Cosmetics and their manufacturing methods

A manufacturing method and technology for cosmetics, applied in cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of uneven color, reduced availability and use feeling, insufficient adhesion of the retainer, etc., and achieve sufficient adhesion and accessibility. and excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

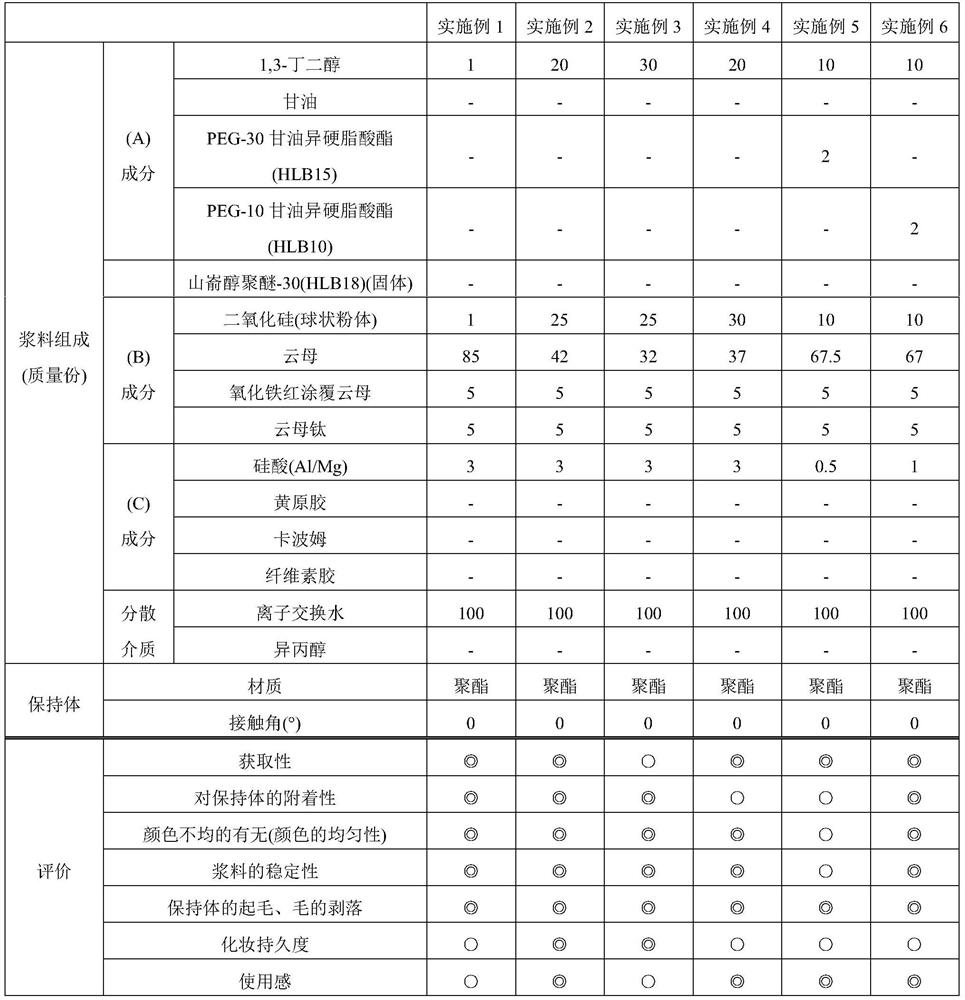

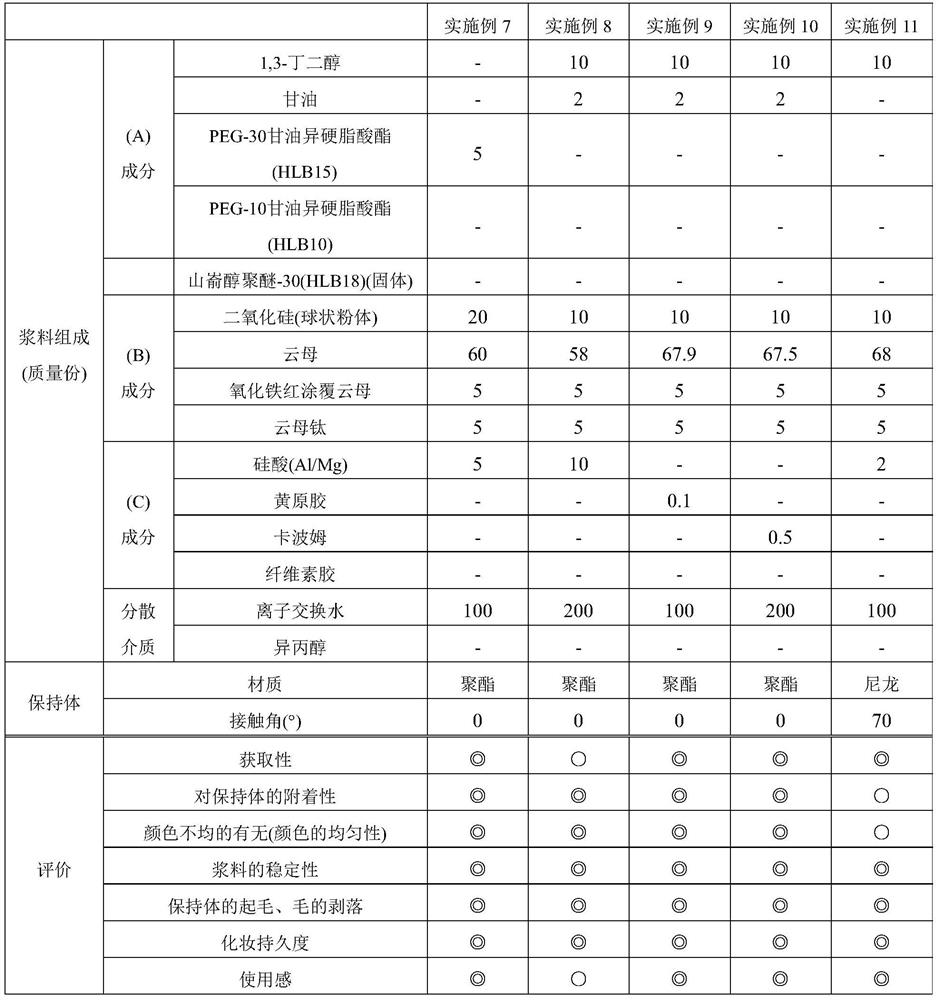

Embodiment 1~11 and comparative example 1~3

[0104] Prepare the slurry of the composition shown in Tables 1 to 3, immerse the artificial flowers of the material shown in Tables 1 to 3 in the slurry, take it out, and dry it at room temperature for more than 12 hours, and obtain the surface of the artificial flower as Blush powder makeup layer of cosmetics.

[0105] Separately, a slurry was prepared by dissolving component (A) or beheneth-30 in a dispersion medium at 80° C., adding component (B) and uniformly dispersing it, and then slowly adding ( C) ingredients and further stirring after addition.

[0106] As for the artificial flower as a support body, an artificial flower formed of a polyester textile and an artificial flower formed of a nylon film were prepared. In addition, the contact angle of the support surface with water was measured by the following method.

[0107]

[0108] Drops of water were dropped on the surface of the holder, and it was photographed from the front side with a camera. Based on the acqui...

Embodiment 12

[0130] (Embodiment 12: pressed powder)

[0131]

[0132]

[0133] Dispersion medium: 100 parts by mass of ion-exchanged water relative to 100 parts by mass of the above-mentioned components 1 to 9 in total

[0134] The above ingredients are detailed as follows:

