Anti-magnetic heat-conducting film and preparation method thereof

A heat-conducting film and heat-conducting layer technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve problems such as poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

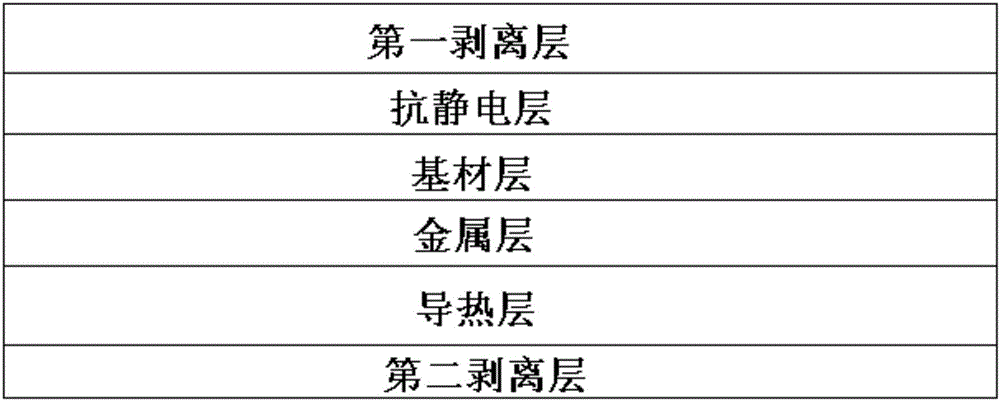

[0043] The present invention also provides a method for preparing a diamagnetic heat-conducting film, comprising the following steps:

[0044] A) one side of the substrate is coated with antistatic glue, and cured to obtain a substrate compounded with an antistatic layer;

[0045] B) attaching a peeling film on the surface of the antistatic layer to form the first peeling layer;

[0046] C) plating a layer of metal on the other side of the substrate to form a metal layer;

[0047] D) Coating heat-conducting glue on the surface of the metal layer, and obtaining a heat-conducting layer after curing, heat-conducting particles are dispersed in the heat-conducting glue, and the heat-conducting particles include alumina particles, aluminum hydroxide particles, boron nitride particles and copper-zinc alloy particles one or more of them;

[0048] E) Attaching a release film on the surface of the heat conduction layer to obtain a diamagnetic heat conduction film.

[0049]The present...

Embodiment 1

[0058] On the 50μm thick PET insulating film, apply a 4μm thick antistatic glue with a micro concave roller, and cure it with a UV lamp to obtain an antistatic layer;

[0059] Take a PET film with a thickness of 50 μm, and apply a layer of 10 μm silica gel on one side with a comma-type spatula. After baking and curing, cover the side with the glue on the surface of the antistatic layer to form a peeling layer;

[0060] Plating a layer of metal copper with a thickness of 500nm on the other side of the PET insulating film by sputtering to form a metal layer;

[0061] Coating a layer of thermally conductive adhesive on the surface of the copper metal layer, baking and curing to form a 10 μm thick thermally conductive layer, and finally covering a layer of 50 μm thick release film to obtain a diamagnetic thermally conductive film.

Embodiment 2

[0063] Apply 5 μm thick antistatic glue on the 50 μm thick PET insulating film with a micro concave roller, and cure it with a UV lamp to obtain an antistatic layer;

[0064] Take a PET film with a thickness of 50 μm, and apply a layer of 10 μm silica gel on one side with a comma-type spatula. After baking and curing, cover the side with the glue on the surface of the antistatic layer to form a peeling layer;

[0065] A layer of 300nm thick metal copper is plated on the other side of the PET insulating film by sputtering to form a metal layer;

[0066] Coating a layer of thermally conductive adhesive on the surface of the copper metal layer, baking and curing to form a 25 μm thick thermally conductive layer, and finally covering a layer of 50 μm thick release film to obtain a diamagnetic thermally conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com