Positive type photosensitive composition

A photosensitive composition, positive type technology, applied in the directions of optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc. Film and other problems, to achieve the effect of less film reduction, improved scratch resistance, and small change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

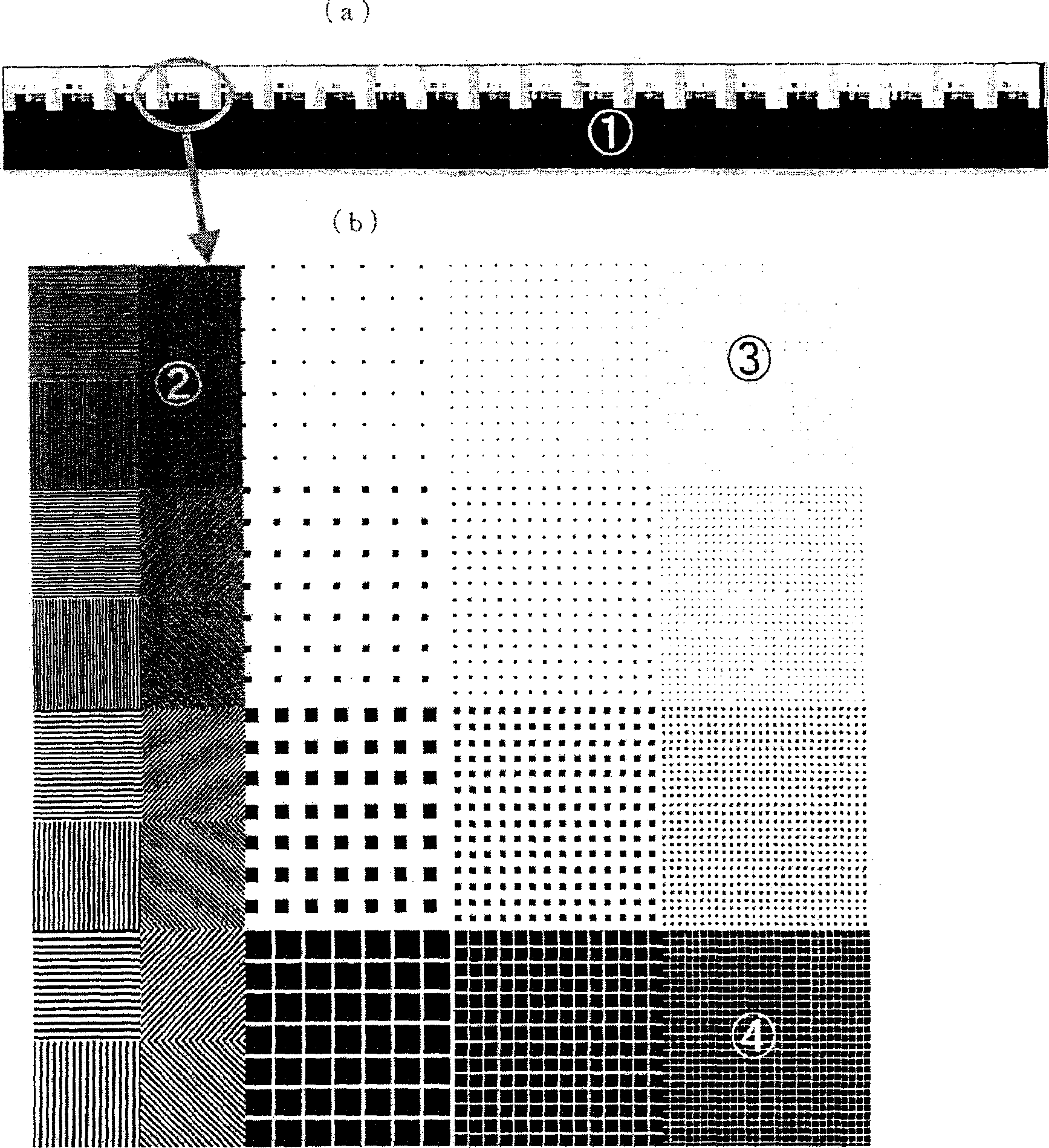

Image

Examples

Embodiment 1

[0142] A positive-type photosensitive composition (5% solid content) was prepared as a photosensitive liquid for measurement according to the blended substances and the blending ratio shown in Table 1.

[0143] Complex substance

Compounding amount

(parts by weight)

ingredient (A)

Novolac resin

100

ingredient (B)

Near Infrared Absorbing Pigment 1

1

ingredient (C)

PVP / VA copolymer

5

ingredient (D)

Solvolysis inhibitor 1

5

PM

IPA

MEK

800

800

600

[0144] Each component in Table 1 is as follows.

[0145] Novolak resin: PR-NMD-100 (manufactured by Sumitomo Bakerite Co., Ltd.)

