Patents

Literature

125results about How to "Improve anti-blue light effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-blue-ray optical thin-film and application thereof

ActiveCN104849789ALow toxicityComply with ROHS regulationsOrganic dyesLensLight equipmentHigh energy

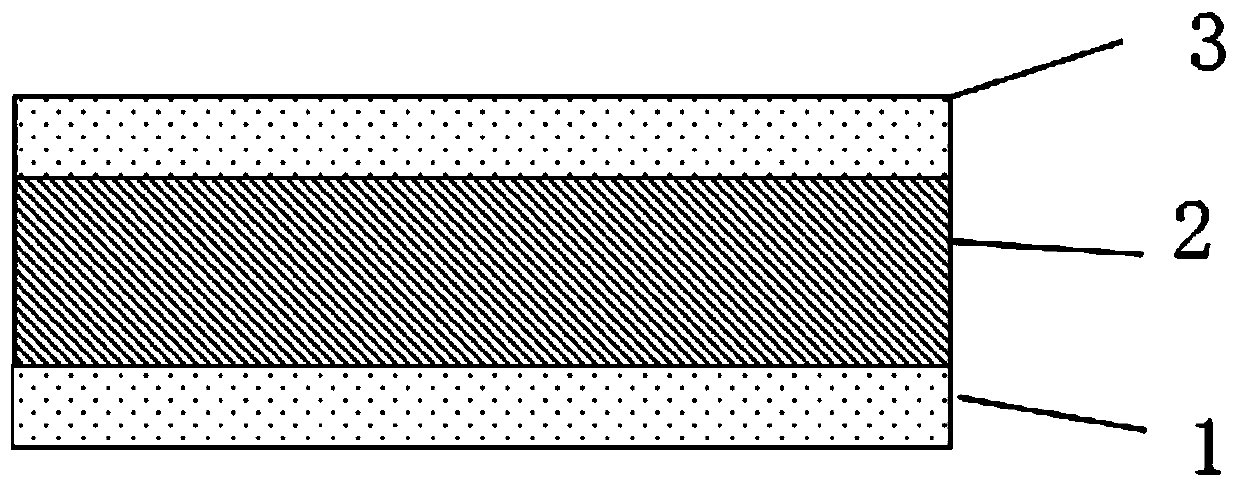

The invention relates to the technical field of thin-film display, and particularly relates to an anti-blue-ray optical thin-film applied to a displayer, a television display screen, a lamp box, an LED screen and a lamp, and an application thereof. In order to filer high-energy shortwave blue rays which are from the displayer and lighting equipment and damage eyes, the invention provides the anti-blue-ray optical thin-film and the application thereof. The optical thin-film comprises a functional layer, a base material layer and a protective coating layer. The base material layer is arranged between the functional layer and the protective coating layer. Anti-blue-ray additives are added in the functional layer and / or the protective coating layer. The anti-blue-ray additives are organic dyestuffs. The anti-blue-ray optical thin-film is applied to the displayer, the television display screen, the lamp box, the LED screen or the lamp so that a great anti-blue-ray effect can be achieved.

Owner:XIANGSHAN JIZHI NEW MATERIAL CO LTD

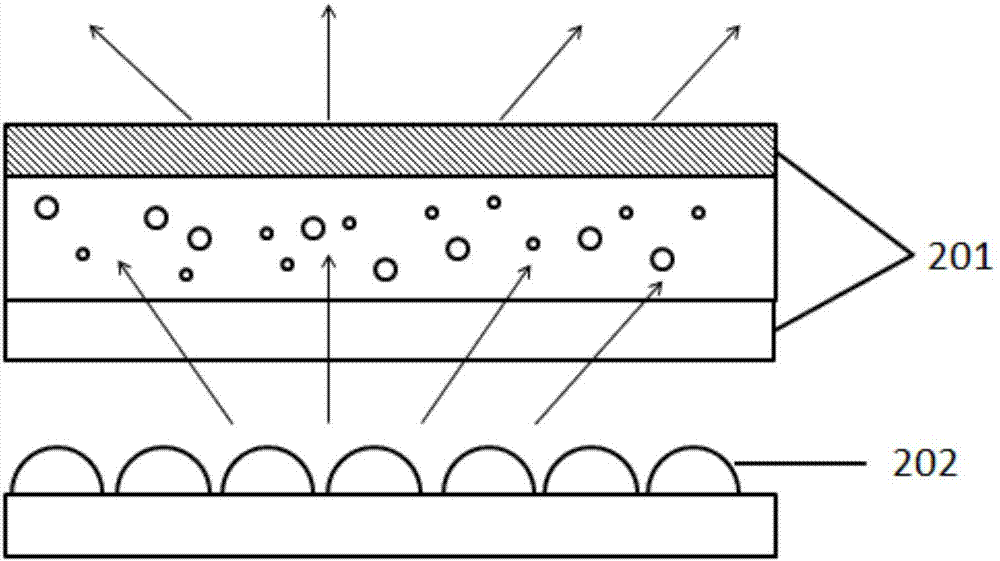

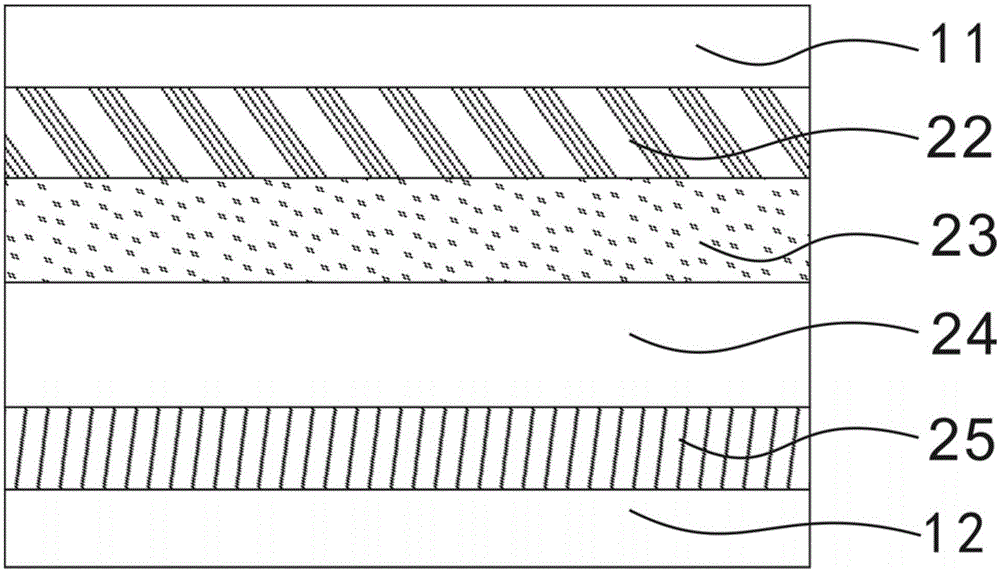

Quantum dot film with blue light preventing effect

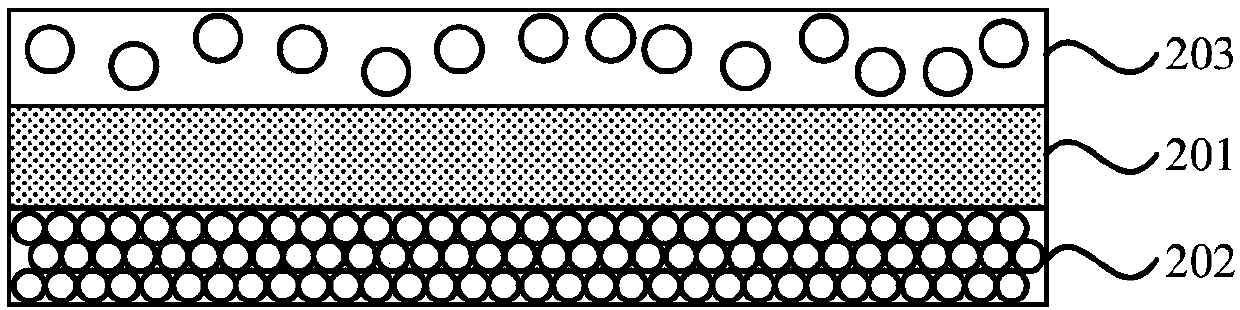

ActiveCN107975763AGuaranteed to pass throughGuarantee throughSynthetic resin layered productsElectrical equipmentQuantum dotQuantum

The invention relates to an optical film, in particular to a quantum dot film with a blue light preventing effect. In order to solve the problem that an existing quantum dot film is poor in blue lightpreventing stability in the using process, the invention provides the quantum dot film with the blue light preventing effect. The quantum dot film comprises a quantum dot layer; the upper surface ofthe quantum dot layer is provided with an upper blocking layer; the lower surface of the quantum dot layer is provided with a lower blocking layer; the quantum dot layer comprises quantum dots and anadhesive agent; the upper blocking layer comprises a blue light preventing material which is selected from one or more of a blue light preventing auxiliaries or blue light preventing particles. The quantum dot film has good blue light preventing stability, and solves the problem that because quantum dots in the quantum dot film lose efficacy, blue light is too much.

Owner:NINGBO EXCITON TECH

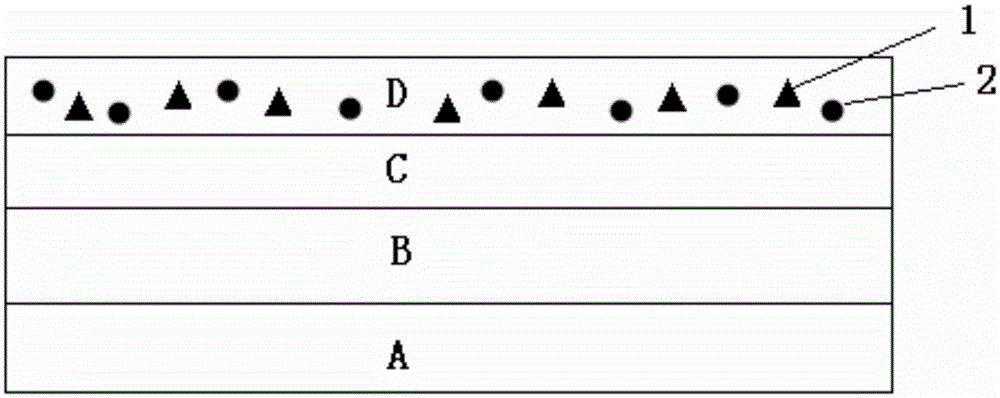

Multifunctional screen protection film

ActiveCN105058929AHigh hardnessImprove adhesionSynthetic resin layered productsAntistatic agentBiochemical engineering

The invention provides a multifunctional screen protection film which sequentially comprises a release film layer, an optimal adhesive layer, a base material layer and a multifunctional layer, wherein the optical adhesive layer is arranged on the release film layer, the base material layer is arranged on the optical adhesive layer, and the multifunctional layer is arranged on the base material layer and comprises an anti-blue-light agent, an antistatic agent and anti-newton's-ring coating resin. The multifunctional screen protection film has antistatic, anti-blue-light and anti-newton's-ring functions and has better anti-blue-light performance and the lower yellowing degree, so that the comfort degree of the screen protection film in use is increased. Besides, the multifunctional screen protection film is high in hardness, large in adhesive force, simple in structure, easy to produce and low in cost.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Blue light-proof protective film

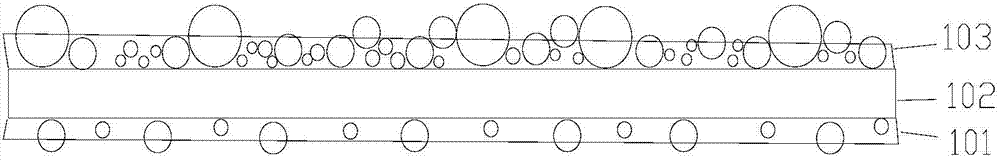

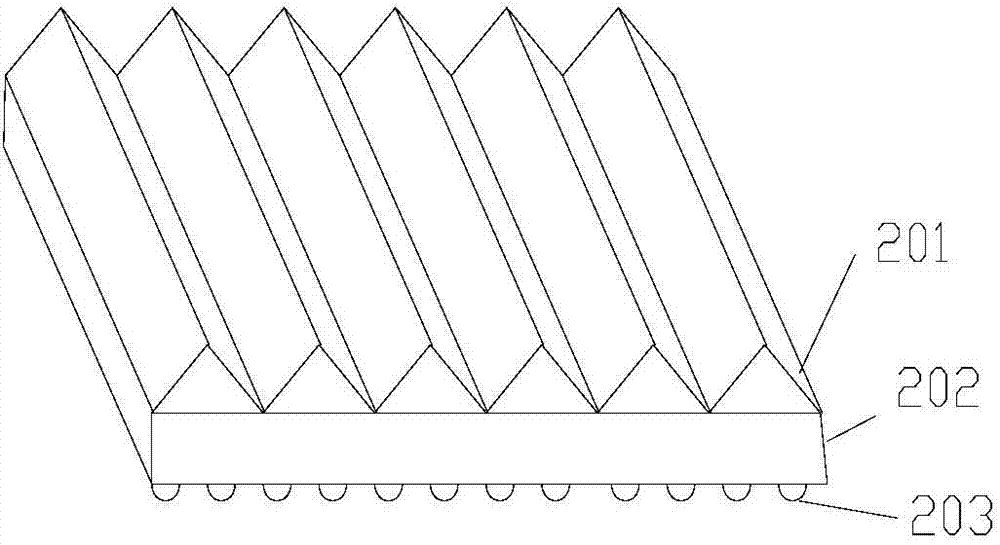

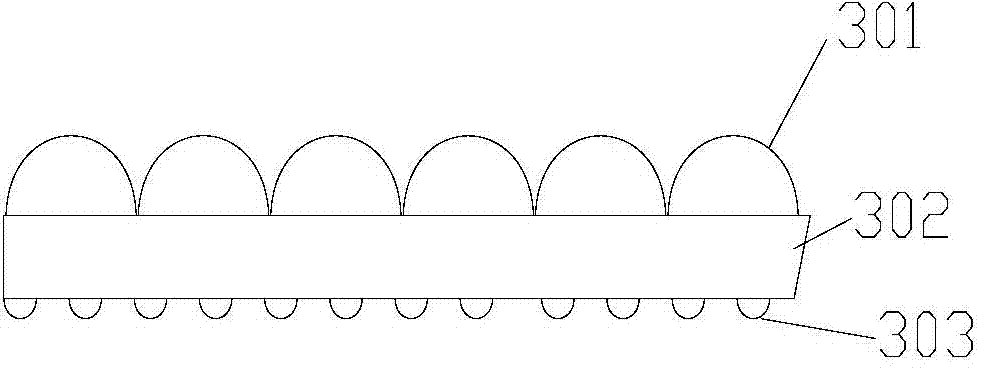

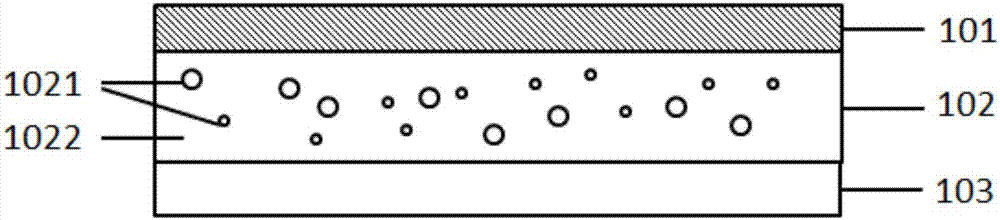

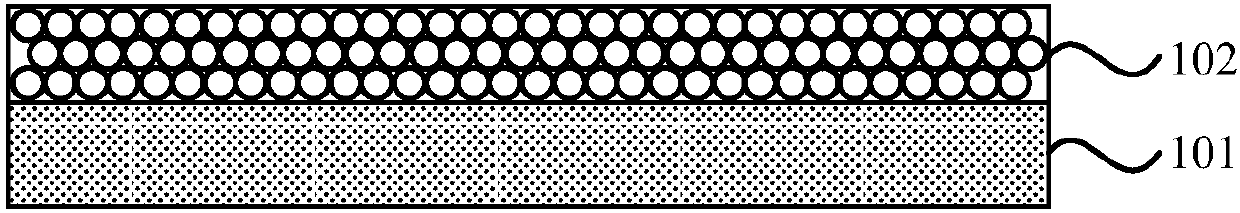

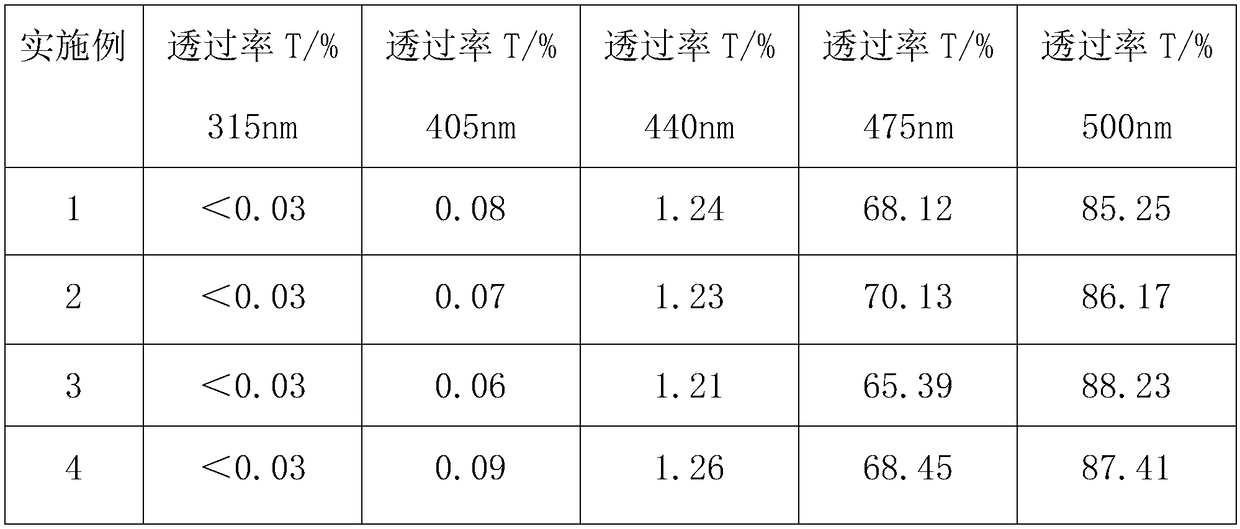

PendingCN108047981AHigh blue light blocking rateGood anti-blue light effectFilm/foil adhesivesVacuum evaporation coatingTectorial membraneOptical transmittance

