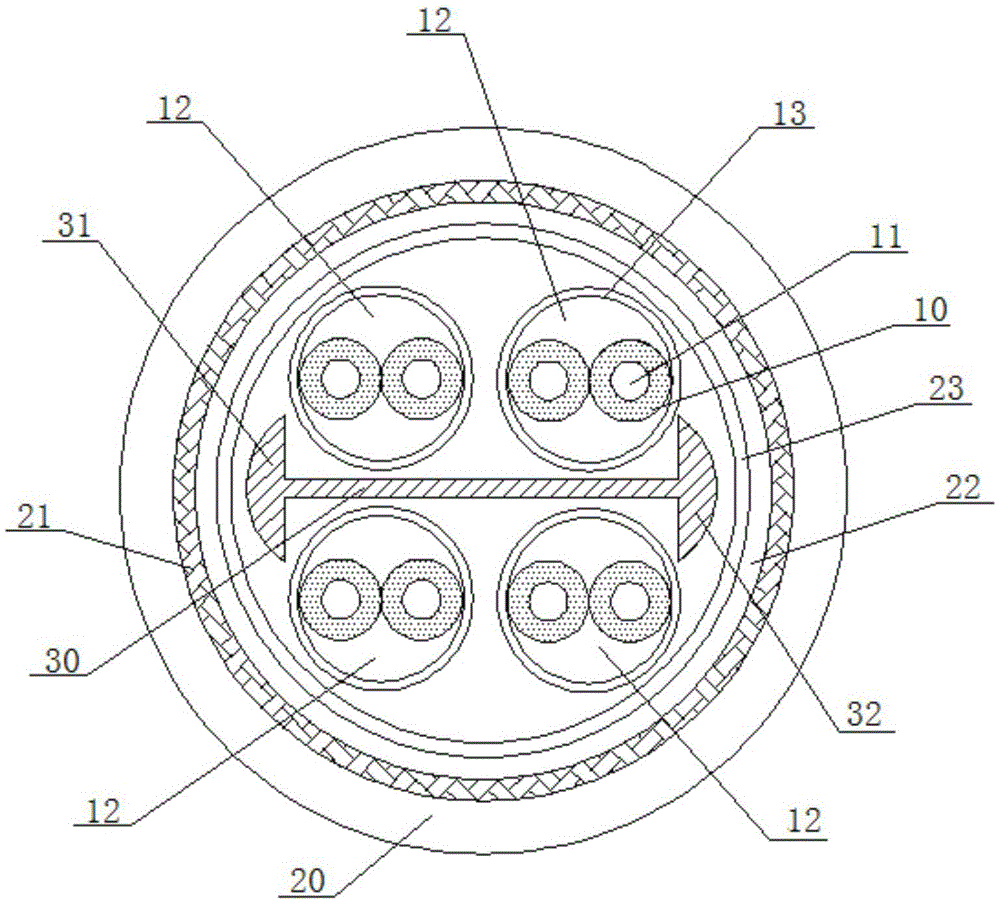

Anti-interference symmetrical communication cable

ActiveCN104036871BStable jobGuaranteed weather resistanceClimate change adaptationInsulated cablesMagnetic barrierWeather resistance

The invention discloses an anti-interference symmetric communication cable which is formed by wrapping a plurality of cable cores through insulation outer layers. The cable cores are symmetric, every two cable cores are regarded as a set to be wrapped by the insulation outer layers and vertically symmetric, and a barrier is arranged between every two vertical cable cores wrapped by the insulation outer layers. According to the anti-interference symmetric communication cable, the anti-magnetic barriers made of composite materials are arranged between upper sets of cable cores and lower sets of cable cores to play a good role of anti-electromagnetic interference, two arc blocking heads are integrally formed on each barrier to better fix the cable cores, and stable work of the cable is guaranteed. Barium sulfate is added in the materials of the barriers, so that good diamagnetism is achieved, silicon nitride materials have good temperature variation resistance, weather resistance of the cable is guaranteed, yttrium oxide effectively enhances zirconium oxide, and insulation property is better.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

