Lamp cover for blue light filtering, sterilization and reflection resisting and manufacturing method thereof

A technology for filtering blue light and manufacturing methods, applied to lampshades, optical elements for changing the spectral characteristics of emitted light, optics, etc., which can solve problems affecting the light transmittance of lampshades, less sterilization, and physical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

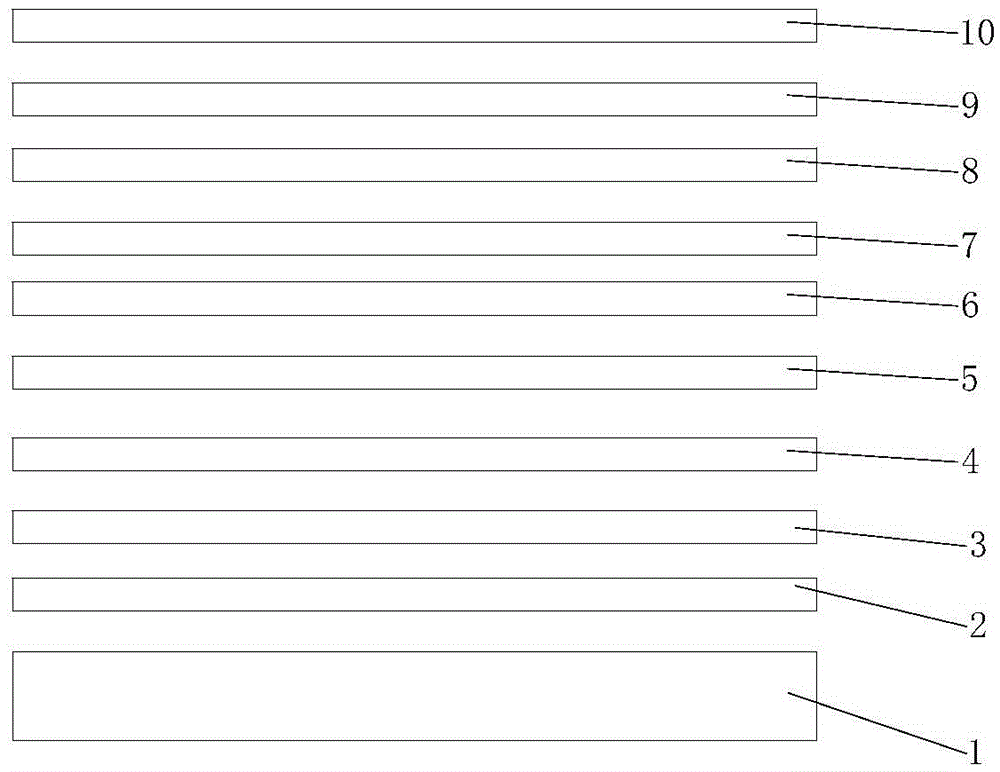

[0073] When the substrate 1 is molded by resin, the manufacturing method of the lampshade that filters blue light for sterilization and anti-reflection specifically includes the following steps:

[0074] 1) Clean and dry the substrate 1: place the substrate in a vacuum chamber, and bombard the outer surface of the substrate with an ion gun for 2-3 minutes to clean;

[0075] 2) Coating the outer surface of the substrate 1;

[0076] A. Coating the first film layer 2:

[0077] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 50-70°C, use an electron gun to bombard the film material of the first film layer 2, and the film material of the first film layer 2 evaporates and deposits on the outer surface of the substrate in the form of nano-scale molecules , while controlling the evaporation rate of the first film layer 2 to be 2.5 ? / S, the thickness of the first film layer 2 af...

Embodiment 2

[0097] When the substrate 1 is formed from glass, the manufacturing method of the lampshade that filters blue light for sterilization and anti-reflection specifically includes the following steps:

[0098] 1) Clean and dry the substrate 1: place the substrate in a vacuum chamber, and bombard the outer surface of the substrate with an ion gun for 5-10 minutes to clean;

[0099] 2) Coating the outer surface of the substrate 1;

[0100] A. Coating the first film layer 2:

[0101] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 200-300°C, use an electron gun to bombard the film material of the first film layer 2, and the film material of the first film layer 2 evaporates and deposits on the outer surface of the substrate in the form of nanometer molecules , while controlling the evaporation rate of the first film layer 2 to be 2.5 ? / S, the thickness of the first film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com