The invention provides a blue light-proof protective film which comprises a functional layer; the functional layer comprises a first transparent substrate (101) and a blue light-proof layer (102) arranged on one side of the first transparent substrate (101); the blue light-proof layer (102) consists of one or at least two of nanometer tungsten oxide particles, nanometer titanium dioxide particles,nanometer silicon dioxide particles or nanometer yttrium aluminum garnet particles. The adopted blue light-proof layer with a specific material and a specific structure has relatively high blue lightobstruction rate, so that the blue light-proof protective film has a relatively good blue light-proof. The light transmittance of the blue light-proof protective film is greater than or equal to 92%,the obstruction rate to blue light with wave lengths of 380-430nm is up to 40-60%, the obstruction rate to blue light with wave lengths of 430-450nm is up to 70-80%, and the obstruction rate to bluelight with wave lengths of 450-470nm is up to 30-50%.

Owner:浙江欣麟新材料技术有限公司

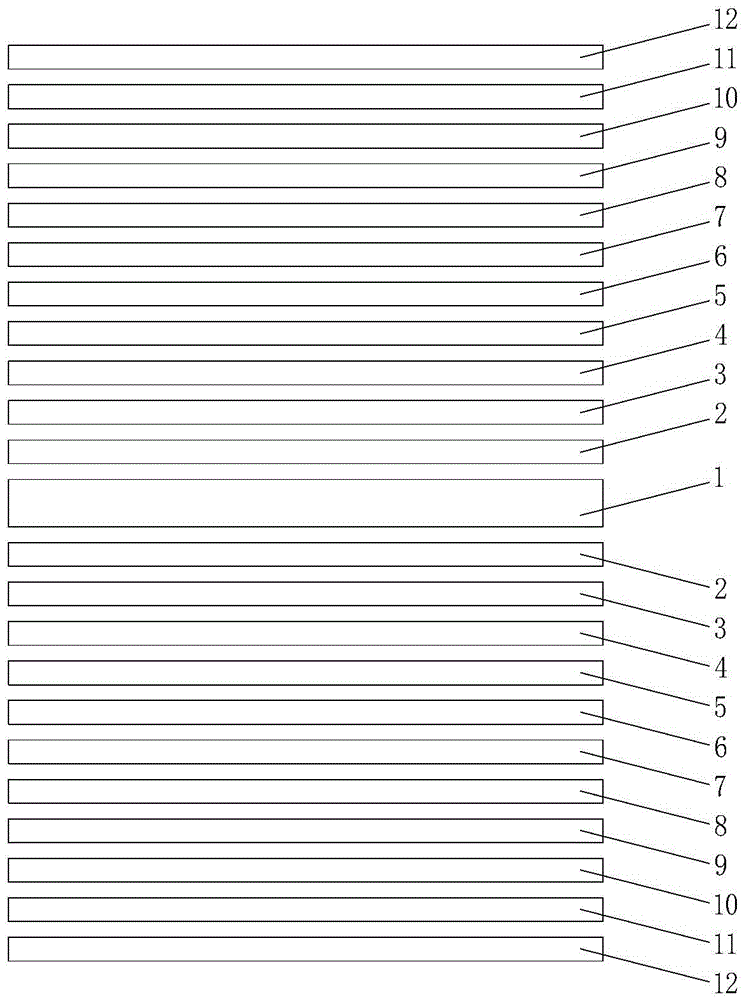

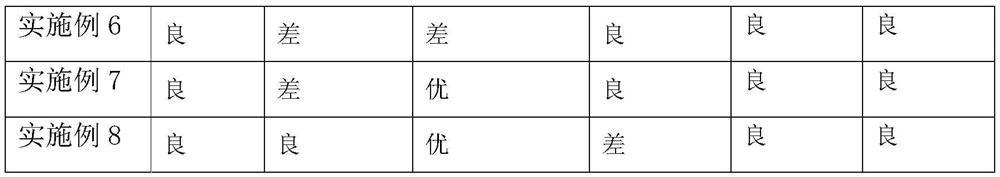

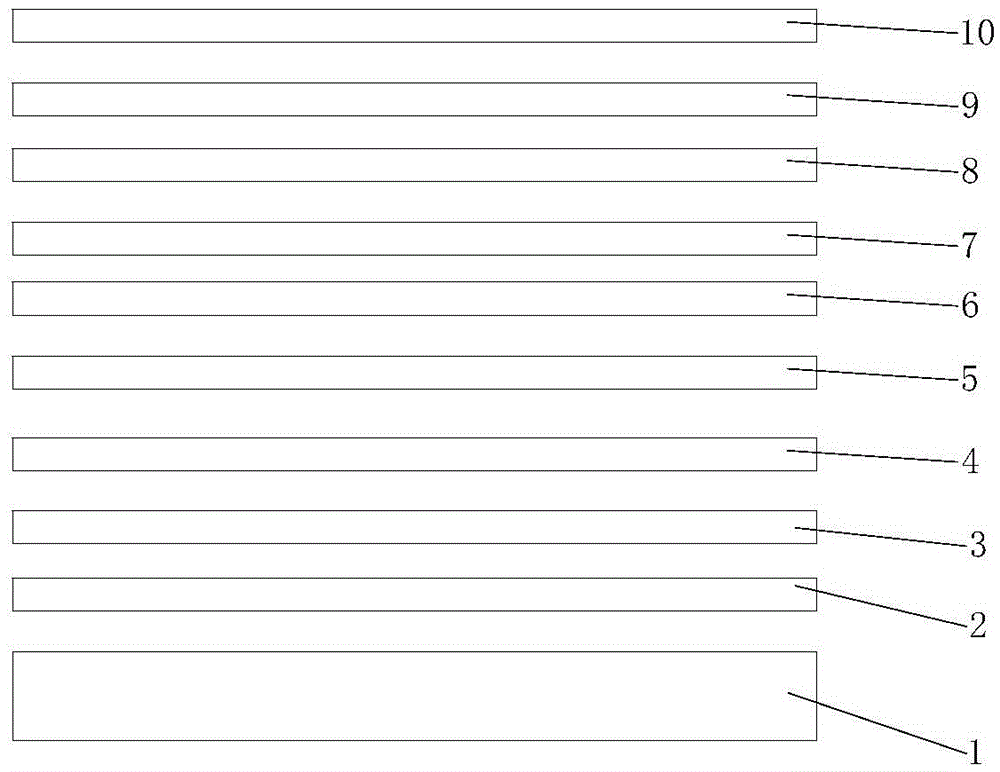

Multifunctional lens and preparing method thereof

InactiveCN105629508AHigh refractive indexImprove wear resistanceOptical partsOptical elementsHardnessFluoride

The invention relates to a multifunctional lens and a preparing method thereof. The lens comprises a base piece; a first membrane layer, a second membrane layer, a third membrane layer, a fourth membrane layer, a fifth membrane layer, a six membrane layer, a seven membrane layer, an eighth membrane layer, a ninth membrane layer, a tenth membrane layer and an eleventh layer are symmetrically sequentially arranged at the inner and outer surfaces of the base piece; the first, fourth and sixth membrane layers are Ti3O5 layers and have a thickness of 10-100nm; the second, fifth and seventh membrane layers are SiO2 layers and have a thickness of 50-100nm; the third membrane layer is a metal layer and has a thickness of 5-20nm; the eighth membrane layer is an ITO layer and has a thickness of 10-100nm; the ninth membrane layer is a nanosilver layer and has a thickness of 5-20nm; the tenth membrane layer is a high hardness layer and has a thickness of 10-50nm; the eleventh membrane layer is a fluoride layer and has a thickness of 3-10nm. The lens can effectively filter more than 30 percent of harmful blue light and dazzle light, can effectively relieve visual fatigue and the lens abrasion resistance is obviously improved by the high hardness layer.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

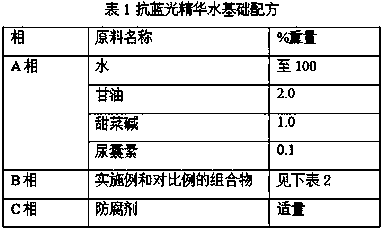

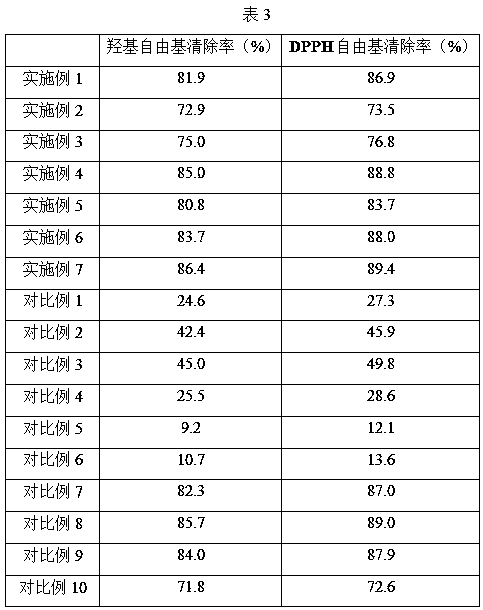

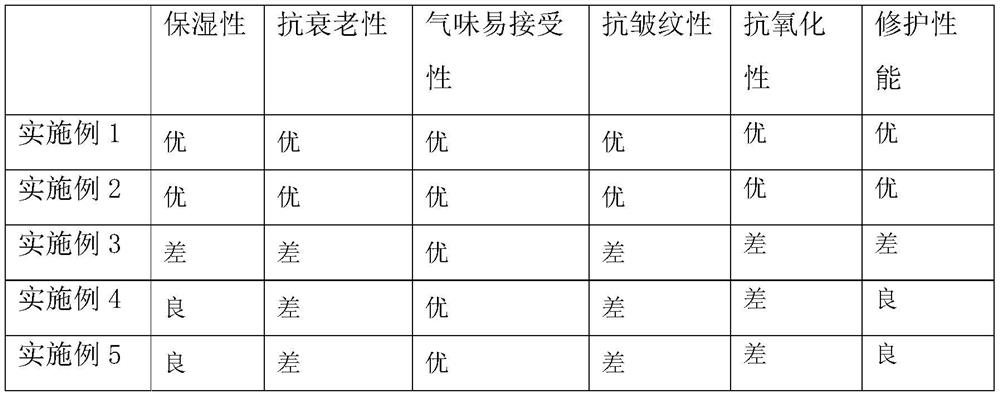

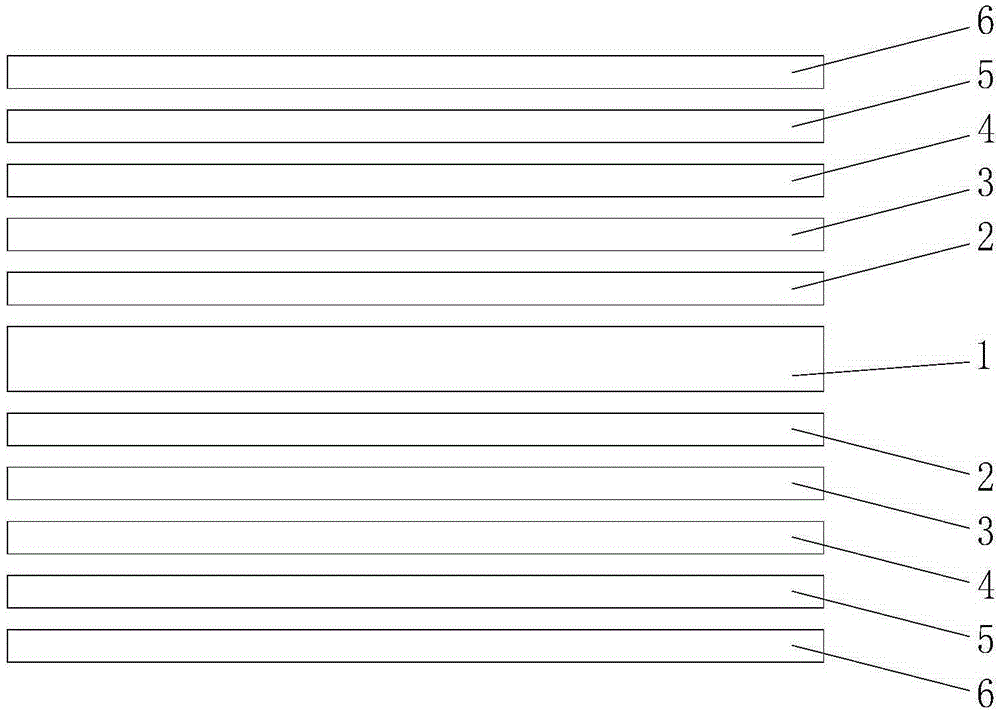

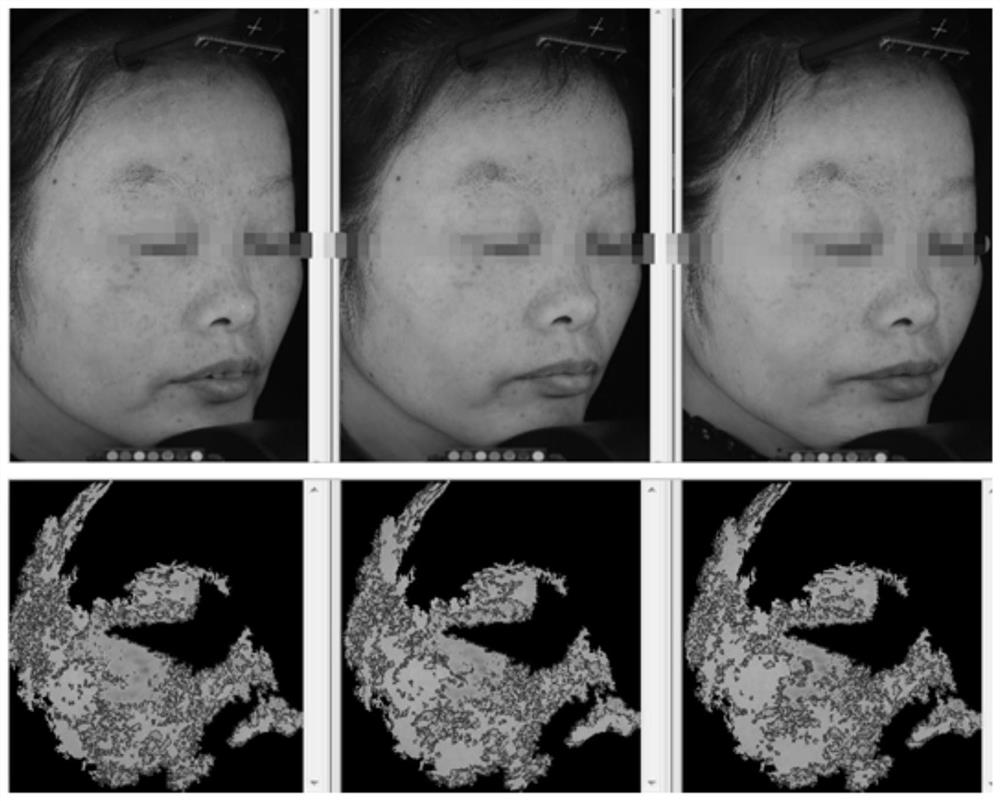

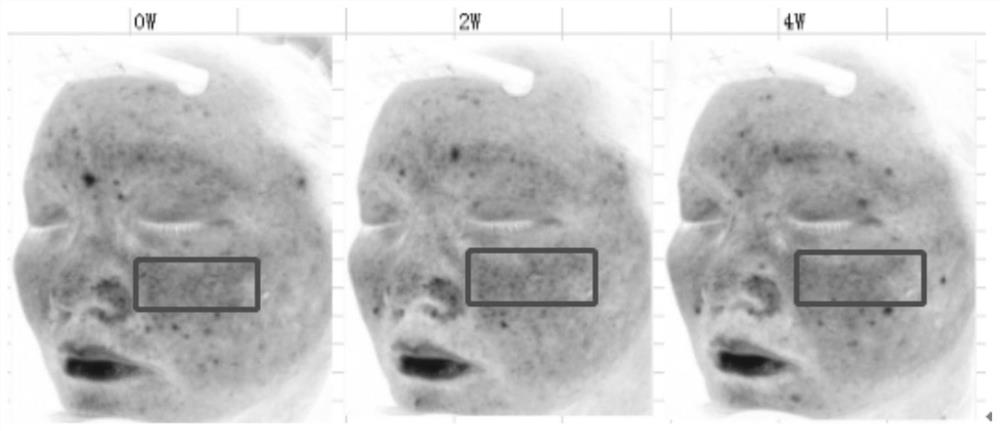

Composition containing L-Ergothioneine extract, brown rice fermentation filtrate and acetylchitosamine and application of composition

