Environment-friendly type coating with sterilization, mildew-prevention and air purification functions

An air-purifying and environmentally friendly technology, applied in the field of coatings, can solve problems such as poor water resistance, mildew, and endless emergence of environmentally friendly coatings, and achieve excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

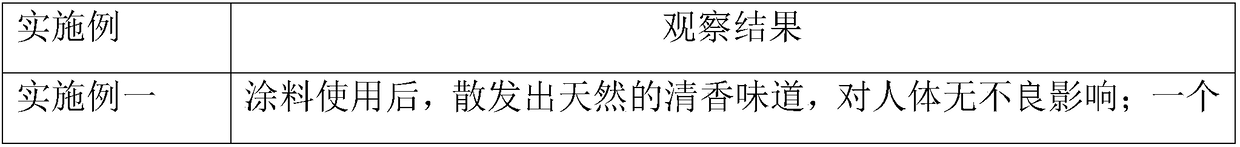

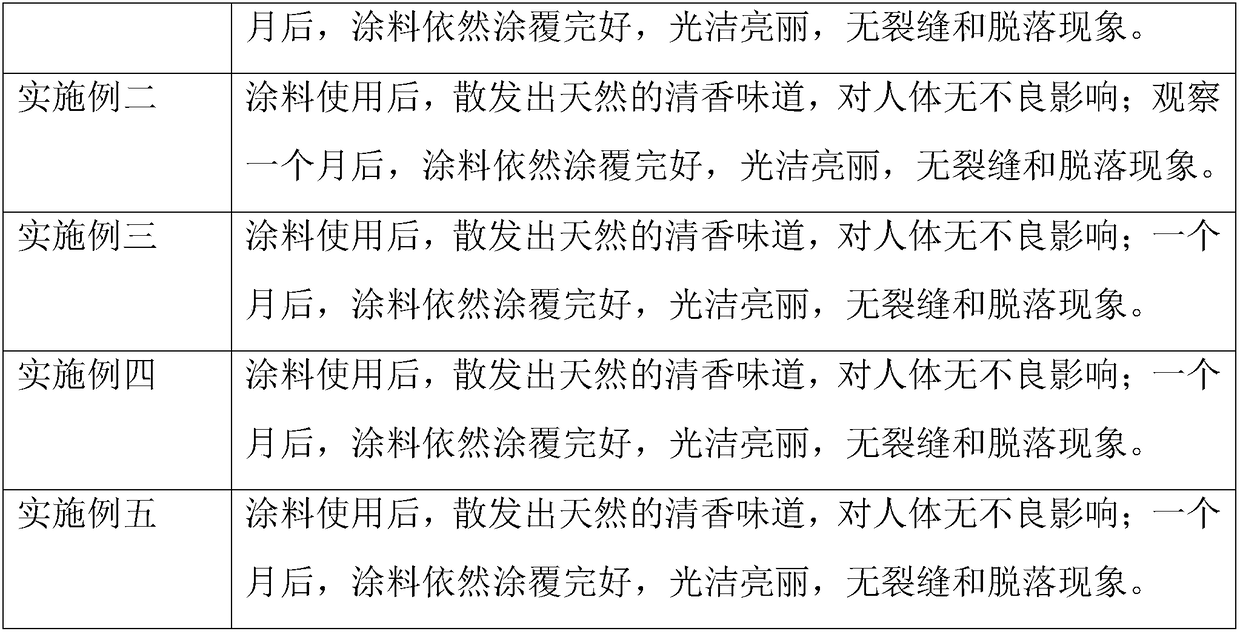

Examples

preparation example Construction

[0019] In the present embodiment, the preparation method of described environment-friendly coating comprises the following steps:

[0020] a. Grinding diatomite, lithium silicate and organobentonite into fine powder first, then uniformly mixing with nano-attapulgite, nano-kaolinite, nano-titanium oxide and air-purifying sterilizing powder to obtain a mixed powder;

[0021] b. Mix alkyd resin, polyacrylate emulsion and polyamide resin, and stir at a stirring speed of 300r / min for at least 30min, then add polyacrylate ammonium salt dispersant, mineral oil defoamer, carboxymethyl Cellulose, coconut oil, deionized water and the mixed powder prepared in step a, and stirred at a stirring speed of 1000r / min for 8h, promptly made an environment-friendly coating with bactericidal, anti-mildew and air-purifying functions; it is beneficial to each raw material Better dispersion, better compatibility, and better synergistic effect.

Embodiment 1

[0024]In this embodiment, an environment-friendly paint with bactericidal, mildew-proof and air-purifying functions is provided. The raw materials of the paint include the following components in parts by weight: 55 parts of alkyd resin, 20 parts of polyacrylate emulsion, nano-attapulgite 10 parts, 15 parts of nano kaolinite, 8 parts of diatomite, 6 parts of lithium silicate, 5 parts of polyamide resin, 0.8 parts of mineral oil defoamer, 0.8 parts of nano titanium oxide, 10 parts of air purification and sterilization powder, organic 0.5 part of bentonite, 0.2 part of polyacrylic acid ammonium salt dispersant, 0.1 part of carboxymethyl cellulose, 6 parts of coconut oil, 45 parts of deionized water; the air-purifying and sterilizing powder is composed of dried wormwood, gardenia, lemon eucalyptus, Apple eucalyptus and lemongrass are mixed in a mass ratio of 3:1:1:2:1 and then crushed.

[0025] In the present embodiment, the preparation method of described environment-friendly co...

Embodiment 2

[0029] In this embodiment, an environment-friendly paint with bactericidal, mildew-proof and air-purifying functions is provided. The raw materials of the paint include the following components in parts by weight: 60 parts of alkyd resin, 20 parts of polyacrylate emulsion, nano-attapulgite 12 parts, 15 parts of nano kaolinite, 10 parts of diatomite, 6 parts of lithium silicate, 8 parts of polyamide resin, 0.8 parts of mineral oil defoamer, 1.2 parts of nano titanium oxide, 10 parts of air purification and sterilization powder, organic 0.8 parts of bentonite, 0.2 parts of polyacrylic acid ammonium salt dispersant, 0.2 parts of carboxymethyl cellulose, 6 parts of coconut oil, and 55 parts of deionized water; Apple eucalyptus and lemongrass are mixed in a mass ratio of 3:1:1:2:1 and then crushed.

[0030] In the present embodiment, the preparation method of described environment-friendly coating comprises the following steps:

[0031] a. Grinding diatomite, lithium silicate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com