Anti-blue ray/color-changing bifunctional optical resin material and preparation method thereof

An optical resin, anti-blue light technology, applied in the field of light absorbing materials, can solve problems such as damage, and achieve the effect of good effect, good anti-blue light, and enhanced mutual synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

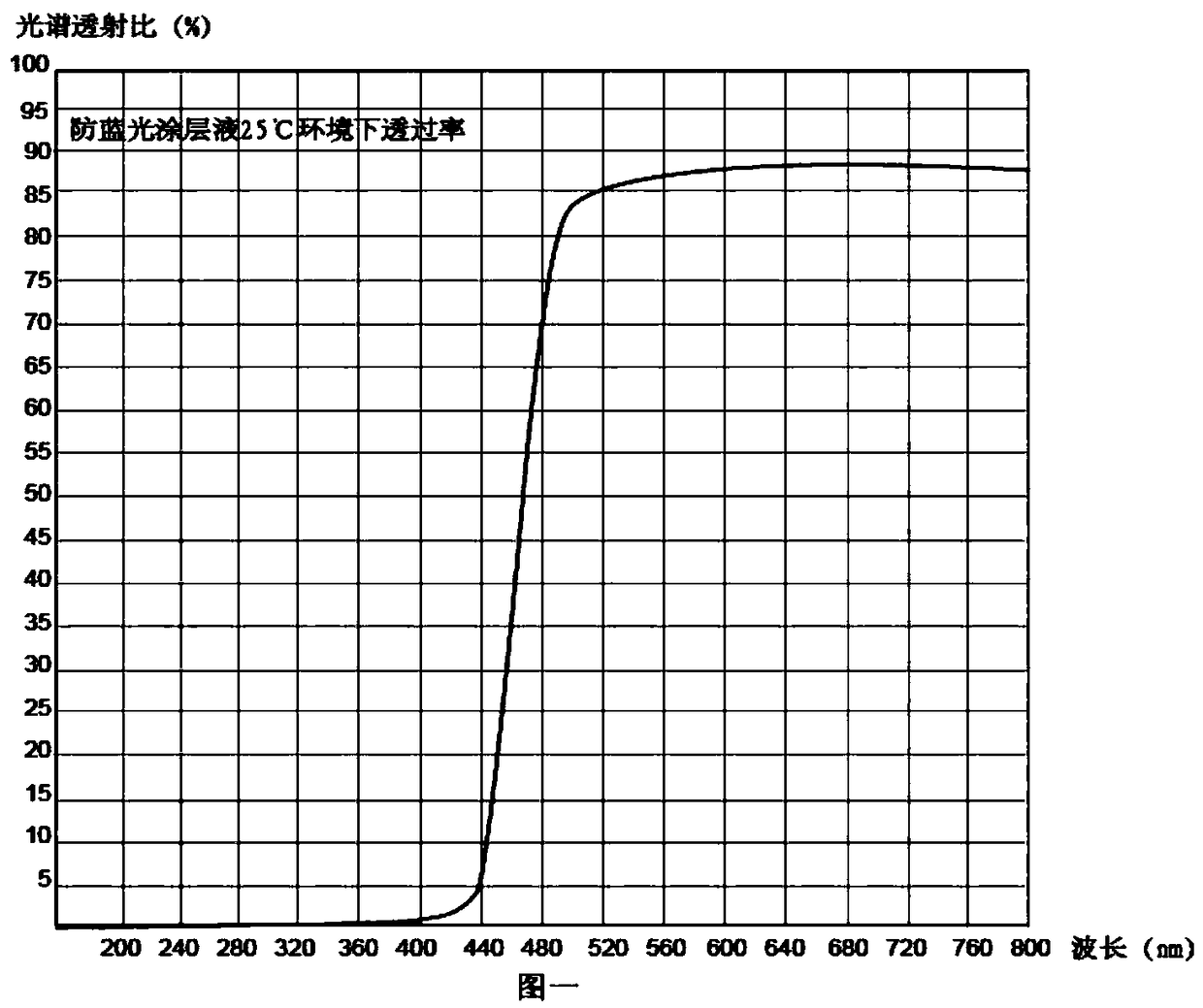

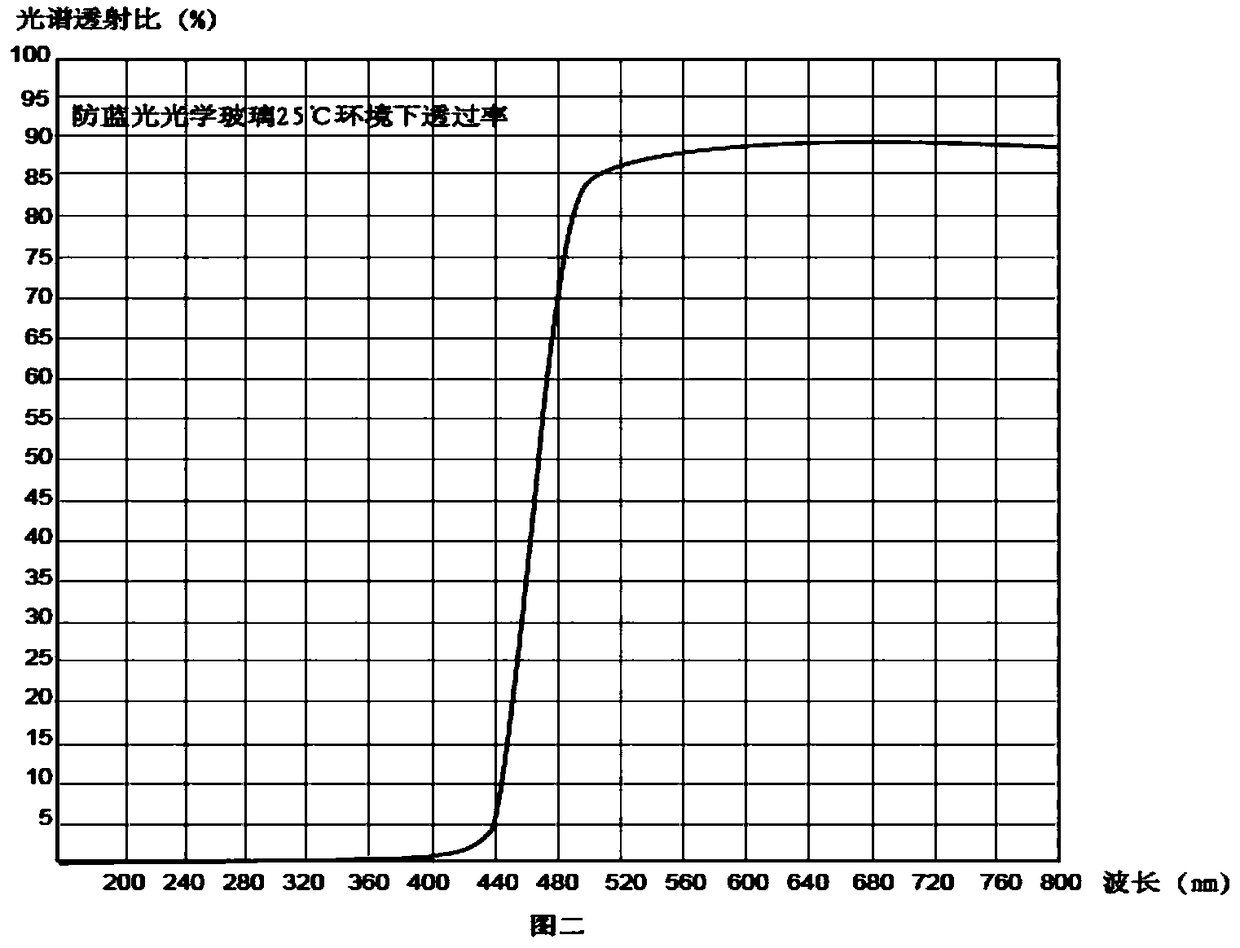

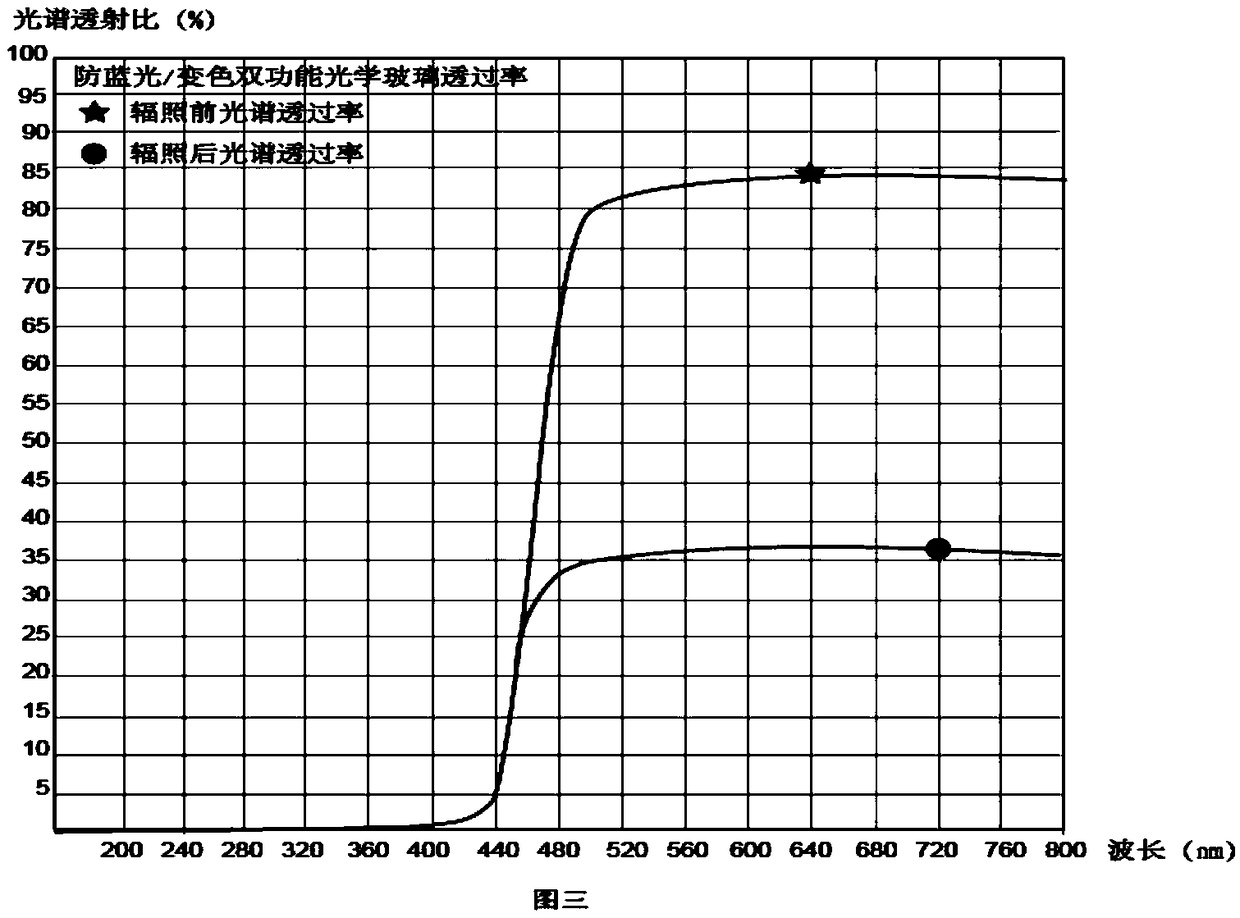

[0052] Example 1: Preparation of anti-blue light nanocomposite microspheres, anti-blue light coating solution, anti-blue light optical glass, anti-blue light / color-changing dual-function optical glass and anti-blue light / color-changing dual-function optical resin material

[0053] (1) Preparation of anti-blue light nanocomposite microspheres:

[0054] 1. Add 80g of sodium acetate to 1000g of pure water, gradually raise the temperature to 100°C, after turning into a transparent sodium acetate aqueous solution, add 130g of nano-titanium oxide, stir for 20 minutes, cool to room temperature, the reaction solution gradually precipitates in layers, and solid-liquid filtration After separation