ActiveCN110917061ARegulation stateImprove fatigueCosmetic preparationsToilet preparationsBiotechnologyAbsorption (skin)

The invention discloses a composition containing L-Ergothioneine extract, brown rice fermentation filtrate and acetylchitosamine and application of the composition. The composition includes 0.1-2.0 parts of L-Ergothione extract, 0.1-4.0 parts of brown rice fermentation filtrate and 0.1-2.0 parts of acetylchitosamine. Since the three natural fermentation source components which include the L-Ergothioneine extract, brown rice fermentation filtrate and acetylchitosamine are selected, the composition has the advantages of naturalness, high activity, easy absorption and high safety, an obvious synergistic effect is achieved through sieving of the dosage of the components, meanwhile, the effects of regulating the biological rhythm of skin, delaying skin aging and improving pigmentation are achieved, and damage of blue light to the skin is prevented from the three aspects, so that comprehensiveness is achieved, and the blue light resistant effect is achieved.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

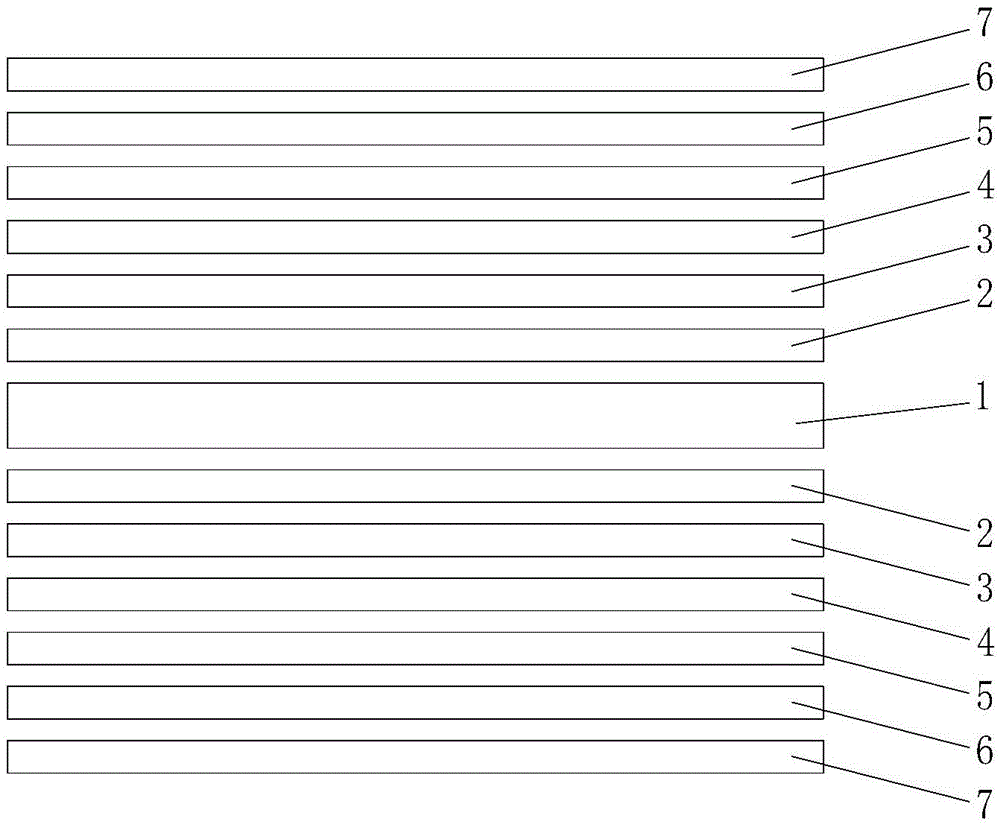

Sterilizing, anti-dazzle, anti-reflection and wear-resisting lens and preparing method thereof

InactiveCN105467620AHigh refractive indexImprove anti-reflection effectOptical filtersOptical partsEngineeringHardness

