Solenoid valve for automatic transmission

A technology of automatic transmission and solenoid valve, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems affecting the performance and service life of solenoid valve, difficulty in maintaining coaxiality, difficult processing and assembly, etc. Simple, reduced machining accuracy, and the effect of low machining accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

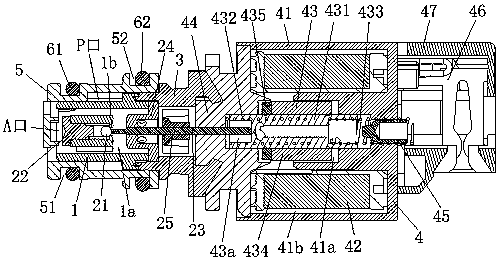

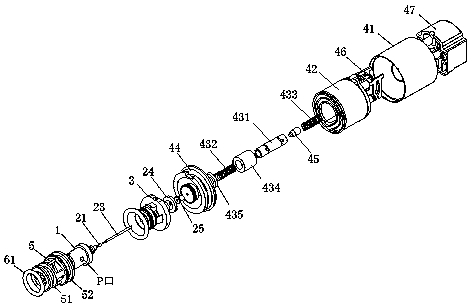

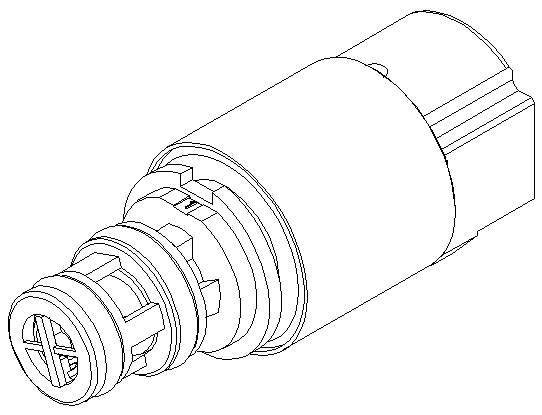

[0021] Such as Figure 1 to Figure 4 Shown is the structural representation of the present invention,

[0022] The reference signs are: valve body 1, valve cavity 1a, one-way oil port 1b, steel ball 21, plastic valve plug 22, ejector rod 23, copper seat 24, copper seat guide hole 24a, lubricating oil hole 24b, ejector rod Seat 25, plastic package body 3, electromagnetic coil assembly 4, coil casing 41, central step hole 41a, annular assembly cavity 41b, electromagnetic coil 42, moving iron core group 43, positioning concave hole 43a, thick ejector rod 431, front spring 432, Rear spring 433, moving iron core 434, aluminum gasket 435, static iron core 44, rear spring seat 45, insert piece 46, socket cover 47, filter screen connector 5, annular sealing groove 51, annular channel 52, the first A sealing ring 61 and a second sealing ring 62 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com