TBM hob full-state real-time on-line monitoring system and measurement method thereof

A monitoring system and full-state technology, applied in the direction of measuring force, measuring device, measuring heat, etc., can solve problems such as unreliable monitoring data, and achieve the effect of avoiding cable laying, reducing failure rate, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

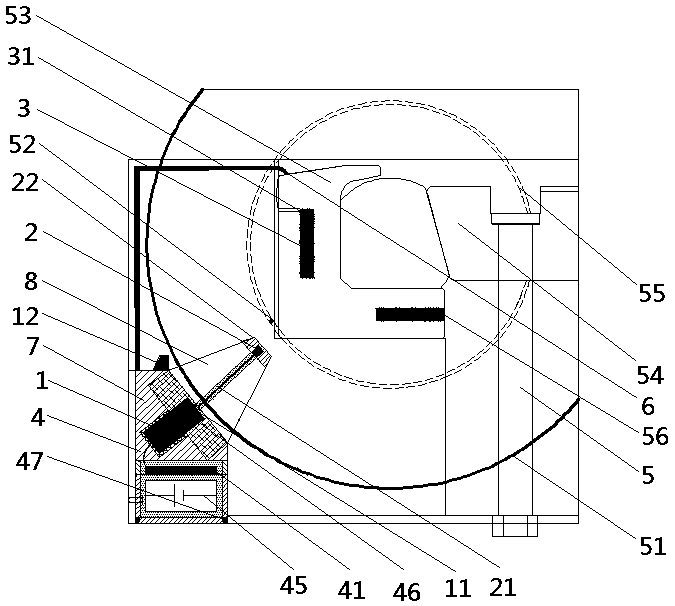

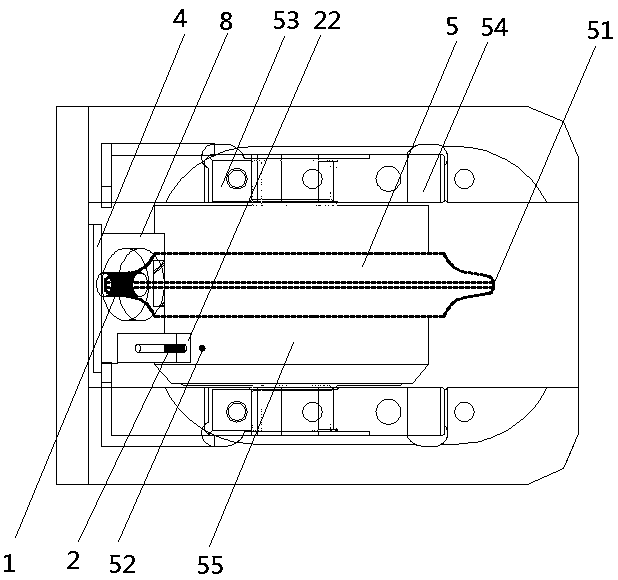

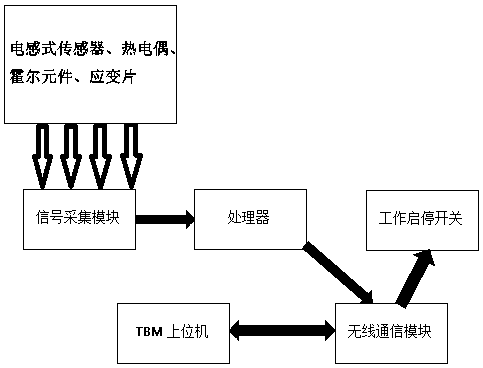

[0027] Embodiment 2, a full-state real-time online monitoring system for a TBM hob, two strain gauges 3 are provided, and the two strain gauges 3 are vertically arranged in the support wedge 53, and the strain gauges 3 pass through The profile block 56 is arranged tightly within the support wedge 53 . Setting two strain gauges perpendicular to each other can monitor the force of the TBM hob in the longitudinal and transverse directions, making the monitoring data more accurate and reliable.

[0028] Further, the strain gauge 3 is provided with a thermocouple 31 for monitoring the temperature of the TBM hob, and the thermocouple 31 is connected to a signal processing unit 41 . Set the thermocouple to work with strain gauges, inductive sensors, and Hall elements, and can simultaneously monitor the four index parameters of TBM hob wear, TBM hob speed, TBM hob force, and TBM hob operating temperature, so that the detection effect can be improved. More precise and reliable. Other...

Embodiment 3

[0029] Embodiment 3, a full-state real-time online monitoring system for a TBM hob, the base is provided with a protective cushion 21 for preventing the Hall element 2 from getting wet and vibrating, the protective cushion 21 is made of AB glue, and the Hall The outer end of the element 2 is provided with a non-magnetic titanium alloy end cap 22 . Setting a protective pad behind the Hall element can effectively protect the Hall element from damage, and at the same time reduce the vibration amplitude of the Hall element, which can ensure the reliability of the TBM hob speed measurement; the non-magnetic titanium alloy end cover The setting not only plays the role of collision protection, but also can effectively avoid the inaccurate influence of magnetic metal on the Hall element.

[0030] Further, the sensor base 4 is provided with a positioning sleeve 46, the inductive sensor 1 is arranged in the positioning sleeve 46, the outer end of the inductive sensor 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com