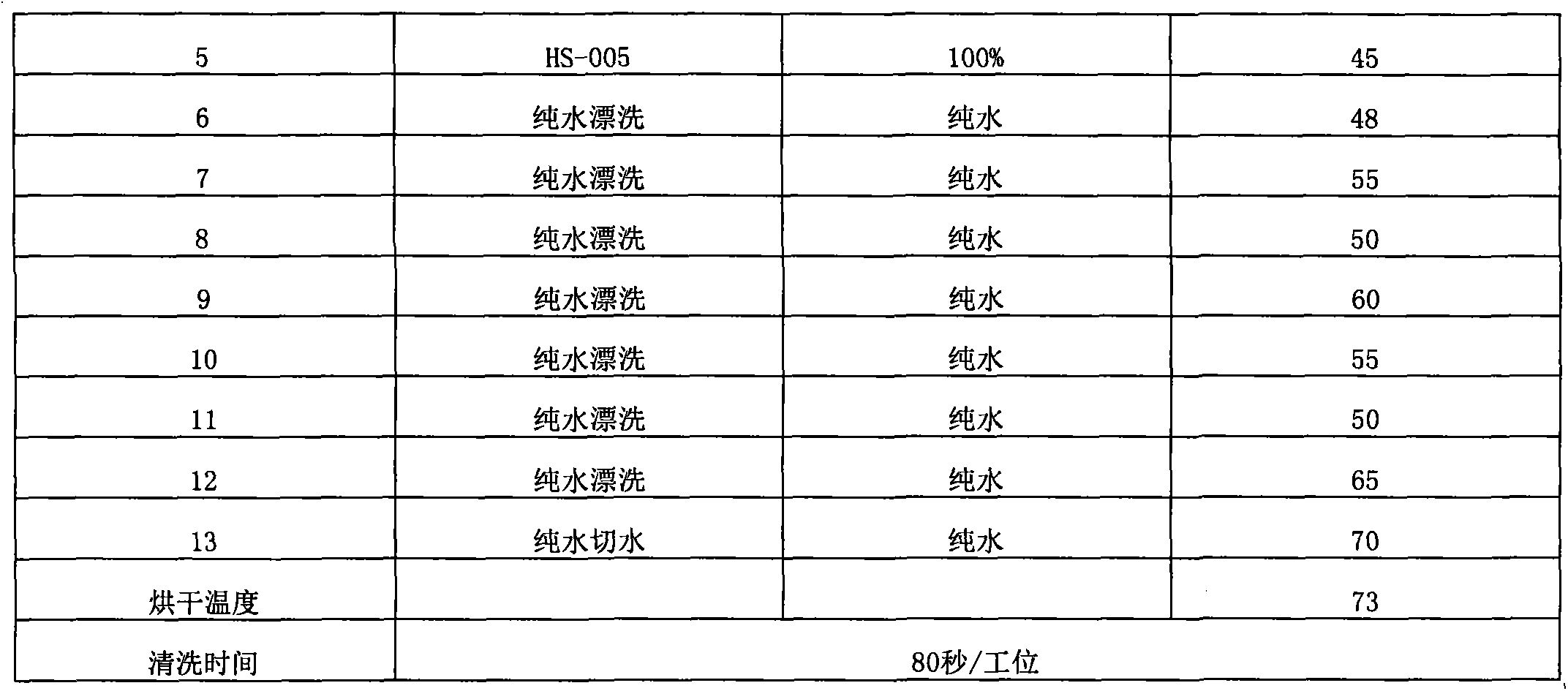

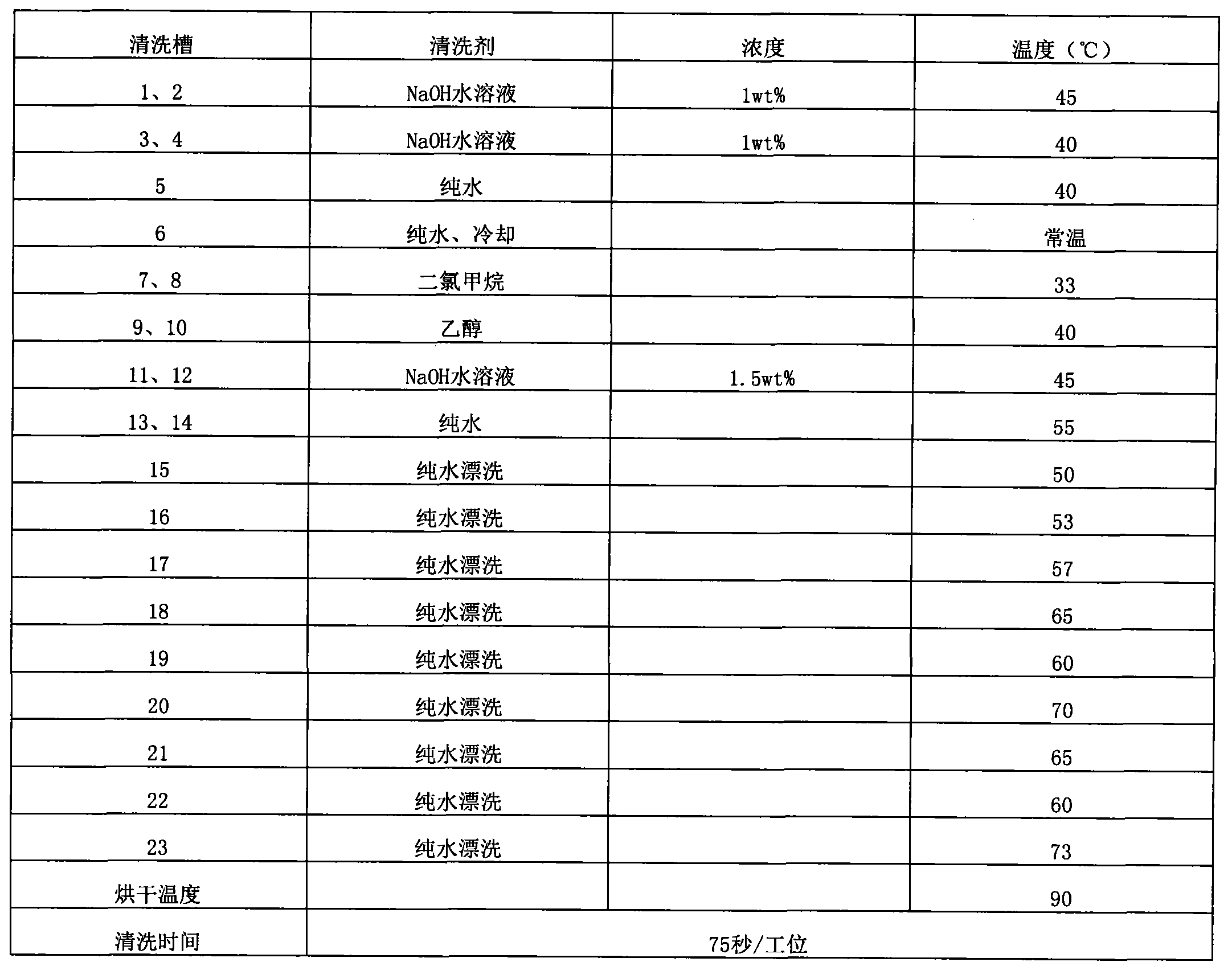

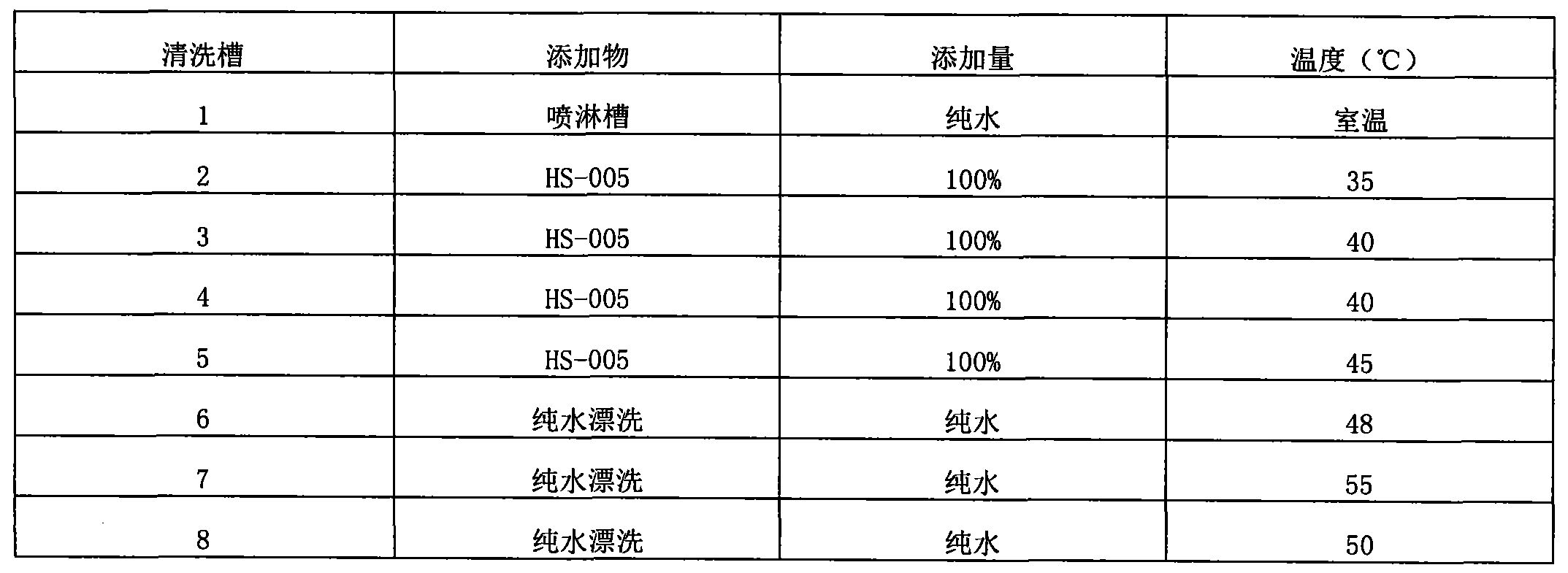

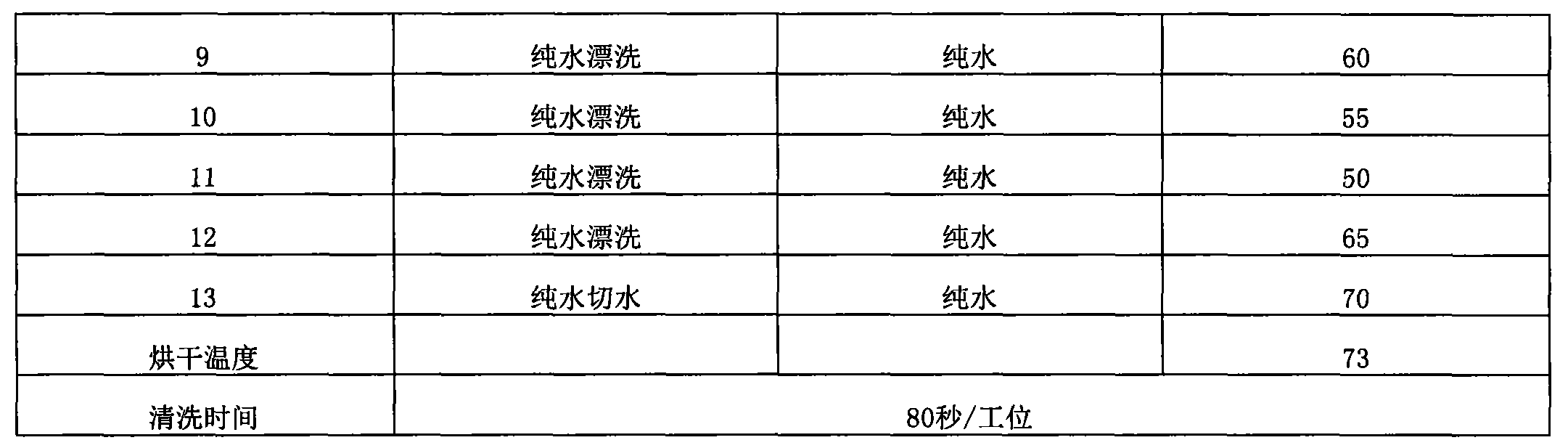

The invention relates to a sterilizing, anti-dazzle, anti-reflection and wear-resisting lens and a preparing method thereof. The lens comprises a substrate. The inner surface of the substrate is sequentially provided with a first film, a second film, a third film, a fourth film, a fifth film and a sixth film from inside to outside, the outer surface of the substrate is sequentially provided with a first film, a second film, a third film, a fourth film, a fifth film and a sixth film from inside to outside, and the first film, the second film, the third film, the fourth film, the fifth film and the sixth film of the inner surface and the first film, the second film and the third film, the fourth film, the fifth film and the sixth film of the outer surface are symmetrical. The first films and the third films are trititanium pentoxide layers, and the thickness of the first films and the thickness of the third films both range from 10 nm to 100 nm; the second films and the fourth films are silicon dioxide layers, and the thickness of the second films and the thickness of the fourth films both range from 50 nm to 100 nm; the fifth films are nano-silver layers, and the thickness of the fifth films ranges from 5 nm to 20 nm; the sixth films are high hardness layers, and the thickness of the sixth films ranges from 10 nm to 50 nm. The preparing method includes the following steps that 1, the substrate is washed; 2, the inner surface and the outer surface of the substrate are coated with the films. By means of the lens, the definition can be effectively increased, the anti-blue-light effect can be effectively improved, dazzling can be prevented, the wear resistance can be improved, bacterium growth can be effectively inhibited, and the lens has the harmful-bacterium killing performance.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Heat-insulating protective film capable of preventing blue light and ultraviolet light and resisting fog

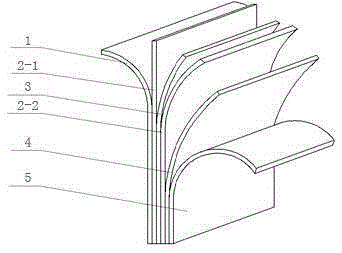

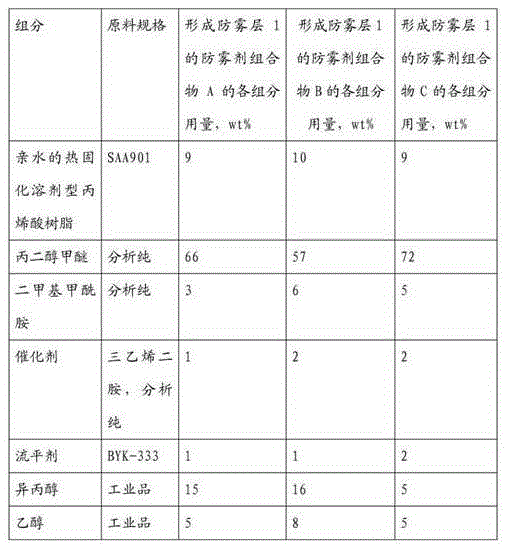

ActiveCN105385377AEasy to prepareEasy to operateNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterAdhesive

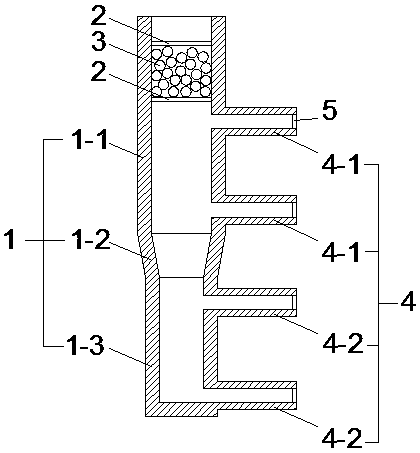

The invention relates to a heat-insulating protective film capable of preventing blue light and ultraviolet light and resisting fog. The heat-insulating protective film is formed by a fog resisting layer (1), a first polyester film (2-1), a blue light-preventing heat-insulating adhesive layer (3), a second polyester film (2-2), an ultraviolet blocking pressure-sensitive adhesive layer (4) and a release film (5), and all the layers are combined into a whole; the blue light-preventing heat-insulating adhesive layer (3) is a mixed material formed by a compound light stabilizer, a heat-insulating material, an adhesive, a curing agent and a solvent and is used for coating the other surface of the first polyester film (2-1), and the ultraviolet blocking pressure-sensitive adhesive layer (4) is a mixed material formed by an adhesive, a curing agent, an ultraviolet absorbent and a solvent and is used for coating the other surface of the second polyester film (2-2). The heat-insulating protective film capable of preventing blue light and ultraviolet light and resisting fog provided by the invention can effectively protect human eyes from being harmed by blue light through being attached to glass surfaces of buildings and automobiles, and meanwhile, has the functions of blocking the ultraviolet light, insulating heat, resisting fog, and the like.

Owner:安徽精一门科技发展有限公司

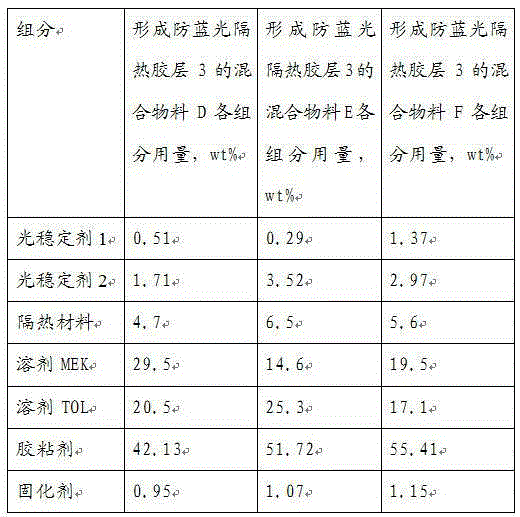

Anti-blue light polarizers and liquid crystal display panels

InactiveUS20170153495A1Increase screen brightnessNo color differencePolarising elementsNon-linear opticsLiquid-crystal displayPolarizer

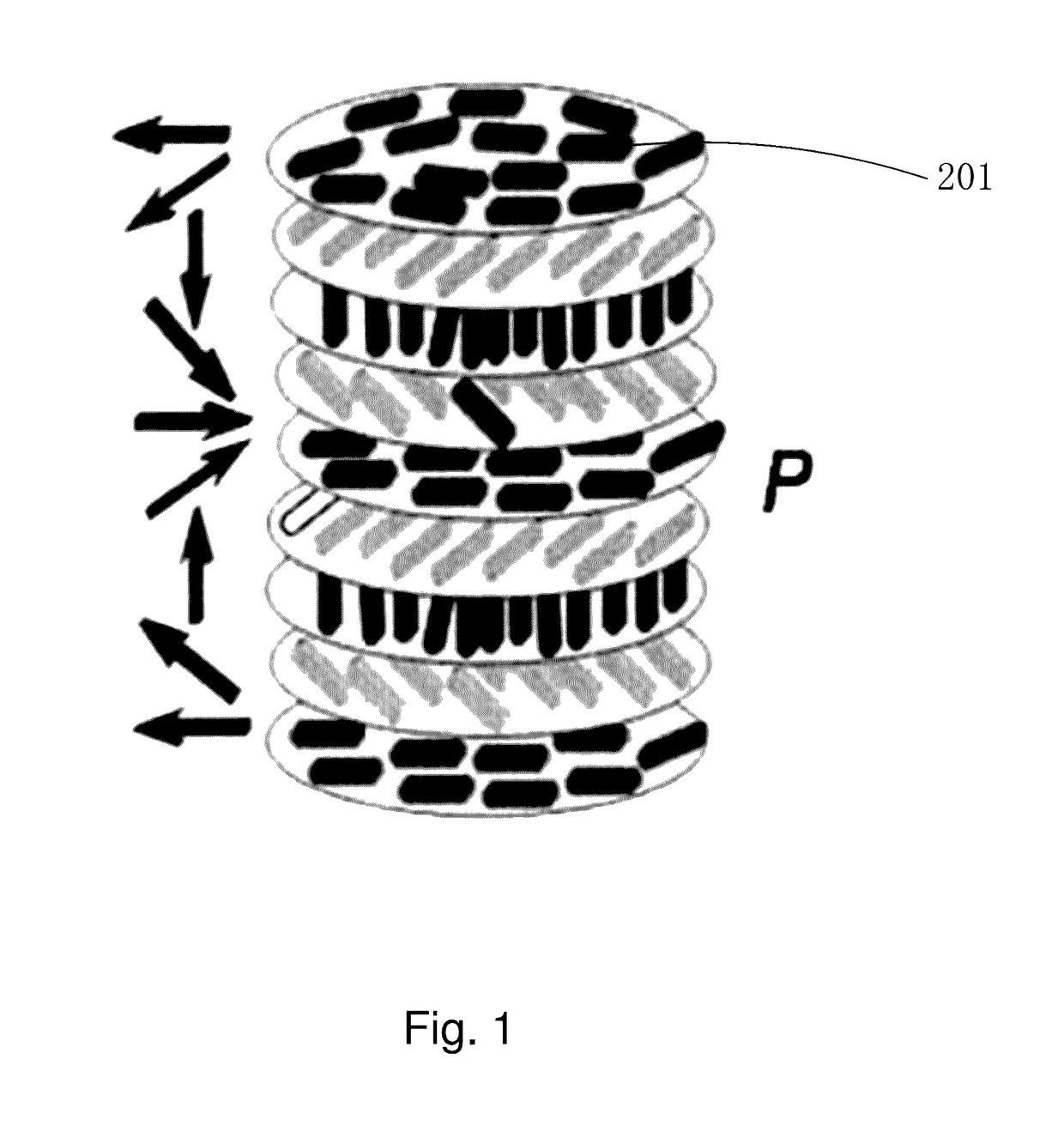

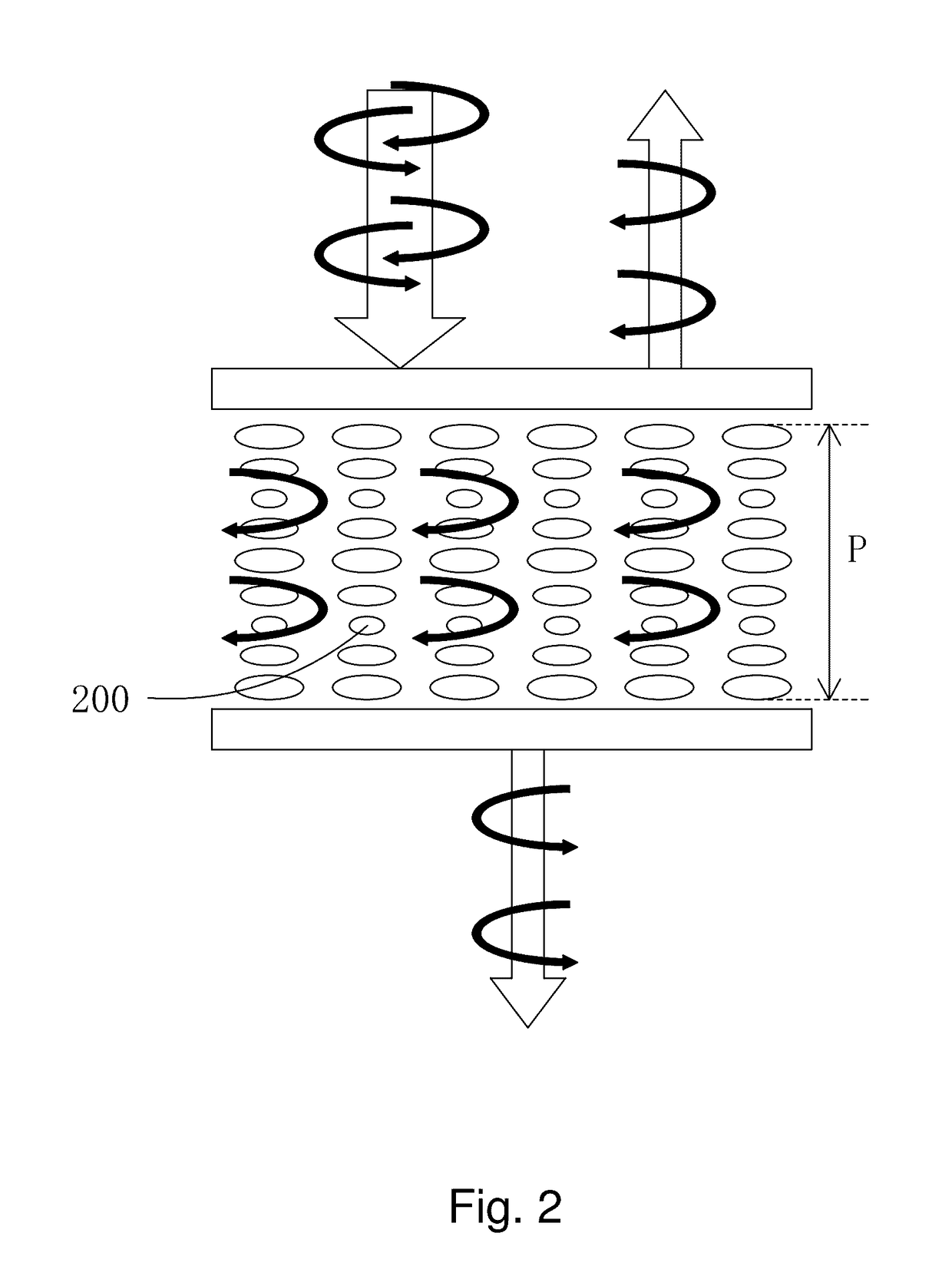

The present application provides an anti-blue light polarizer and a liquid crystal display panel. The anti-blue light polarizer includes at least a left spiral cholesteric phase liquid crystal film and at least a right spiral cholesteric phase liquid crystal film, the left spiral cholesteric phase liquid crystal film and the right spiral cholesteric phase liquid crystal film mutually stack, and pitches of the left spiral cholesteric phase liquid crystal and pitches of the right spiral cholesteric phase liquid crystal are within wavelength range of the blue light, so that the left spiral cholesteric phase liquid crystal film reflects left spiral light in the blue light, the right spiral cholesteric phase liquid crystal film reflects right spiral light in the blue light, then all the blue light are reflected and cannot enter human eyes, and thus a favorable anti-blue light effect is achieved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

