Degradable film and preparation method thereof

A technology for degrading film and inulin, applied in the direction of flexible covering, packaging, wrapping paper, etc., can solve the problems of poor strength and high cost of food packaging film, and achieve good water retention, low cost and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A preparation method of a degradable film, comprising the steps of: dissolving 80 parts by weight of inulin and 10 parts by weight of tea polyphenols in 200 parts by weight of water, stirring evenly, and adding 10 parts by weight of gellan gum, 5 parts by weight of xylitol and 5 parts by weight of sodium alginate were dispersed in an ultrasonic disperser for 40 minutes to obtain a glue liquid; gelatinize the above glue liquid at 40°C, continue to stir, and then pour it into a mold, Dry at 60°C for 10 hours, cool, and peel off the film to obtain the primary product; age the above primary product for 20 hours in an environment with a relative humidity of 60%, and then perform extrusion and tableting, and finally, injection molding to obtain a film.

Embodiment 2

[0013] A preparation method of a degradable film, comprising the steps of: dissolving 100 parts by weight of inulin and 25 parts by weight of tea polyphenols in 300 parts by weight of water, stirring evenly, and adding 15 parts by weight of gellan gum, 8 parts by weight of xylitol and 7 parts by weight of sodium alginate were dispersed in an ultrasonic disperser for 50 minutes to obtain a glue liquid; gelatinize the above glue liquid at 40°C, continue to stir, then pour it into a mold, and Dry at 60°C for 10 hours, cool, and peel off the film to obtain the primary product; age the above primary product for 28 hours in an environment with a relative humidity of 60%, and perform extrusion and tableting, and finally, injection molding to obtain a film.

Embodiment 3

[0015] A preparation method of a degradable film, comprising the steps of: dissolving 120 parts by weight of inulin and 40 parts by weight of tea polyphenols in 400 parts by weight of water, stirring evenly, and adding 20 parts by weight of gellan gum, 10 parts by weight of xylitol and 10 parts by weight of sodium alginate were dispersed in an ultrasonic disperser for 60 minutes to obtain a glue liquid; gelatinize the above glue liquid at 40°C, continue to stir, then pour it into a mold, and Dry at 60°C for 10 hours, cool, and peel off the film to obtain the primary product; age the above primary product in an environment with a relative humidity of 60% for 36 hours, and perform extrusion and tableting, and finally, injection molding to obtain a film.

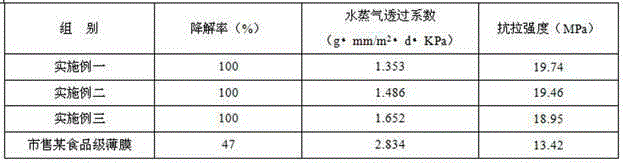

[0016] The three kinds of films obtained from Example 1 to Example 3 and a commercially available food-grade film are selected for natural degradation by soil microorganisms. The pH of the selected soil is 7.83, the mass content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com