Novel three-dimensional printer

A technology of printers and 3D printers, applied in the direction of additive processing, etc., can solve the problems of slow printing speed and single printing direction, and achieve the effect of expanding types, solving blockage, and solving slow manufacturing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

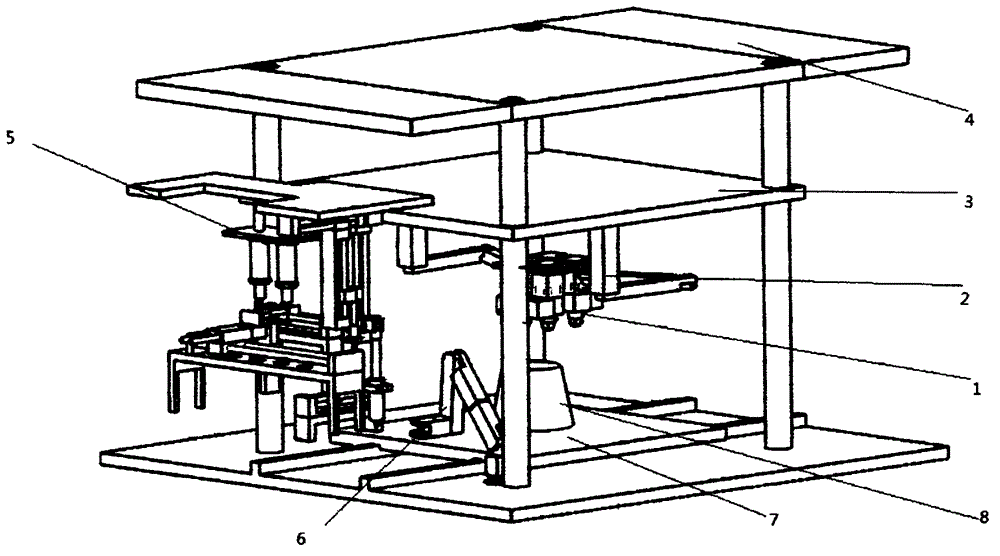

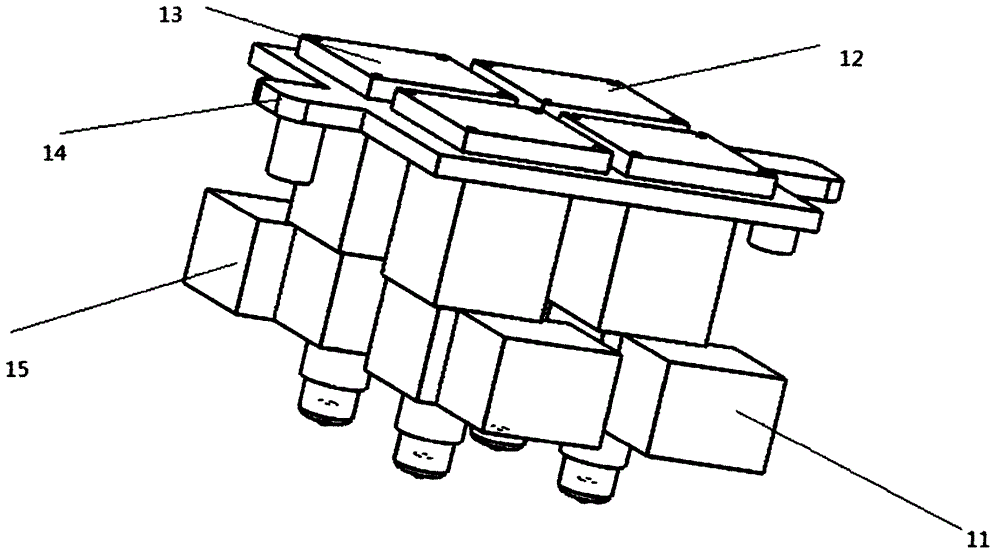

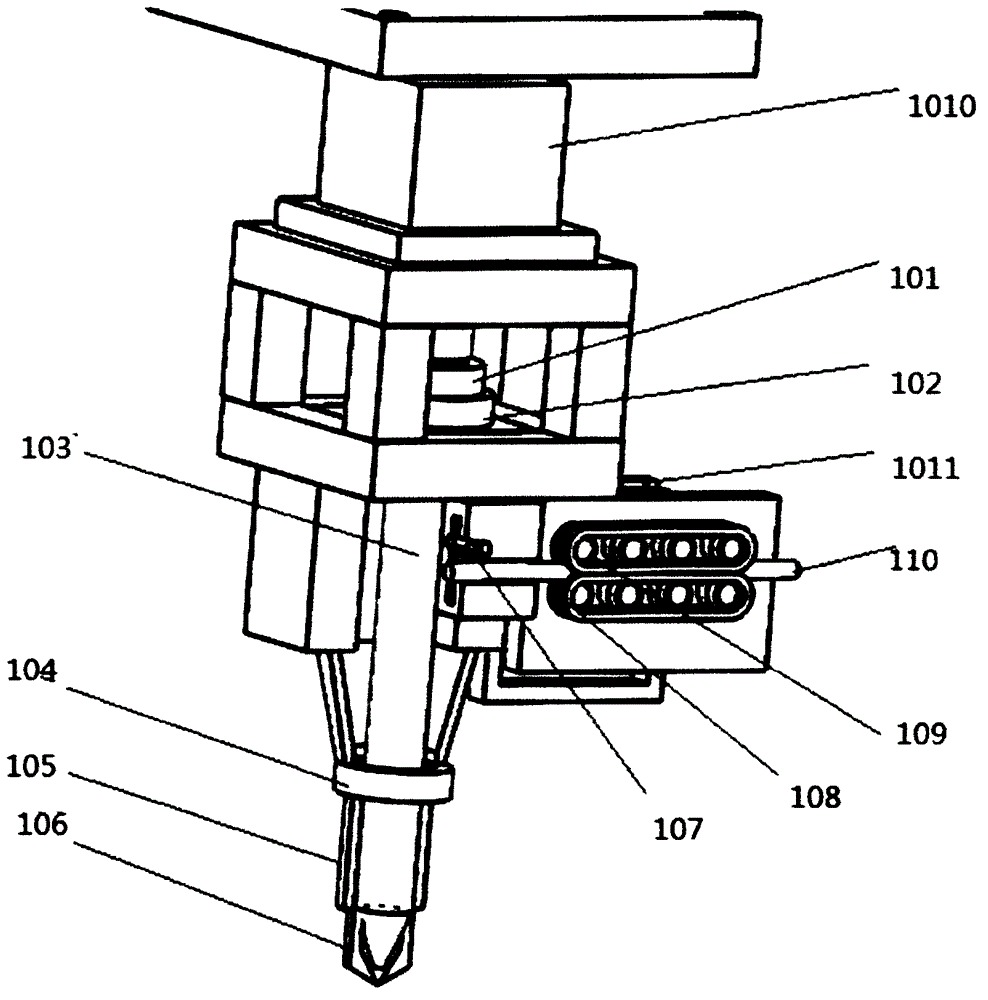

[0026] Such as figure 1 As shown, the 3D printer disclosed in the present invention includes a multi-nozzle assembly 1, a double-arm type nozzle driving device 2, a lifting plate 3, a frame 4, an injection molding liquid mixing device 5, an injection molding robot arm device 6, and a printing base 7 . The multi-nozzle assembly 1 is composed of four individual print nozzles, and the inner diameters of the nozzles of each print head are different. The four print heads are divided into two rows and fixed on the mounting plate 14 of the multi-nozzle assembly 1 in two rows, as shown in FIG. figure 2 The mounting plate of the multi-spray head assembly 1 shown is connected to the double-arm type print head driving device 2, and the joints at the connection can realize the rotation of three rotational degrees of freedom, and the rotation is controlled by a stepping motor. The double mechanical arm spray head driving device 2 is installed under the lifting plate 3, and the joint can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com