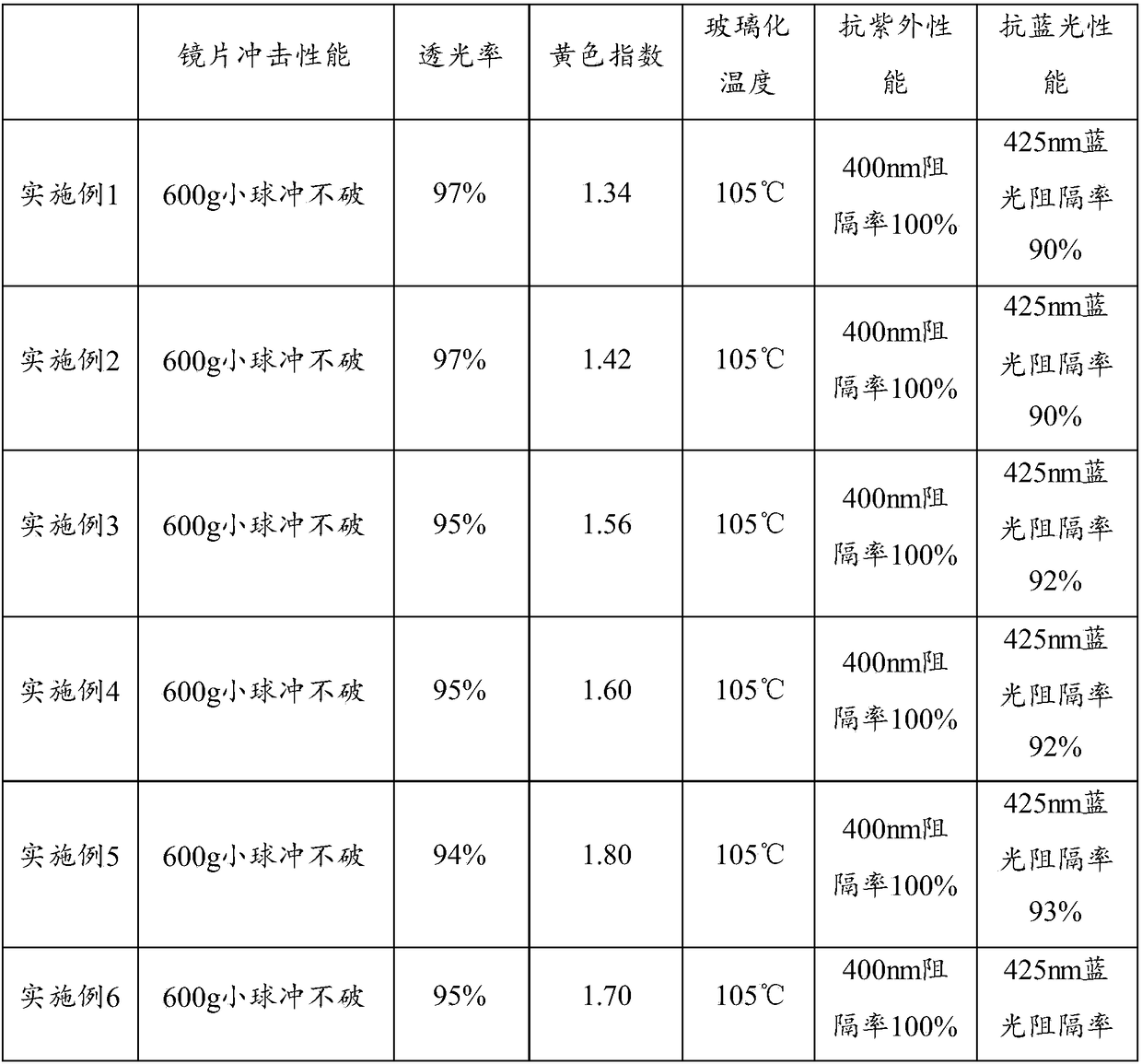

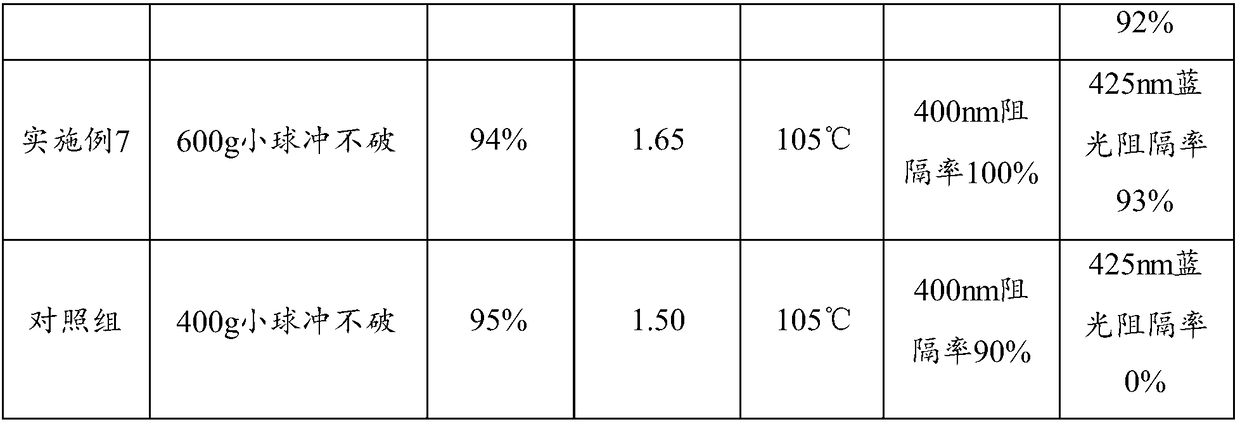

Ultrahigh-toughness anti-blue light resin lens and preparation method thereof

ActiveCN108084385AImprove impact toughnessImprove anti-blue light effectOptical partsPropanoic acidBenzotriazole

The invention provides an ultrahigh-toughness anti-blue light resin lens and a preparation method thereof. The ultrahigh-toughness anti-blue light resin lens is prepared from polyisocyanate, a polythiol compound, a carboxylic compound, a polyphenol compound, a modifying agent, a demoulding agent and a tin catalyst as raw materials according to a mass ratio of (30-60):(2-10):(2-10):(30-60):(0.1-1):(0.01-0.1):(0.01-0.1, wherein the carboxylic compound is one or more of C2-C15 aliphatic dicarboxylic compounds, C3-C20 aliphatic tricarboxylic compounds and C6-C30 aromatic carboxylic compounds; themodifying agent is selected from 3-[3-tert-butyl-4-hydroxy-5-(5-chloro-2H-benzotriazol-2-yl)phenyl] methyl propionate and / or 3-[3-(benzotriazol-2-yl)-5-tert-butyl-4-hydroxyphenyl]propionic acid. The ultrahigh-toughness anti-blue light resin lens has relatively high impact toughness, anti-blue light performance and ultraviolet resistance.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

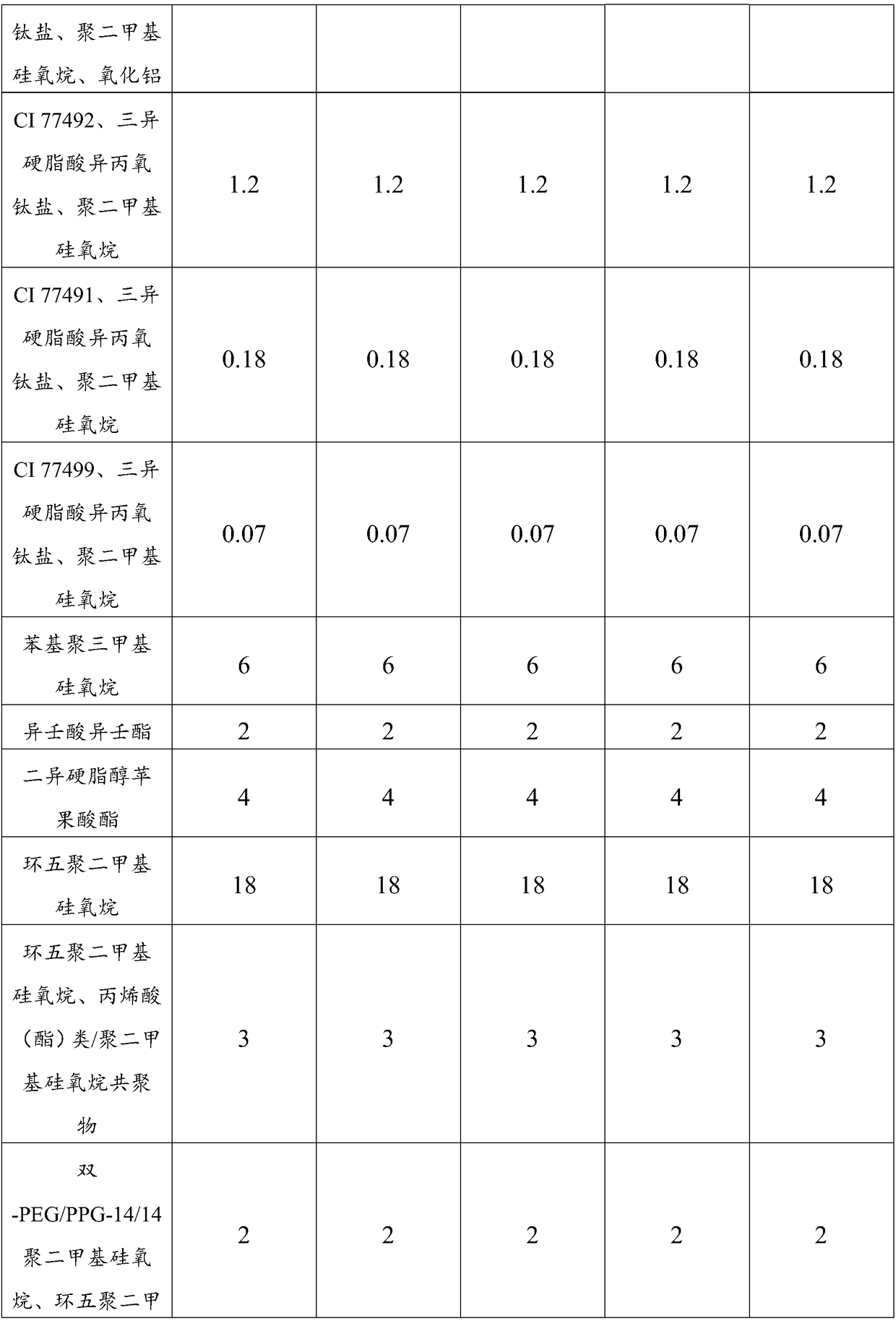

Moisturizing, repairing, anti-aging and anti-saccharificationcomposition and application thereof

PendingCN112891276AGood moisturizing effectImprove repair abilityCosmetic preparationsToilet preparationsBiotechnologyActive enzyme

The invention belongs to the technical field of skin care products, and particularly relates to a moisturizing, repairing, anti-aging and anti-saccharification composition and application thereof. The moisturizing, repairing, anti-aging and anti-saccharification composition is characterized by being prepared from the following raw materials in parts by weight: 0.1-8 parts of vitamin palmitates, 1-6 parts of vitamine, 1-20 parts of a plant extract, 0.1-4 parts of ergothioneine, 0.01-0.5 part of astaxanthin, 1-13 parts of argireline, 0.5-6 parts of fullerene, 0.1-6 parts of a peptide compound, 0.1-7 parts of hydrolyzed collagen, 0.01-0.2 part of an antioxidant active enzyme and 0.1-4 parts of a coenzyme. The composition in the technical scheme is applied to moisturizers, emulsions, creams, essence stock solutions and masks to keep the moisture and elasticity of cells, promote regeneration of damaged tissues, improve the repairing capacity of the skin, delay aging of the cells and improve the anti-aging capacity and anti-saccharification capacity of the skin.

Owner:皓雨(广州)化妆品制造有限公司

Blue light filtering, water and oil dirt preventing and wear resisting lens and preparation method thereof

The invention relates to a blue light filtering, water and oil dirt preventing and wear resisting lens and a preparation method thereof. The lens comprises a substrate, and the inner surface and the outer surface of the substrate are provided with first films, second films, third films, fourth films and fifth films sequentially and symmetrically from inside to outside. The first films are titanium oxide layers, and the thickness ranges from 10 nm to 100 nm. The second films are silicon dioxide layers, and the thickness ranges from 50 nm to 100 nm. The third films are metal layers, and the thickness ranges from 5 nm to 20 nm. The fourth films are high-hardness layers, and the thickness ranges from 10 nm to 50 nm. The fifth films are fluoride layers, and the thickness ranges from 3 nm to 10 nm. The preparation method comprises the following steps that 1, the substrate is washed; 2, the inner surface and the outer surface of the substrate are coated with the films respectively. The lens can effectively filter out 33% of harmful blue light and dazzling light or above, visual fatigue can be effectively relieved, the wear resistance of the lens can be remarkably improved through the high-hardness layers, and the fluoride layers have the good hydrophobicity and oil dirt preventing function.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Cushion compact with anti-blue light effect and preparation method thereof

ActiveCN109125194AEnsure humidity balanceTake precautionsCosmetic preparationsMake-upMedicineActive component

The invention provides a cushion compact with an anti-blue light effect. The cushion compact comprises an emollient, an active effect component and water serving as a solvent; the active effect component comprises an active effect component A accounting for 0.05 to 0.50 percent of the weight of the cushion compact and an active effect component B accounting for 0.50 to 2.0 percent of the weight ofthe cushion compact; the active component A comprises melanin, pentanediol and ethylhexylglycerin; the active effect component B comprises a cephalic branch cotyledon / stem extract, 1,3-propylene glycol and water. The cephalic branch cotyledon / stem extract and the melanin in the cushion compact are reasonably proportioned to protect the skin from being injured by radiation and control the physiological rhythm, so that cells are resynchronized and recover a normal rhythm; the cushion compact is extremely good in blue light preventing and repairing effects and has an extremely good blue light resisting effect. A preparation method provided by the invention is simple in process and low in cost; the prepared cushion compact with the anti-blue light effect is good in effect.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

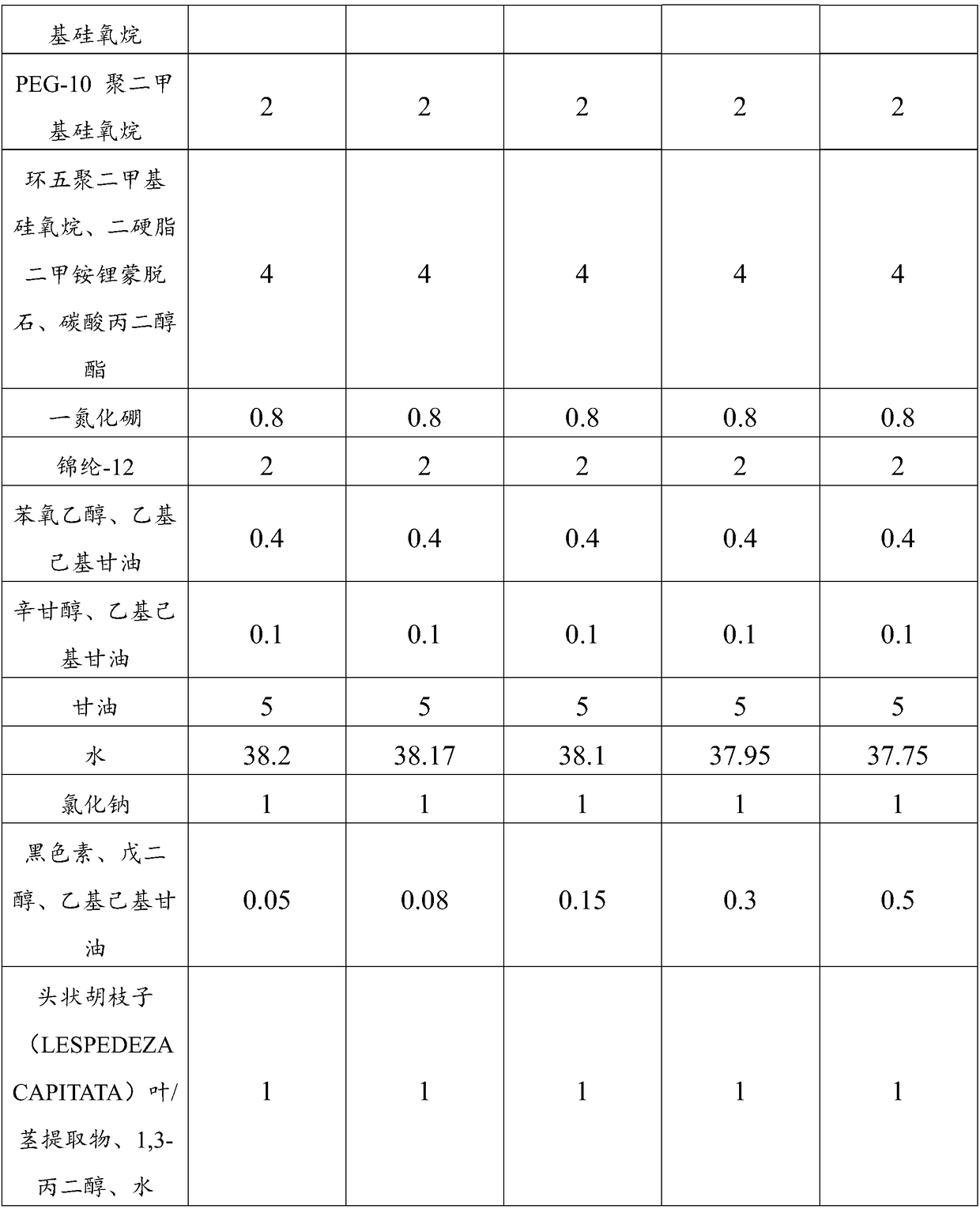

Blue light filtering, dazzling preventing and wear resisting lens and preparation method thereof

