Anti-blue-light resin lens made from fluorescent masking agent

A resin lens and masking agent technology, applied in optics, optical components, instruments, etc., can solve the problems of blue light attenuation, decreased vision, and increased production costs, and achieve the effects of improved blue light protection, advanced technology, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

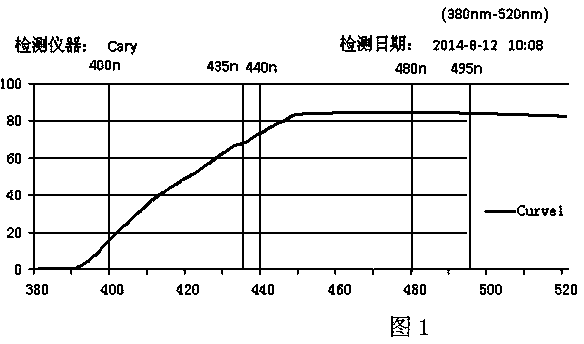

[0020] refer to figure 1 : Prepare the monomer by 0.1% by weight of the fluorescent masking agent: inject the optical resin lens monomer into a special stainless steel preparation tank at room temperature, weigh 2.5-3% of the initiator and 0.01% by weight of the monomer The plasticizer and 0.1 weight ratio of fluorescent masking agent are added into the tank together, and electric stirring is performed under a certain pressure to mix and degas, so that the liquid and air bubbles are separated and then vacuumized to obtain a fluorescent masking agent. The lens is filled with a monomer, and then put into a refrigerator, and kept at a low temperature of -10 degrees for future use.

[0021] 2. Carry out mold pouring, curing forming, demolding procedures and stabilization treatment according to the conventional manufacturing process of resin lenses to obtain an optical resin lens substrate containing a fluorescent masking agent.

[0022] 3. According to the process requirements, t...

Embodiment 2

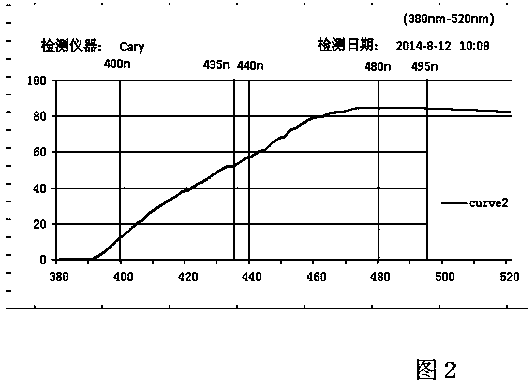

[0025] refer to figure 2 : prepare monomer by 0.2% fluorescent masking agent in weight ratio, and its monomer preparation and lens making each process flow method are the same as embodiment 1.

[0026] As can be seen from the spectrum transmission diagram of the lens product implementation case 2 of the present invention, the UV light attenuation rate at 220-380nm wavelength reaches more than 99% when the monomer is prepared with a fluorescent masking agent in the proportion of 0.2% by weight, which meets the requirements of the Ministry of Lens. UV protection standard. The transmittance of purple and blue light with wavelengths from 380nm to 480 is obliquely attenuated, and the attenuation rate reaches 20% for high-energy short-wave blue light at 450nm. Compared with the spectral transmission diagram of the lens product Example 1 of the present invention, it has a more obvious blue light attenuation.

Embodiment 3

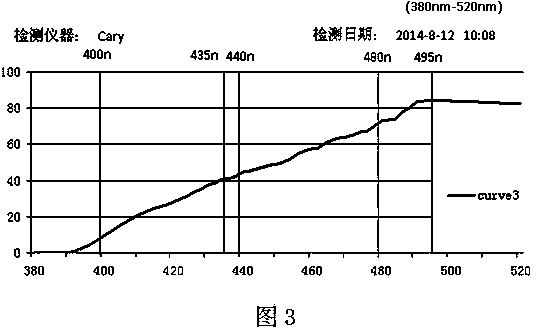

[0028] refer to image 3 : by the fluorescent masking agent preparation monomer of 0.3% weight ratio, its monomer preparation and lens make each technological process method with embodiment 1.

[0029] It can be seen from the spectral transmission diagram of the third embodiment of the lens product of the present invention that the UV light attenuation rate of 220-380nm wavelength reaches more than 99% when the monomer is prepared with a fluorescent masking agent in a proportion of 0.3% by weight, which is in line with the requirements of the ministerial lens. UV protection standard. The transmittance of violet-blue light with a wavelength of 380nm to 480 is attenuated with a large angle, and the attenuation rate of high-energy short-wave blue light at 450nm has reached 30%. Compared with the spectral transmission diagram of the lens product implementation case 1 of the present invention , has obvious blue light attenuation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com