Wear-resisting electromagnetic shielding modified polyformaldehyde material

A polyoxymethylene material and electromagnetic shielding technology, applied in the field of polymer materials, can solve the problems of reduced wear resistance, high price, long delivery cycle, etc., and achieve the effects of outstanding antimagnetic, reduced corrosion, and excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

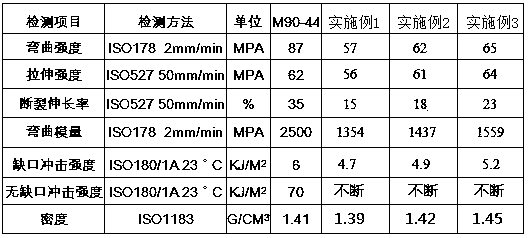

Embodiment 1

[0022] A wear-resistant electromagnetic shielding modified polyoxymethylene material, comprising the following components by weight fraction: 70 parts of polyoxymethylene, 10 parts of molybdenum disulfide, 5 parts of conductive carbon black, 0.5 parts of liquid dispersant, and 0.2 parts of metal passivator , heat stabilizer 0.2 part, antioxidant 0.2 part.

[0023] Among them, aerospace-grade molybdenum disulfide is used, with small particle size and good dispersion. Special molybdenum disulfide is used to improve the overall wear resistance of the system, and at the same time increase the excellent characteristics of magnetic shielding. Conductive carbon black is further added to increase the excellent characteristics of electrical shielding, specifically Degussa conductive carbon black.

[0024] Specifically, the polyoxymethylene is copolymerized high-flow polyoxymethylene, and the mechanical properties and processing performance of the material are improved by copolymerizing...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that a wear-resistant electromagnetic shielding modified polyoxymethylene material includes the following components by weight fraction: 80 parts of polyoxymethylene, 15 parts of molybdenum disulfide, 7 parts of conductive carbon black, liquid 3 parts of dispersant, 0.5 part of metal deactivator, 0.5 part of heat stabilizer, 0.3 part of antioxidant.

[0034] The invention also discloses a method for preparing the wear-resistant electromagnetic shielding modified polyoxymethylene material, comprising the following steps: weighing 80 parts of polyoxymethylene, 15 parts of molybdenum disulfide, 7 parts of conductive carbon black, and 3 parts of liquid dispersant , 0.5 part of metal deactivator, 0.5 part of heat stabilizer, and 0.3 part of antioxidant are mixed uniformly, then melt-extruded and granulated by a twin-screw extruder to obtain a modified polyoxymethylene material.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is that a wear-resistant electromagnetic shielding modified polyoxymethylene material includes the following components by weight fraction: 90 parts of polyoxymethylene, 20 parts of molybdenum disulfide, 10 parts of conductive carbon black, liquid 5 parts of dispersant, 0.8 part of metal deactivator, 0.8 part of heat stabilizer, 0.5 part of antioxidant.

[0037] The invention also discloses a method for preparing the wear-resistant electromagnetic shielding modified polyoxymethylene material, comprising the following steps: weighing 90 parts of polyoxymethylene, 20 parts of molybdenum disulfide, 10 parts of conductive carbon black, and 5 parts of liquid dispersant , 0.8 part of metal deactivator, 0.8 part of heat stabilizer, and 0.5 part of antioxidant are mixed uniformly, then melt-extruded and granulated by a twin-screw extruder to obtain a modified polyoxymethylene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear volume | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com