InactiveCN105425415AImprove purityImprove compactnessOptical filtersOptical partsHardnessWear resistance

The invention relates to a blue light filtering, dazzling preventing and wear resisting lens and a preparation method thereof. The lens comprises a substrate, and the inner surface and the outer surface of the substrate are provided with first films, second films, third films, fourth films, fifth films, sixth films, seventh films and eighth films sequentially and symmetrically from inside to outside. The first films, the fourth films and the sixth films are titanium oxide layers, and the thickness ranges from 10 nm to 100 nm. The second films, the fifth films and the seventh films are silicon dioxide layers, and the thickness ranges from 50 nm to 100 nm. The third films are metal layers, and the thickness ranges from 5 nm to 20 nm. The eighth films are high-hardness layers, and the thickness ranges from 10 nm to 50 nm. The preparation method comprises the following steps that 1, the substrate is washed; 2, the inner surface and the outer surface of the substrate are coated with the films respectively. The lens can effectively filter out 33% of harmful blue light and dazzling light or above, visual fatigue can be effectively relieved, and the wear resistance of the lens can be remarkably improved through the high-hardness layers.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

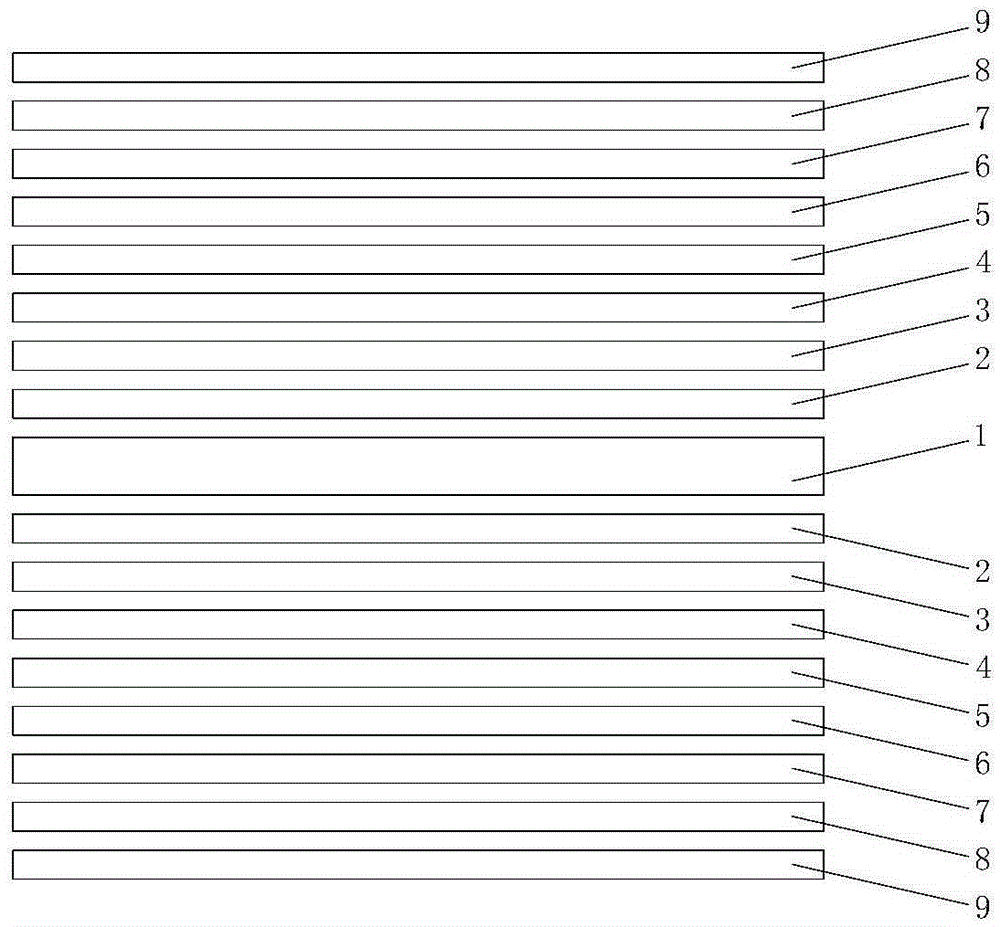

Anti-reflection and wear-proof lens capable of filtering blue light and preparation method of anti-reflection and wear-proof lens

InactiveCN105445960AHigh refractive indexImprove anti-reflection effectOptical partsOptical elementsHardnessLens plate

The invention relates to an anti-reflection and wear-proof lens capable of filtering blue light and a preparation method of the anti-reflection and wear-proof lens. The lens comprises a substrate, wherein first film layers, second film layers, third film layers, fourth film layers, fifth film layers, sixth film layers, seventh film layers, eighth film layers and ninth film layers are symmetrically and sequentially arranged on the inner surface and the outer surface of the substrate from inside to outside; the first film layers, the third film layers and the fifth film layers are all trititanium pentoxide layers with the thickness being 10-100 nm; the second film layers, the fourth film layers and the sixth film layers are all silicon dioxide layers with the thickness being 50-100 nm; the seventh film layers are metal layers with the thickness being 5-20 nm; the eighth film layers are high-hardness layers with the thickness being 10-50 nm; the ninth film layers are acrylic acid layers with the thickness being 5-15 nm. The preparation method comprises steps as follows: 1), the substrate is cleaned; 2), the inner surface and the outer surface of the substrate are plated with films respectively. The lens can filter harmful blue light and dazzle light, and the wear resistance and the antireflection property can be improved.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Anti-blue-ray protective film

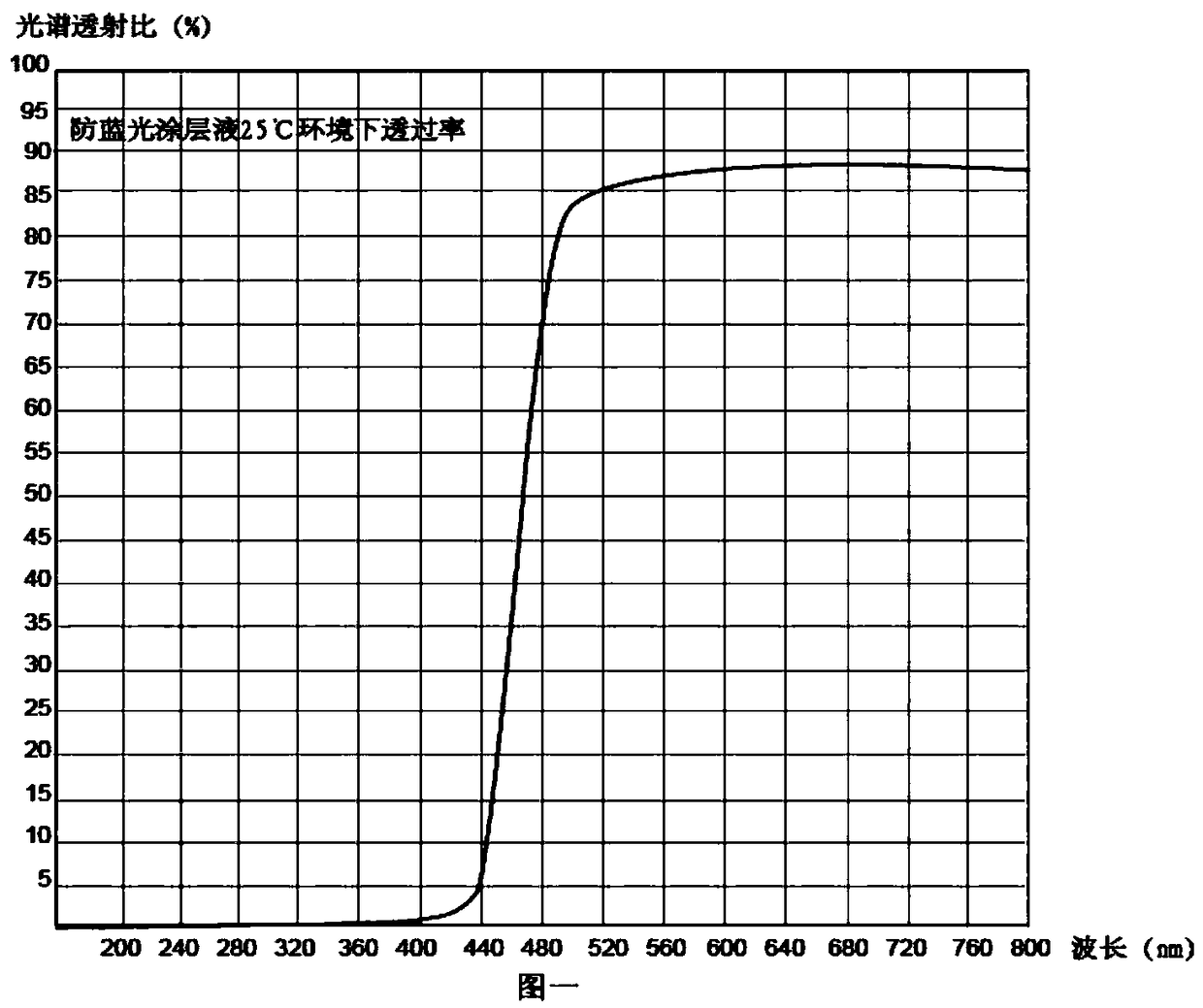

An anti-blue-ray protective film comprises a transparent substrate, an anti-blue-ray layer and a hardening protective layer, wherein the anti-blue-ray layer and the hardening protective layer are sequentially laminated; the anti-blue-ray layer is prepared by coating with a coating solution and then carrying out thermal curing, the coating solution comprises the following components in parts by weight: 2-10 parts of thermosetting resin, 0.5-3 parts of nano metal oxide, 80-98 parts of an organic solvent, 0.3-1.6 parts of a dispersing agent and 0.4-1.1 parts of a curing agent; the difference between the refractive index of the nano metal oxide and the thermosetting resin is 0.1-1.3, the viscosity of the thermosetting resin is 5000 cps-10000 cps, parameters in curing are successively as follows: in the first step, the curing temperature is 40 DEG C-60 DEG C, and the curing time is 1 min-5 min; in the second step, the curing temperature is 60 DEG C-90 DEG C, and the curing time is 1 min-5 min; in the third step, the curing temperature is 90 DEG C-110 DEG C, and the curing time is 1 min-5 min; in the fourth step, the curing temperature is 110 DEG C-150 DEG C, and the curing time is 1 min-3 min. According to the invention, an internal structure in which a high refractive index is matched with a low refractive index is formed, so that the transmittance of blue ray with the wavelength of 400 nm-450 nm is less than 40%, and a good anti-blue-ray effect is achieved.

Owner:HEFEI LUCKY SCI & TECH IND

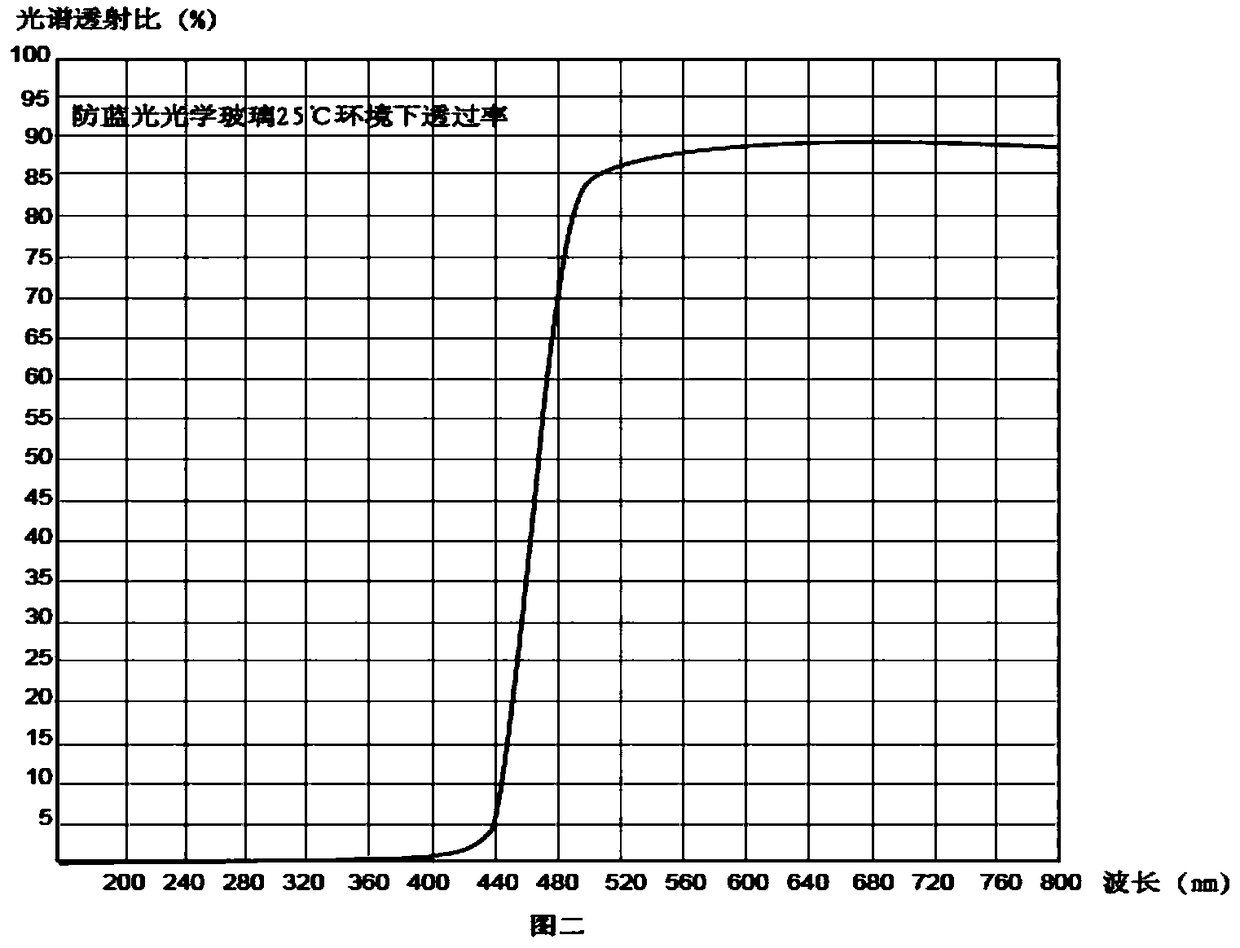

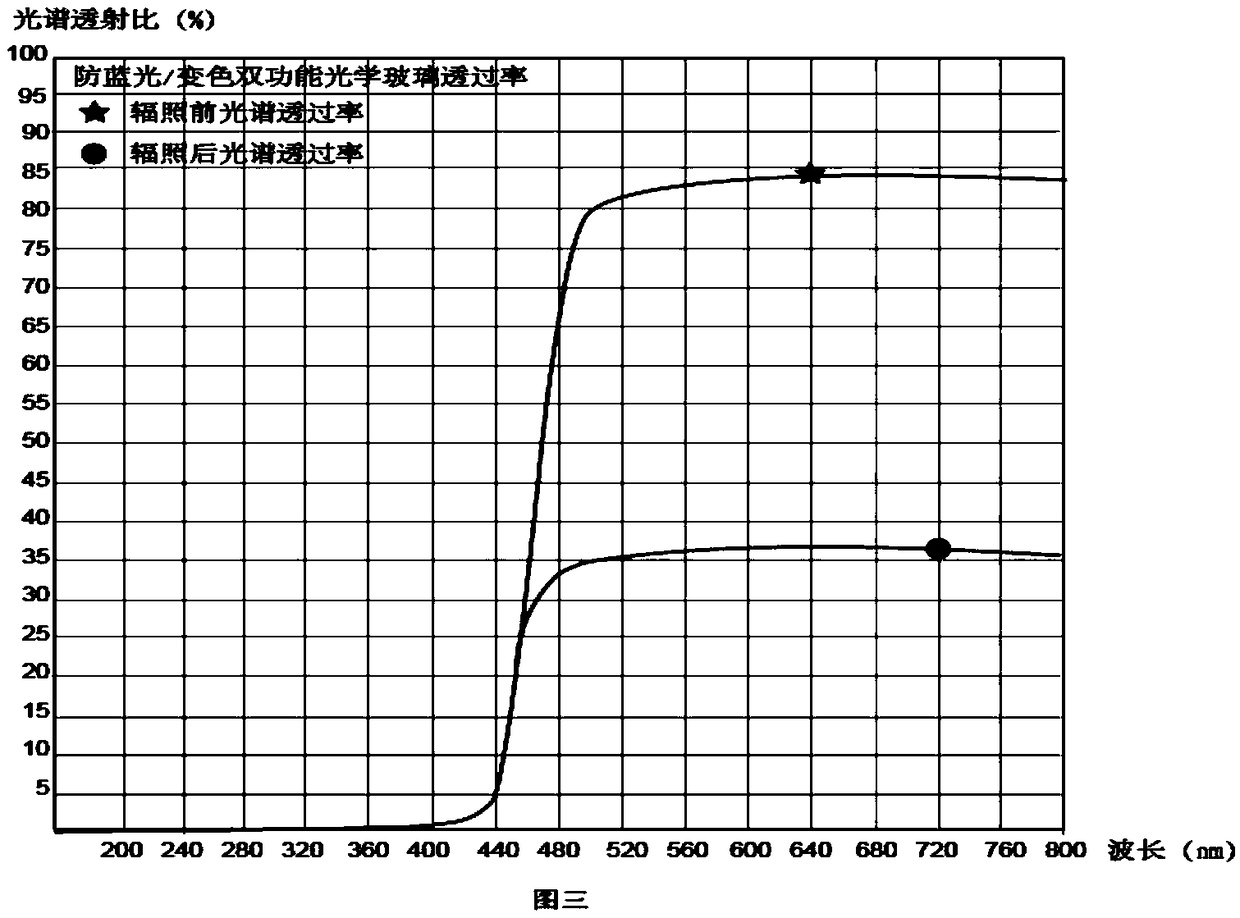

Anti-blue ray/color-changing bifunctional optical resin material and preparation method thereof

