Three-dimensional micro channel and a pulsating flow heat dissipation device

A heat dissipation device and micro-channel technology, applied in cooling/ventilation/heating transformation, modification by liquid cooling, electrical components, etc., can solve the problems of low heat exchange rate and slow heat dissipation, and achieve uniform temperature distribution and large heat dissipation area , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

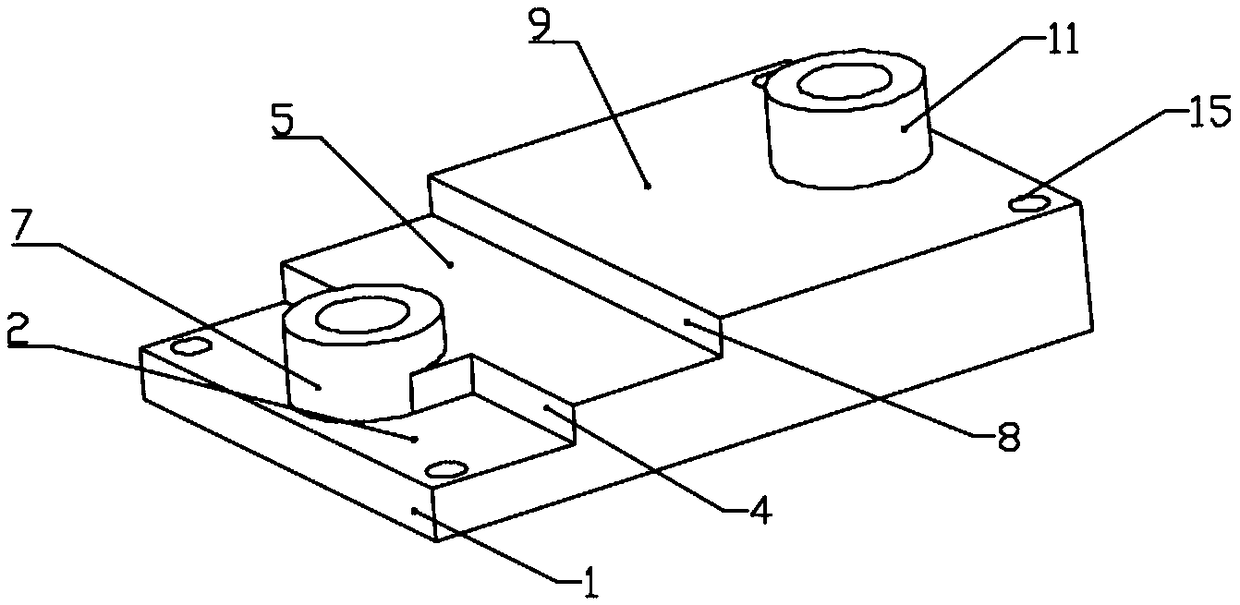

