Patents

Literature

64results about How to "Abbe's error is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

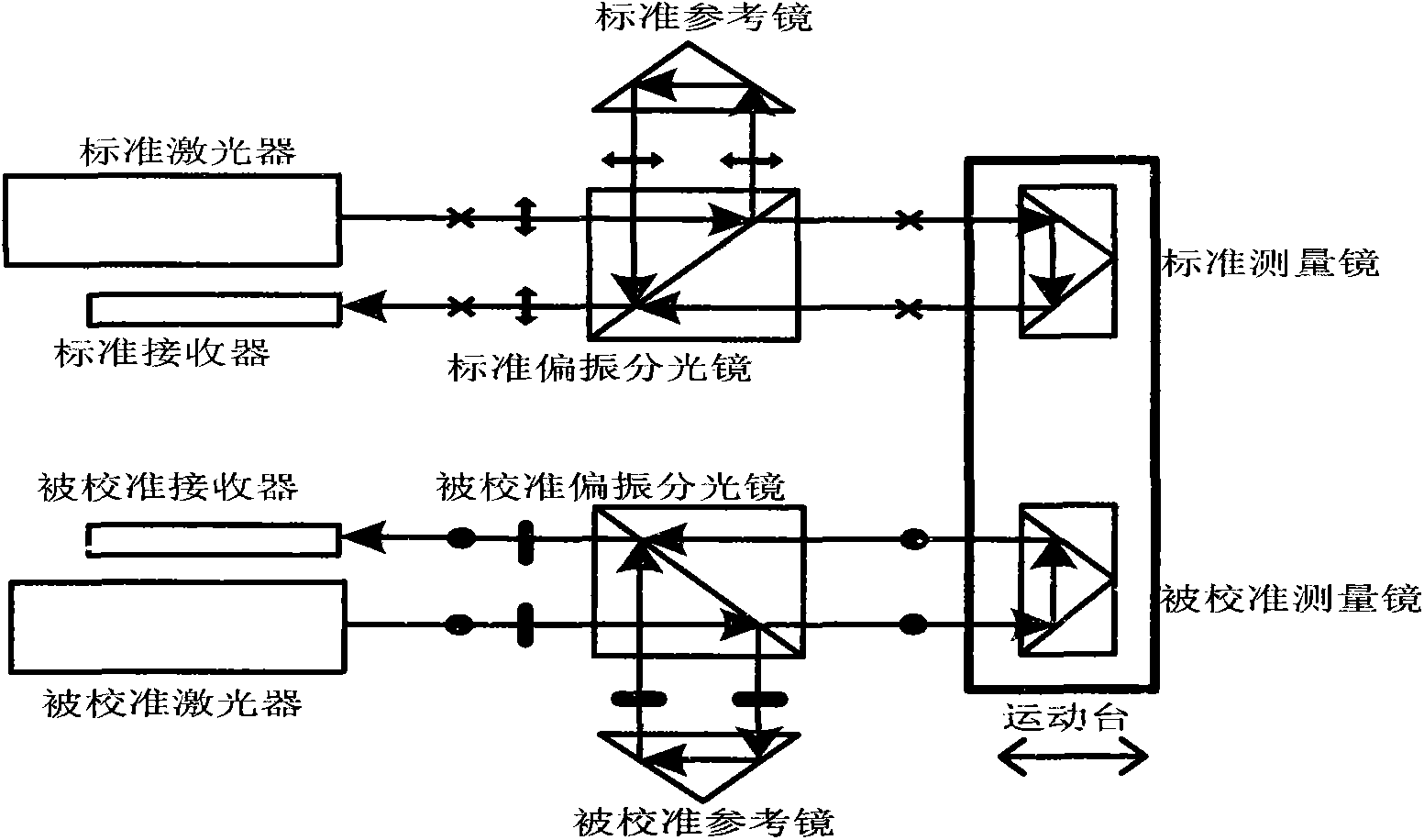

Morphology compensation type double-optical-axis linear displacement laser interferometer calibration method and device

ActiveCN103528499AAbbe's error is smallGuaranteed accuracyUsing optical meansLinear displacementLine segment