InactiveCN109369939AGood synergistic performanceImprove photocatalytic activityCoatingsMicroballoon preparationMicrosphereUv spectrum

The invention discloses an anti-blue ray / color-changing bifunctional optical resin material and a preparation method thereof. The bifunctional optical resin material is composed of an anti-blue ray optical resin material and a photochromic coating coated on the material surface. The anti-blue ray optical resin material is prepared by dispersing polyurethane / light absorber / titanium oxide nanocomposite microspheres in a polyurethane optical resin. The nanocomposite microspheres are of a three-layer composite core-shell structure, the core refers to titanium oxide nano microspheres, the middle layer refers to a light absorber, and the shell is polyurethane. The spectrum blocking range of the anti-blue ray optical resin material is expanded from an ultraviolet spectrum region to a blue-ray spectrum region, and the anti-blue ray optical resin material has distinguished absorption performance on blue rays of different bands on the premise of ensuring high transmittance. The anti-blue ray optical resin material and the photochromic coating are subjected to matching and function integration, the transmittance can be automatically regulated according to light intensity, darkness control isrealized by selectively transmitting beneficial light and cutting off harmful light, and light transmission is performed according to needs.

Owner:南京米兰达视光科学研究院有限公司

Photoprotective plant extract composition and application thereof

InactiveCN111821235AInhibition of increased synthesisSynthetic resistanceCosmetic preparationsToilet preparationsBiotechnologyRHODIOLA ROSEA ROOT

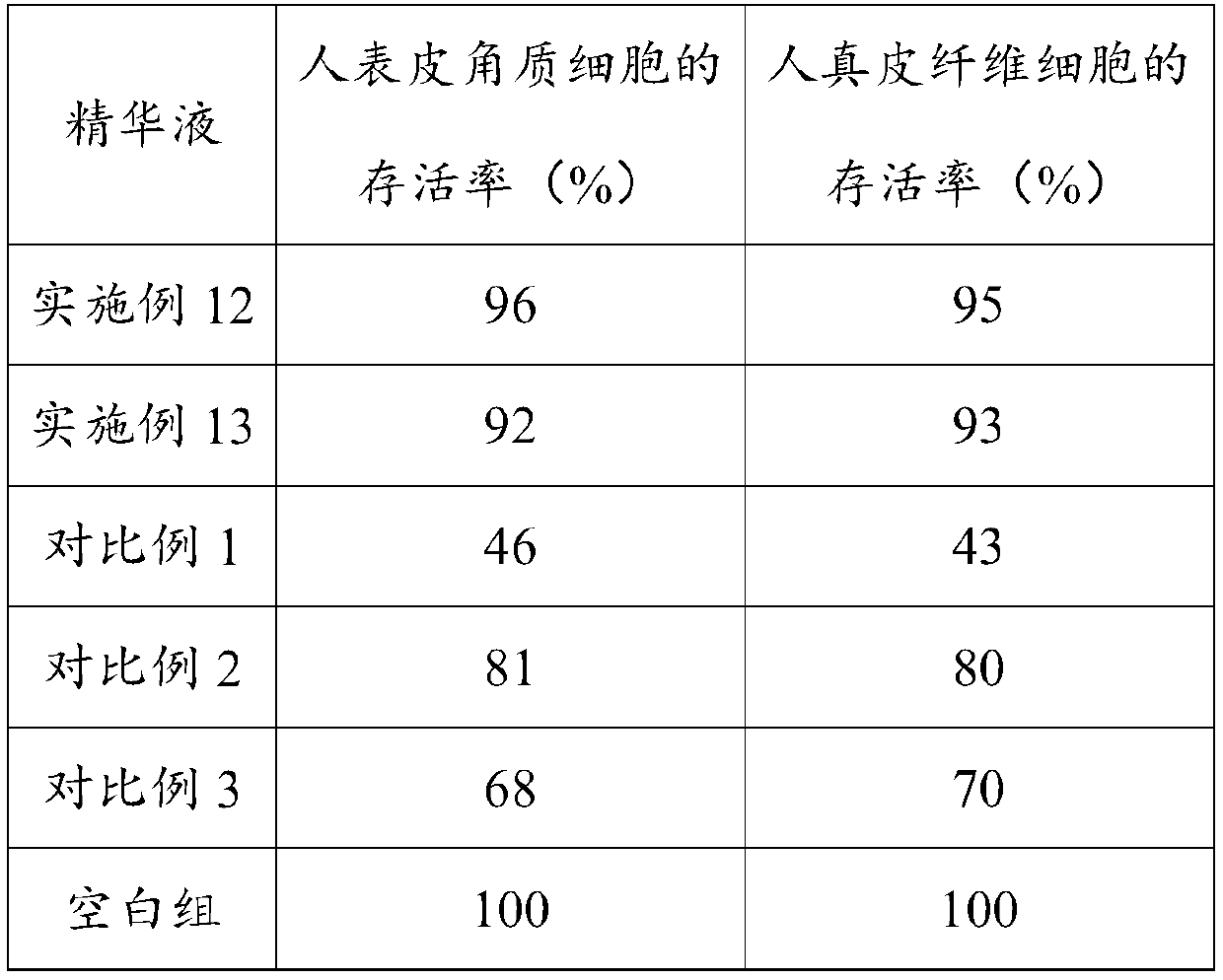

The invention discloses a photoprotective plant extract composition and application thereof. The photoprotective plant extract composition comprises the following components: a Feronia limonia Swingleextract, a butterflybush flower extract, a rhodiola rosea extract and a dried meat floss extract. The photoprotective plant extract composition effectively absorbs ultraviolet light and blue light through the synergistic effect of all the components, has excellent anti-ultraviolet and anti-blue-light effects, can effectively inhibit ultraviolet, blue light and red light induction from causing active oxygen increase, and maintains the activity of human epidermal keratinocytes and human dermal cells, so that the generation of collagen is promoted, the generation of free radicals is effectivelyresisted, a comprehensive photoprotective effect can be achieved, and the composition is beneficial to repairing the damage of radiation to the skin and relieving the skin sensitivity problem.

Owner:DOCTOR PLANT GUANGDONG BIOTECHNOLOGY CO LTD

Anti-blue-light resin lens made from fluorescent masking agent

InactiveCN104181617AImprove anti-blue light effectAchieve linear adjustmentCoatingsOptical elementsUltrasound attenuationUltraviolet lights

An anti-blue-light resin lens made from a fluorescent masking agent is manufactured in the following steps of (1) monometer preparation, (2) pouring, solidification, demoulding and stabilization and (3) hardening and film coating according to percentage by weight. According to the anti-blue-light resin lens, the broadband fluorescent masking agent is added into a lens monometer according to a certain ratio and is evenly dispersed, as a result, 99 percent of ultraviolet light, with wave length ranging from 220 nanometers to 380 nanometers, harmful to the human body can be attenuated through absorption, part of purple light and blue light with wave length ranging from 400 nanometers to 480 nanometers is attenuated through absorption in a relatively linear mode at the same time, in this way, original anti-blue-light capacity of a lens is remarkably improved on the premise that high light transmittance of the lens is guaranteed, and the blue light attenuation rate is increased to over 40 percent from originally 10-20 percent after film coating, linear adjustment of blue light frequency attenuation is realized, and the anti-blue-light resin lens has the advantages of being advanced in technology, simple in process, high in practicability and capable of selectively adjusting the blue light frequency attenuation rate.

Owner:JIANGSU WANXIN OPTICAL

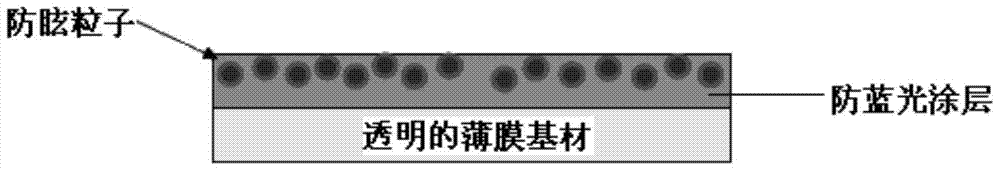

Anti-glare and anti-blue light protection film

ActiveCN104476874BImprove anti-blue light effectGlare suppressionSynthetic resin layered productsTectorial membraneHardness

The invention provides an anti-dazzle and anti-blue-light protection film which comprises a transparent film substrate and an anti-blue-light coating arranged on the surface of the transparent film substrate, wherein a blue light absorbent and anti-dazzle particles are arranged in the anti-blue-light coating. According to the anti-dazzle and anti-blue-light protection film, the anti-dazzle particles are arranged in the anti-blue-light coating, so that dazzle light in external light can be inhibited without an influence on wavelength absorptivity of blue light; the anti-dazzle and anti-blue-light protection film provided by the invention has relatively good anti-dazzle and anti-blue-light effects at the same time and can ensure that the injury of the blue light and the dazzle light on eyes is reduced while the eyes of a user are comfortable when the user watches an electronic screen; in addition, the anti-dazzle and anti-blue-light protection film provided by the invention is good in transparency, high in hardness, strong in adhesion power and good in processability; besides, the anti-dazzle and anti-blue-light protection film provided by the invention is simple in structure and low in cost.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Blue-light-resistant resin lens of 1.60 in refractivity and preparation method thereof

InactiveCN103675954AImprove performancePerformance is not affectedOptical partsOptical elementsRefractive indexLength wave

The invention relates to a blue-light-resistant resin lens of 1.60 in refractivity. The blue-light-resistant resin lens comprises a resin substrate of 1.60 in refractivity, a hardened film layer is dipcoated on the resin substrate, and a first SiO2 film layer, a ZrO2 film layer, a second SiO2 film layer, a Ti2O3 film layer, an In2O3 film layer and a third SiO2 film layer are sequentially deposited on the surface of the hardened film layer. The blue-light-resistant resin lens can filter 40-50% of blue light of 400-500nm in wavelength and can effectively filter blue light radiation, pricking and soreness of eyes can be reduced, eye dryness and eye fatigue can be reduced, and cataract and maculopathy can be prevented.

Owner:江苏硕延光学眼镜有限公司

Anti-blue-ray resin lens with refraction index of 1.56 and preparation method thereof

InactiveCN103676202AStable performanceStrong adhesionSynthetic resin layered productsOptical partsCataractsChemistry

The invention relates to an anti-blue-ray resin lens with the refraction index of 1.56. The anti-blue-ray resin lens with the refraction index of 1.56 comprises a resin substrate with the refraction index of 1.56; the resin substrate is dip-coated with a hardened film; a first SiO2 film, a ZrO2 film, a second SiO2 film, a Ti2O3 film, an In2O3 film and a third SiO2 film are deposited on the surface of the hardened film in sequence. According to the resin lens disclosed by the invention, the effect of filtering blue rays with the wavelength of 400 to 500 nm can reach 40 to 50 percent; blue ray radiation can be filtered effectively; sharp pain, soreness and swelling of eyes can be reduced; eye dryness and eye fatigue can be reduced; cataract and macular degeneration can be prevented.

Owner:江苏硕延光学眼镜有限公司

Anti-blue ray optical resin and preparation method thereof

The invention discloses anti-blue ray optical resin. The anti-blue ray optical resin comprises an acrylate macromolecule monomer for manufacturing an optical material, modified metallic oxide nanometer particles, an ultraviolet light absorbent and an initiating agent, wherein the modified metallic oxide nanometer particles are 1-5wt% of the acrylic macromolecule monomer; the ultraviolet light absorbent is 0.2-2wt% of the acrylic macromolecule monomer; and the initiator is 0.1-0.5wt% of the acrylic macromolecule monomer. The anti-blue ray optical resin can shield high-energy harmful blue rays and ultraviolet rays with the wavelength in the range of 380 to 450 nm effectively and endurably, and has a good comprehensive performance.

Owner:望江县天长光学科技有限公司

Dip-coating technology for hardening film of anti-blue ray resin lens surface

InactiveCN109188573AImprove anti-blue light effectEffective filteringCoatingsOptical elementsDiethyl etherWavelength

The invention provides a dip-coating technology for a hardening film of an anti-blue ray resin lens surface. The dip-coating technology comprises the following steps that, a resin lens is subjected topretreatment, first the resin lens is put in a cleaning machine to wash, after cleaning is finished, surface water liquid is dried with an absorbent gauze, then the absorbent gauze is used for dipping into mixed liquid of ethyl alcohol and diethyl ether and wiping the surface of the resin lens outwards from the center of the lens surface after wiping is finished, the pretreatment is finished; thepretreated resin lens is soaked in hardening film liquid; the lens after soaking is placed on a drying film clamp and sent into a drying oven, a colloid film is dried and dewatered, film drying temperature is controlled within 250-290 DEG C, holding time is control within 30-45min; and after the lens is dried, natural cooling and temperature reduction are carried out. The surface hardness of thelens is improved, the reflectivity can be reduced to 0.5-0.8%, the lens is given a better anti-blue ray effect, the filtering effect of the blue ray with 400-500nm wave length can achieve 55-65%, andthe radiation of the blue ray can be effectively filtered.

Owner:江苏硕延光学眼镜有限公司

Anti-blue-light and anti-oxidation composition, preparation method and application thereof

InactiveCN111514057AStrong blue light filtering abilityEasy to prepareCosmetic preparationsToilet preparationsVitamin b6Nutrition

The invention is applicable to the technical field of cosmetics, and provides an anti-blue-light and anti-oxidation composition, a preparation method and application thereof. The composition compriseslycopene liquid, glucosylrutin, a nutritional supplement and a complexing agent, wherein the nutritional supplement comprises at least one of serine, threonine, tryptophan, tyrosine, valine, vitaminH, folic acid, cyanocobalamin, vitamin B3, pantothenic acid, vitamin B6, vitamin B2, vitamin B1 and yeast polypeptides; the complexing agent comprises EDTA-2Na and an emulsifying agent. The composition has strong blue light filtering capability, can block harm of blue light to skin, effectively removes free radicals generated by blue light irradiation, reduces skin damage caused by excessive freeradicals, and can play roles in inhibiting inflammation, supplementing skin nutrients and brightening skin.

Owner:BEIJING SINOCELL CO LTD

Eye cream composition containing anti-blue-light lipidosome and preparation method thereof

ActiveCN113730308AAlleviate chronic photodamageAvoid damageCosmetic preparationsToilet preparationsLiposomeSkin elasticity

The invention discloses an eye cream composition containing an anti-blue-light lipidosome and a preparation method thereof. The anti-blue-light eye cream is prepared from the following raw material components: 1.0-35.0% of an anti-blue-light lipidosome, 5.0-40.0% of an emollient, 0.5-30.0% of an emulsifier, 0.5-20.0% of a filler, 0.1-10.0% of a thickener, 0.3-5.0% of a preservative, 0.01-1.0% of daily essence and the balance deionized water. The eye anti-blue-light lipidosome is prepared by combining a rhodiola crenulata root extract, a porphyra umbilicalis extract and carnosine. Therefore, the liposome is prepared from the three anti-blue-light functional components and has better transdermal absorption and slow release effects. The anti-blue-light functional components have strong antioxidant ability, can remove free radicals generated by blue light irradiation, effectively delay skin aging caused by blue light, reduce pigmentation and stain generation, repair light loss skin, effectively maintain skin elasticity, make skin bright and uniform, keep skin young and vigor, and improve other aging phenomena of skin around eyes.

