Anti-blue-ray protective film

A technology of anti-blue light and protective film, applied in the direction of coating, etc., can solve the problems of cumbersome process, color deviation, high cost, etc., and achieve good anti-blue light effect, excellent applicability, and anti-sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

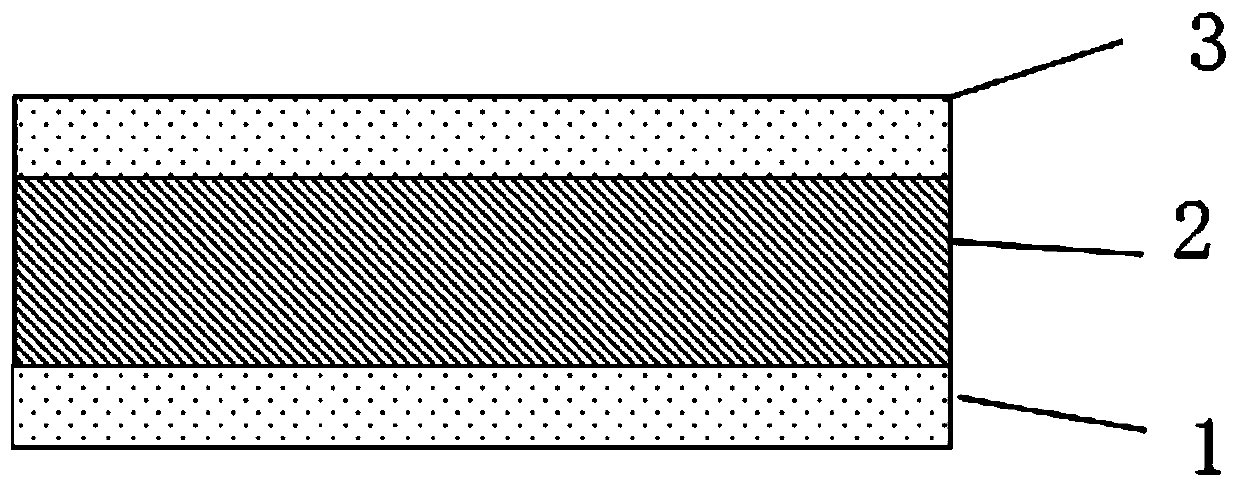

Image

Examples

Embodiment 1

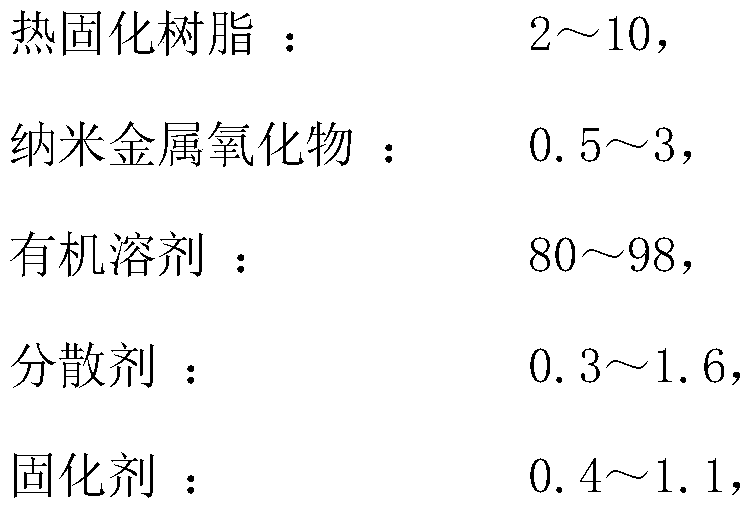

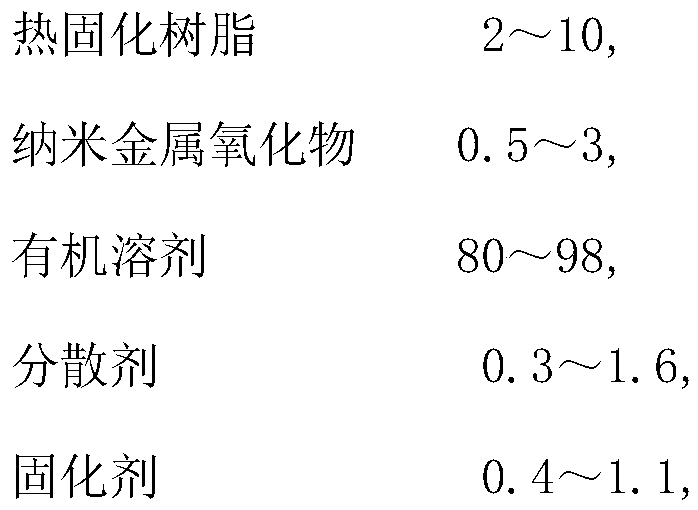

[0034] Add 10 grams of acrylate oligomer A-848-RN [refractive index 1.53, DIC], 3 grams of indium oxide [refractive index 1.7; average particle size 60 nm], 53 grams of methyl ethyl ketone and 27 grams of Isobutyl acetate, 1.6 grams of dispersant CA 394-60S [Eastman], 1.1 grams of curing agent BL3175SN [Bayer], stirred to obtain the anti-blue light layer coating solution, ready for use.

[0035] Coating the prepared coating liquid on any optical surface of a polyethylene terephthalate (PET) film with a thickness of 250 μm, through the first curing temperature of 60 ° C, the curing time is 5 min; the second curing temperature is 90°C, curing time is 5min; the third curing temperature is 110°C, curing time is 5min; the fourth curing temperature is 150°C, curing time is 3min. Blu-ray layer.

[0036] Coating is performed on the anti-blue light layer to prepare a hardened protective layer with a thickness of 10um to obtain an anti-blue light protective film.

Embodiment 2

[0038] Add 10 grams of acrylate oligomer A-1300 [refractive index 1.50, DIC], 2.5 grams of tin oxide [refractive index 2; average particle size 50nm], 56 grams of cyclopentanone and 29 grams of Propylene glycol methyl ether, 1.3 g of dispersant CAB 171-15 [Eastman], and 0.9 g of curing agent IL1351 [Bayer] were stirred to obtain a coating solution for the anti-blue light layer, which was set aside.