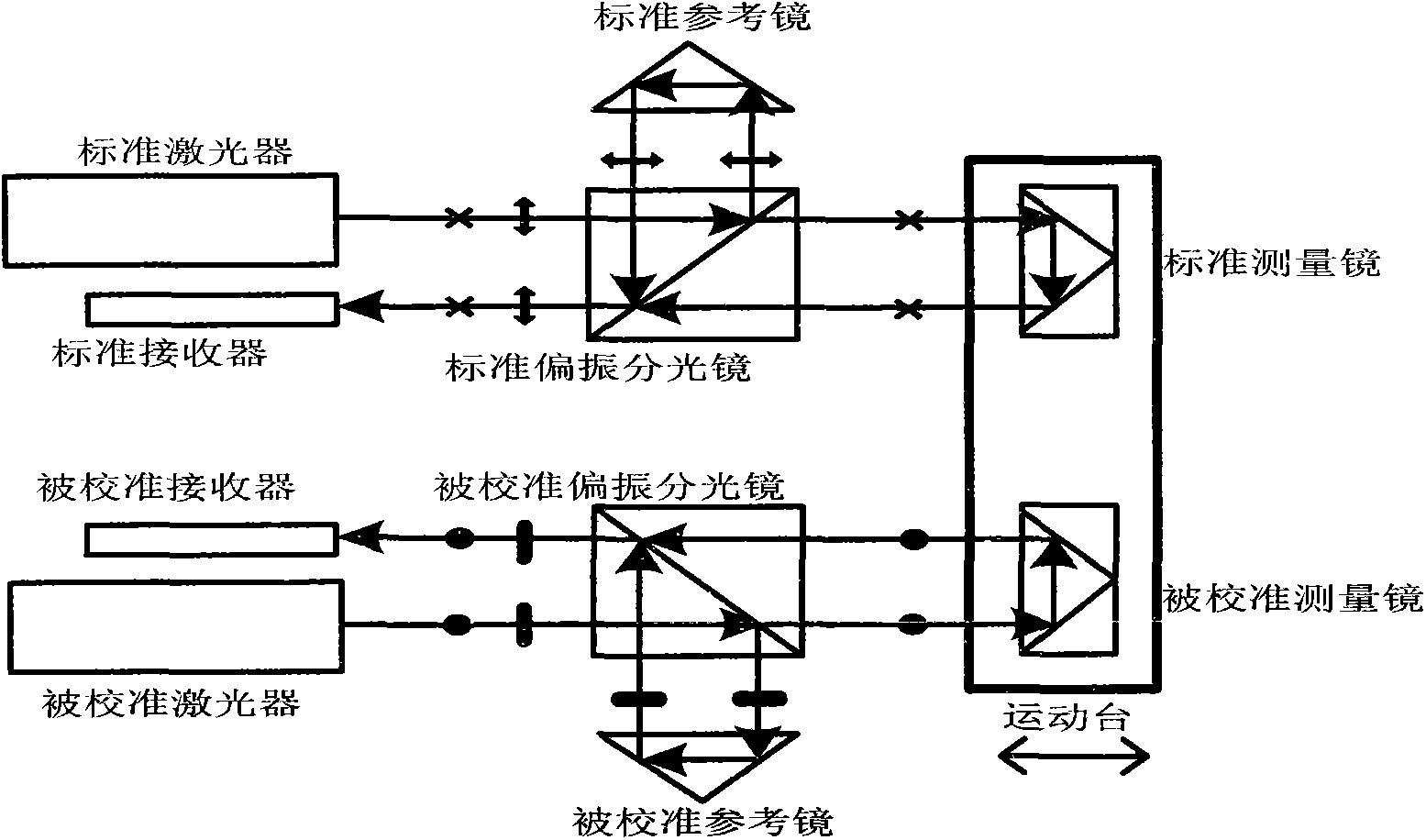

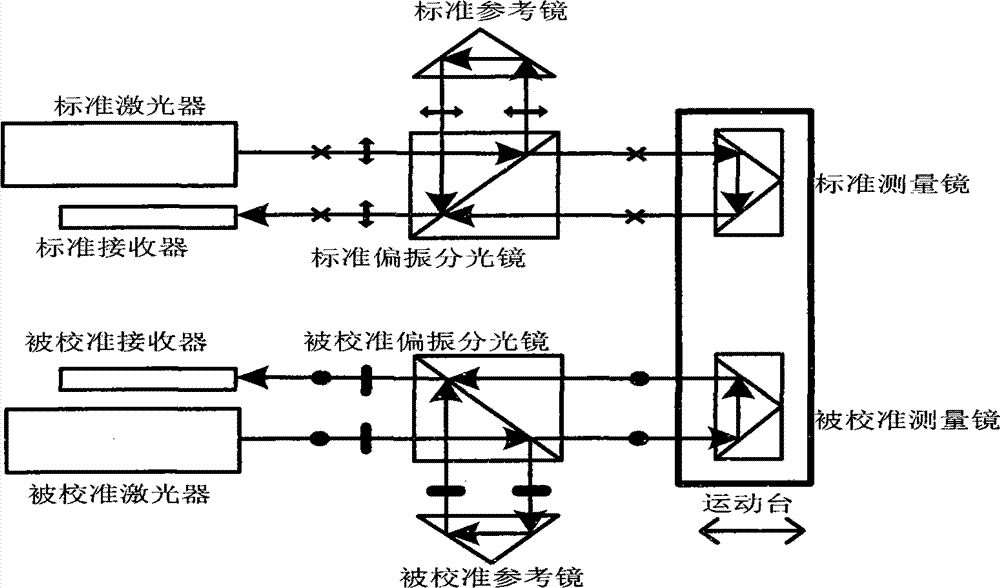

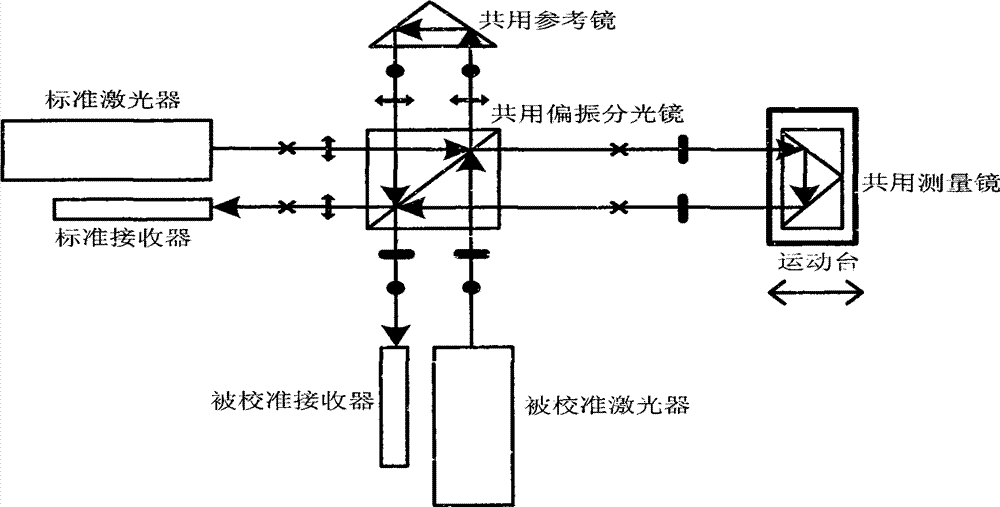

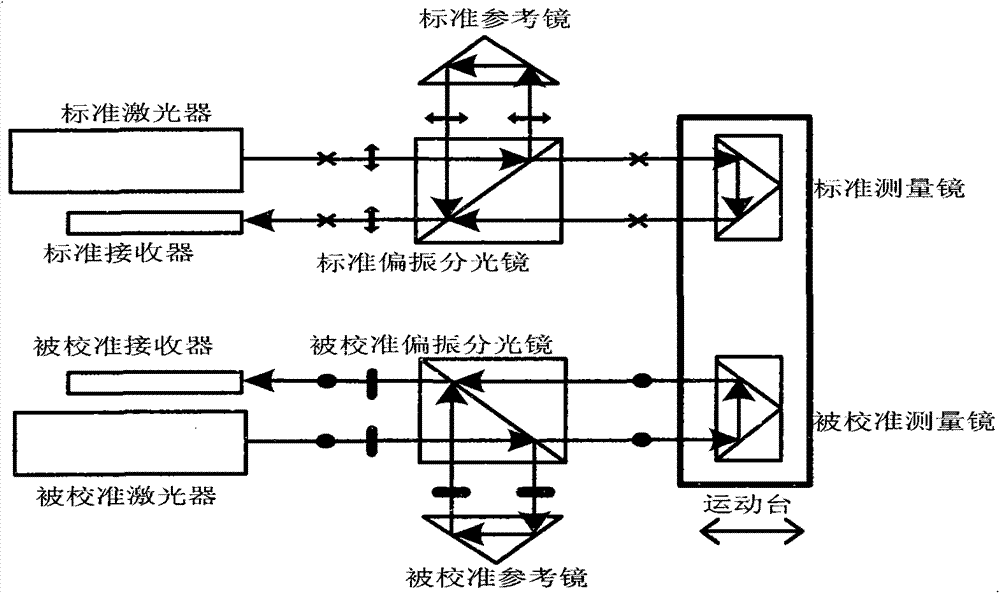

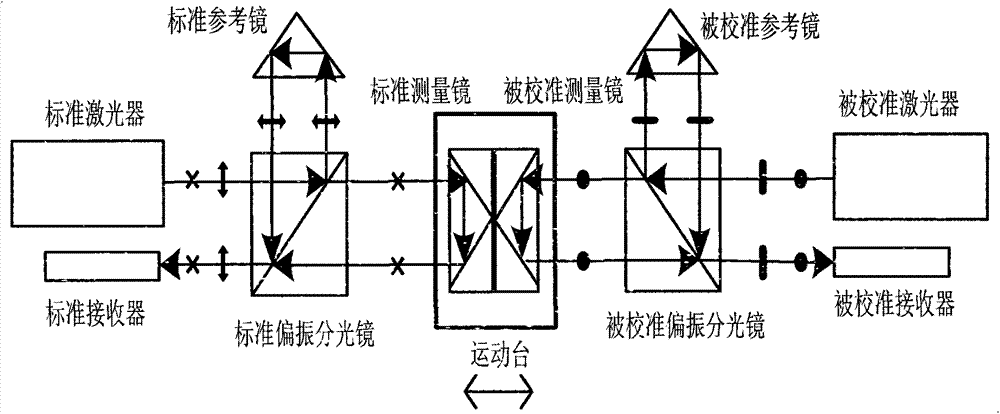

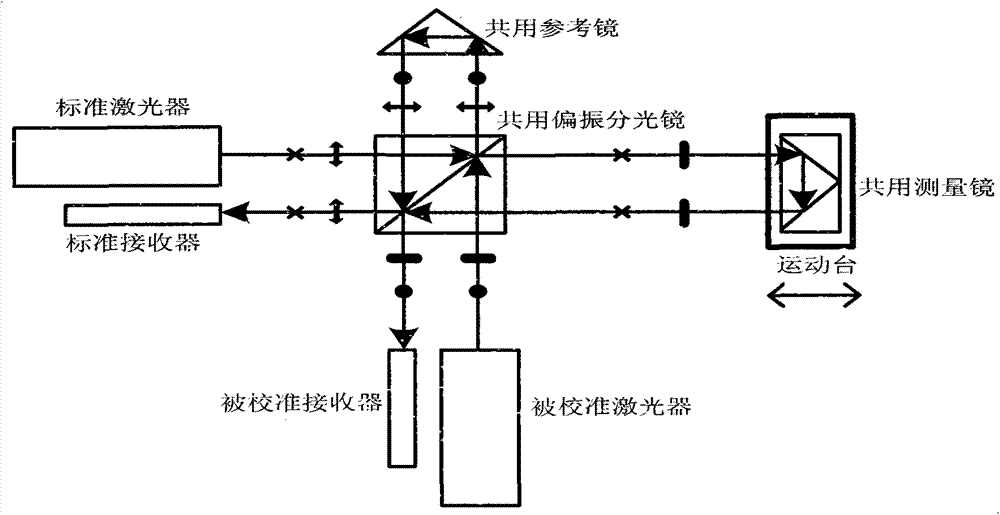

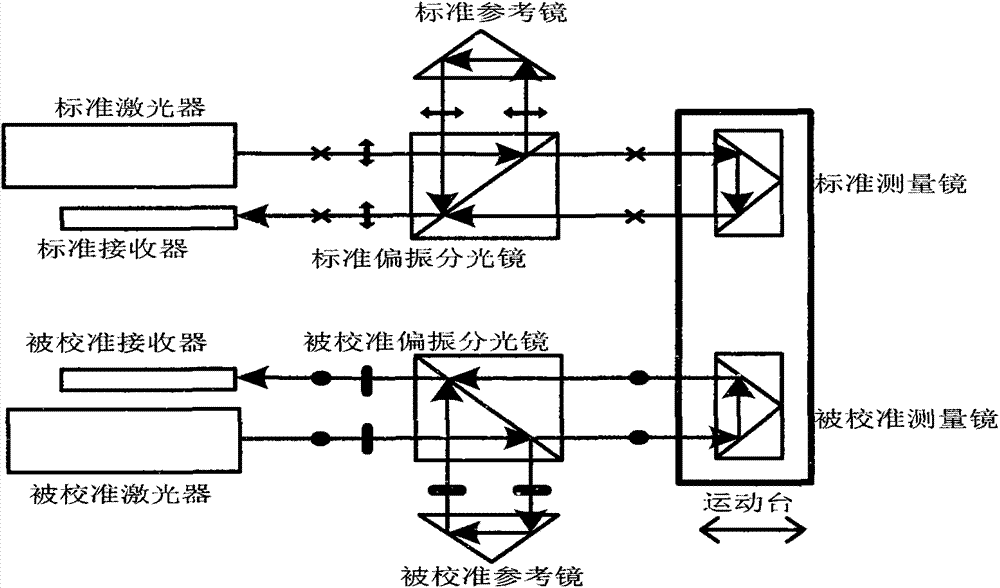

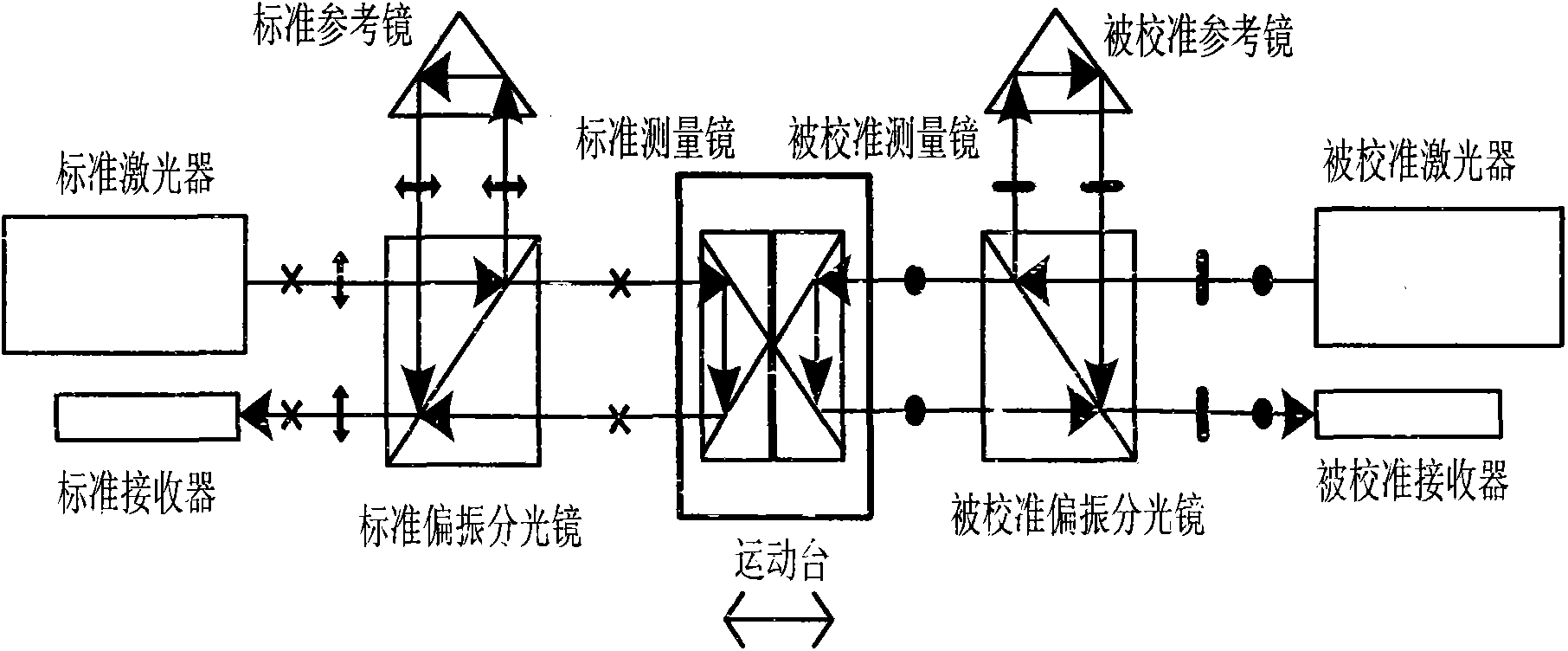

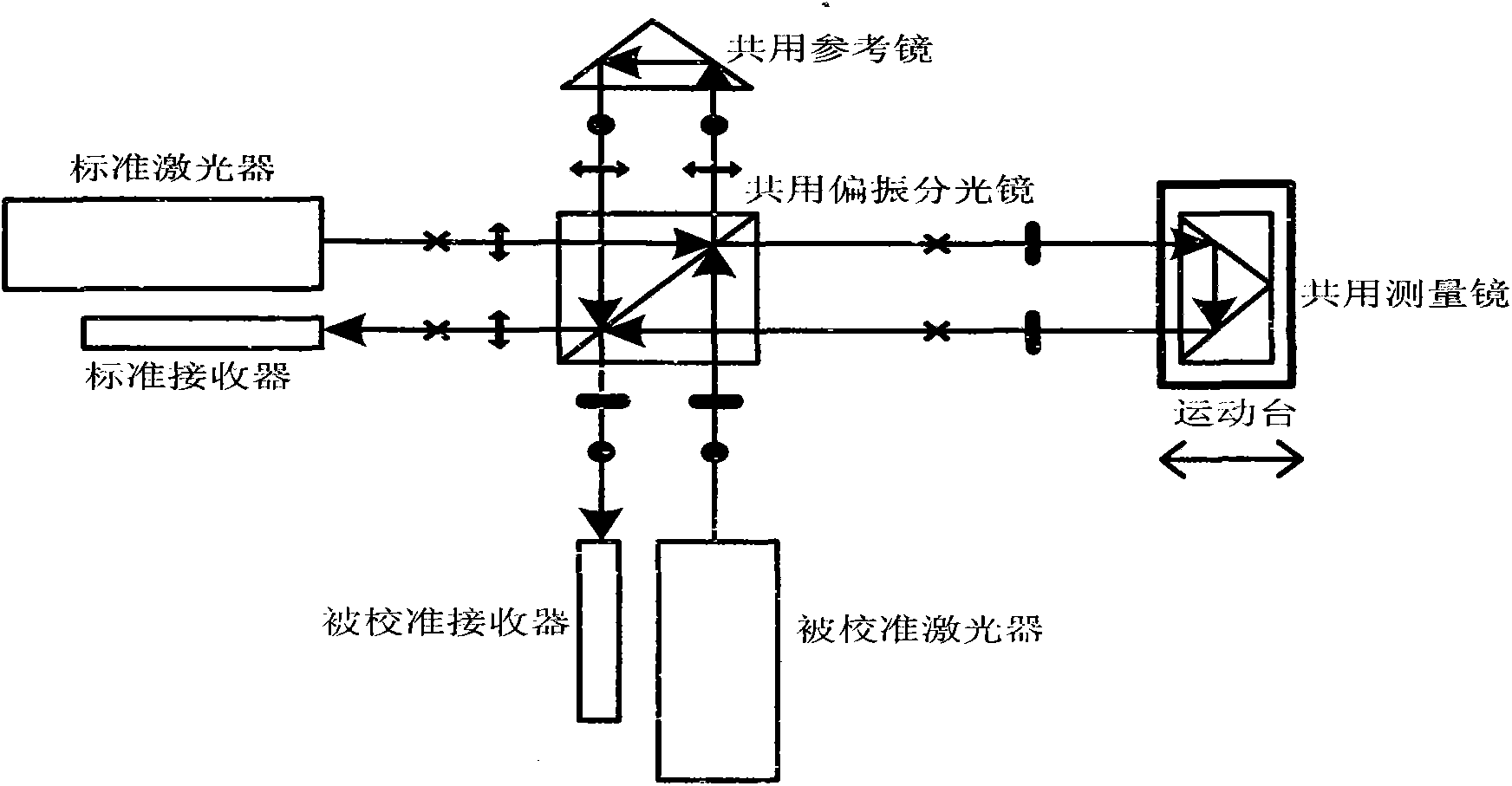

The invention discloses a morphology compensation type double-optical-axis linear displacement laser interferometer calibration method and device, and belongs to the technical field of laser measurement. A calibrated laser interferometer measurement light beam is caused to pass through a middle through hole of a double-axis hollow laser interferoscope group and is arranged on the center position of two parallel standard measurement light beams in parallel; in a plane vertical to the two standard measurement light beams, the difference of the environment interference degree between the two standard measurement light beams and the calibrated laser interferometer measurement light beam is small in a line segment area formed by the two standard measurement light beams in the plane projection points; the air refractive index average value of the two standard measurement light beams is approximate to the air refractive index value of the calibrated laser interferometer measurement light beam; a measurement error caused by the surface morphology of a target reflecting mirror reflecting surface is compensated into a linear displacement measurement result to guarantee the accuracy of a linear displacement measurement value.

Owner:HARBIN INST OF TECH

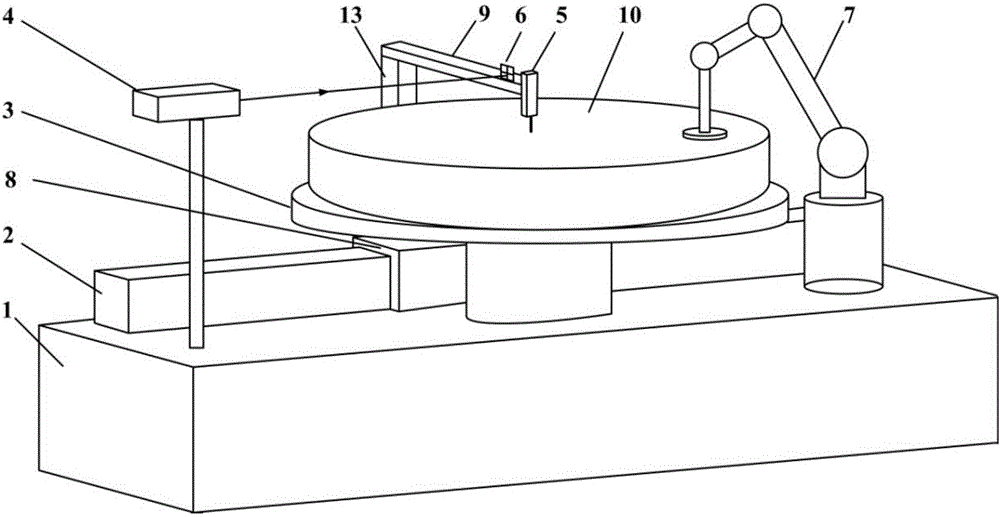

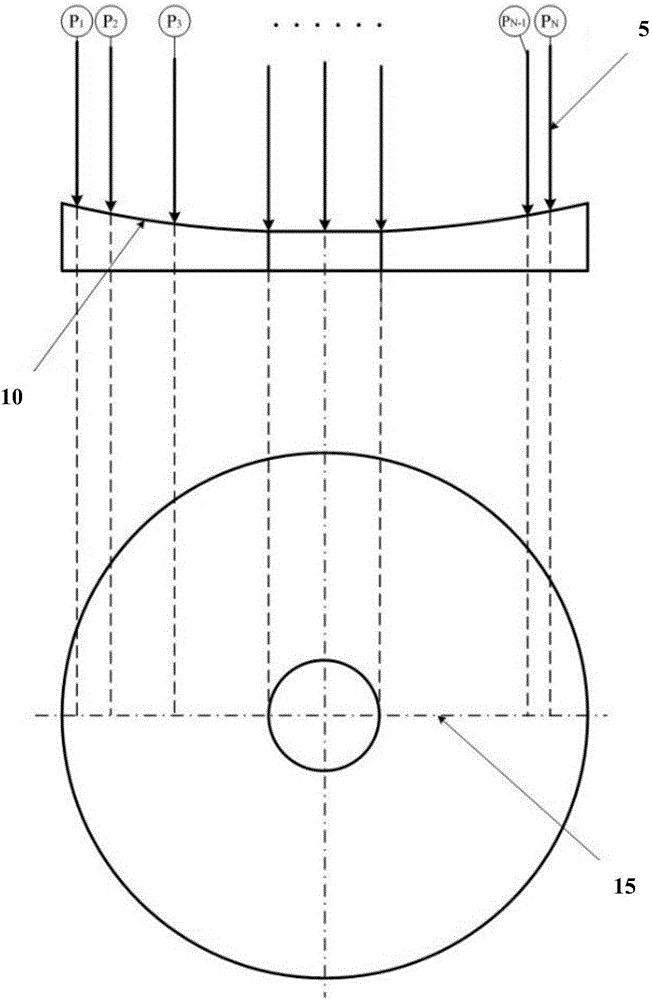

Method and device for measuring free-form surface based on reference plane comparative measurement

ActiveCN110057337AImproved scan detection accuracyAbbe's error is smallUsing optical meansFree formSurface level

The invention discloses a method and a device for measuring a free-form surface based on reference plane comparative measurement, and belongs to the technical field of optical precision detection. Themethod uses the high-precision plane flat crystal as a reference plane of an X-Y surface, utilizes the high-precision height measurement sensor and the free-form surface measurement sensor which arecoaxially installed to detect the high-precision plane flat crystal and the surface height information of the measured free-form surface respectively, utilizes the high-precision height measurement sensor to acquire the surface height information of the high-precision plane flat crystal to monitor and compensate the straightness error of an X-direction air-floatation guide rail and a Y-direction air-floatation guide rail, performs dimension reduction error separation on the surface appearance of the free-form surface, and realizes the nanometer precision detection of the appearance of the free-form surface. The method and the device for measuring the free-form surface based on reference plane comparative measurement can realize the detection of the free-form surface, provide high-precisionthree-dimensional linear positioning and scanning measurement, inhibit the influence of the straightness error of the movement of the X-direction guide rail and the Y-direction guide rail on the measurement of the free-form surface, reduce the influence of the Abbe error of the Z axis on the measurement, and realize the large-range and nanometer precision measurement of the free-form surface.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