Owner:湖北省麦诗特生物科技有限公司

Bird's nest acid anti-blue-light nano composition, preparation method and application thereof

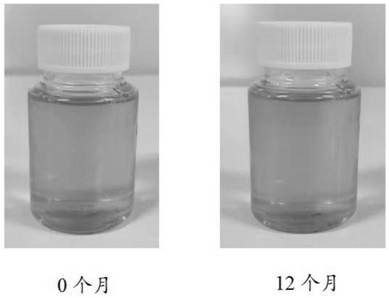

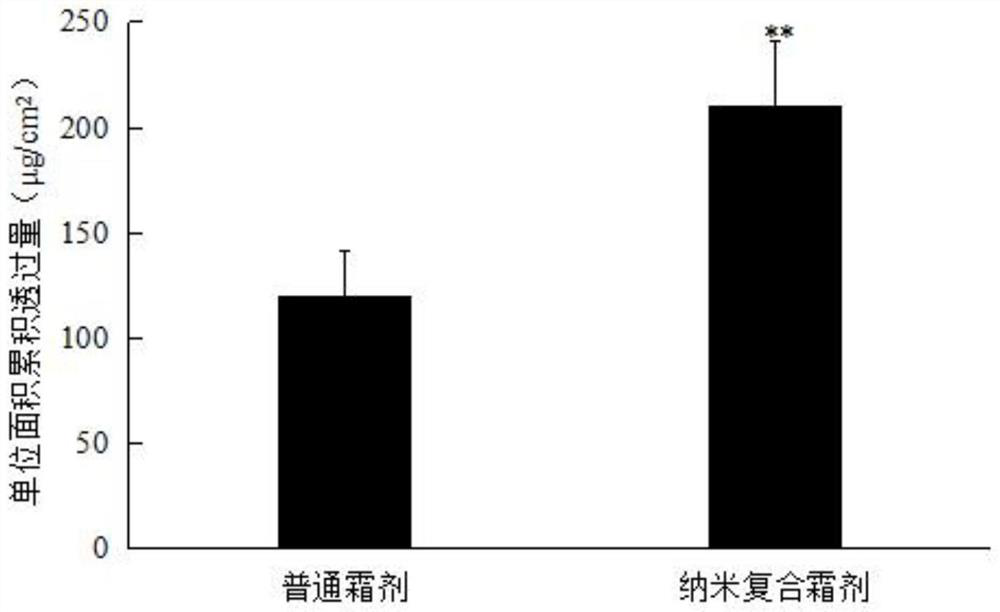

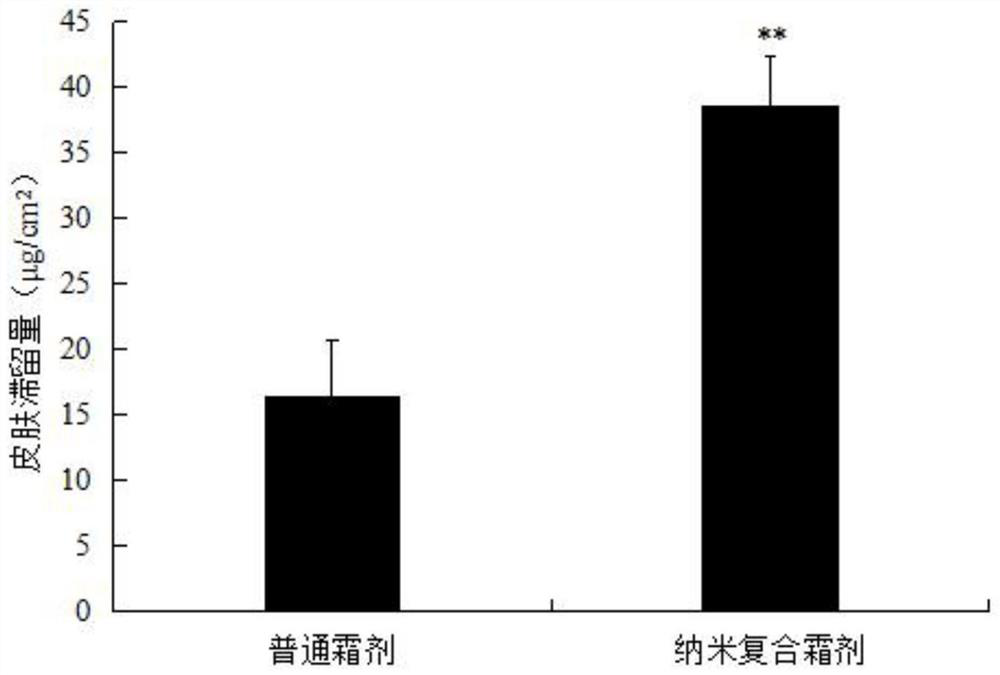

PendingCN114159360AAnti agingImproves pigmentationCosmetic preparationsToilet preparationsPolyolSkin penetration

The invention relates to the technical field of cosmetics, in particular to a sialic acid anti-blue-light nano composition, a preparation method and application thereof. The invention provides a sialic acid anti-blue-light nano composition. The sialic acid anti-blue-light nano composition comprises an anti-blue-light active component and an auxiliary material, the anti-blue-light active components comprise sialic acid, carnosine, xanthophyll, lespedeza head cotyledon / stem extract and cocoa seed extract; the auxiliary materials comprise an emulsifier, a co-emulsifier, polyol, liquid lipid and water. According to four chemical anti-blue-light mechanisms of absorbing radiation, improving hyperpigmentation, regulating physiological rhythm and delaying skin aging, five anti-blue-light active components are entrapped together, and are reasonably matched according to the proportion in the anti-blue-light anti-blue-light active components to achieve synergistic interaction. The nano composition disclosed by the invention can effectively improve the stability of active matters, the skin penetration amount and the skin retention amount, is mild and non-irritant to the skin, and can be widely applied to cosmetics.

Owner:WUHAN BEST CARRIER NANO TECH +1

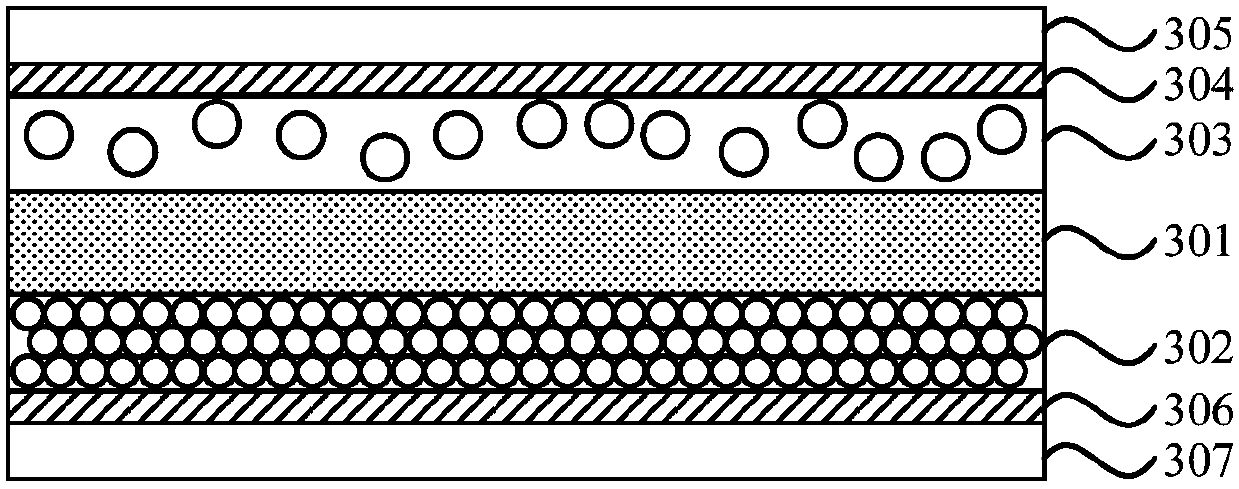

An anti-blue-light antimagnetic film and a preparing method thereof

ActiveCN106566430AFree from harmGood antimagneticFilm/foil adhesivesOrganic non-macromolecular adhesiveProtecting eyeElectromagnetic interference

An anti-blue-light antimagnetic film and a preparing method thereof are disclosed. The film has a good antimagnetic property and good anti-blue-light effects, thus playing a role of protecting glasses of persons and protecting electronic elements. The film includes, from top to bottom, an upper release film, an anti-blue-light layer, an antimagnetic metal layer, an insulating substrate, an acrylic adhesive layer and a lower release film. The thickness of the anti-blue-light layer is 50-100 [mu]m. The thickness of the antimagnetic metal layer is 50-100 [mu]. The thickness of the carrier insulating substrate is 50-150 [mu]. Anti-blue-light and antimagnetic functions are combined, and therefore the anti-blue-light antimagnetic film not only protects eyes of persons from being damaged by blue light, but also protects electronic products from electromagnetic interferences.

Owner:NALI OPTICAL MATERIAL DONGGUAN

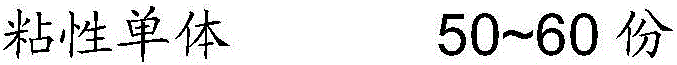

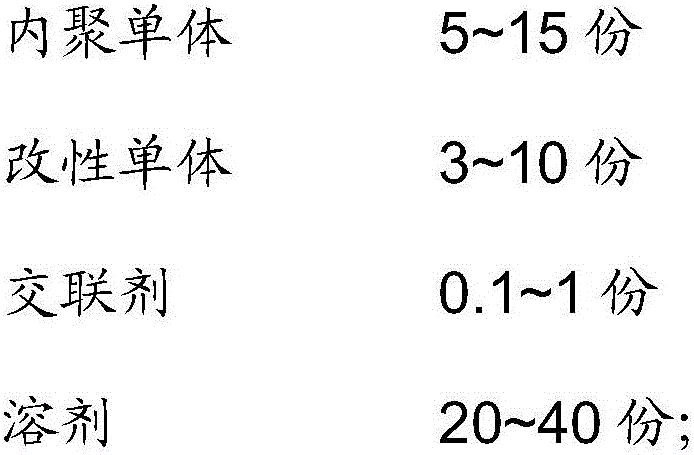

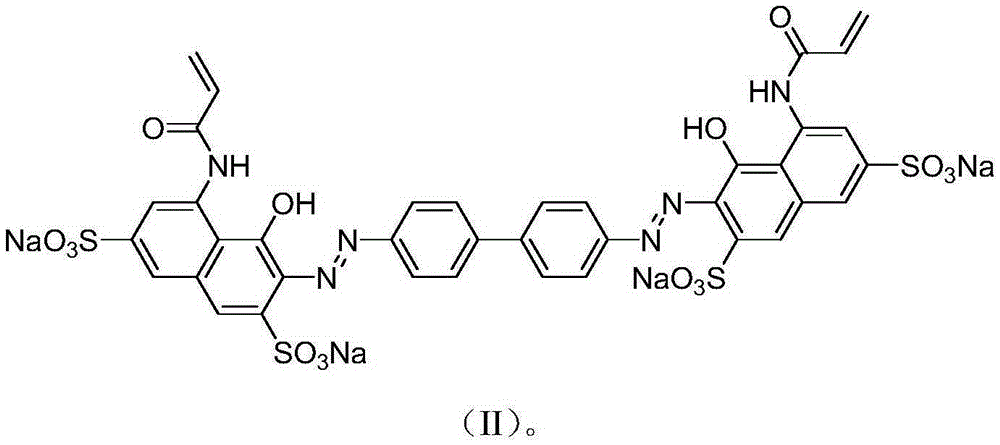

Eyeglass blue light prevention film

InactiveCN105353436AGood blue light absorption performanceImprove transmittanceOptical partsOptical elementsCompound aAdhesive

The invention relates to the technical field of blue light prevention, and specifically discloses an eyeglass blue light prevention film. The eyeglass blue light prevention film comprises two layers of transparent substrates and a blue light prevention glue layer arranged between the two layers of transparent substrates. The materials of the blue light prevention glue layer comprises, by weight, 100 parts of an adhesive, 0.50-2.15 parts of a blue light absorbent and 10-20 parts of a solvent. The blue light absorbent is a mixer of a compound A and a compound B. The chemical structural formula of the compound A is shown as a formula (I), the chemical structural formula of the compound B is shown as a formula (II), and the mol ratio of the compound A to the compound B is 1-3:2. According to the invention, the compounds A and B are selected as the composite blue light absorbent, both the compound A and the compound B comprise large [pi] bonds, the two compounds have a synergistic effect after being mixed, and the blue light absorption performance is better.

Owner:NANCHANG YIDUN SCI & TECH

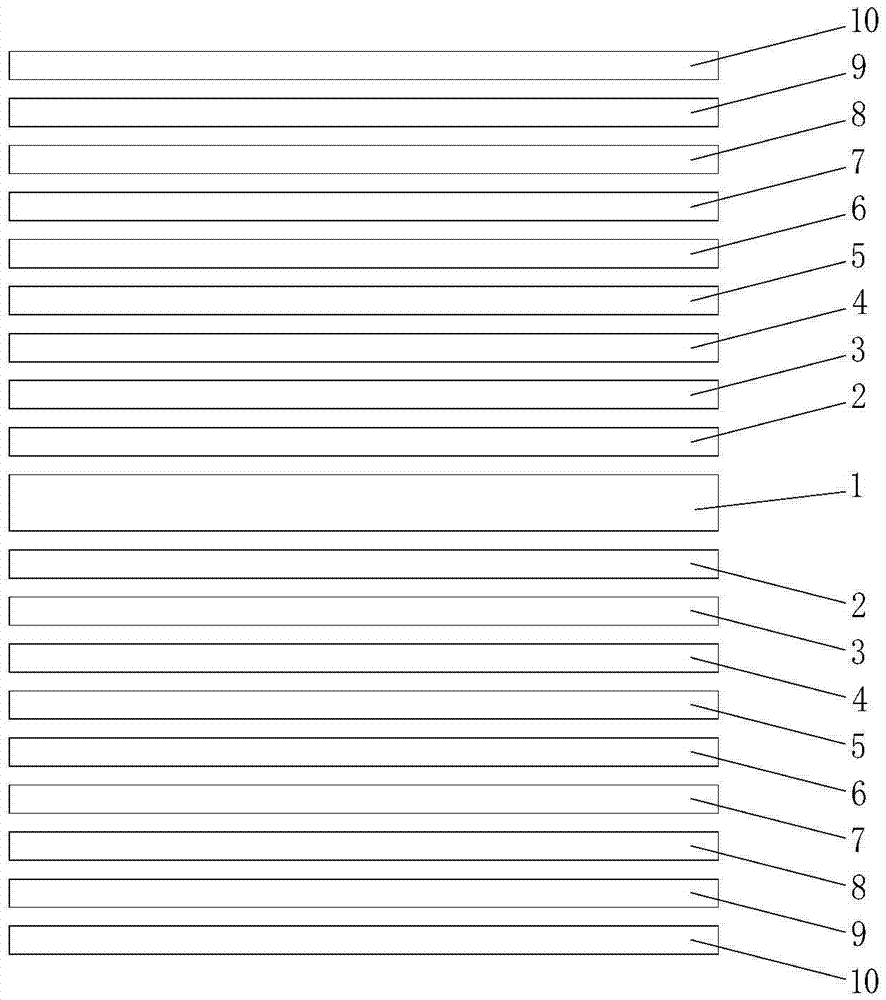

Lamp cover for blue light filtering, sterilization and reflection resisting and manufacturing method thereof

InactiveCN105629351AThickness is easy to controlImprove purityVacuum evaporation coatingSputtering coatingEngineeringFilm-coated tablet

The invention discloses a lamp cover for blue light filtering, sterilization and reflection resisting and a manufacturing method thereof. The lamp cover comprises a substrate. A first film layer, a second film layer, a third film layer, a fourth film layer, a fifth film layer, a sixth film layer, a seventh film layer, an eighth film layer and a ninth film layer are successively arranged from inside to outside on the outer surface of the substrate. The first film layer, the fourth film layer and the sixth film layer are trititanium pentoxide layers. The thickness of each of the trititanium pentoxide layers is 10-100 nm. The second film layer, the fifth film layer and the seventh film layer are silicon dioxide layers. The thickness of each of the silicon dioxide layers is 50-100 nm. The third film layer is a metal layer of which the thickness is 5-20 n. The eighth film layer is a nano-silver layer of which the thickness is 5-20 nm. The ninth film layer is an acrylic acid layer of which the thickness is 5-15 nm. The manufacturing method comprises following steps of 1) cleaning the substrate; and 2) carrying out film coating on the outer surface of the substrate. The lamp cover is capable of effectively filtering harmful blue light and dazzling light, so reflection resisting performance can be improved and the lamp cover has a sterilization function.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com