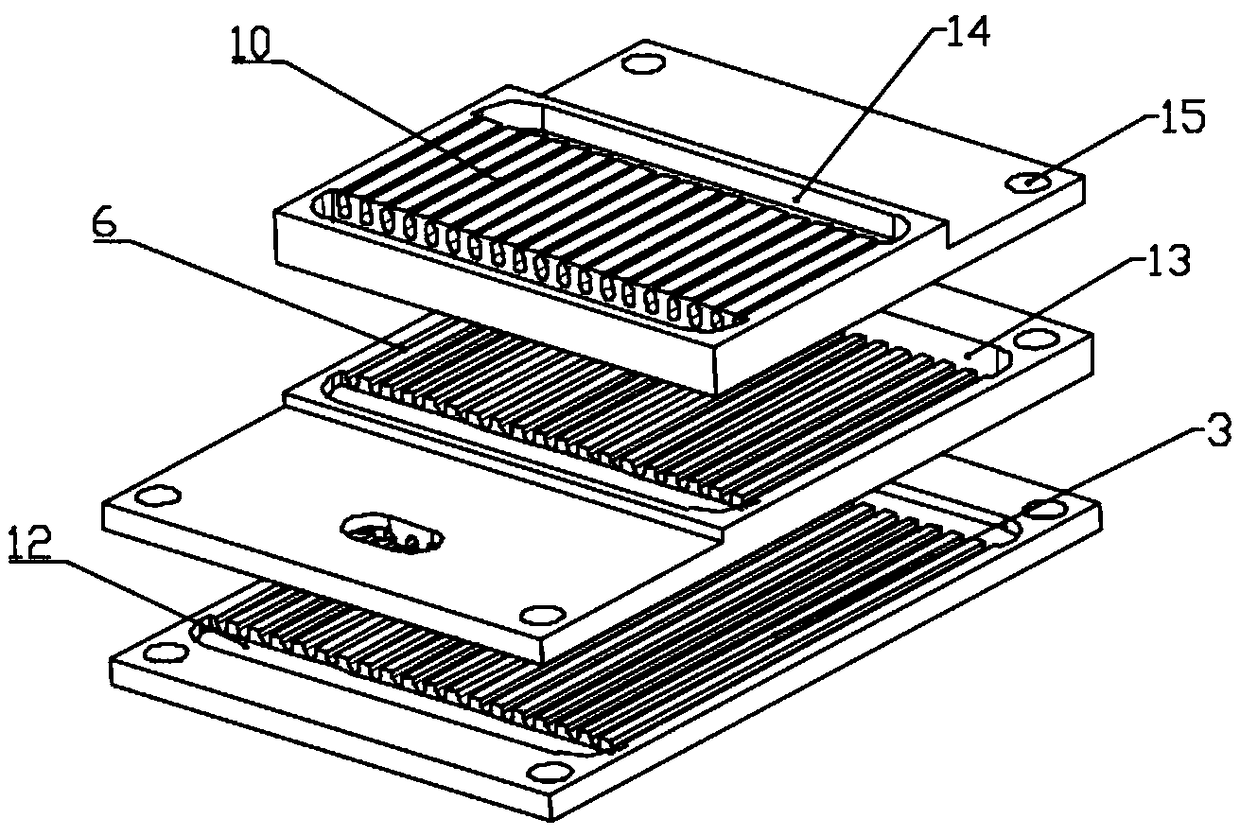

[0043] A micro-channel cold plate based on metal 3D printing technology, the micro-channel cold plate includes a bottom cold plate body 1, a middle layer cold plate body and a top layer cold plate body, distributed on the working surface of the plate body 1 Oval or rhombus-shaped microchannel components, each layer of cold plate is provided with heat dissipation channels, so that the coolant can pass through each layer of cold plate one by one to complete a round of heat dissipation.