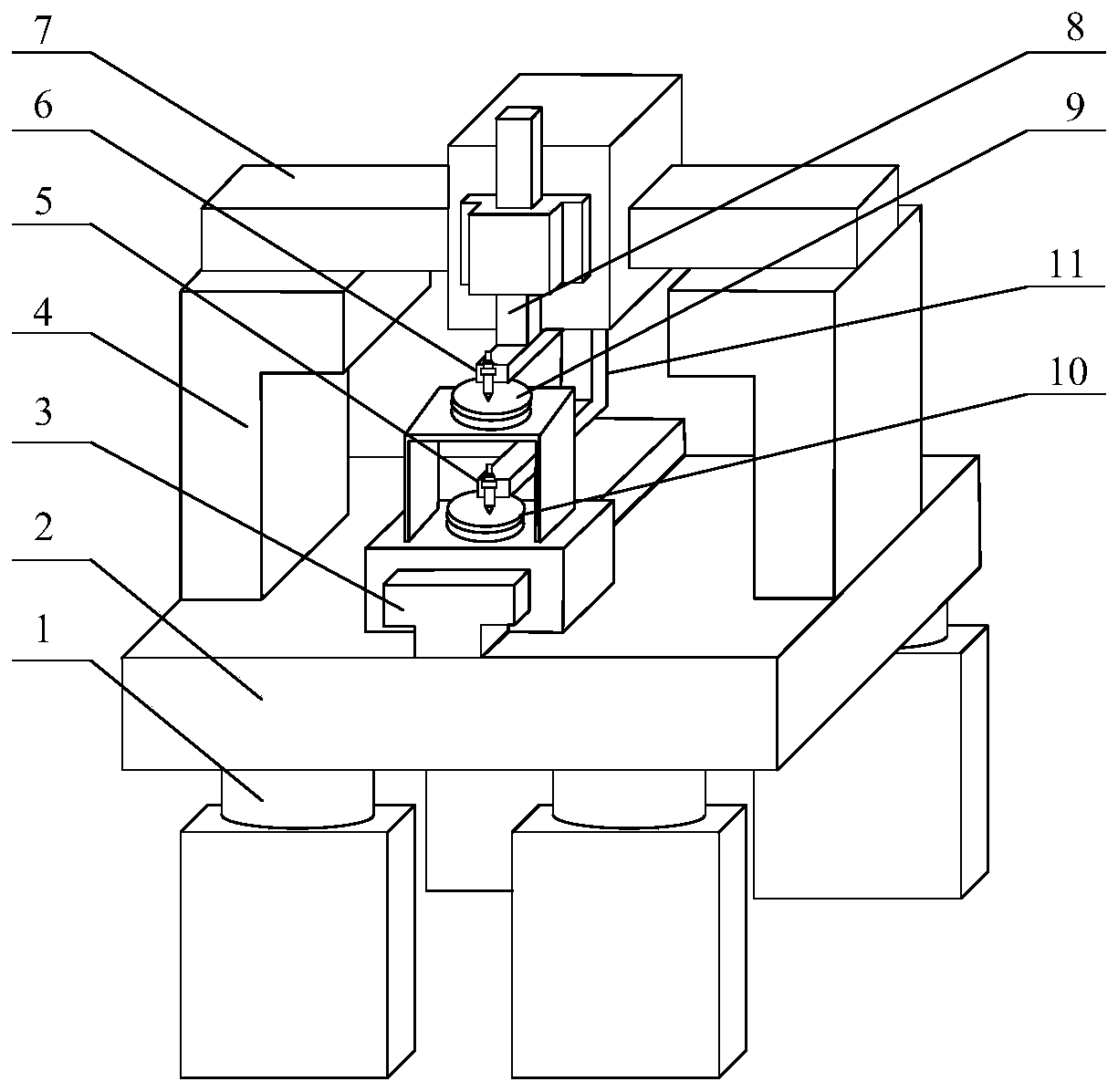

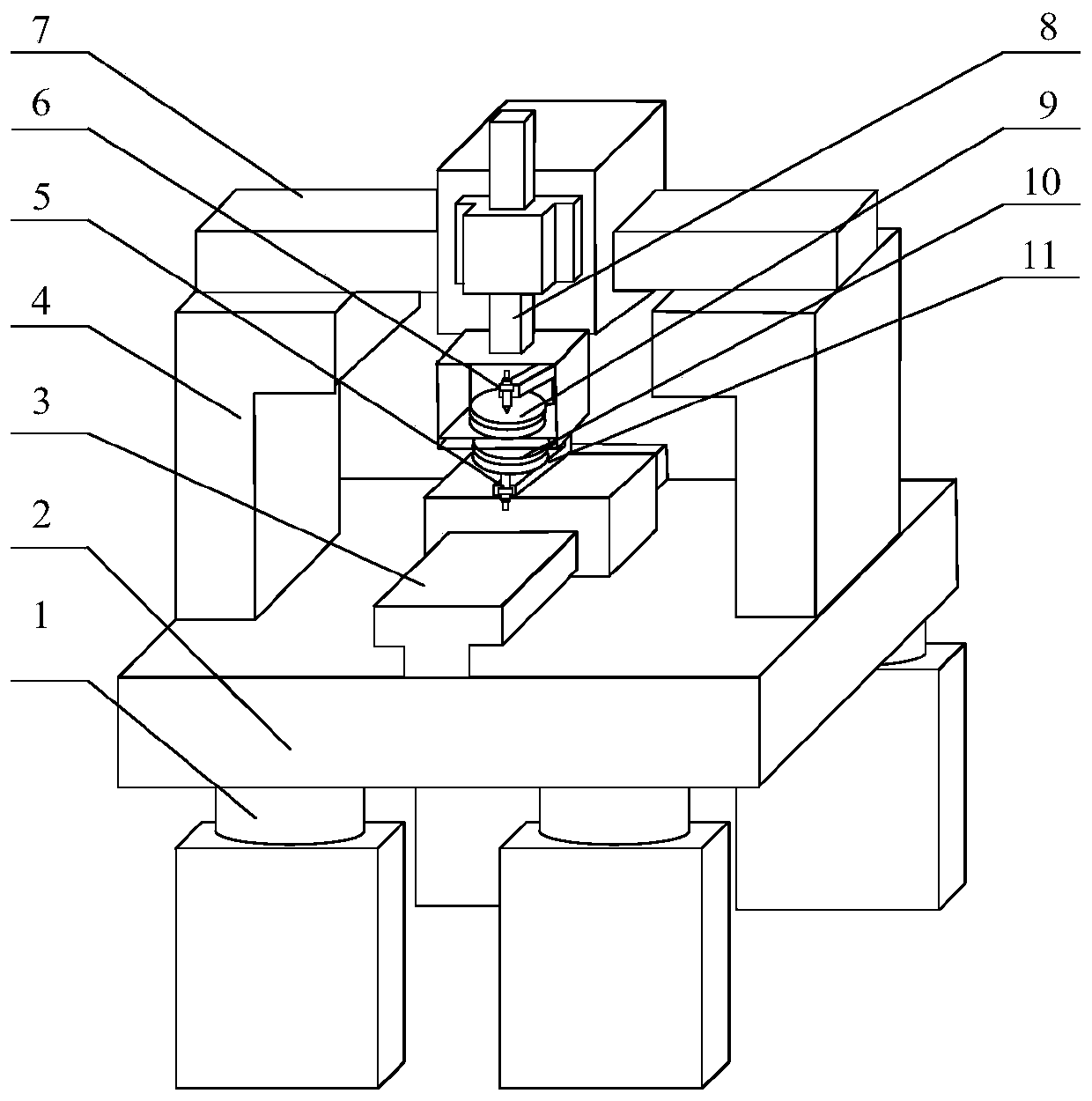

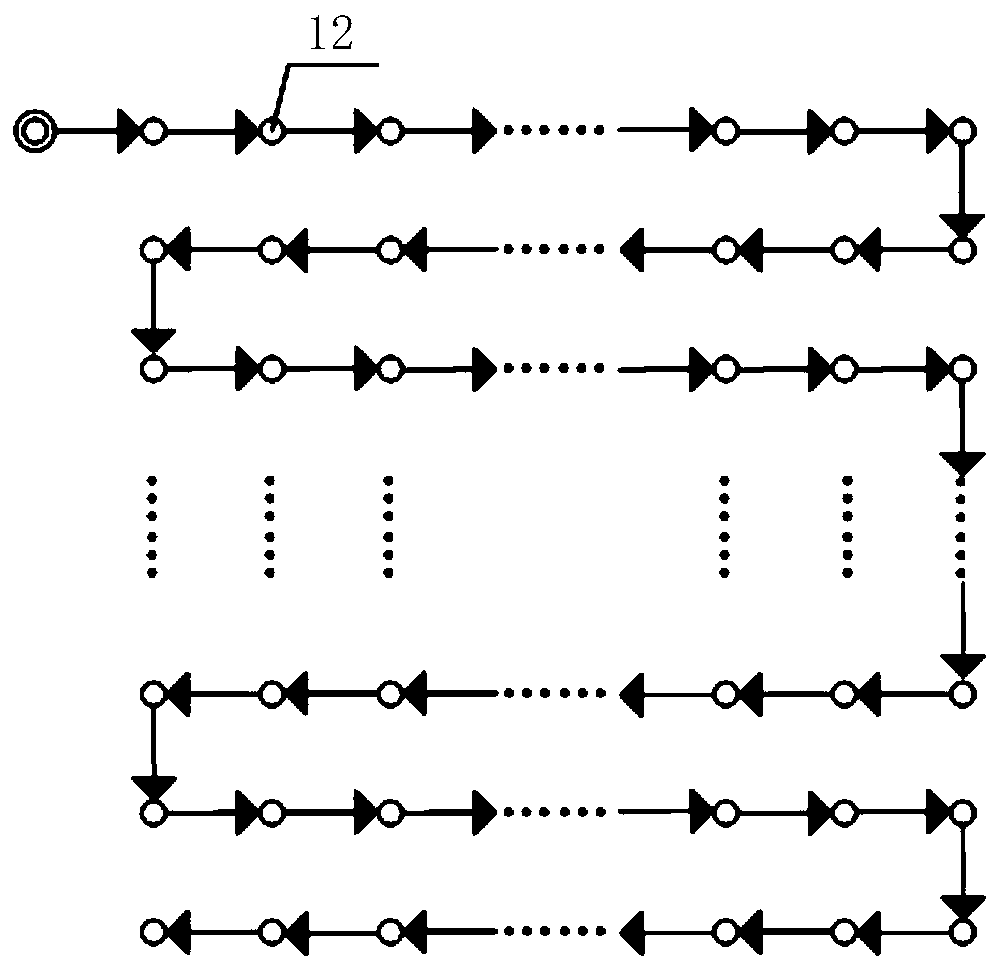

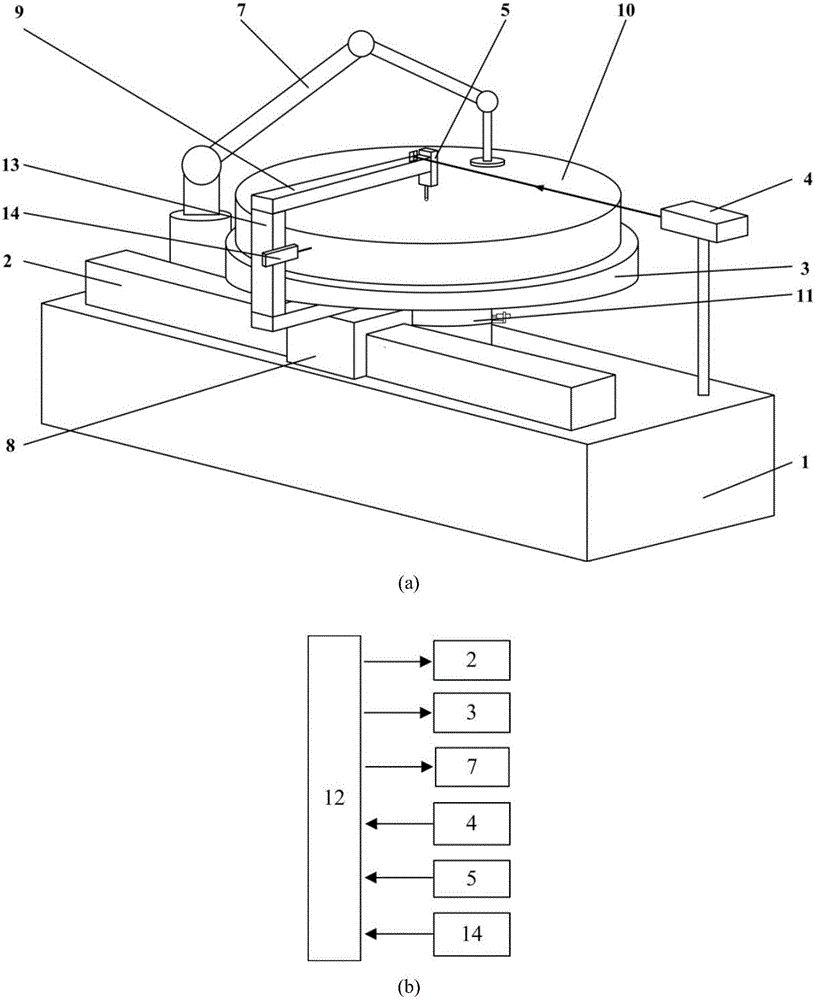

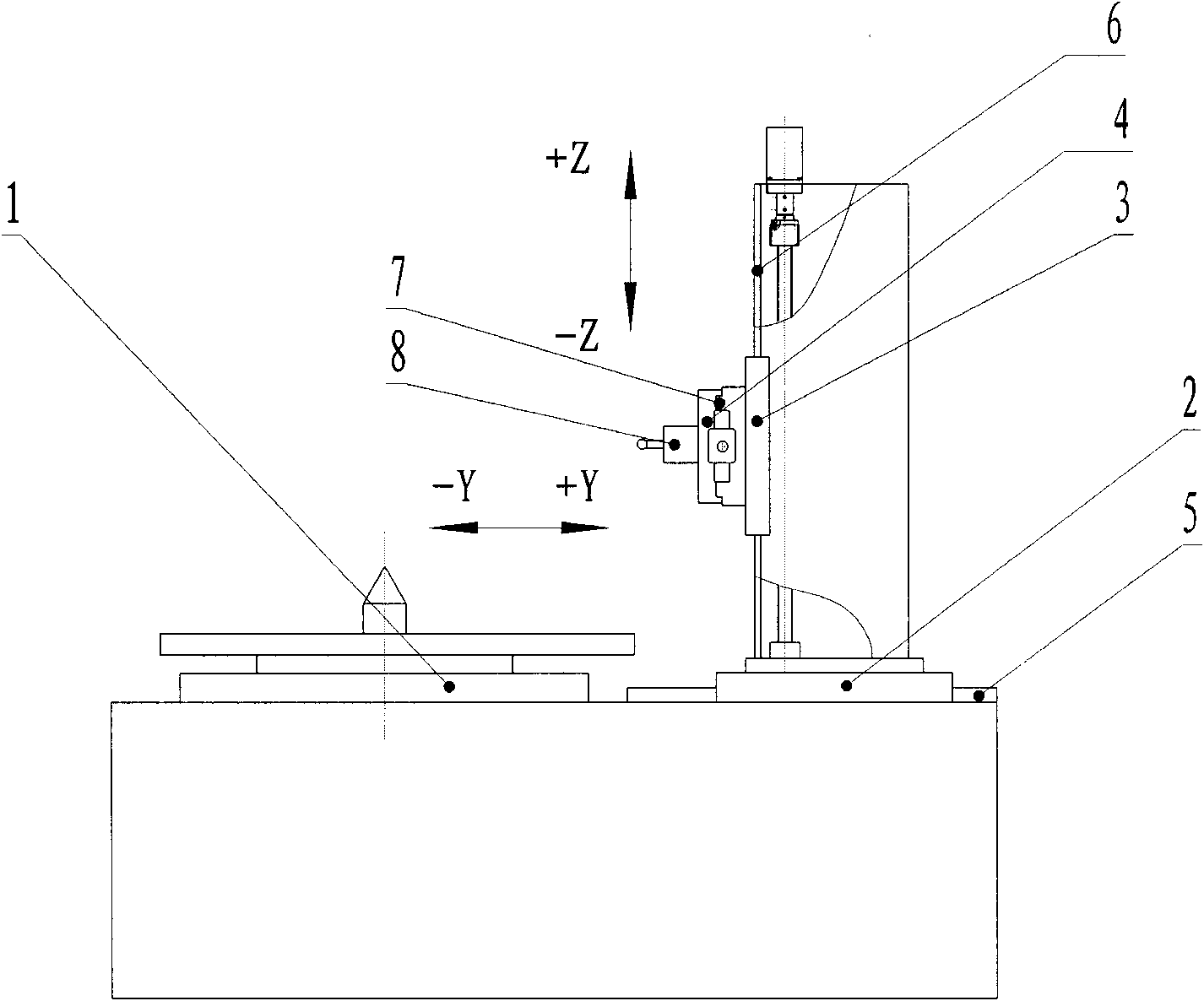

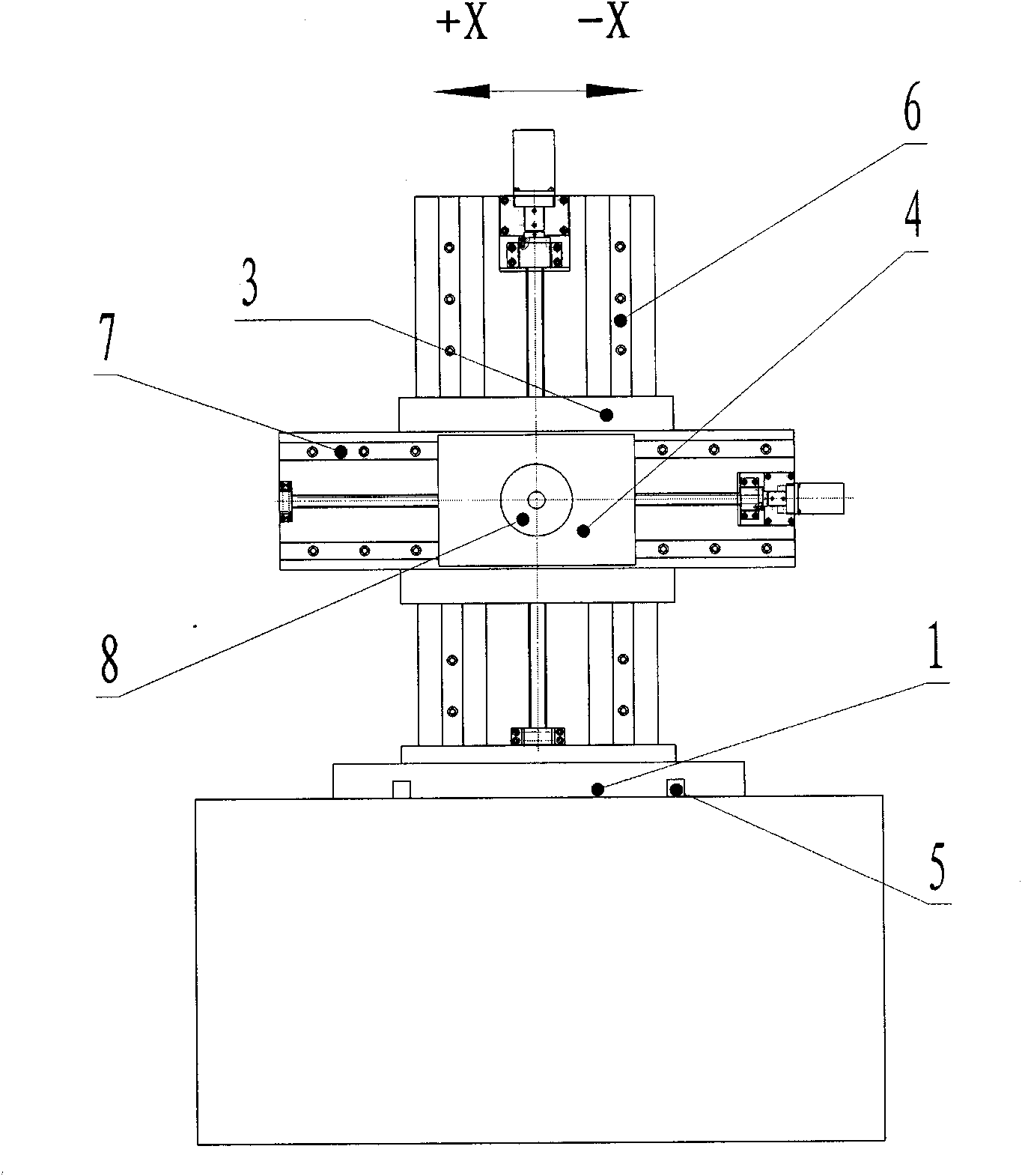

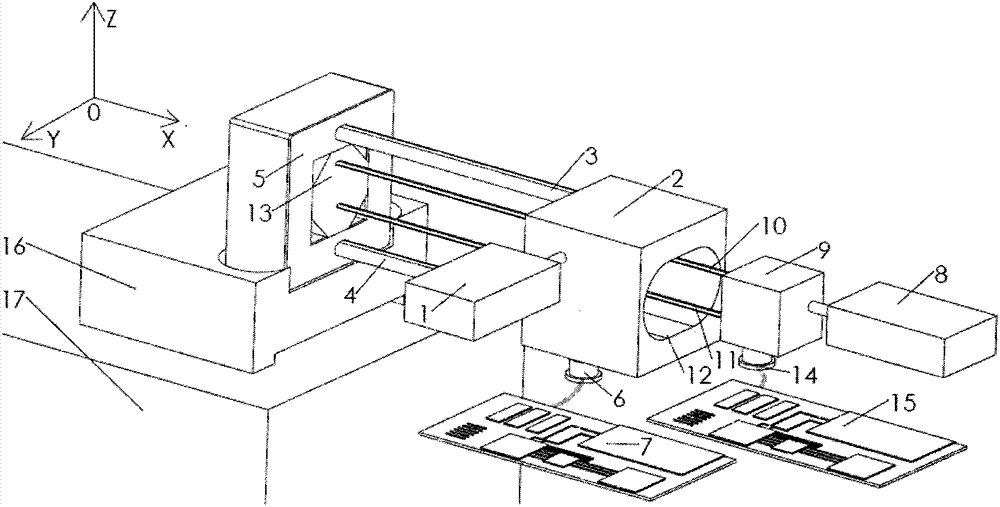

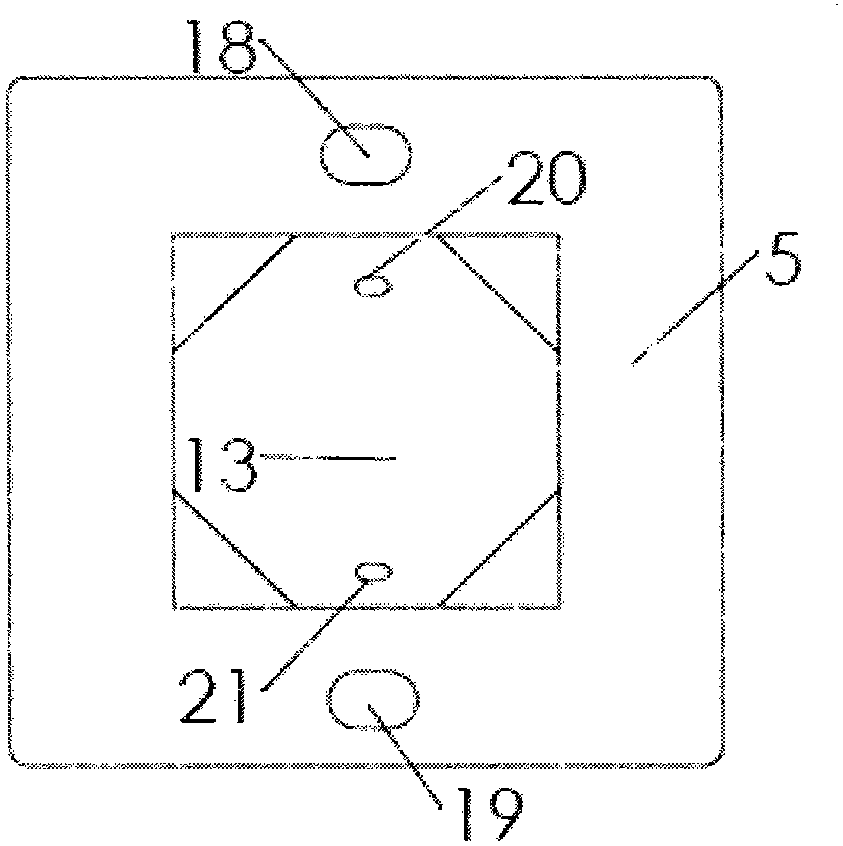

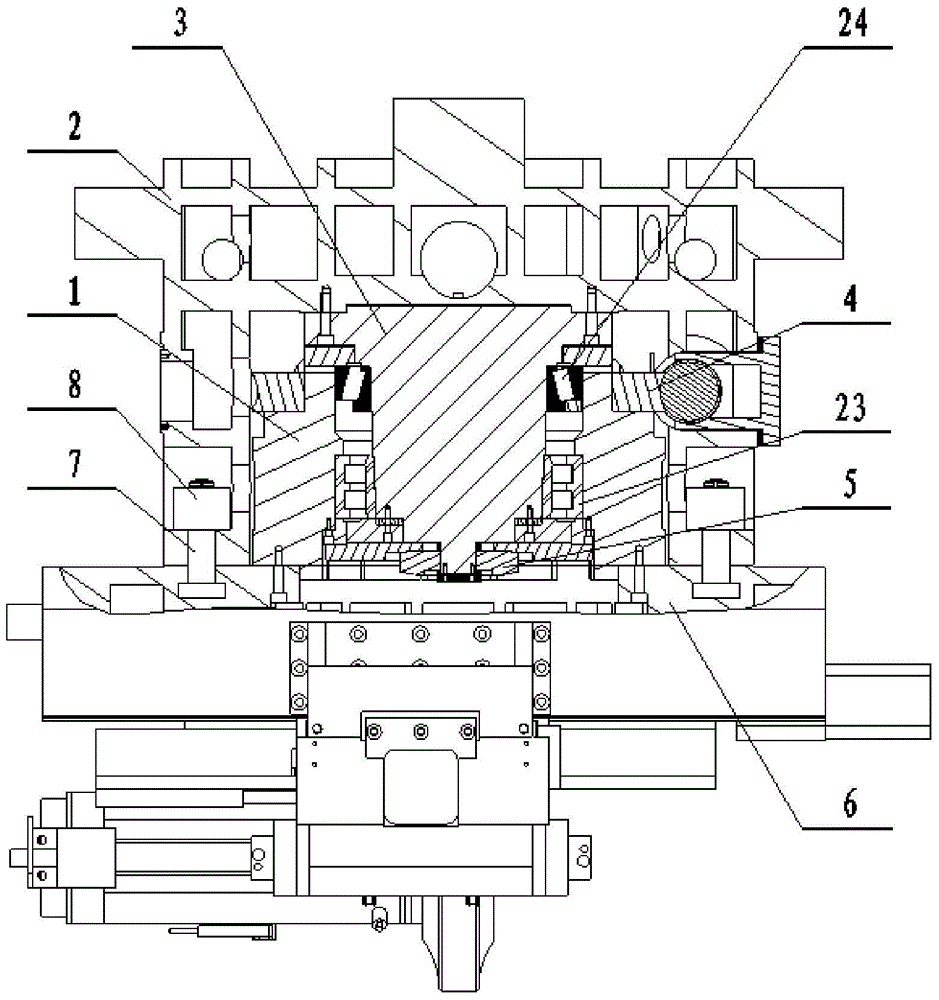

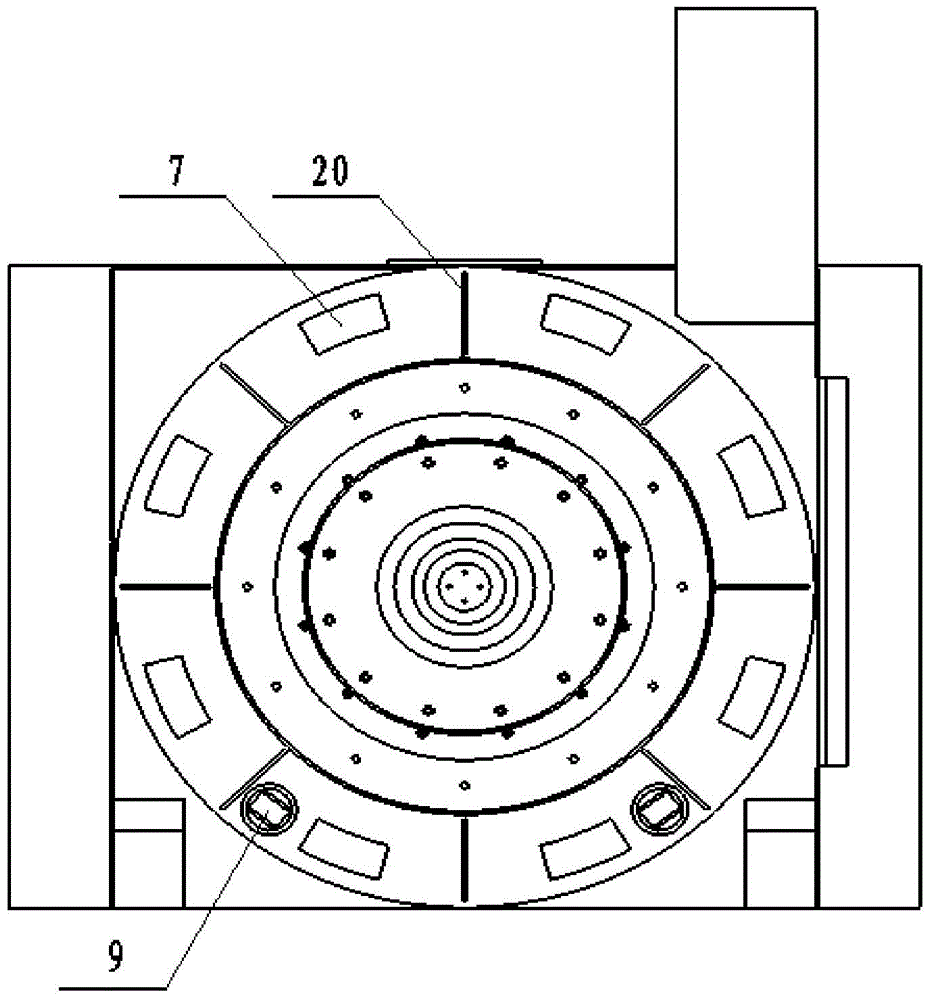

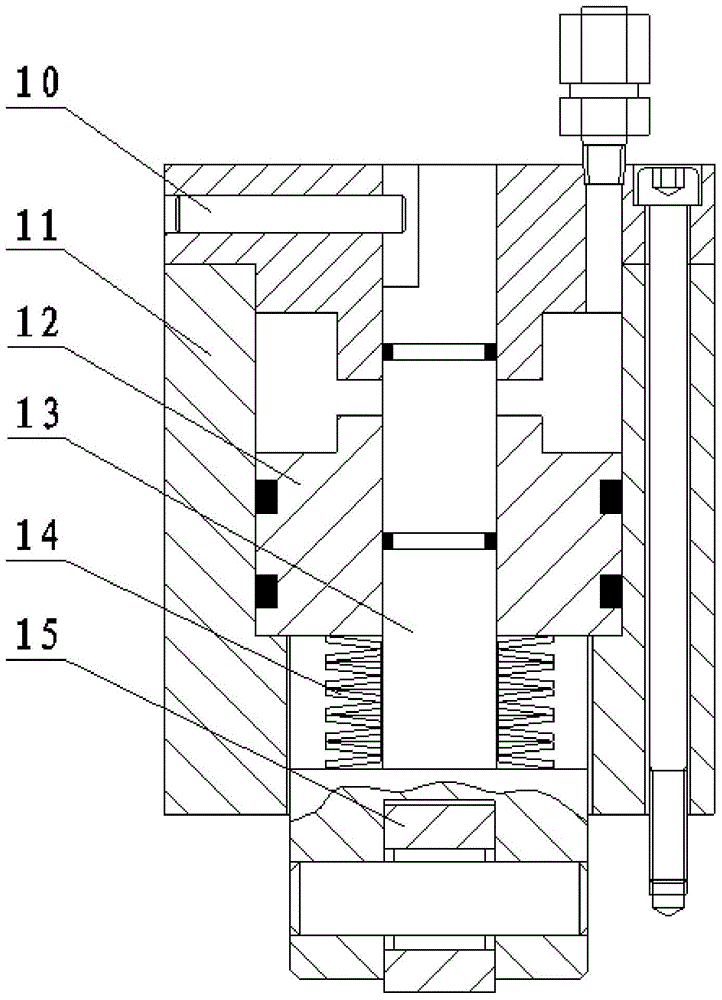

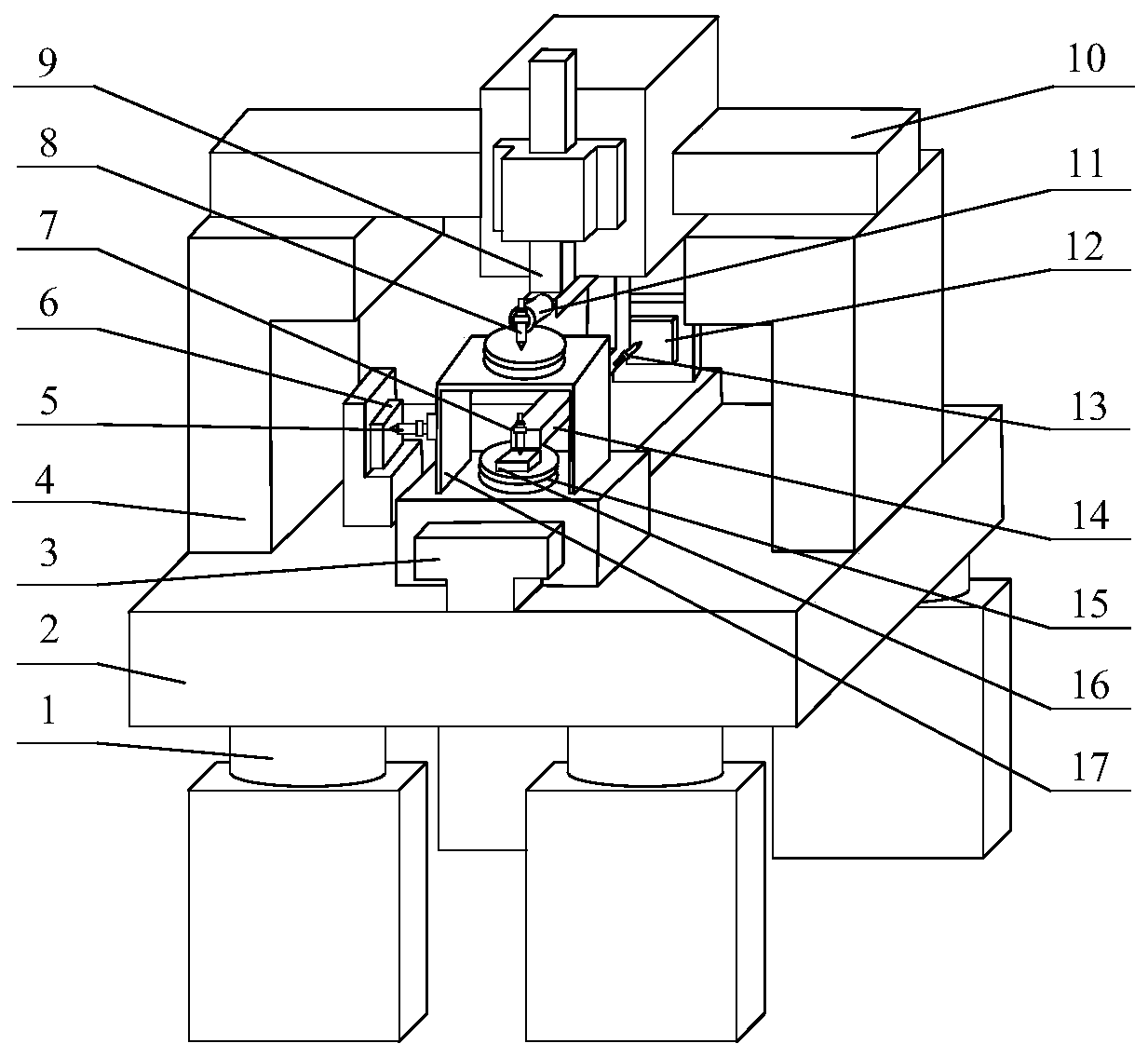

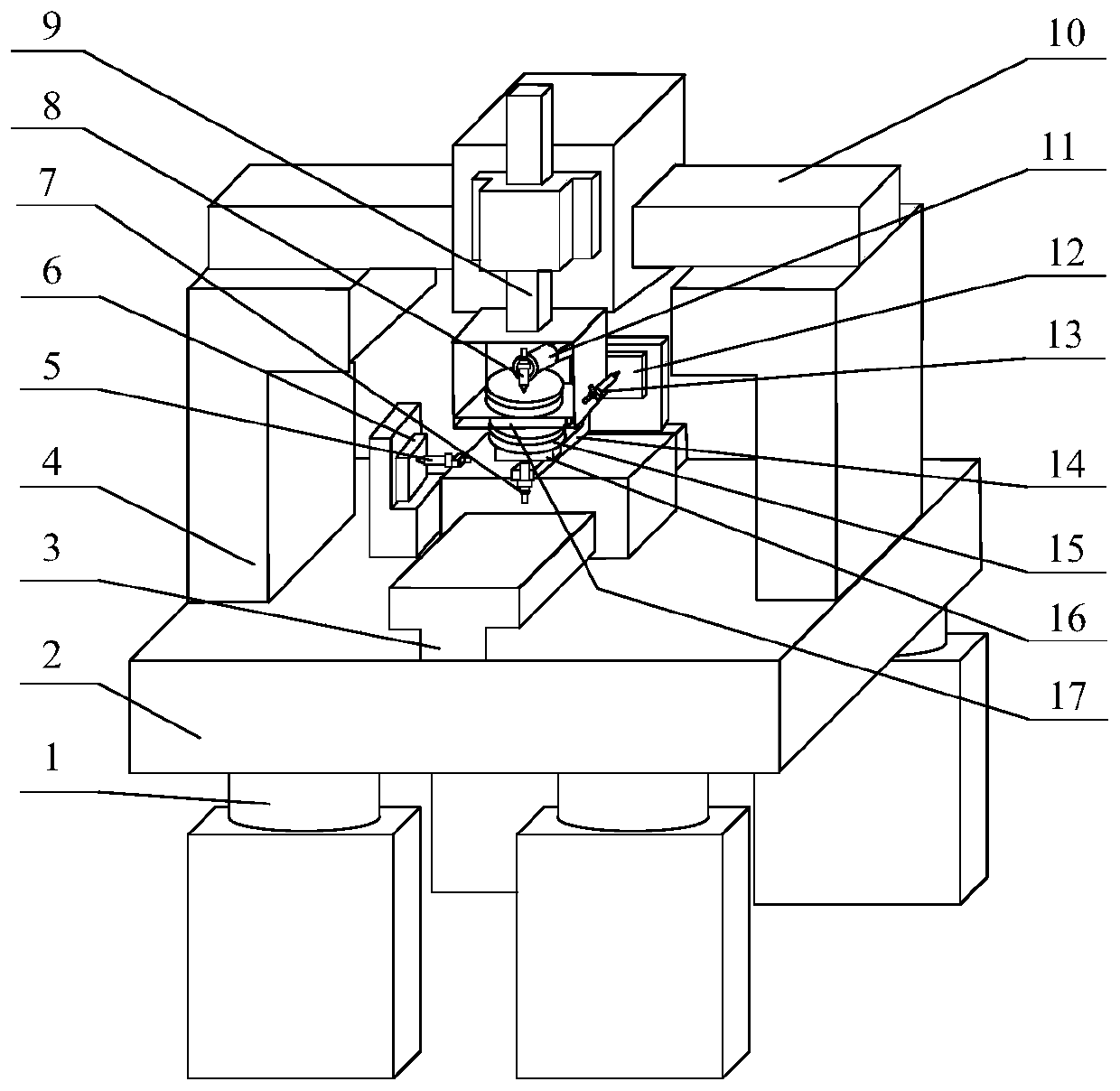

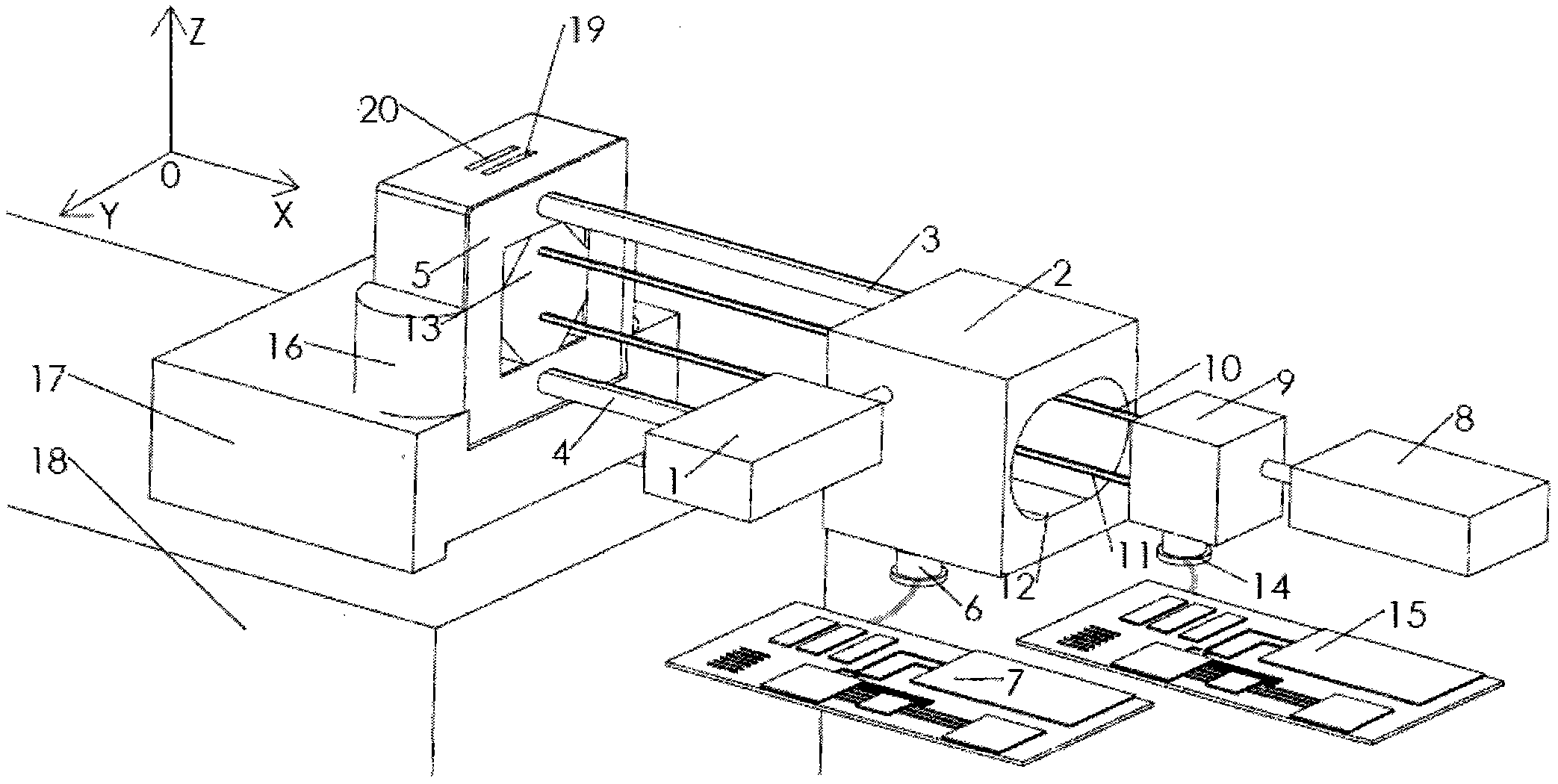

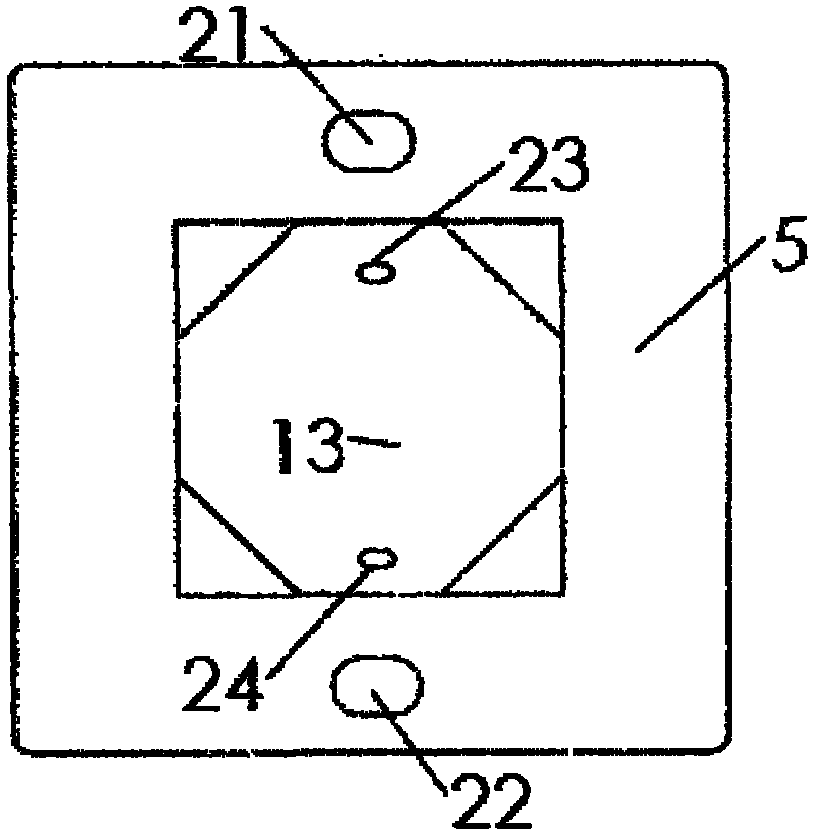

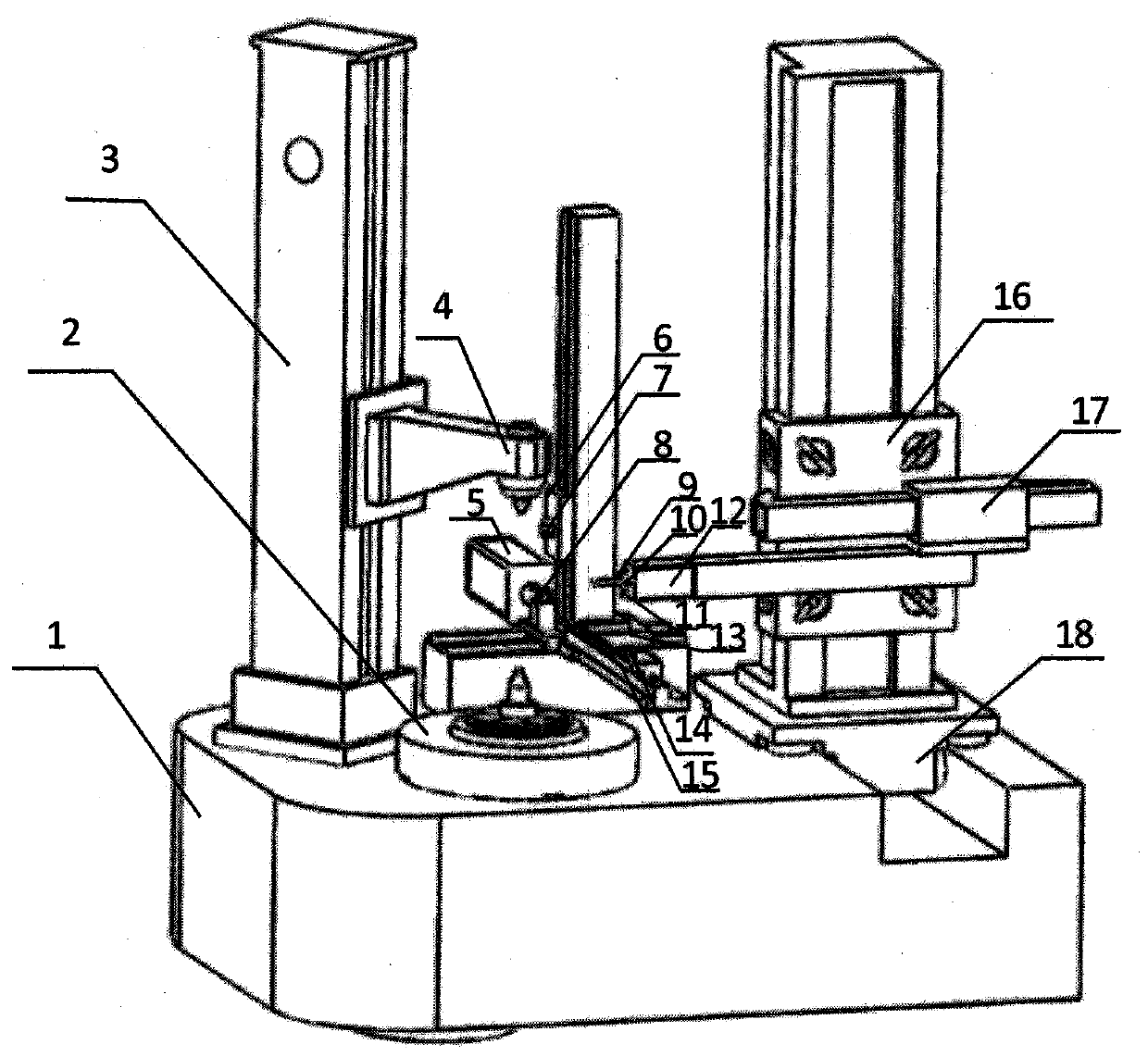

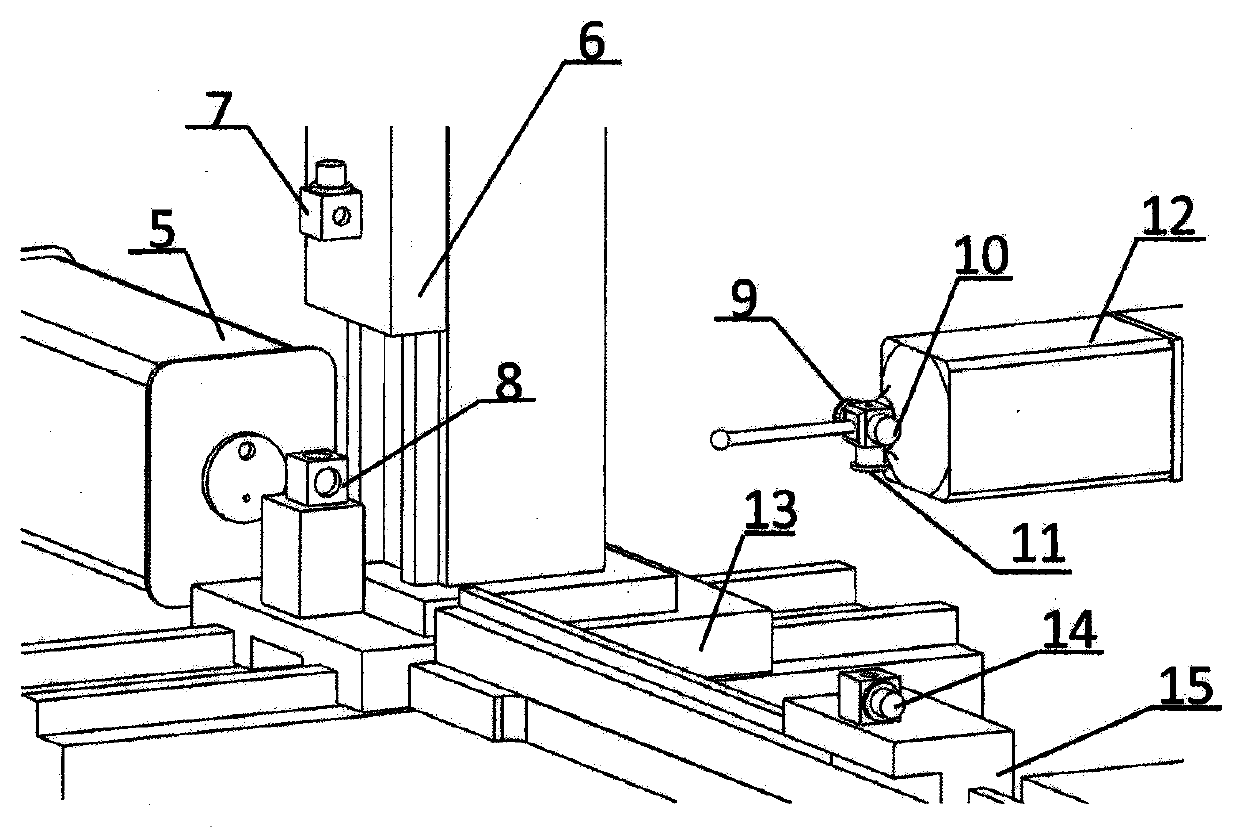

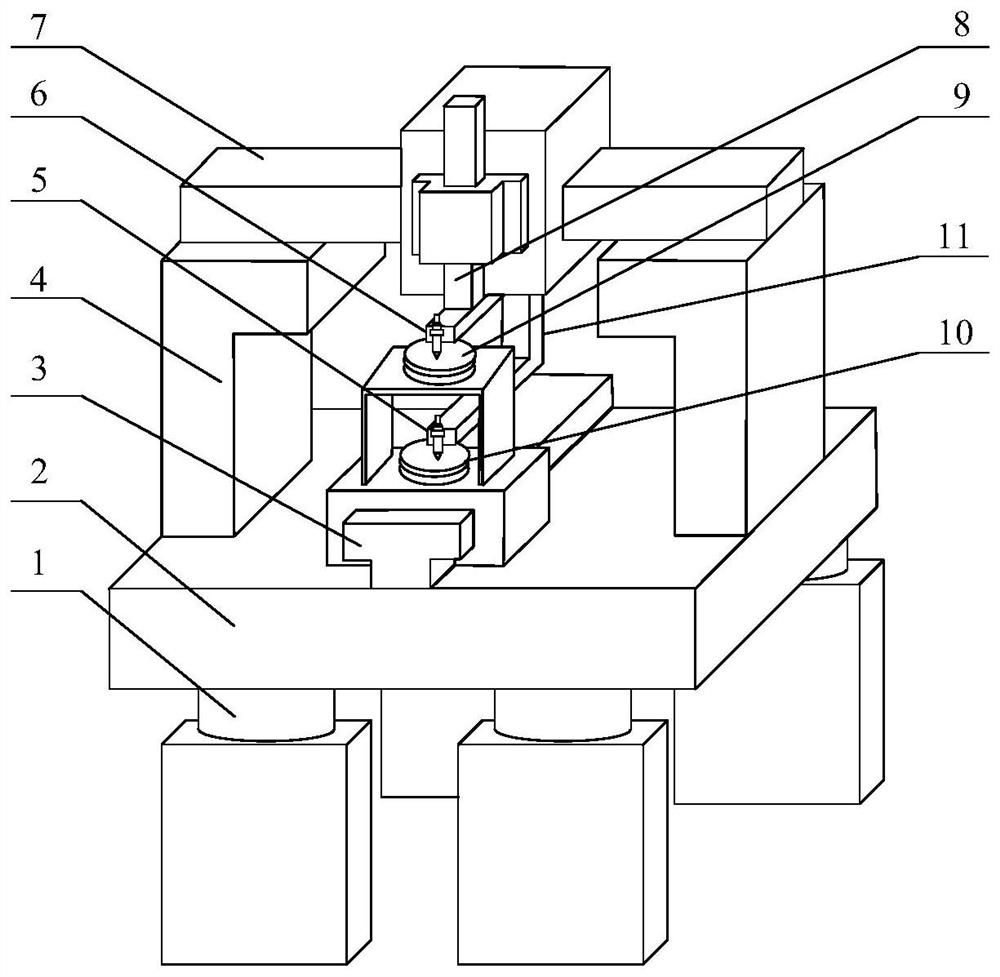

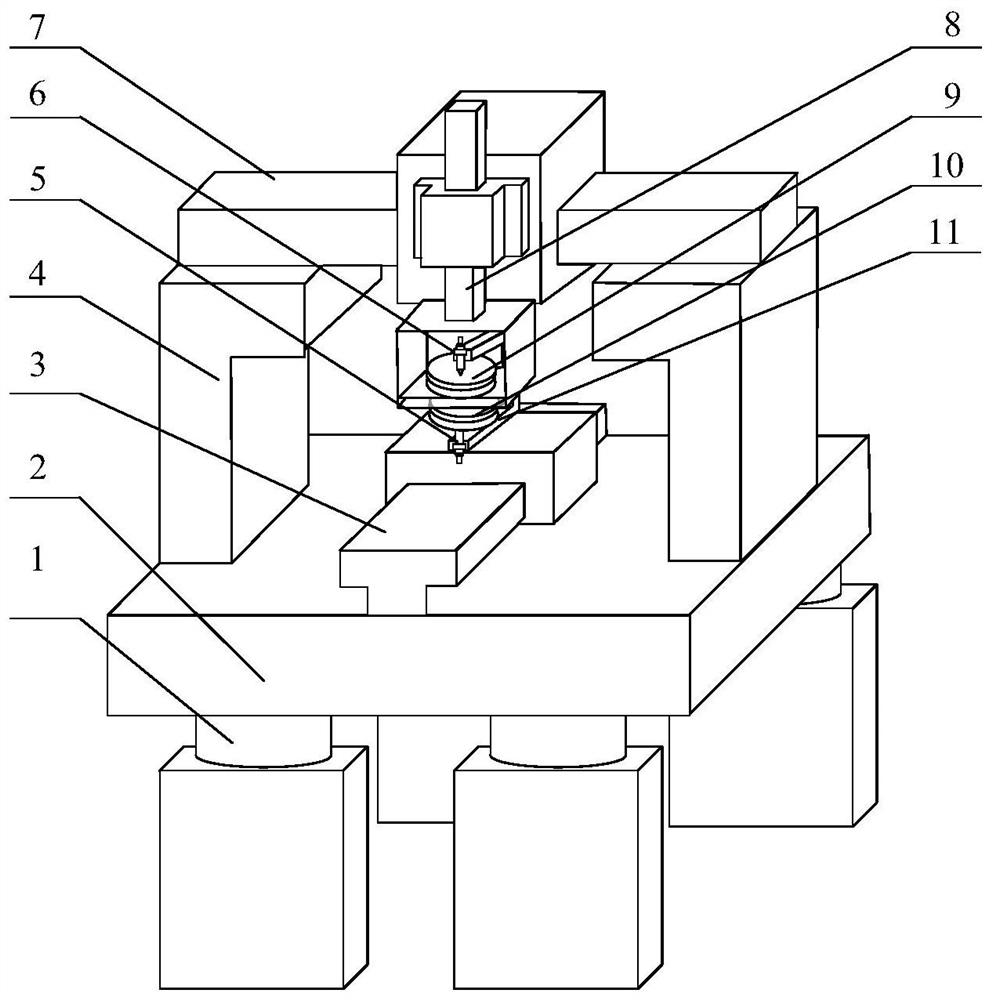

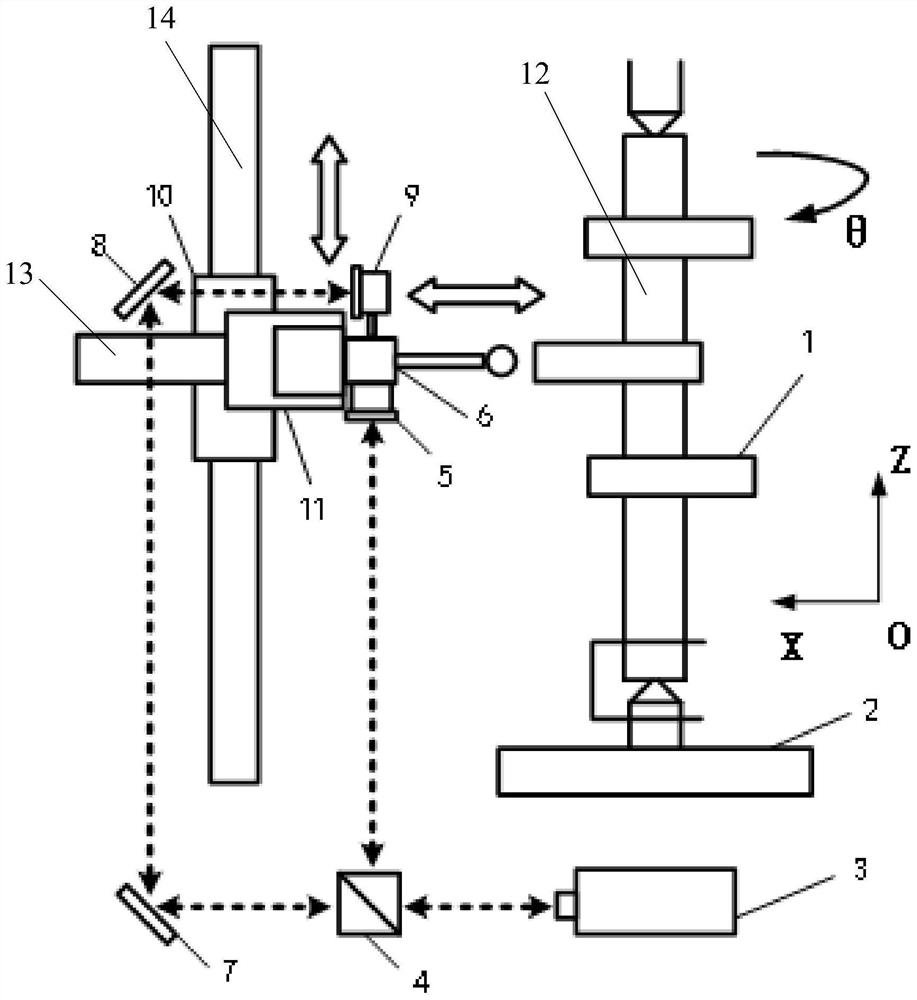

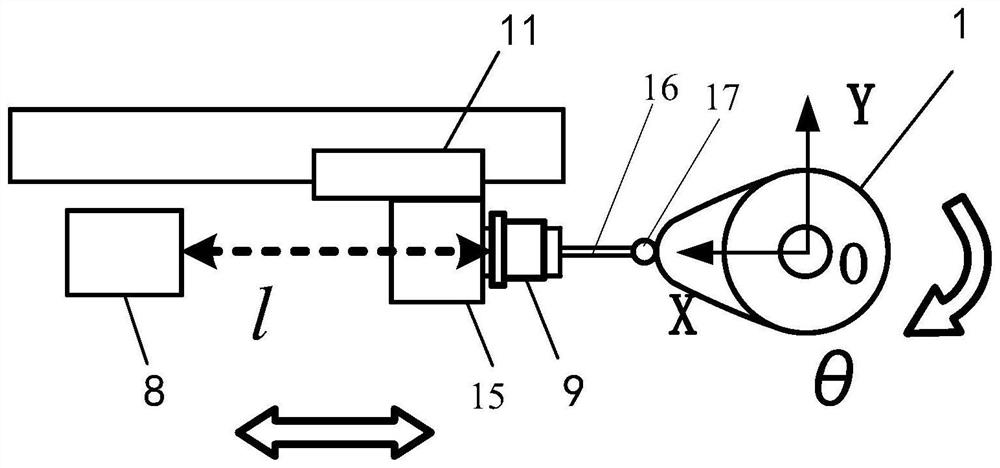

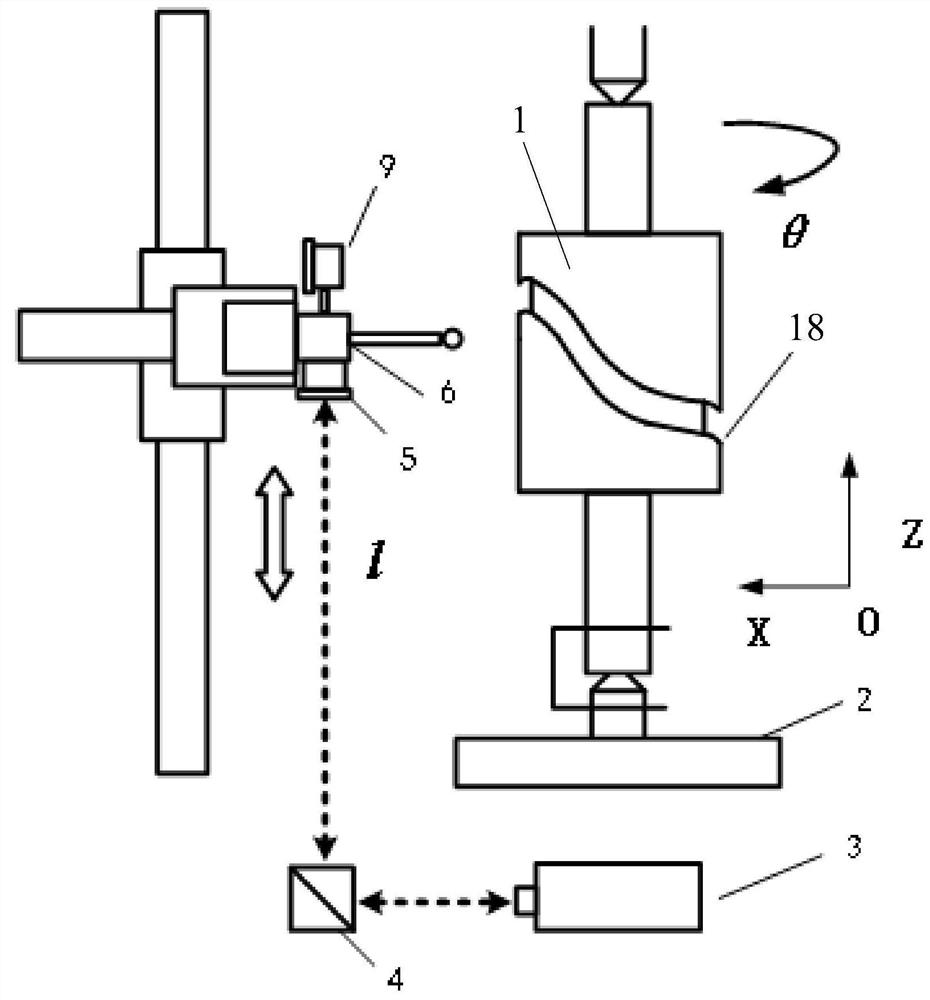

