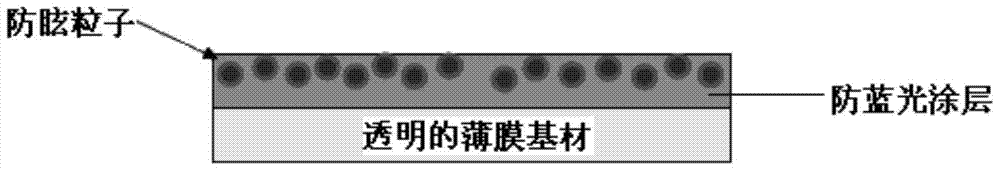

Anti-glare and anti-blue light protection film

An anti-blue light and protective film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of single anti-glare or anti-blue light of protective film, and achieve reduced eye comfort, good transparency, Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The particle size that 2.5g of Degussa provides is that the inorganic silicon dioxide amorphous particle of 1.5 micron is dissolved with propylene glycol monomethyl ether (PM), and the glue of CB-33031 model that 50g of Lida Chemical Industry provides is added in the mixed solution that obtains, obtains The mass concentration of inorganic silicon dioxide amorphous particles is a mixture of 30%; the mixture is coated on the surface of polyethylene terephthalate (PET) provided by Mitsubishi Corporation of Japan with a thickness of 100 microns to obtain an anti-blue light coating layer; after placing the anti-blue light coating in a circulating oven at 80°C for 2 minutes, the via intensity was 500mJ / cm 2 UV light irradiation to obtain anti-glare and anti-blue light protective film.

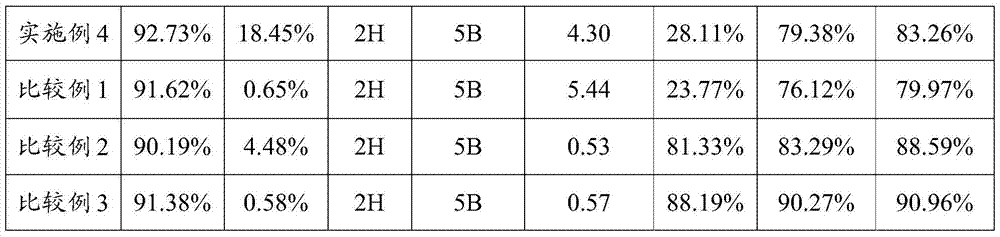

[0060] According to the method described in the above technical solution, the total light transmittance, the light transmittance of 400nm, the light transmittance of 430nm, the light transmitt...

Embodiment 2

[0062] 5g of the inorganic silicon dioxide amorphous particles with a particle size of 1.5 microns provided by Degussa are dissolved with propylene glycol methyl ether (PM), and 50g of CB-33031 glue provided by Lida Chemical Industry is added to the obtained mixed solution to obtain inorganic The mass concentration of silicon dioxide amorphous particles is a mixture of 30%; the mixture is coated on the surface of polyethylene terephthalate (PET) provided by Japan's Mitsubishi Corporation with a thickness of 100 microns to obtain an anti-blue light coating ; After placing the anti-blue light coating in a circulating oven at 80°C for 2 minutes, the via strength was 500mJ / cm 2 UV light irradiation to obtain anti-glare and anti-blue light protective film.

[0063]According to the method described in the above technical scheme, the total light transmittance, the light transmittance of 400nm, the light transmittance of 430nm, the light transmittance of 450nm, Haze, pencil hardness,...

Embodiment 3

[0065] Dissolve 2.5g of MX-180TA acrylic particles with a particle size of 2.5 microns provided by Soken with propylene glycol methyl ether (PM), and add 50g of CB-33031 glue provided by Lida Chemical to the obtained mixed solution to obtain The mass concentration of acrylic particles is a mixture of 30%; the mixture is coated on the surface of polyethylene terephthalate (PET) provided by Mitsubishi Corporation of Japan with a thickness of 100 microns to obtain an anti-blue light coating; After the anti-blue light coating is dried in a circulating oven at 80°C for 2 minutes, the via intensity is 500mJ / cm 2 UV light irradiation to obtain anti-glare and anti-blue light protective film.

[0066] According to the method described in the above-mentioned technical scheme, test the total light transmittance, the light transmittance of 400nm, the light transmittance of 430nm, the light transmittance of 450nm, Haze, pencil hardness, adhesion and degree of yellowing, the test results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com