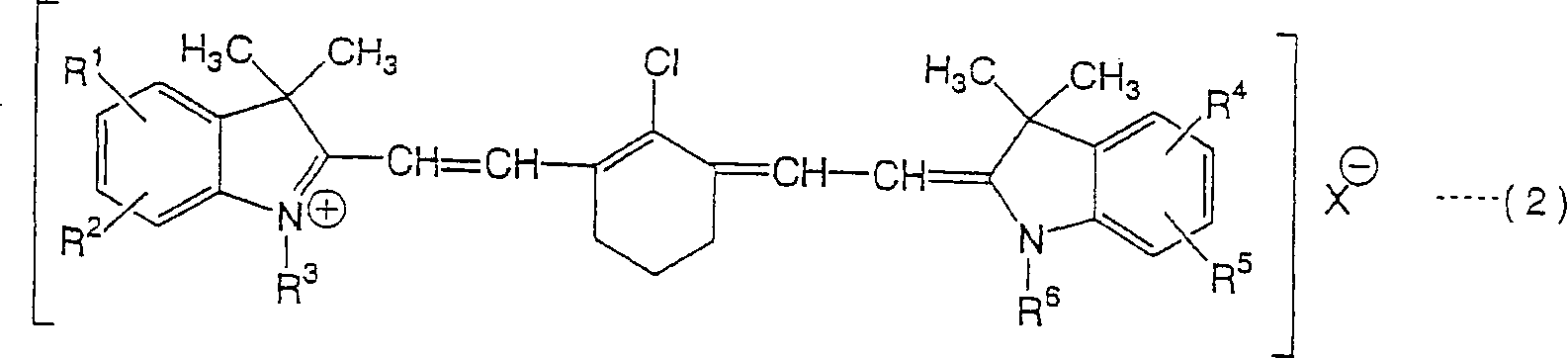

[0146] Light-absorbing pigment 1: Anthocyanin-based pigment PVP / VA copolymer: a copolymer of vinylpyrrolidone and vinyl acetate with a molecular weight of 46,000 and a glass transition temperature of 96°C (vinylpyrrolidone / vinyl acetate 50 / 50)

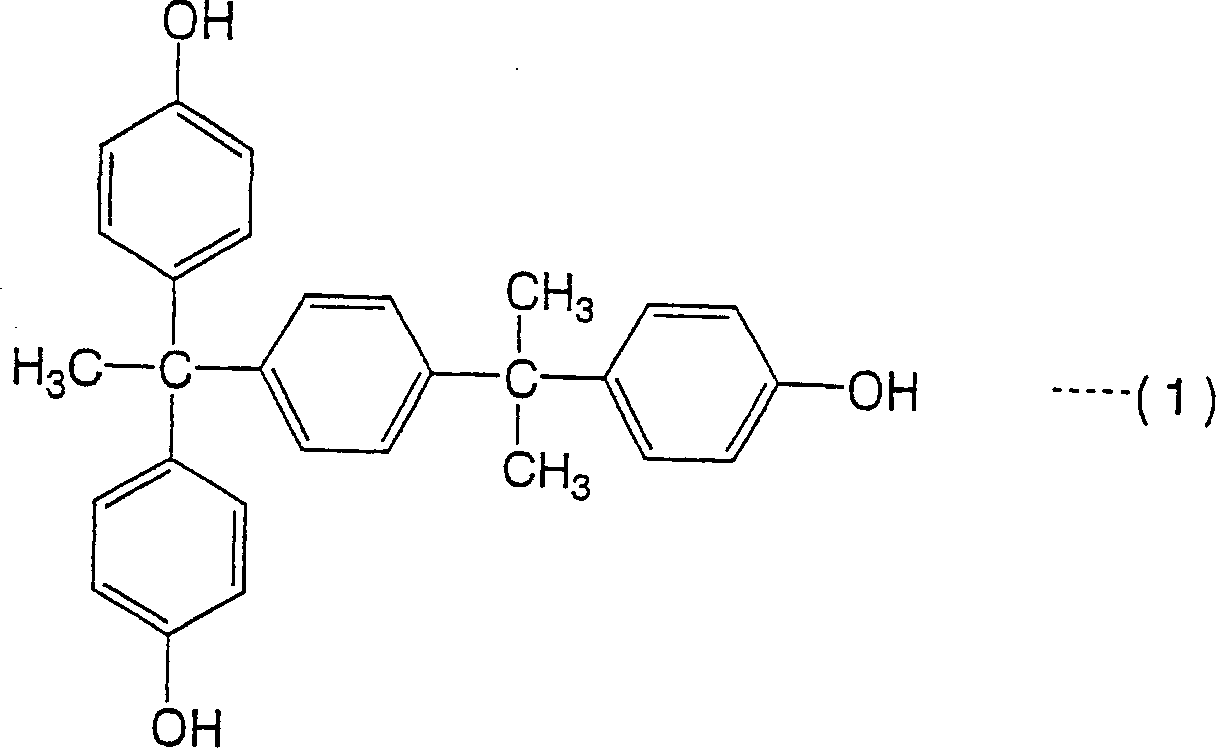

[0147] Dissolutio...

Embodiment 2~6

[0177] As shown in Table 4, it tested similarly to Example 1 except having changed the component (B) in a composition. In addition, it is a test performed under the measurement condition of 45% of humidity. The results are shown in Table 4 together.

[0178] Element

[0179] The compounding quantity of the component (B) in Table 4 is the same as that of Example 1, and the dyes 2 to 6 are compounds represented by the aforementioned formulas (2), (4) to (7), respectively.

Embodiment 7~9

[0181] As shown in Table 5, it tested similarly to Example 1 except having changed (A) component in a composition. In addition, it is a test performed under the measurement condition of 45% of humidity. The results are shown in Table 5 together.

[0182] Element

(A)

Adhesion

Sensitivity

(mJ / cm 2 )

development

(second)

Residual film rate

(%)

image

Marginal

development

scope

Example 7

Resin 1

◎

220

75

72

◎

◎

◎

Example 8

Resin 2

◎

220

75

74

◎

◎

◎

Example 9

Resin 3

◎

220

75

75

◎

◎

◎

[0183] In Table 5, the compounding quantity of a component (A) is the same as Example 1, and resins 2-4 are as follows.

[0184] Resin 1: Alkylphenolic resin (trade name Hitano-ru 2181, manufactured by Hitachi Chemical Co., Ltd.)

[0185] Resin 2: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com