Machining and detecting device and method for large-aperture aspheric contour

ActiveCN106514456AImprove machining efficiency and precisionAbbe's error is smallGrinding feed controlLensLarge apertureEngineering

The invention belongs to the technical field of optical precision test and precision machining, and relates to a machining and detecting device and method for a large-aperture aspheric surface, which can be used for detecting and machining the surface shape of a large-sized high-precision aspheric element in a precise optical system. According to the invention, based on technologies such as a straight-line / rotating benchmark technology, the high-precision machining and detection of a large-sized aspheric element, which are based on a precise air-floatation rotation center and integrate machining and detecting functions, are realized by combining the functions of machining equipment and detecting equipment. According to the invention, a workpiece is polished repeatedly by a polishing joint arm according to set technological machining parameters, then contour parameters of a polished working surface are directly detected by a sensing measurement system on a measuring arm, and a computer measurement control system determines the machining path and polishing quantity of the polishing joint arm according to detected contour data, so that the machining efficiency and precision of the large-aperture aspheric element are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

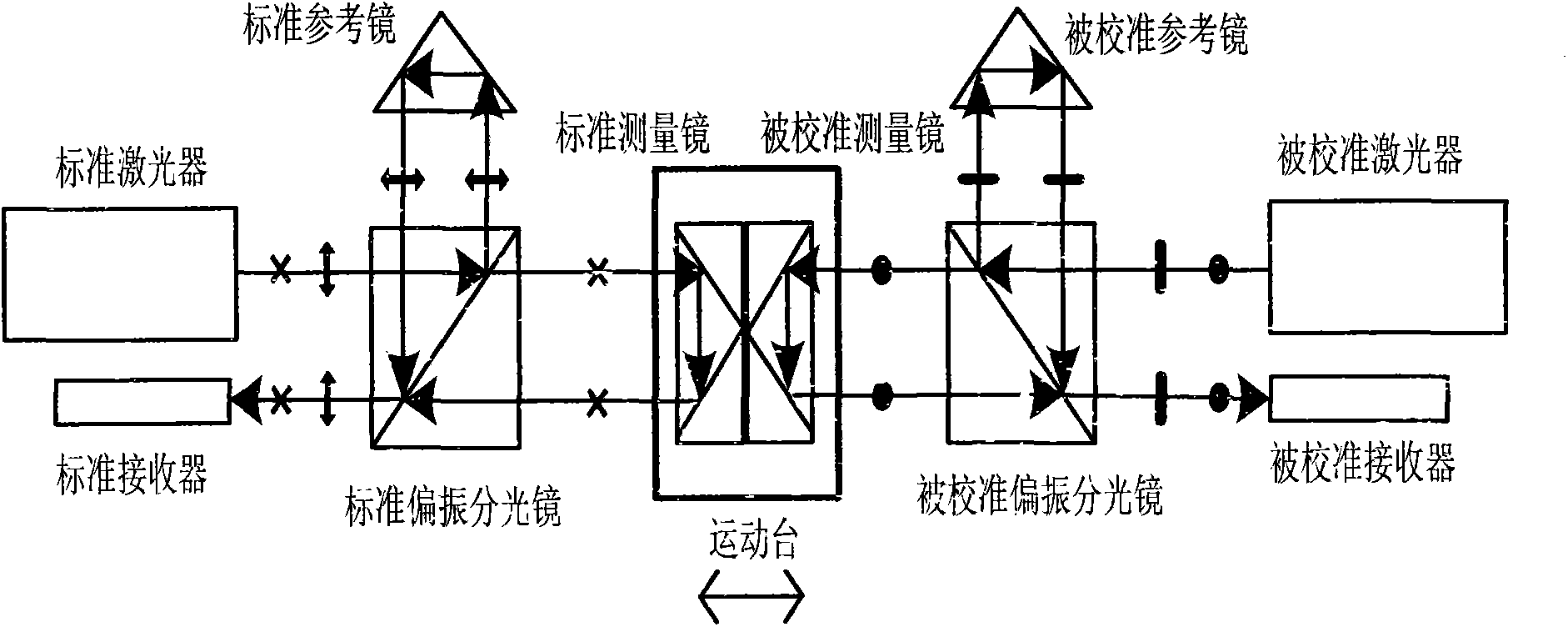

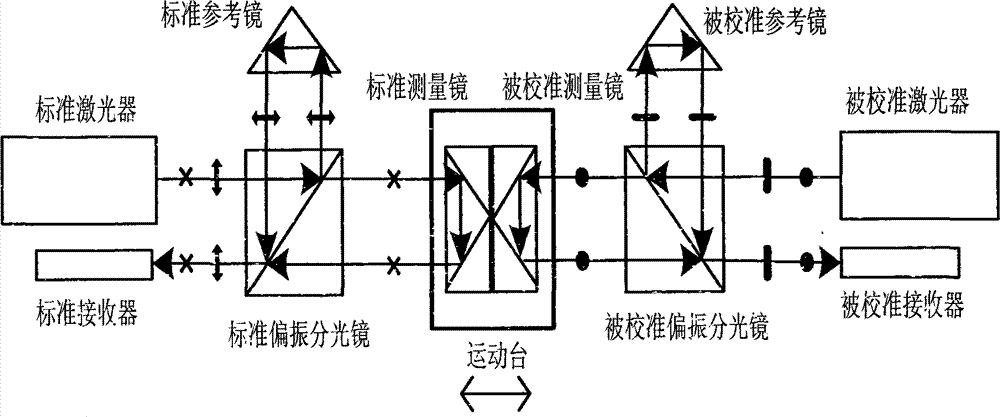

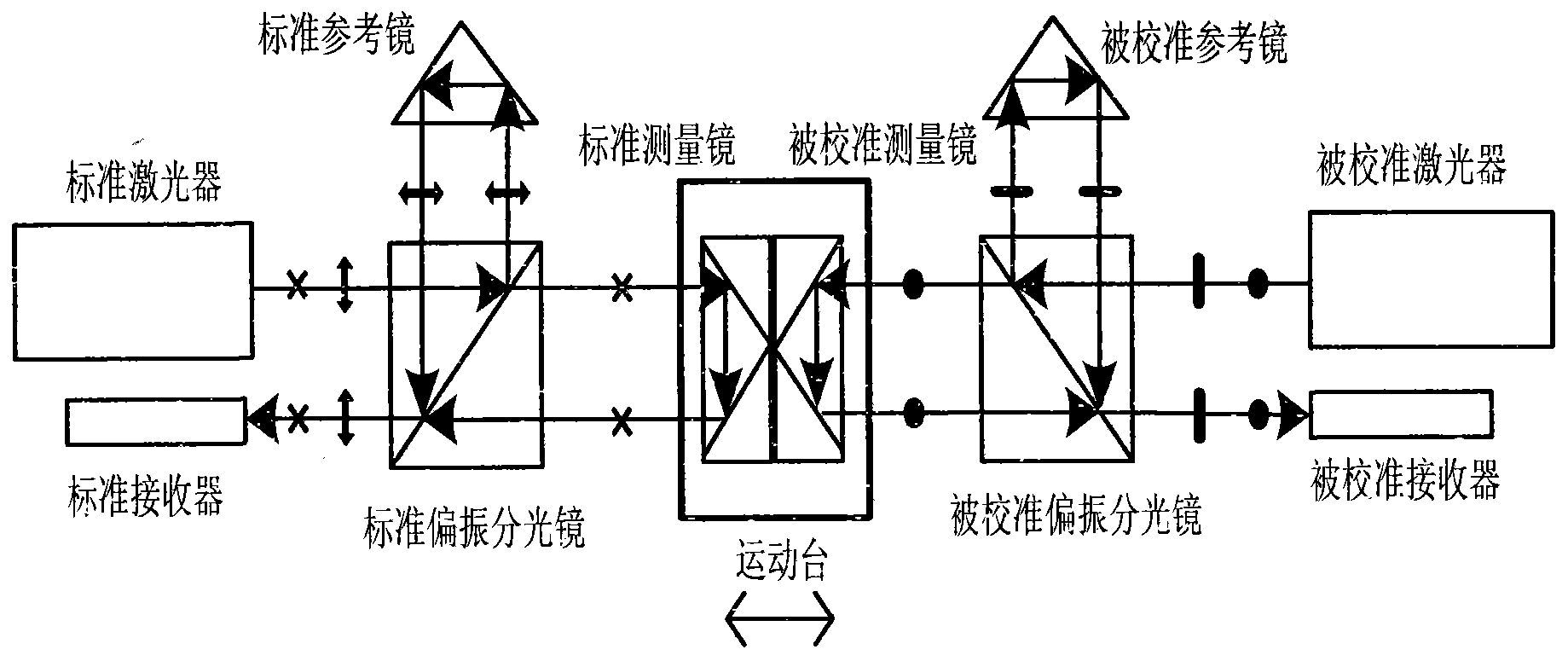

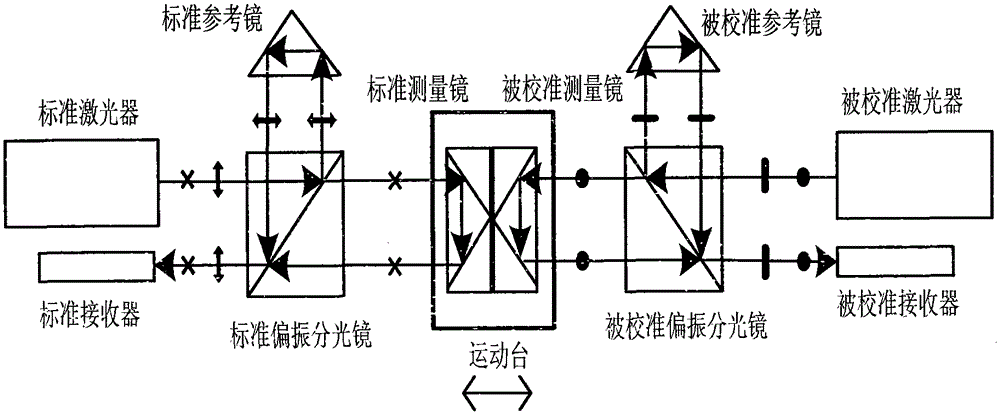

Morphology compensation type three-optical-axis linear displacement laser interferometer calibration method and device

