Anti-blue-ray optical thin-film and application thereof

An optical film and anti-blue light technology, applied in optics, optical components, lenses, etc., can solve the problems of low market share and inconvenient wearing of anti-blue light glasses, and achieve the goal of avoiding brightness loss, soft light, and good anti-blue light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

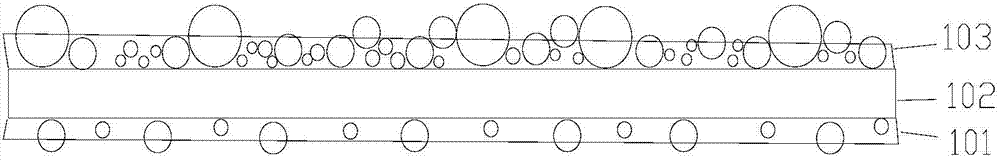

[0065] An anti-blue light optical film provided by the present invention, wherein the substrate layer is made of PET material with a thickness of 100 μm; a functional layer is provided on one side of the substrate layer, and the functional layer is a diffusion functional layer, including 100 parts by weight Polyurethane adhesive, 60 parts by weight of PMMA diffusion particles, the particle size of the diffusion particles is 10 μm; the other side of the substrate layer is provided with a protective coating, the protective coating consists of 100 parts by weight of acrylic adhesive and 0.5 It consists of titanium dioxide anti-adhesion particles in parts by weight, and the particle size of the titanium dioxide particles is 3 μm; the quinophthalone dye C.I. Pigment Yellow 138 is added to the diffusion functional layer, and the addition amount is 1% of the adhesive resin used in the diffusion functional layer.

Embodiment 2

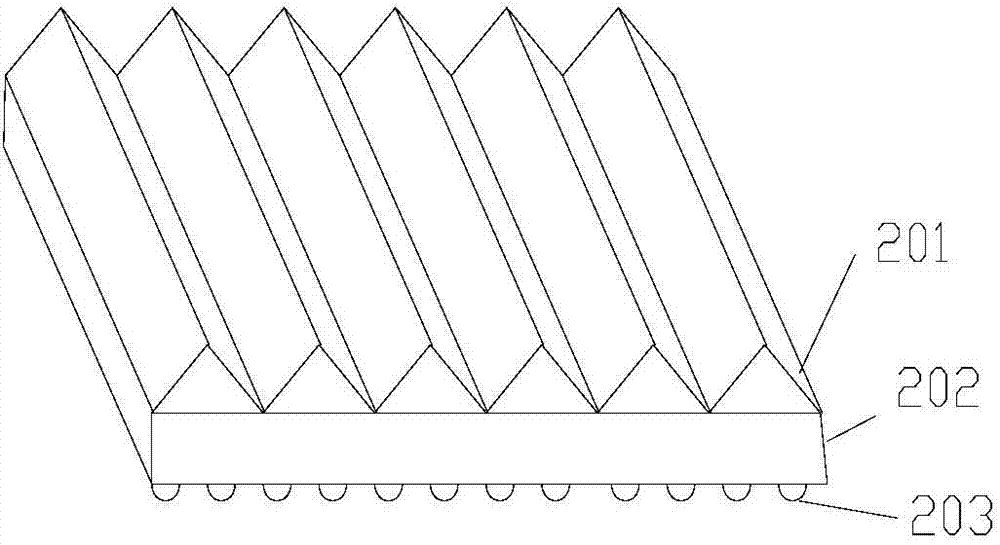

[0067] A kind of anti-blue light optical film provided by the present invention, wherein, substrate layer is PET material, and thickness is 75 μm; One side of substrate layer is provided with functional layer, and described functional layer is the UV functional layer of microprism structure, micro The prism structure is made of acrylic resin, the height of the prism bar of the micro prism structure is 55 μm, and the angle is 90°. figure 2 As shown; there is a protective coating on the other side of the substrate layer, the protective coating is made of acrylic resin, and the surface of the coating is provided with 5 μm high hemispherical protrusions, the protrusions are the same as the composition of the coating; azo dyes are selected C.I. Pigment Yellow 1 is added to the UV functional layer of the microprism structure, and the added amount is 0.5% of the resin used in the UV functional layer.

Embodiment 3

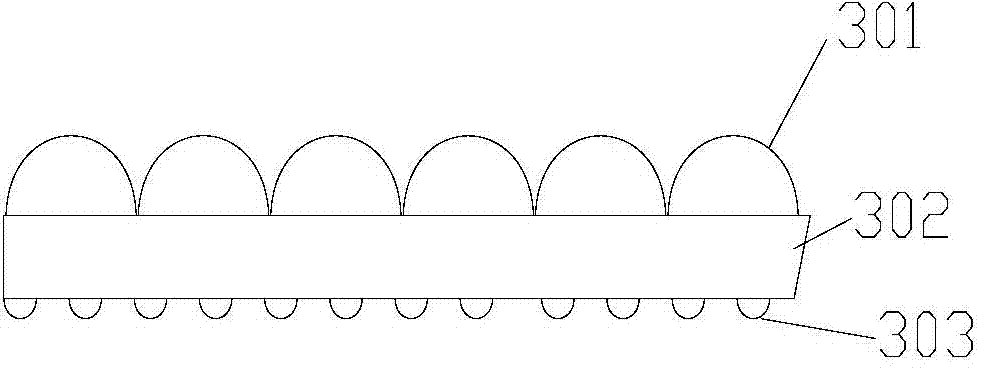

[0069] A kind of anti-blue light optical film provided by the present invention, wherein, substrate layer is PC substrate, and thickness is 200 μm; One side of substrate layer is provided with functional layer, and described functional layer is the UV functional layer of microlens structure, The microlens structure is made of polyurethane resin, and the microlens structure is a hemispherical protrusion with a diameter of 30 μm and a height of 15 μm, such as image 3 As shown; there is a protective coating on the other side of the substrate, the protective coating is composed of epoxy resin, and the surface of the coating is provided with 8 μm high hemispherical protrusions, and the protrusions are the same as the composition of the coating; select isoindoline The ketone dye C.I. Pigment Yellow 109 was added to the protective coating in an amount of 2% of the resin used for the protective coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com