Epoxy resin composition

A technology of epoxy resin and composition, which is applied in printed circuits, electrical components, circuits, etc., can solve problems such as damage to film properties, difficulty in forming thin films, difficulty in thermal conductivity and insulation balance, etc., and achieve low dielectric loss factor, Effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2、 comparative example 1~5

[0089] The varnishes of the resin compositions were prepared in the formulations shown in Table 1. Then, a thin film was formed from the obtained varnish, and tests were performed according to the following evaluations 1 to 9. Table 1 shows the results.

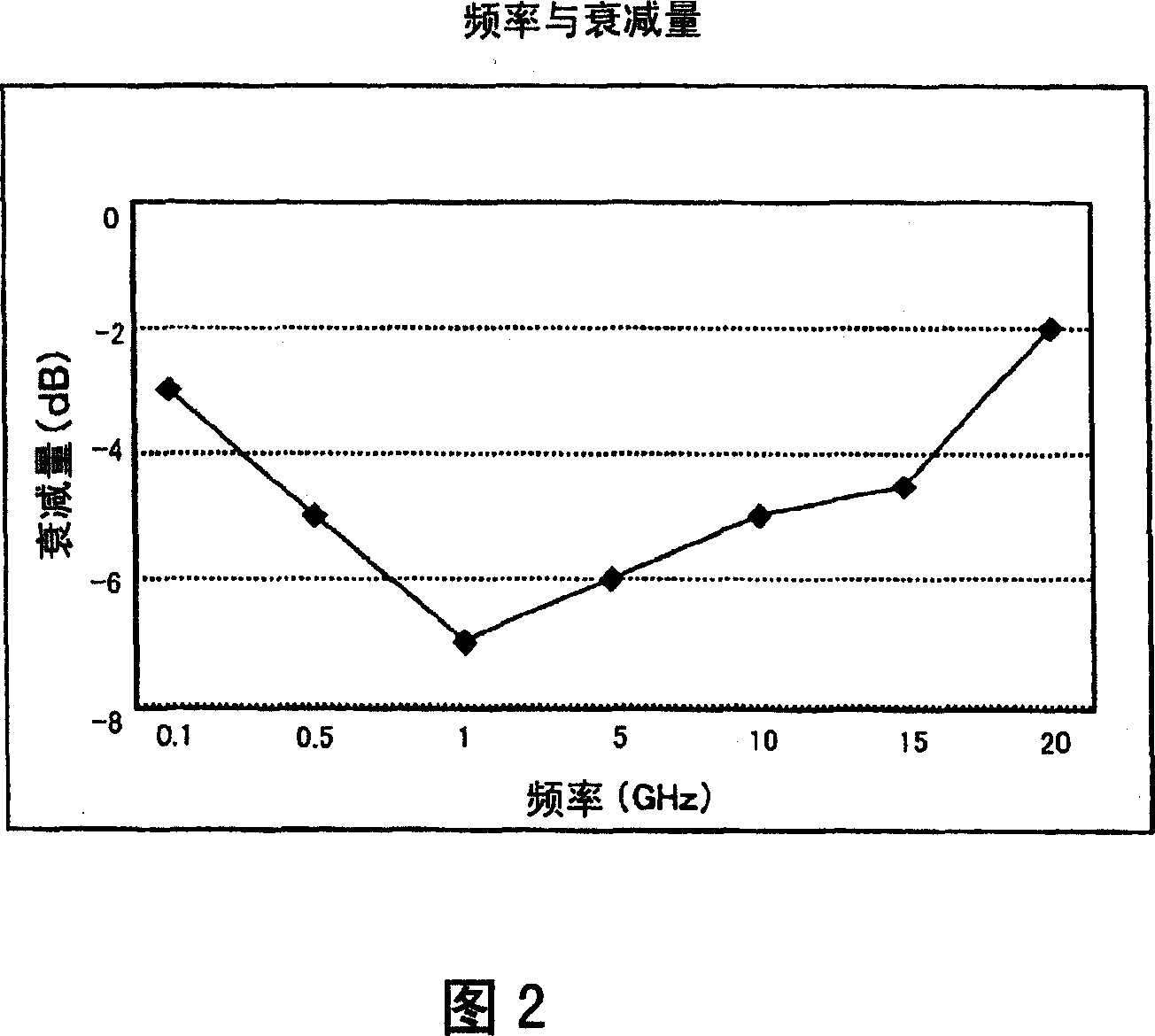

[0090] Evaluation 1 (dielectric characteristics)

[0091] On a film with a release agent (silicone-based release agent, PET film) as a support, it is coated using a doctor blade coater, slot die coater or micro gravure coater so that The cured thickness is 2-90 μm, and an uncured film is obtained after drying.

[0092] Then, it was cured under the conditions of 80°C for 30 minutes, 100°C for 60 minutes, 150°C for 60 minutes, and 180°C for 60 minutes. state, a thin film is obtained. On this cured film, an uncured thin film of the same composition is further laminated and cured by vacuum heating. The obtained film was processed into a width of 1.5 mm, a length of 80 mm, and a thickness of 0.5 mm to prepare a sample.

[009...

Embodiment 3~10、 comparative example 6~7

[0126] A varnish was prepared as an inorganic filler-added resin composition in the formulation shown in Table 2. Then, a thin film was formed from the obtained varnish, and a test was performed according to the above evaluations 1 and 2 to 9 and the following evaluations 10 to 13. The results are shown in Table 2.

[0127] Evaluation 10 (film formability)

[0128] A film of 20 to 200 μm was produced on PET using a slot die coater. Uncured films can be produced with a dry thickness accuracy of ±5%. The results are shown in Table 2.

[0129] Evaluation 11 (winding property of film)

[0130] A 10 m uncured film (thickness 30 μm) was wound on a 37 mm core, and then unrolled, and cracks and the like on the film were observed. The results are shown in Table 2.

[0131] Evaluation 12 (thermal conductivity)

[0132] Using the varnishes of the resin compositions of Examples 6 and 7 to which thermally conductive fillers were added, a cured film with a thickness of 100 μm was obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com