Novel material for hardware button and processing technique thereof

A technology of processing technology and new materials, applied in the field of new materials for hardware buttons, can solve the problems of toughness, ductility and wear resistance of hardware buttons being not very strong, the composition needs to be improved, and the hardware buttons are cumbersome, etc. The effect of toughness, toughness and ductility enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

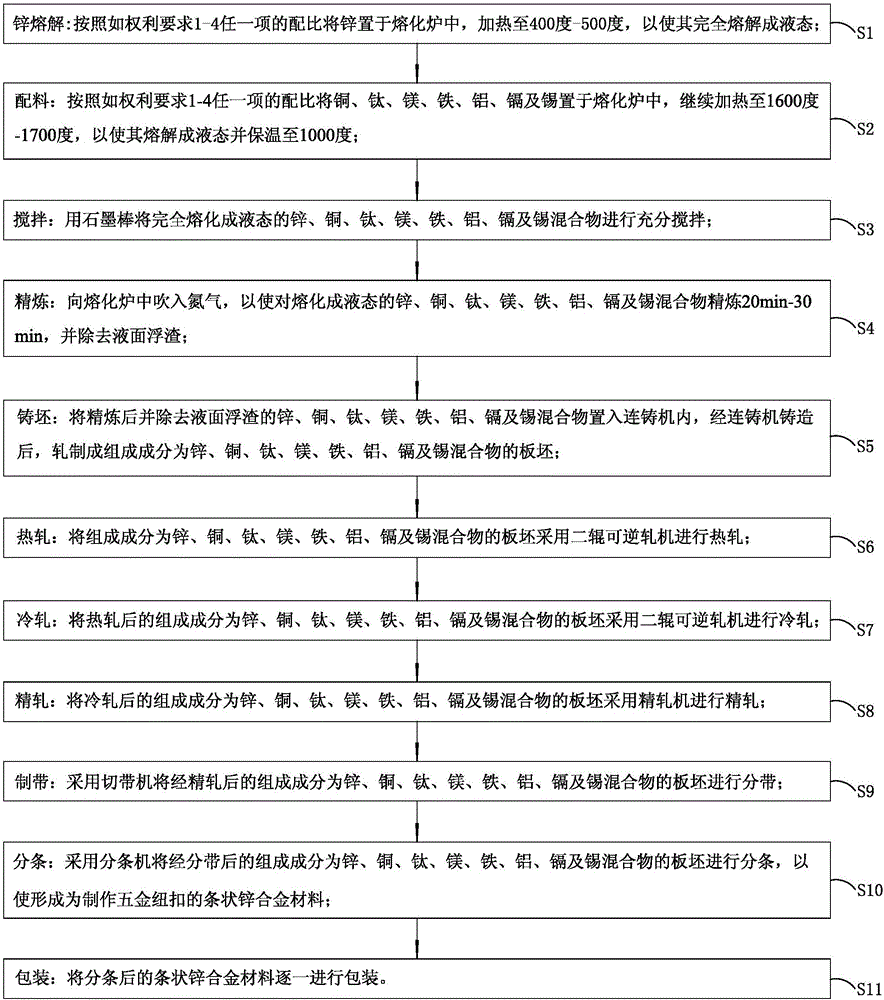

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a new hardware button material provided by the present invention is composed of 0.55% copper, 0.1% titanium, 0.04% magnesium and zinc as the balance.

[0037] In this embodiment, the weight percentage content of the remaining zinc is 99.31%.

Embodiment 2

[0039] In this embodiment, a new hardware button material provided by the present invention is composed of 1.5% copper, 0.19% titanium, 0.07% magnesium, 0.06% iron, 0.02% aluminum, 0.002% cadmium, Tin 0.001% and the balance zinc.

[0040] In this embodiment, the weight percentage content of the remaining zinc is 98.157%.

Embodiment 3

[0042] In this embodiment, a new hardware button material provided by the present invention is composed of 1.0% copper, 0.15% titanium, 0.058% magnesium, 0.03% iron, 0.01% aluminum, 0.001% cadmium, Tin 0.001% and the balance zinc.

[0043] In this embodiment, the weight percentage content of the remaining zinc is 98.75%.

[0044] Regardless of Embodiment 1, Embodiment 2 or Embodiment 3, it is clear that in this technical solution, the weight percentage content of the corresponding new metal button material contains magnesium and titanium, and magnesium and titanium have a certain weight ratio. The proportion of magnesium also makes the hardware buttons made of the corresponding new hardware button materials have certain ductility and heat dissipation, and the proportion of titanium also makes the hardware buttons made of the corresponding new hardware button materials have a certain metallic luster, Strength and resistance to wet chlorine corrosion.

[0045]At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com