Alloy material for automobile brake pump piston and preparation method of alloy material

An alloy material and automobile braking technology, applied in the field of iron-based alloys, can solve problems such as easy magnetization, driving safety threats, and reduced sealing performance, and achieve the effects of not easily deformed, excellent antimagnetic properties, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

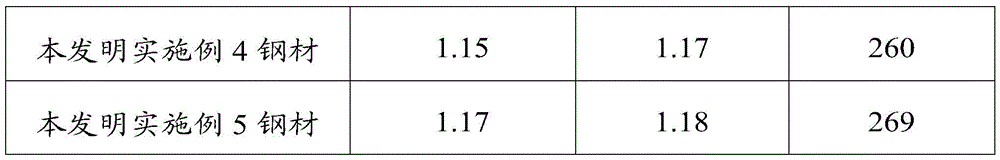

Examples

Embodiment 1

[0040] An alloy material used for automobile brake pump pistons, wherein the percentage of raw material components is:

[0041] C: 0.08%, Mn: 1.50%, P: 0.03%, S: 0.03%, Si: 1.50%, Cr: 18.0%, Ni: 10.0%, Ti: 0.70%, Ta: 0.5%, Nb: 0.20%, Cu: 1.0%, Ge: 0.7%, Sc: 0.30%, Eu: 0.40%, and the rest is Fe.

[0042] Prepared by:

[0043] (1) Add Fe, Mn, Cr, Ni, Ti, Ta, Nb, Cu, Sc, Eu elemental substances to be smelted into the vacuum chamber of the water-cooled copper crucible, vacuumize, and melt at a sintering temperature of 875°C;

[0044] (2) Add C, P, S, Ge, Si simple substances under the condition of metal melting, keep warm for 42min, and stir evenly;

[0045] (3) Cool the molten metal to room temperature at a cooling rate of 70° C. / min to obtain a rod.

[0046] (4) Fill the smelted metal blank with N at normal pressure 2 Under the conditions of tempering and holding for 42min, cool to room temperature at a cooling rate of 70°C / min to obtain rods.

Embodiment 2

[0048] An alloy material used for automobile brake pump pistons, wherein the percentage of raw material components is:

[0049] C: 0.04%, Mn: 0.80%, P: 0.03%, S: 0.03%, Si: 1.0%, Cr: 17.0%, Ni: 8.0%, Ti: 0.45%, Ta: 0.20%, Nb: 0.20%, Cu: 0.70%, Ge: 0.70%, Sc: 0.20%, Eu: 0.20%, and the rest is Fe.

[0050] Prepared by:

[0051] (1) Add the Fe, Mn, Cr, Ni, Ti, Ta, Nb, Cu, Sc, Eu elemental substances to be smelted into the vacuum chamber of the water-cooled copper crucible, vacuumize, and melt at a sintering temperature of 870°C;

[0052] (2) Add C, P, S, Ge, Si simple substances under the condition of metal melting, keep warm for 20min, and stir evenly;

[0053] (3) Cool the molten metal to room temperature at a cooling rate of 50° C. / min to obtain a rod.

[0054] (4) Fill the smelted metal blank with N at normal pressure 2 Under the conditions of tempering and holding for 20 minutes, cool to room temperature at a cooling rate of 50°C / min to obtain rods.

Embodiment 3

[0056] An alloy material used for automobile brake pump pistons, wherein the percentage of raw material components is:

[0057] C: 0.10%, Mn: 2.0%, P: 0.04%, S: 0.04%, Si: 2.0%, Cr: 20.0%, Ni: 11.0%, Ti: 0.70%, Ta: 0.50%, Nb: 0.50%, Cu: 1.20%, Ge: 1.20%, Sc: 0.50%, and the rest is Fe.

[0058] Prepared by:

[0059] (1) Fe, Mn, Cr, Ni, Ti, Ta, Nb, Cu, Sc to be smelted are added to the vacuum chamber of the water-cooled copper crucible, vacuumed, and melted at a sintering temperature of 850°C;

[0060] (2) Add C, P, S, Ge, and Si simple substances under the condition of metal melting, keep warm for 50min, and stir evenly;

[0061] (3) Cool the molten metal to room temperature at a cooling rate of 80° C. / min to obtain a rod.

[0062] (4) Fill the smelted metal blank with N at normal pressure 2 Under the conditions of tempering and heat preservation for 50min, the rod was obtained by cooling to room temperature at a cooling rate of 80°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com