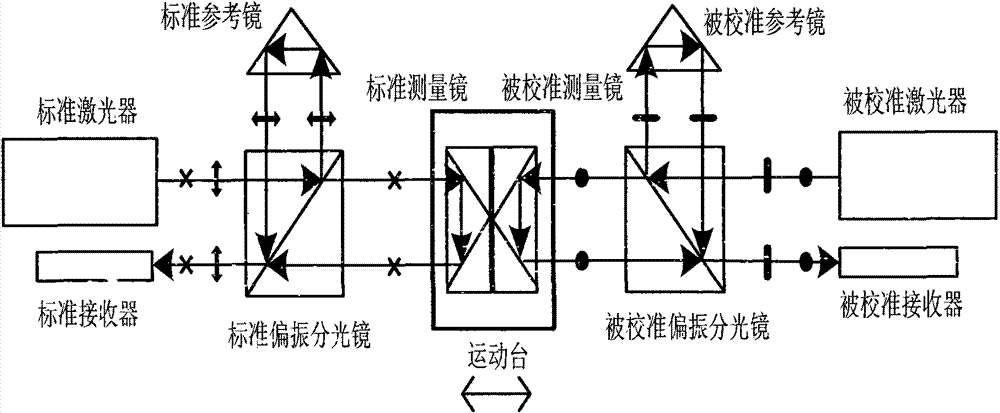

ActiveCN103528526AAbbe's error is smallGuaranteed accuracyUsing optical meansLinear displacementTriangular prism

The invention discloses a morphology compensation type three-optical-axis linear displacement laser interferometer calibration method and device, and belongs to the technical field of laser measurement. A calibrated laser interferometer measurement light beam is caused to pass through a middle through hole of a three-axis hollow laser interferoscope group and is arranged on the center position of three parallel standard measurement light beams distributed in a regular triangular prism side edge mode in parallel; in a plane vertical to the three standard measurement light beams, the difference of the environment interference degree between the three standard measurement light beams and the calibrated laser interferometer measurement light beam is small in an equilateral triangle area formed by the projection points of the three standard measurement light beams in the plane; the air refractive index average value of the three standard measurement light beams is approximate to the air refractive index value of the calibrated laser interferometer measurement light beam; a measurement error caused by the surface morphology of a target reflecting mirror reflecting surface is compensated into a linear displacement measurement result to guarantee the accuracy of a linear displacement measurement value.

Owner:HARBIN INST OF TECH

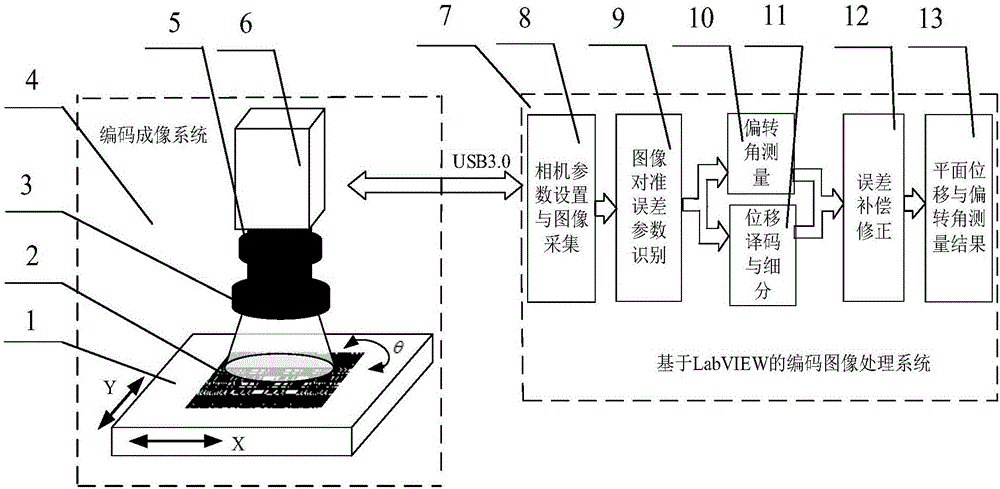

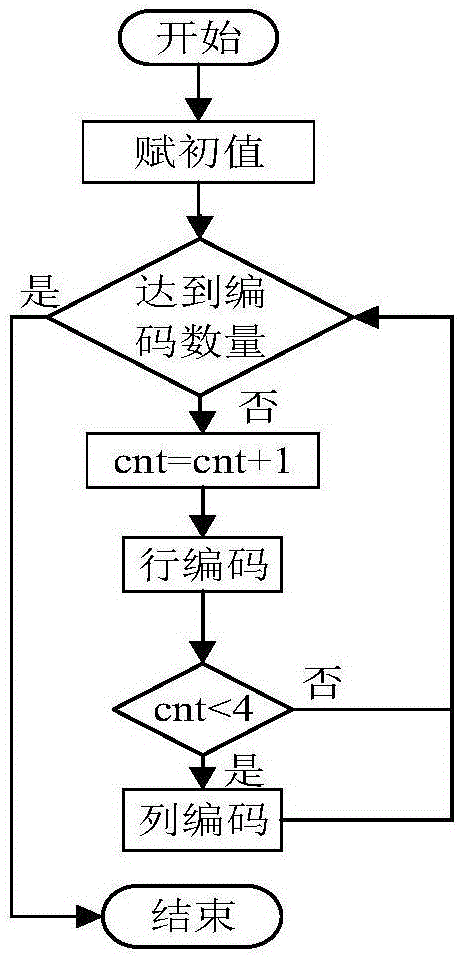

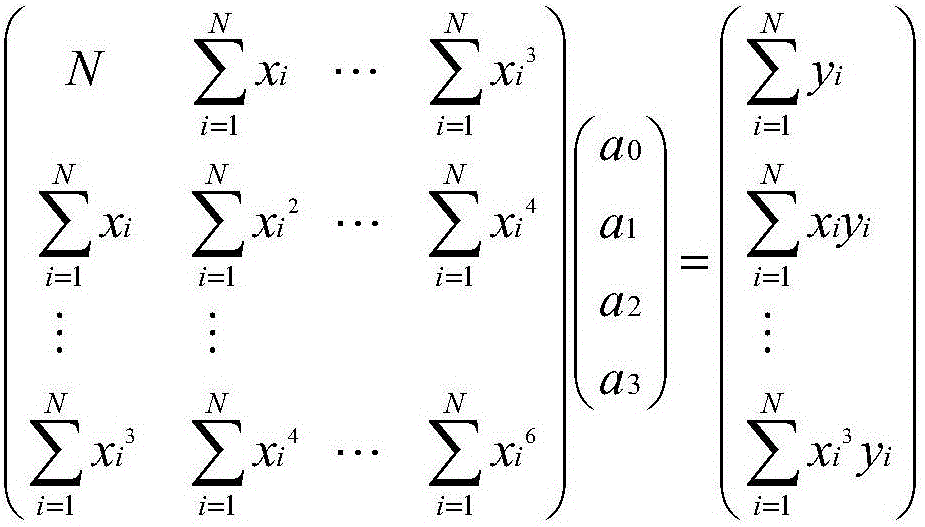

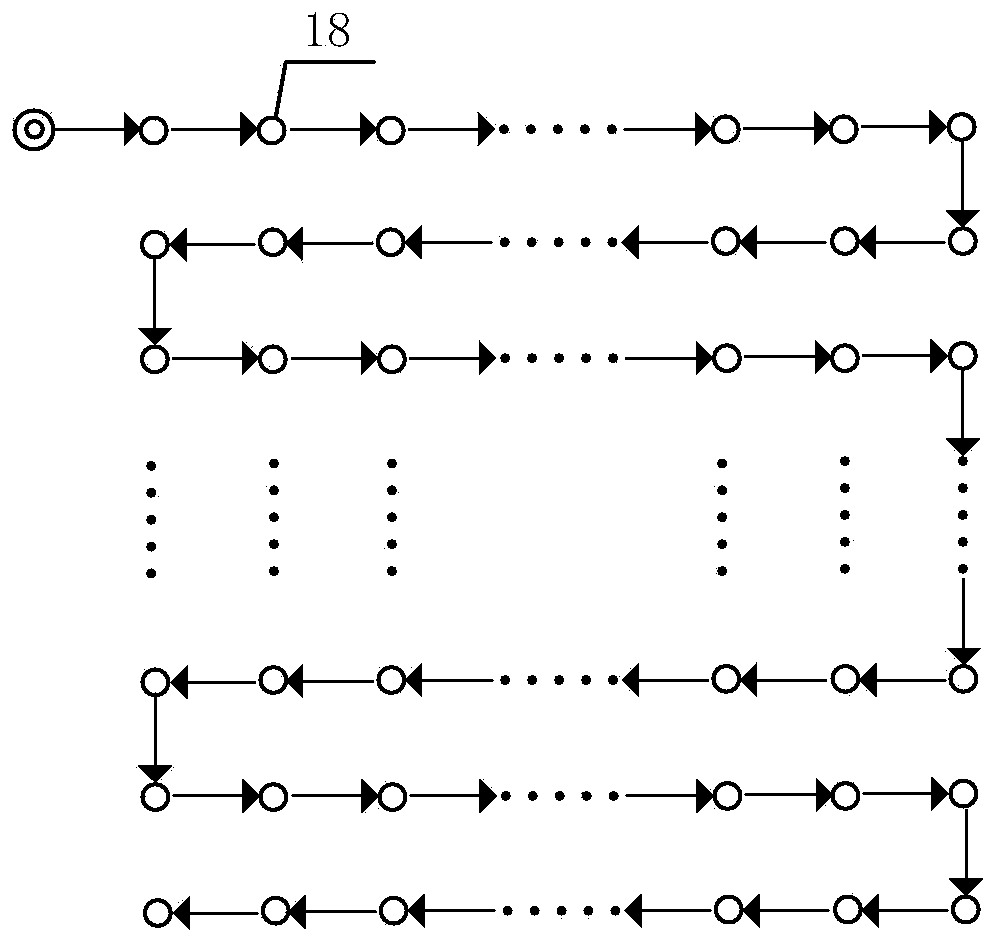

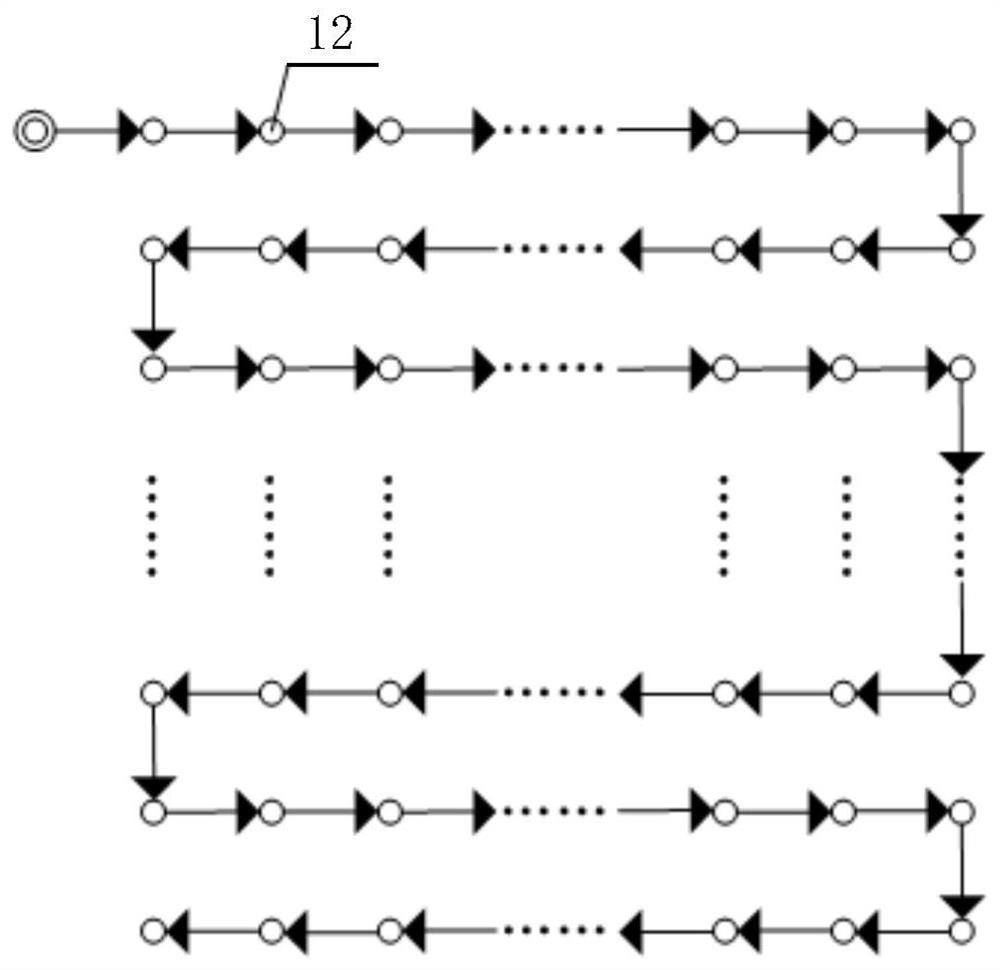

Two-dimensional absolute coding three-freedom moving platform measuring system

ActiveCN107525471AAbbe's error is smallHighly integratedUsing optical meansConverting sensor outputBase codeImaging processing

The invention discloses a two-dimensional absolute coding three-freedom moving platform measuring system which comprises three parts, namely a two-dimensional absolute position coding board, a coding imaging camera and a LabVIEW-based coding image processing system. The coding imaging camera performs imaging on a two-dimensional coding pattern in an imaging area. The LabVIEW-based coding image processing system mainly realizes functions of setting camera parameters and acquiring images, identifying an image alignment error parameter, measuring a deflection angle, decoding a displacement and performing subdividing, performing error compensation correction, and obtaining a planar displacement and deflection angle measurement result. According to the two-dimensional absolute coding three-freedom moving platform measuring system, the two-dimensional absolute position coding board is fixed on a three-freedom moving platform; the displacement and the deflection of the three-freedom moving platform in the plane are in one-to-one correspondence to coding images of an industrial camera detecting area; and precise measurement for the two-dimensional absolute position and the three-freedom movement of the deflection angle is realized through demodulating the image information by the LabVIEW-based coding image processing system.