[0135] Component 1: WILBRIDE S-753 (manufactured by NOF CORPORATION, trade name)

[0136] Component 4: KS-66 (manufactured by Shin-Etsu Chemical Co., Ltd., trade name)

[0137] Ingredient 6: TIMICA SPARKLE (manufactured by BASF JAPAN LTD., brand name)

[0138] Ingredient 7: PDM-10S (manufactured by TOPY INDUSTRIES LIMITED., trade name)

[0139] Component 8: SUNPMMA-S (manufactured by Sunjin Chemical Co., Ltd., trade name)

[0140] Ingredient 9: KUNIPIA-G (manufactured by KUNIMINE INDUSTRIES CO.,LTD., trade name)

[0141]

[0142] Components 1 to 3 are dissolved in a dispersion medium, and components 4 to 8 are added and uniformly dispersed. Thereafter, component 9 was gradually added while stirring, and ...

Embodiment 13

[0145] (Example 13: Foundation)

[0146]

[0147] Dispersion medium:

[0148] Ion-exchanged water: 80 parts by mass relative to 100 parts by mass of the above components 1 to 13 in total

[0149] Ethanol 20 parts by mass relative to 100 parts by mass of the above components 1 to 13 in total

[0150] The above ingredients are detailed as follows:

[0151] Ingredient 1: Neosolue-Aqua (manufactured by NIPPON FINE CHEMICAL CO., LTD., trade name)

[0152] Component 3: KF-6011 (manufactured by Shin-Etsu Chemical Co., Ltd., trade name)

[0153] Component 5: KS-66 (manufactured by Shin-Etsu Chemical Co., Ltd., trade name)

[0154] Component 6: Tipaque PFC407 (manufactured by ISHIHARA SANGYO KAISHA, LTD., trade name)

[0155] Component 7: TAROX synthetic iron oxide LL-100P (manufactured by Titan Kogyo, Ltd., trade name)

[0156] Component 8: TAROX synthetic iron oxide R-516P (manufactured by Titan Kogyo, Ltd., trade name)

[0157] Component 9: TAROX synthetic iron oxide BL-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com