[0039]Coating the prepared coating liquid on any optical surface of a triacetylcellulose (TAC) film with a thickness of 200 μm, after the first curing temperature of 60 ° C, the curing time is 4 minutes; the second curing temperature is 80 ° C, the curing time The third curing temperature is 110°C, and the curing time is 4 minutes; the fourth curing temperature is 140°C, and the curing time is 3 minutes. Thermal curing is performed under different temperature conditions to form an anti-blue light layer with a thickness of 600nm.

[0040] Coating is performed on the anti-blue light...

Embodiment 3

[0042] Add 10 grams of acrylate oligomer Miramer SC2152 [refractive index 1.58, Meiyuan Special Chemicals], 2 grams of antimony pentoxide [refractive index 2.3; average particle size is 45nm], 45 grams of isopropanol and 43 grams of butyl acetate, 1 gram of dispersant CAB 381-2.0 [Eastman], and 0.7 gram of curing agent Aradur9506 [Hunsman] were stirred to obtain an anti-blue light layer coating solution, which was set aside.

[0043] Coating the prepared coating solution on any optical surface of a triacetylcellulose (TAC) film with a thickness of 180 μm, after the first curing temperature of 55 ° C, the curing time is 3 minutes; the second curing temperature is 75 ° C, the curing time The third curing temperature is 100°C, and the curing time is 3 minutes; the fourth curing temperature is 130°C, and the curing time is 3 minutes. Thermal curing is performed under different temperature conditions to form an anti-blue light layer with a thickness of 500nm.

[0044] Coating is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com