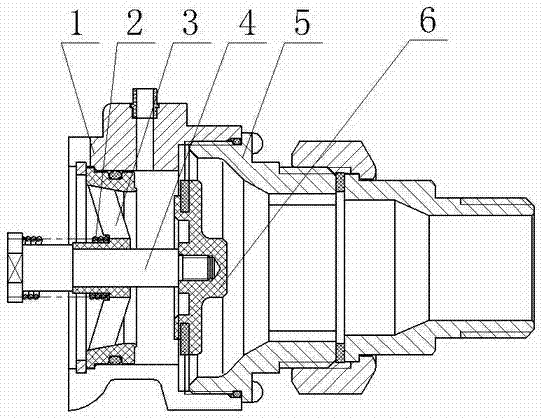

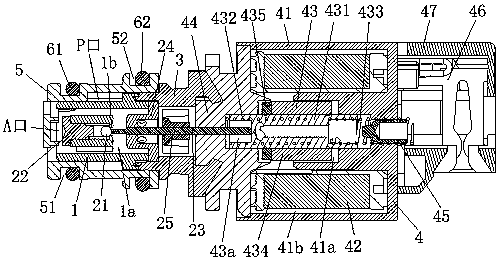

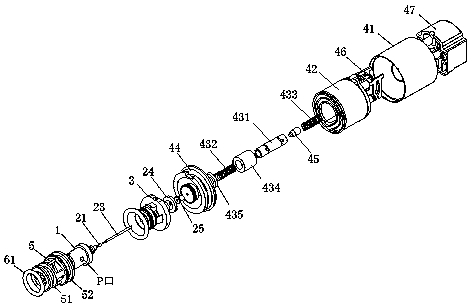

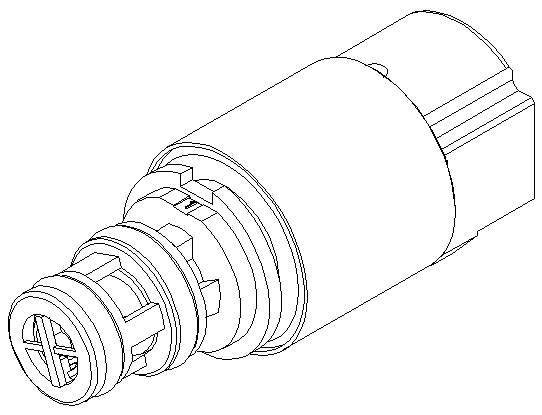

Solenoid valve for automatic transmission

ActiveCN106402408BEasy to installGood orientationClutchesOperating means/releasing devices for valvesAutomatic transmissionSolenoid valve

The invention discloses an electromagnetic valve of an automatic gearbox. The electromagnetic valve comprises a valve body with a valve cavity and an electromagnetic coil assembly. A hydraulic oil opening P and a hydraulic oil opening A are machined in the valve body. A valve element assembly is installed in the valve cavity of the valve body. The valve body is a plastic valve body formed by processing plastic. The valve element assembly is composed of a steel ball, a plastic valve stopper and an ejector rod, wherein the steel ball and a one-way oil opening in the valve cavity can form steel-plastic type soft sealing cooperation, and the ejector rod is used for axially pushing the steel ball to open the one-way oil opening so that an oil path between the opening P and the opening A can be through. An oil hole is formed in the plastic valve stopper, the electromagnetic coil assembly and the valve body are connected into a whole through a plastic sealing body, the tail end of the ejector rod extends into the electromagnetic coil assembly, and the electromagnetic coil assembly controls the ejector rod to push the steel ball through combination of electromagnetic force and spring force. The valve body is fixedly provided with a filter net connector which can enable the electromagnetic valve of the automatic gearbox and a speed changer valve plate to achieve quick insertion type installation. The filter net connector is provided with a filter net for filtering hydraulic oil flowing through the opening A and the opening P.

Owner:XINGYU ELECTRON (NINGBO) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com