Copper alloy injection forming technology

An injection molding, copper alloy technology, applied in the field of copper alloy injection molding process, can solve the problems of difficult to meet high strength and high thermal conductivity, unstable product performance, high production cost, achieve excellent antimagnetic performance, shorten production cycle, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

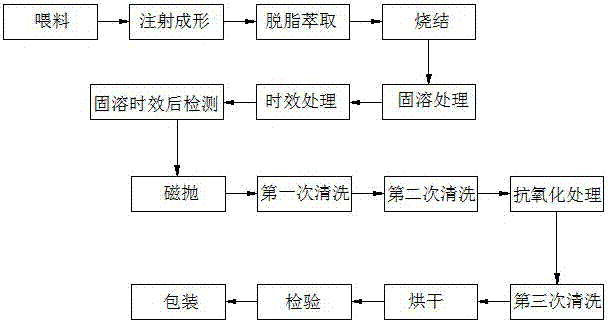

Method used

Image

Examples

Embodiment 1

[0042] A copper alloy injection molding process, comprising the following preparation steps:

[0043] a. Mixing material: uniformly mix copper alloy powder and binder together to make feed for injection, wherein the mass percentage of chemical components in copper alloy powder is: copper 98.8%, chromium 1.2%.

[0044] b. Injection molding: the feed is injected into the injection machine, and the feed is injected into the barrel of the injection machine at an appropriate pressure and heated to form a rheological plastic material. The injection pressure of the feed into the barrel is 120Mpa, and the injection speed is 50g / s, the temperature range of each temperature interval in the barrel is:

[0045] The first section of the barrel: 160°C, the second section of the barrel: 150°C, the third section of the barrel: 140°C, the fourth section of the barrel: 130°C, the fifth section of the barrel: 120°C;

[0046] Then inject it into the mold cavity from the nozzle of the injection ...

Embodiment 2

[0071] A copper alloy injection molding process, comprising the following preparation steps:

[0072] a. Mixing: Evenly mix copper alloy powder and binder together to make feed for injection.

[0073] The mass percentages of the chemical components in the copper alloy powder are: 99.0% copper and 1.0% chromium.

[0074] b. Injection molding: The feed is injected into the injection machine, and the feed is injected into the barrel of the injection machine at an appropriate pressure and heated to form a rheological plastic material. The injection pressure of the feed into the barrel is 115Mpa, and the injection speed is 60g. / s, the temperature range of each temperature range in the barrel is: the first barrel section: 170°C, the second barrel section: 160°C, the third barrel section: 150°C, the fourth barrel section: 140°C, the fifth barrel section: 130°C;

[0075] Then inject it into the mold cavity from the nozzle of the injection machine through a certain injection pressur...

Embodiment 3

[0100] A copper alloy injection molding process, comprising the following preparation steps:

[0101] a. Mixing: Evenly mix copper alloy powder and binder together to make feed for injection.

[0102] The mass percentages of the chemical components in the copper alloy powder are: 99.2% copper and 0.8% chromium.

[0103] b. Injection molding: The feed is injected into the injection machine, and the feed is injected into the barrel of the injection machine at an appropriate pressure and heated to form a rheological plastic material. The injection pressure of the feed into the barrel is 135Mpa, and the injection speed is 55g. / s, the temperature range of each temperature interval in the barrel is:

[0104] One stage of barrel: 180°C, second stage of barrel: 170°C, third stage of barrel: 160°C, fourth stage of barrel: 150°C, fifth stage of barrel: 140°C;

[0105] Then inject it into the mold cavity from the nozzle of the injection machine through a certain injection pressure. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com