and washing, add 1500g of ethanol, then stir and add 50g of ultraviolet absorber UV-P, stir for 20 minutes, let stand for 50 minutes, filter and collect the precipitate, and dry to obtain titanium oxide modified nanomaterials;

[0055] Figure 5 It is the transmission electron microscope TEM i...

Embodiment 2

[0074] Example 2: Preparation of anti-blue light nanocomposite microspheres, anti-blue light coating solution, anti-blue light optical glass, anti-blue light / color-changing dual-function optical glass and anti-blue light / color-changing dual-function optical resin material

[0075] (1) Preparation of anti-blue light nanocomposite microspheres:

[0076] Add 95g of sodium acetate to 1000g of pure water, gradually raise the temperature to 100°C, after turning into a transparent sodium acetate aqueous solution, add 180g of nano-titanium oxide, stir for 20 minutes, cool to room temperature, the reaction solution is gradually layered and precipitated, separated by solid-liquid filtration, After washing, add 1700g of ethanol, then stir and add 36g of ultraviolet absorber UV-P, stir for 25 minutes, let stand for 50 minutes, filter and collect the precipitate, dry to obtain titanium oxide modified nanomaterials;

[0077] Take 7g titanium oxide modified nanomaterials, 4.2g isophorone dii...

Embodiment 3

[0087] Example 3: Preparation of anti-blue light nanocomposite microspheres, anti-blue light coating solution, anti-blue light optical glass, anti-blue light / color-changing dual-function optical glass and anti-blue light / color-changing dual-function optical resin material

[0088] (1) Preparation of anti-blue light nanocomposite microspheres:

[0089] Add 75g of sodium acetate to 1000g of pure water, gradually raise the temperature to 100°C, after turning into a transparent sodium acetate aqueous solution, add 100g of nano-titanium oxide, stir for 20 minutes, cool to room temperature, the reaction solution is gradually layered and precipitated, separated by solid-liquid filtration, After washing, add 1300g of ethanol, then stir and add 28g of ultraviolet absorber UV-P, stir for 20 minutes, let stand for 50 minutes, filter and collect the precipitate, and dry to obtain titanium oxide modified nanomaterials;

[0090] Take 7g of titanium oxide modified nanomaterials, 7g of m-xyly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com