Owner:HEFEI UNIV OF TECH

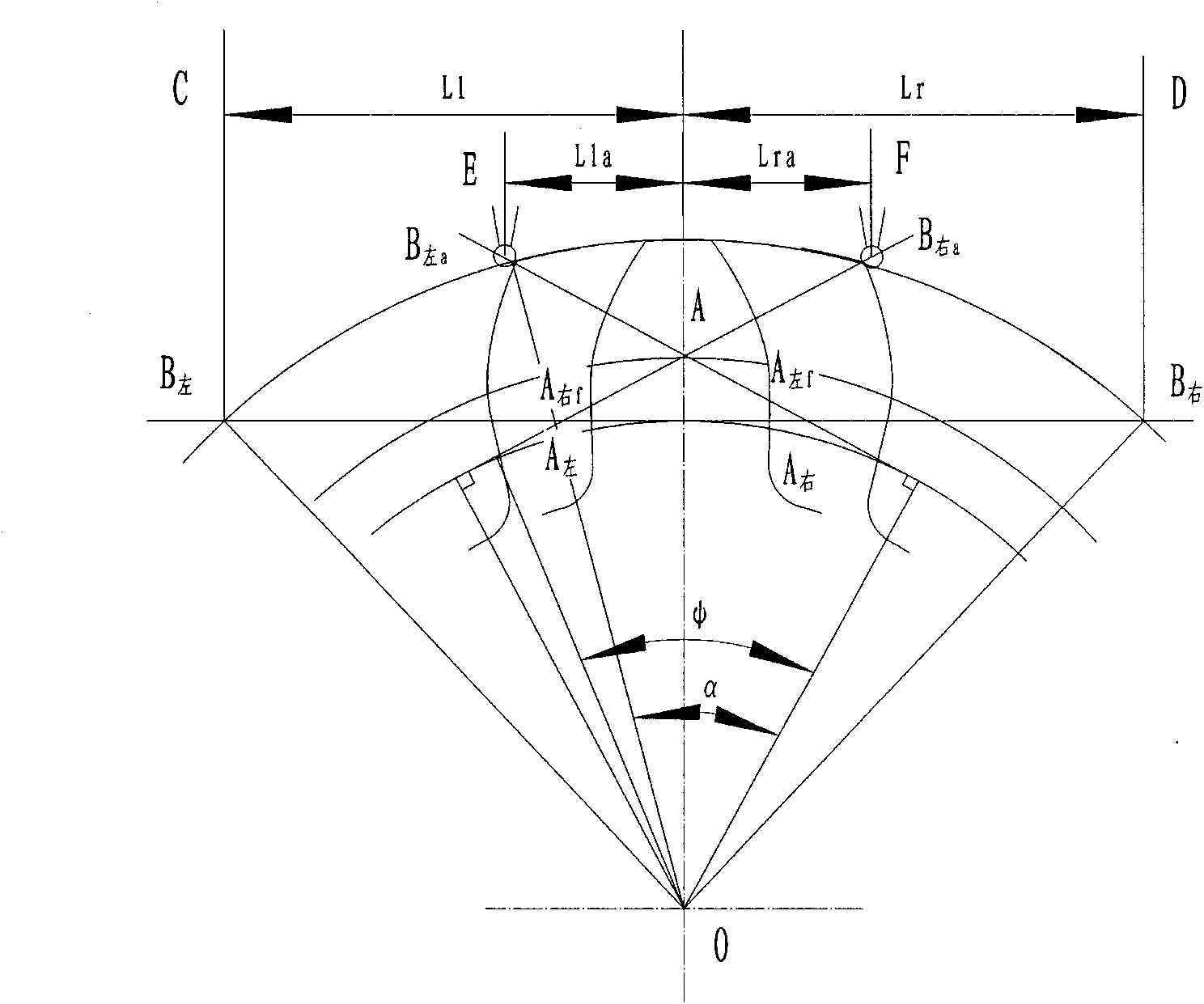

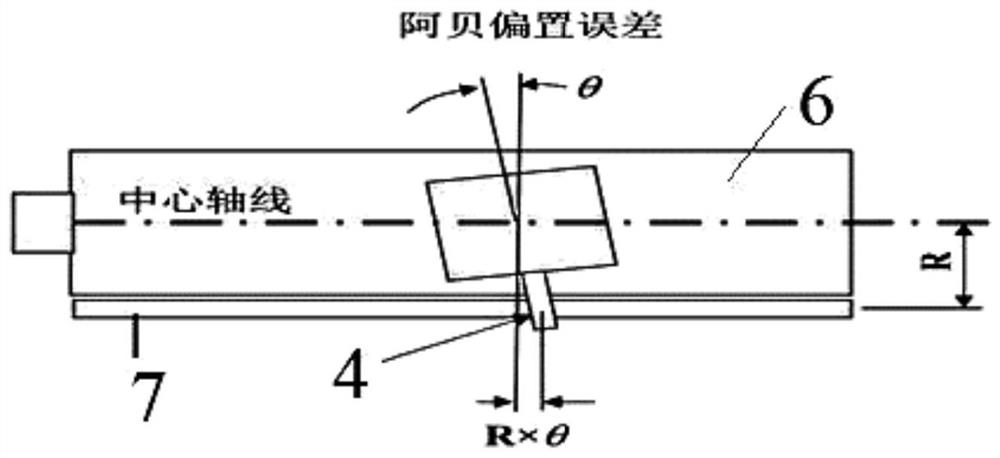

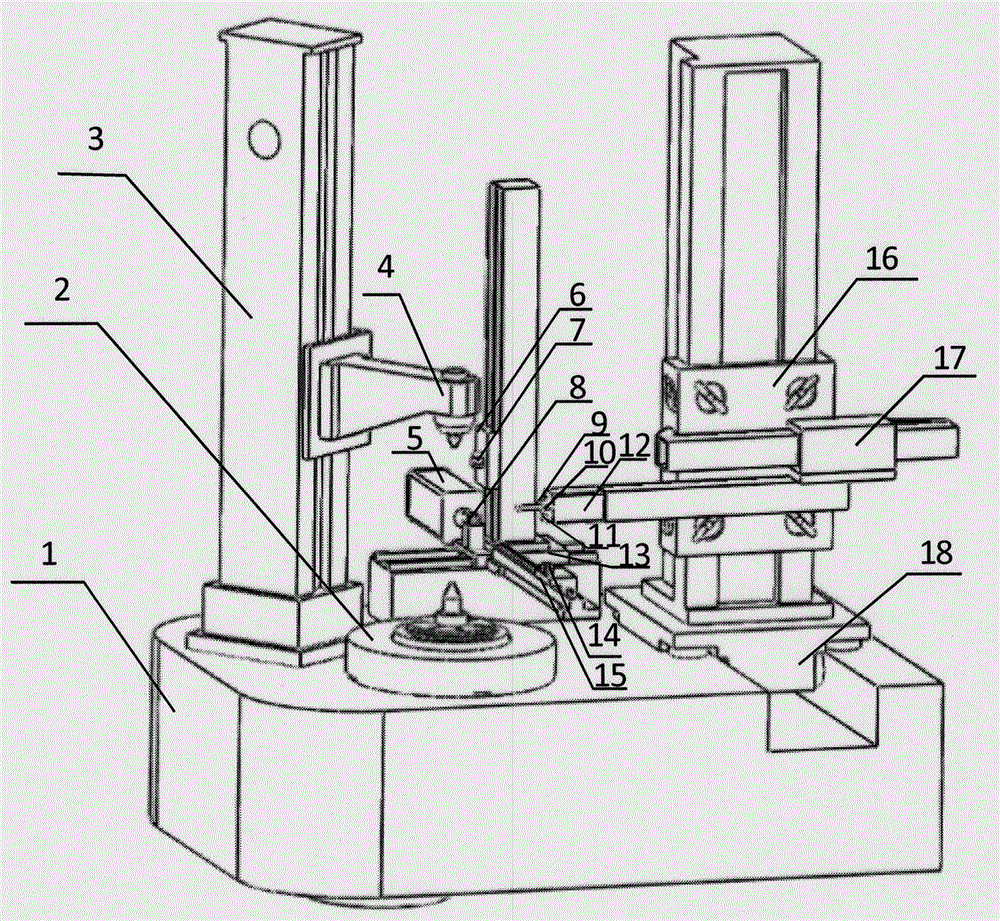

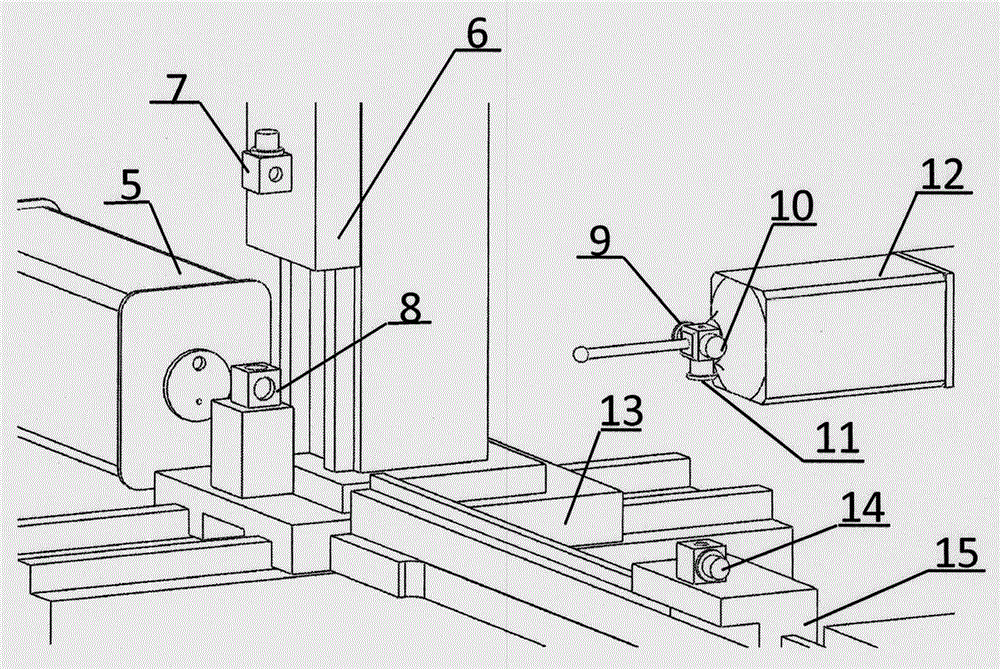

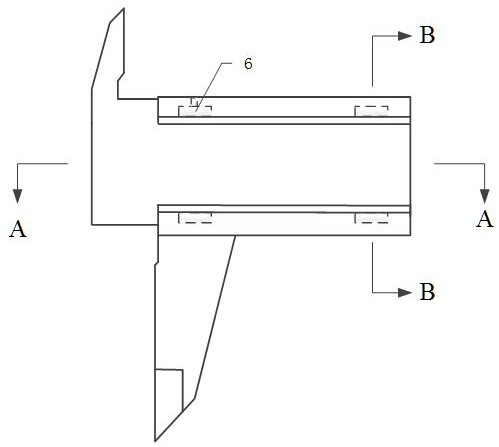

Meshing line large-specification gear measurement center

The invention overcomes the defect of overlarge tangential travel of a gear measurement center when the error of a gear tooth form of a large gear is measured by adopting base circle generating method, thereby providing a meshing line large-specification gear measurement center which has the advantages of optimized layout and high measurement precision and comprises a C shaft used for fixing a gear to be measured, wherein the C shaft is a rotating shaft. The meshing line large-specification gear measurement center also comprises a sensor probe used for acquiring data of the gear tooth form to be measured, wherein the sensor probe is controlled to move along the meshing line of the gear to be measured by a control system. According to the invention, the tangential guide rail size of a measurement apparatus is remarkably shortened, the abbe error of the gear measurement center is effectively reduced without a measurement head alignment error, the tangential travel when the error of the gear tooth form is measured is reduced, the tangential direction and the radial direction of the apparatus are in the vertical coordinate axis, thus the influence of the abbe error is furthest reduced, the optimized layout of the apparatus structure is effectively realized, the measurement precision is improved, and the advantages of simple structure and convenience for installation location and operation are realized.

Owner:HARBIN JINGDA MEASURING INSTR

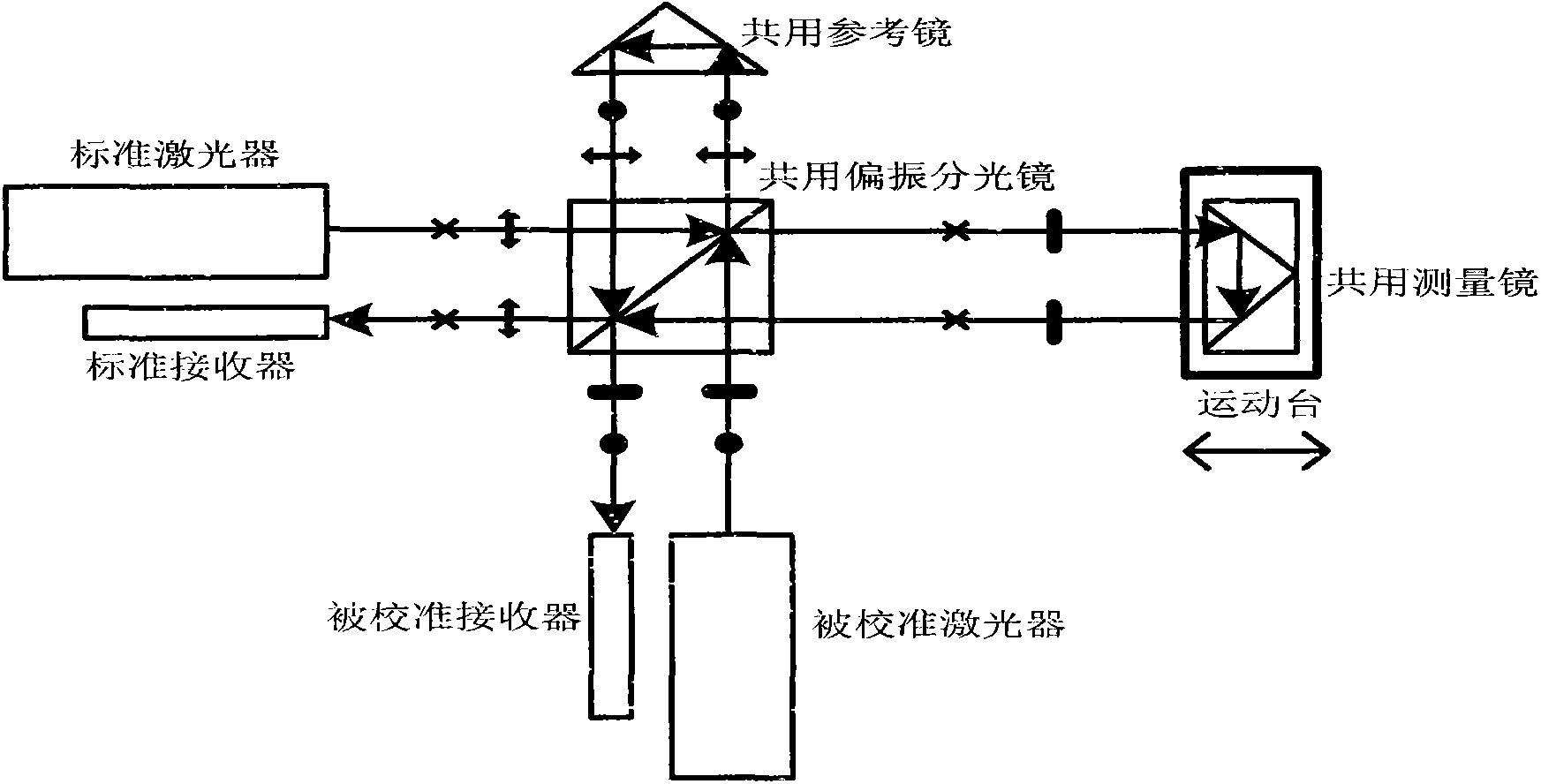

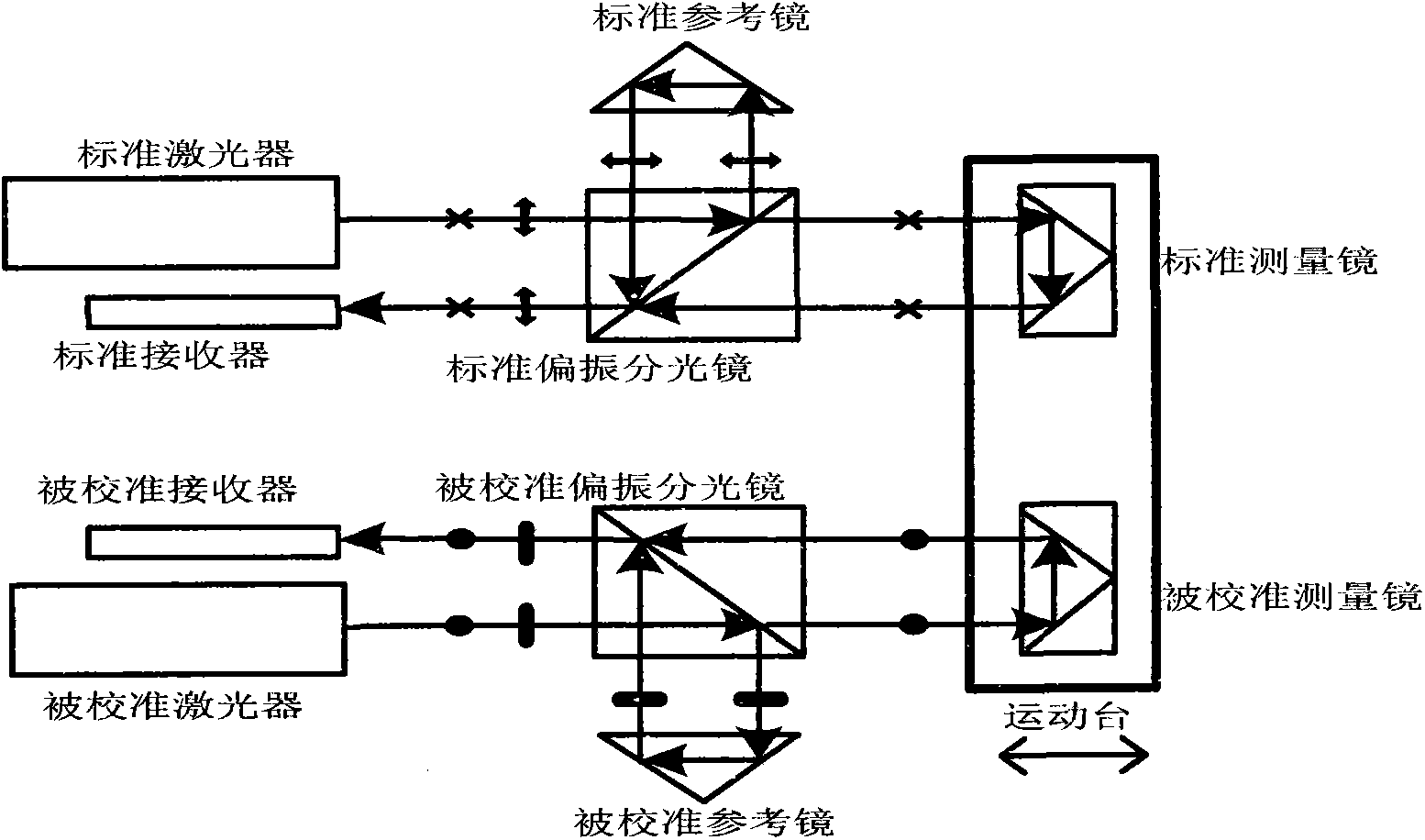

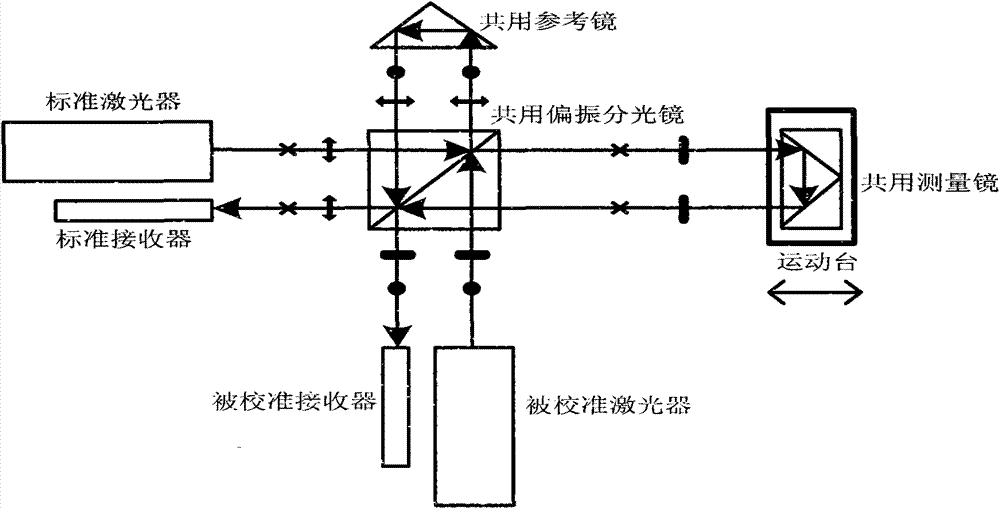

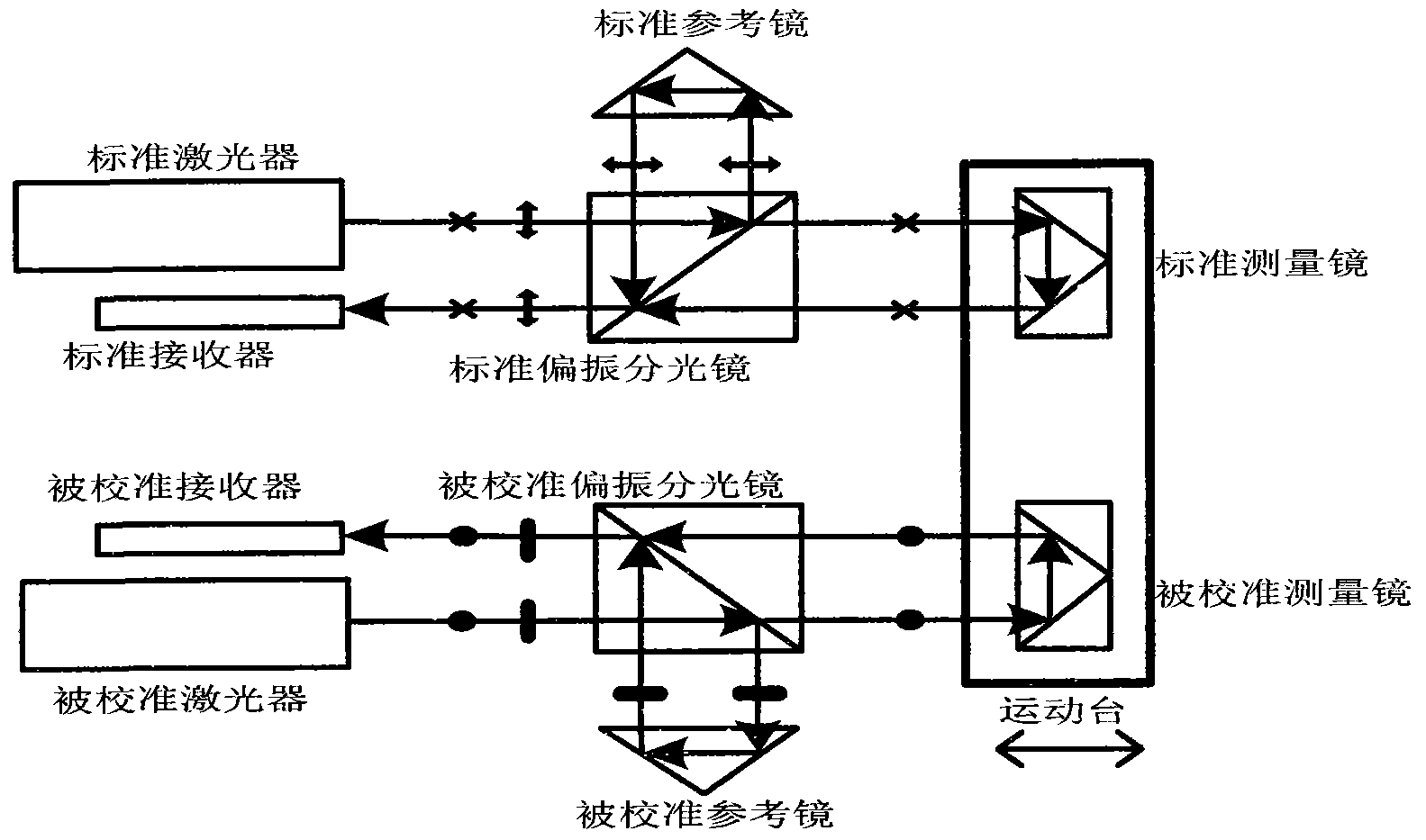

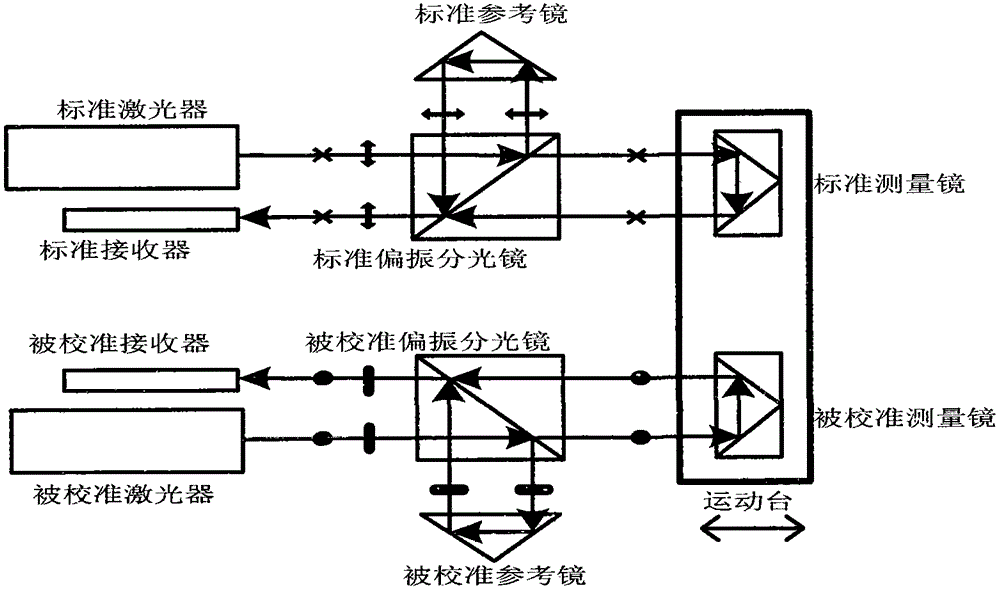

Method and device for calibrating optically biaxial compensation and gas bath type linear displacement laser interferometer

ActiveCN103499285AGood effectShort vertical distanceUsing optical meansObservational errorOptical axis

The invention relates to a method and a device for calibrating an optically biaxial compensation and gas bath type linear displacement laser interferometer and belongs to the technical field of laser measurement. According to the invention, a measurement beam of the calibrated laser interferometer passes through a middle through hole of a biaxial hollow laser interference mirror set and the measurement beam of the calibrated laser interferometer is placed in parallel at the middle position between two parallel standard measurement beams; vertical distances between the standard measurement beams and the measurement beam of the calibrated laser interferometer are very small and the average value of the air refractive indexes of the two standard measurement beams is approximate to the value of the air refractive index of the measurement beam of the calibrated laser interferometer; a stable gas bath environment formed by a gas bath device enables the air temperature, the humidity and the air pressure to be approximately and uniformly distributed and enables the average value of the air refractive indexes of the two standard measurement beams to be more approximate to the value of the air refractive index of the measurement beam of the calibrated laser interferometer; and a measurement error caused by the surface morphology of the reflecting surface of a target reflector is compensated into a linear displacement measurement result so as to ensure accuracy of the linear displacement measurement value.