Embodiment 2

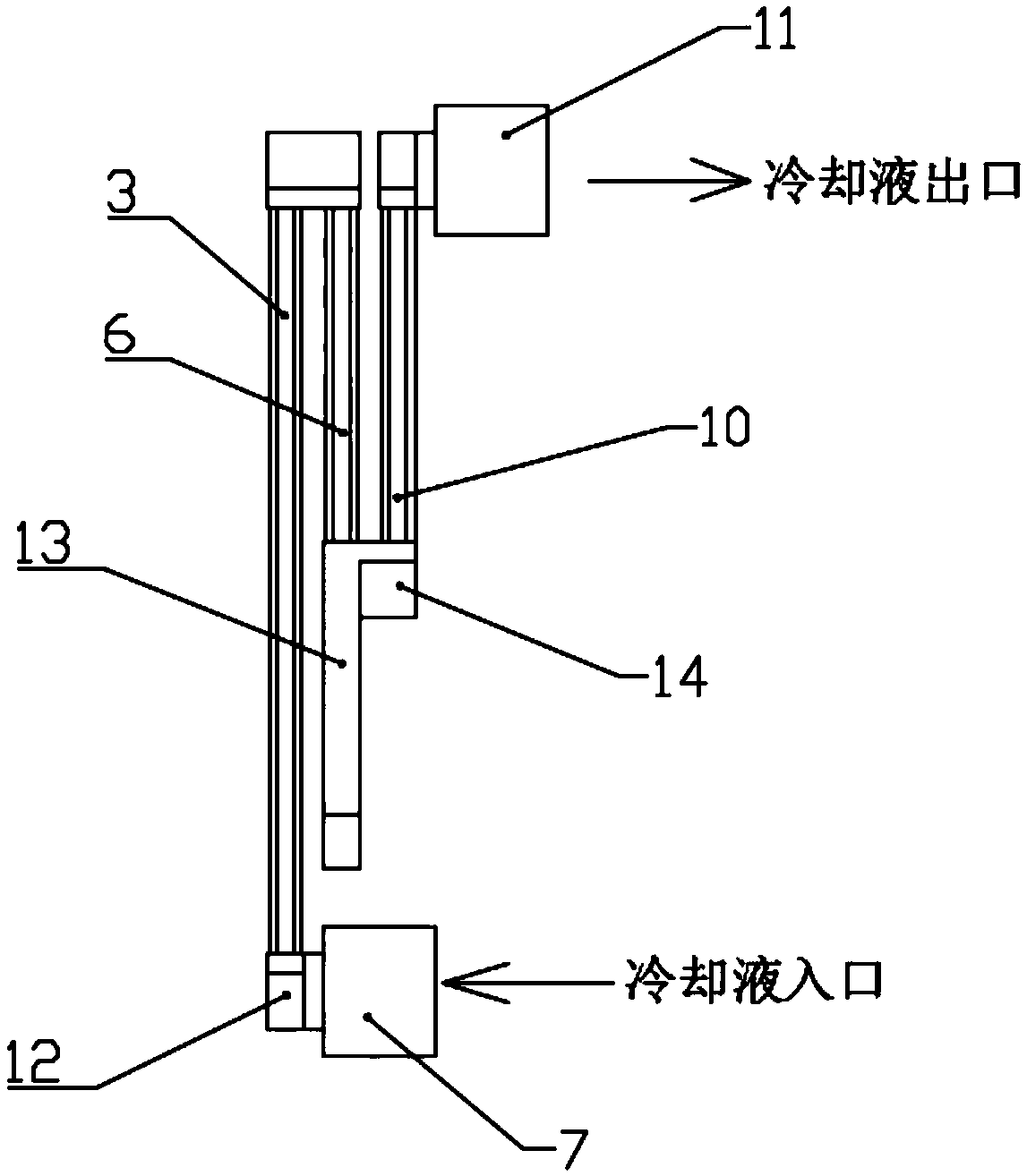

[0045] On the basis of Example 1, in the case where the heat source range of a certain part is relatively large, the cooling liquid can be injected from the liquid injection port 7, through the bottom microchannel 3 and the heat source for convective heat dissipation, and through the aluminum refrigeration plate in the form of heat conduction The heat of the heat source is transferred to the cooling liquid; afterward, the cooling liquid passes through the heat dissipation channel 13 of the middle layer to the micro channel 6 of the middle layer for a new round of convective heat dissipation; Finally, the coolant is discharged from the liquid outlet 11 to complete a round of heat dissipation. After passing through the three-dimensional laminated radiator, compared with the ordinary single-layer radiator, more heat from the heat source can be taken away, and the heat dissipation efficiency is higher.

Embodiment 3

[0047] When metal 3D printing technology is used for one-time printing of the three-dimensional microchannel radiator, the one-time printing of the bottom cold plate 1, the bottom microchannel 3, the bottom heat dissipation channel 12 and the installation hole 15 is firstly completed; then the bottom cover plate 2, The one-time printing of the middle layer cold plate 4, the middle layer heat dissipation channel 13, the liquid injection port 7 and the installation port 14; and then complete the one-time printing of the middle layer cover plate 5, the top layer cold plate 8, the top layer heat dissipation channel 14 and the installation hole 15 ; Finally, the one-time printing of the top cover plate 9, the liquid outlet 11 and the mounting hole 15 is completed;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com