Owner:HARBIN INST OF TECH

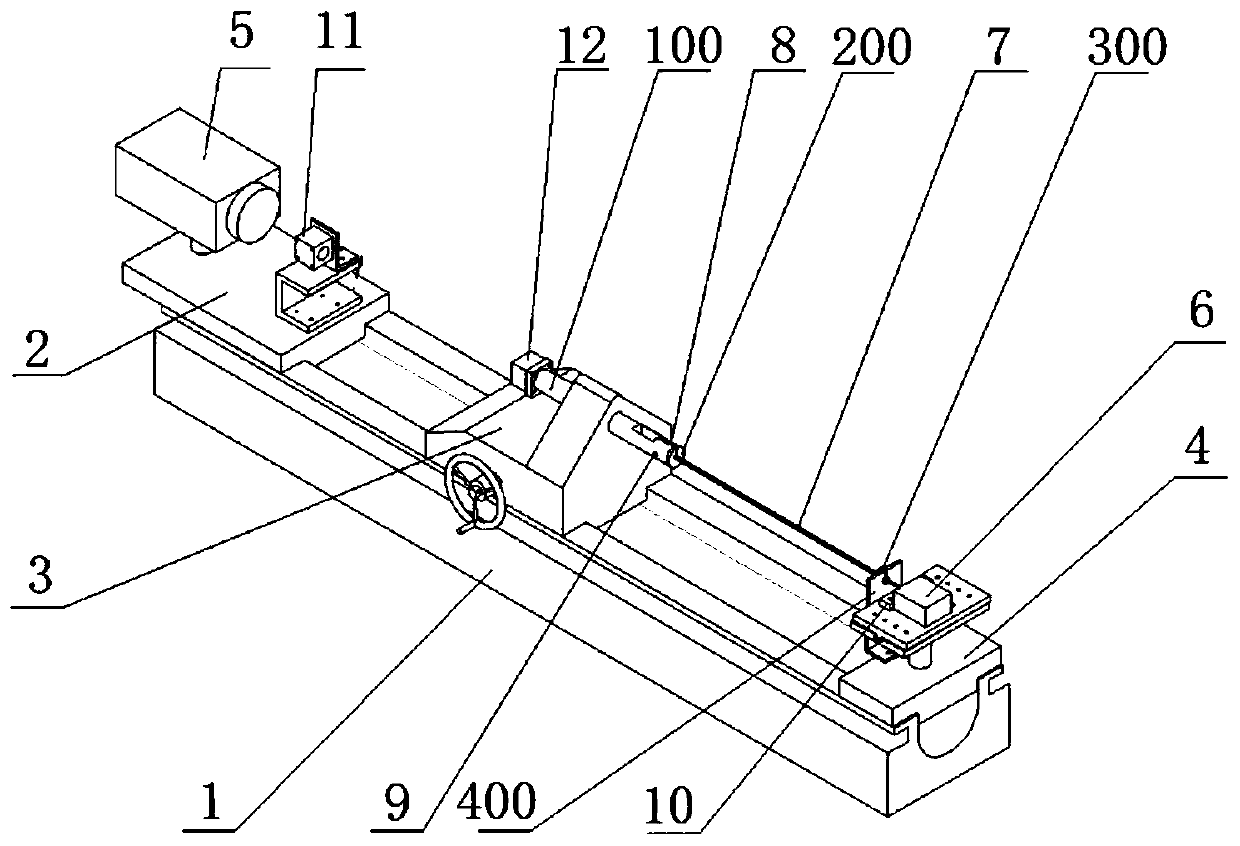

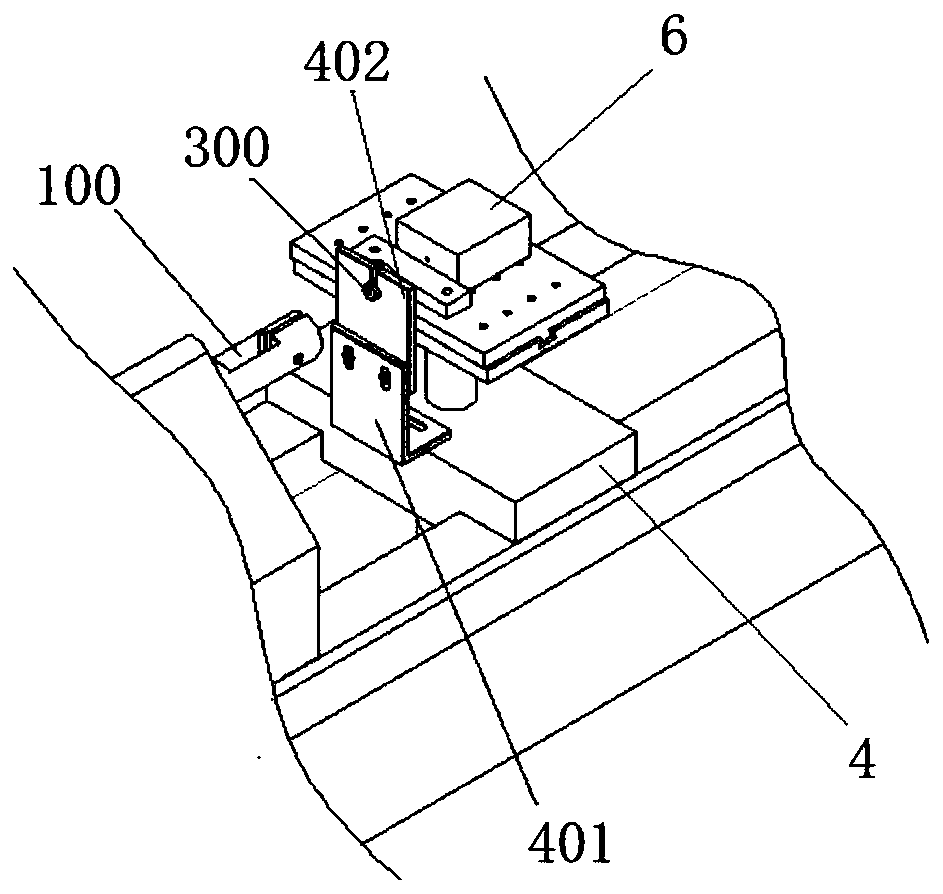

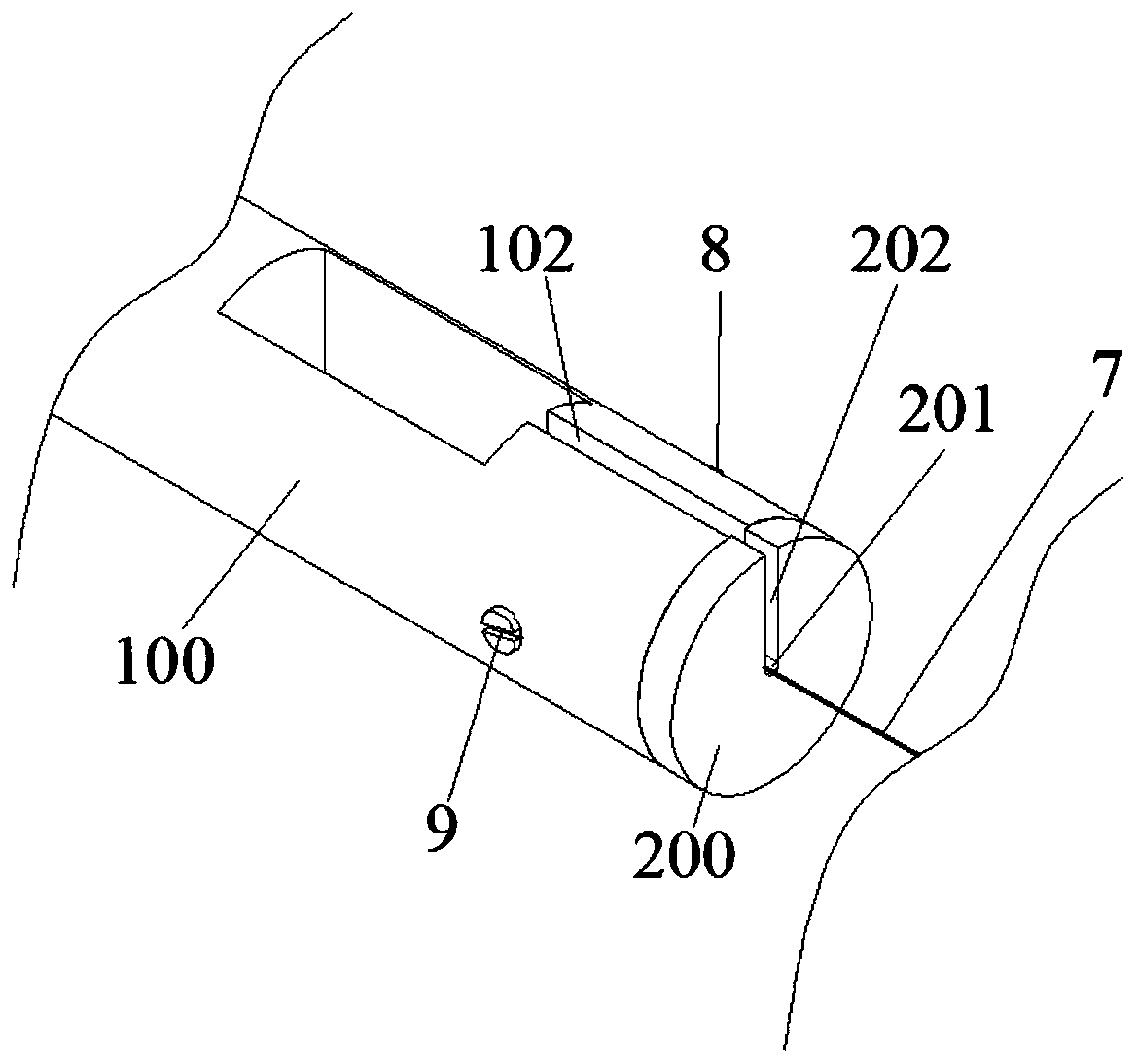

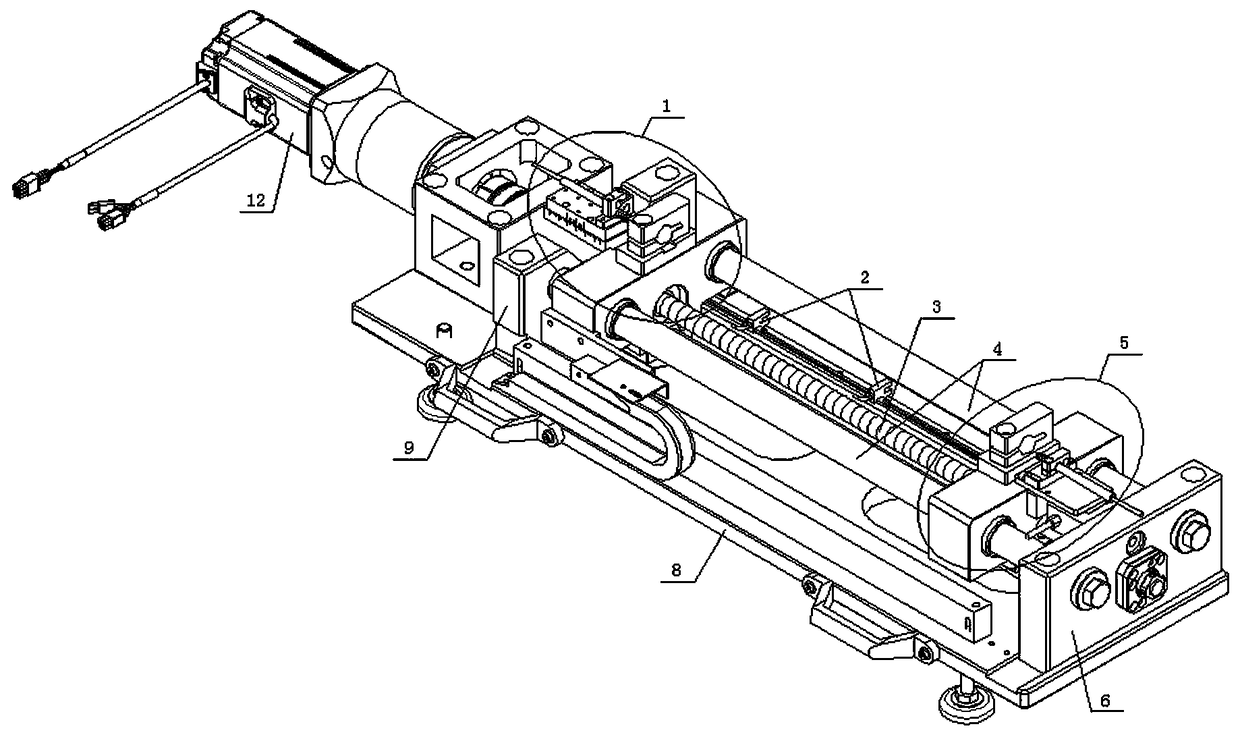

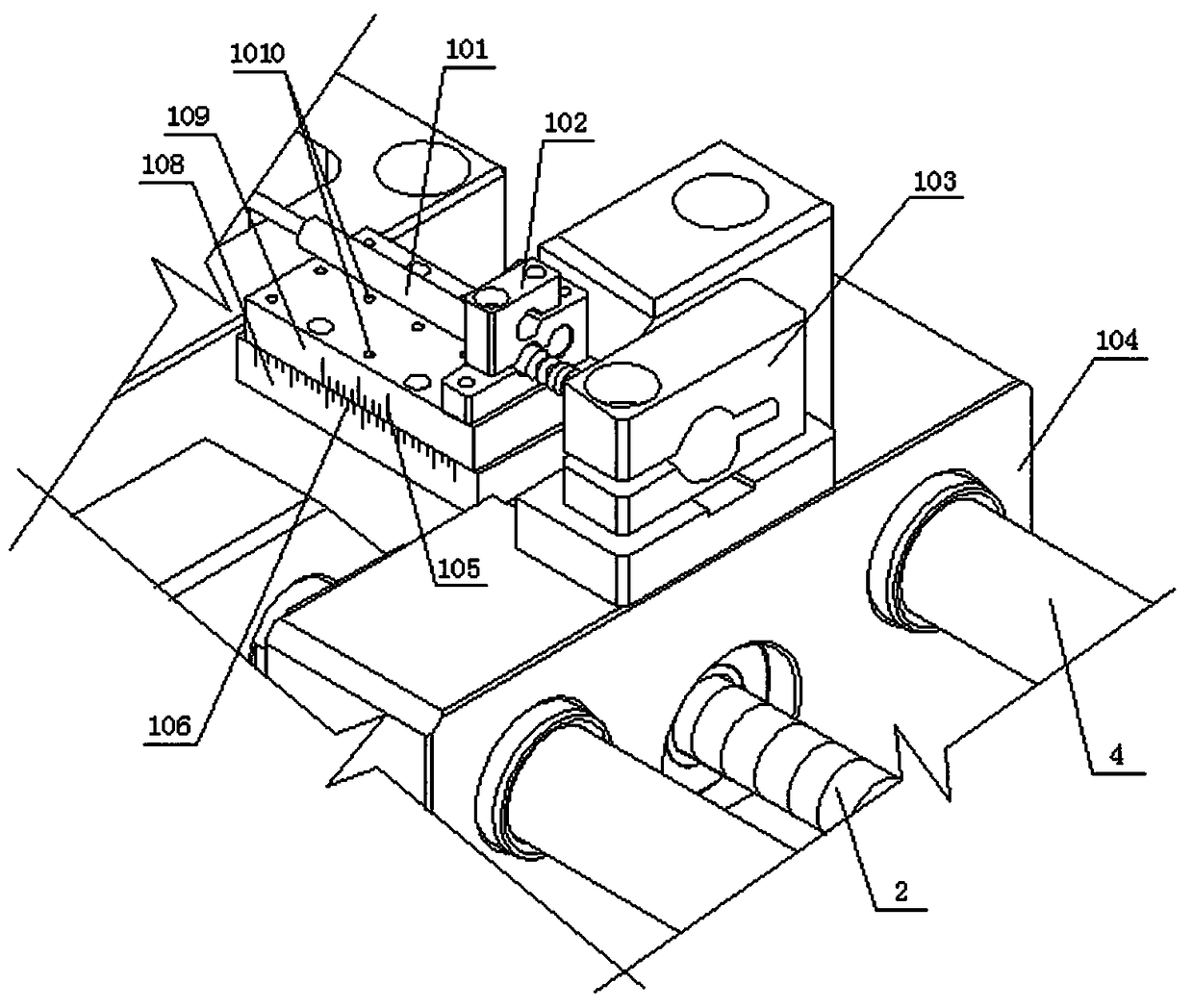

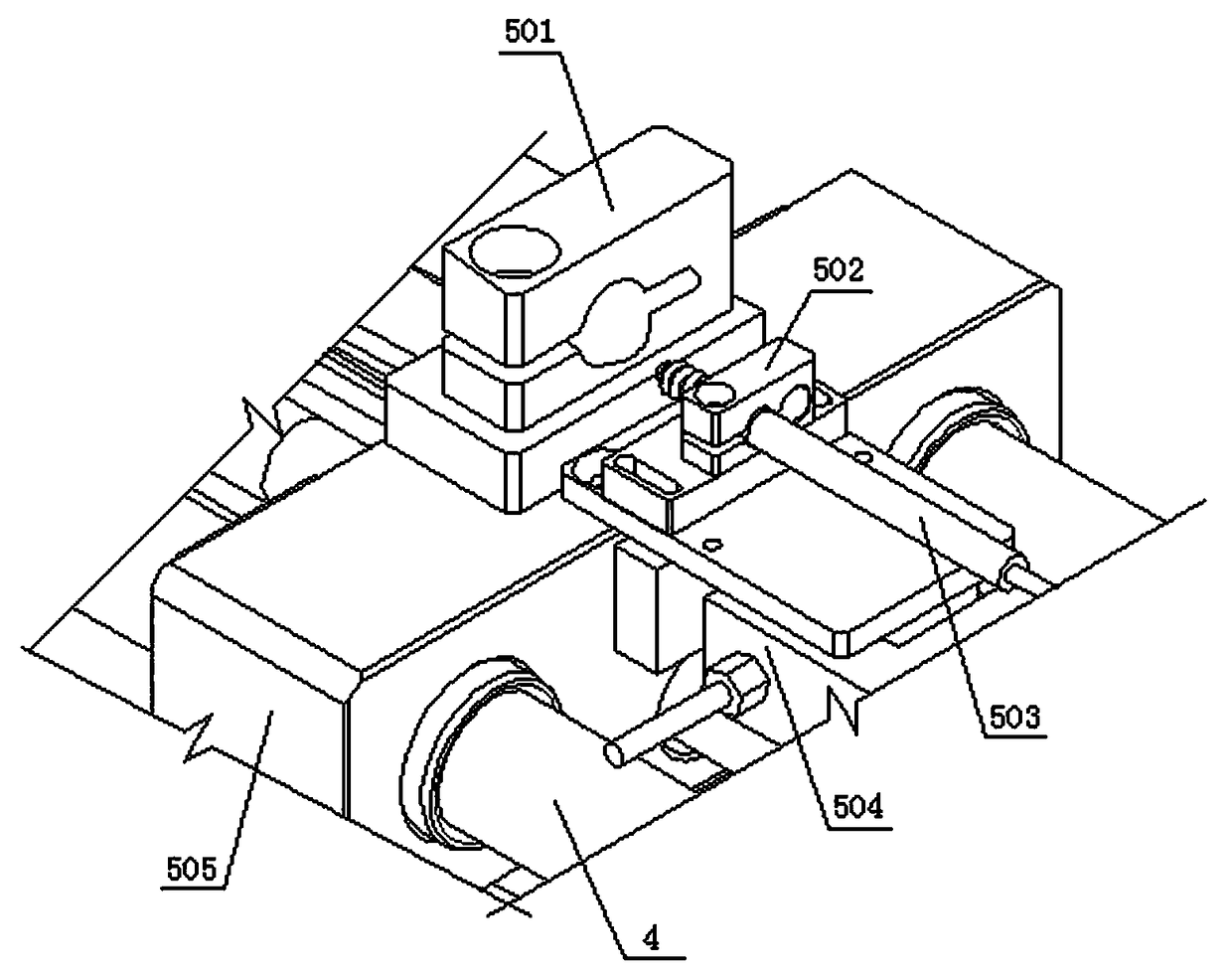

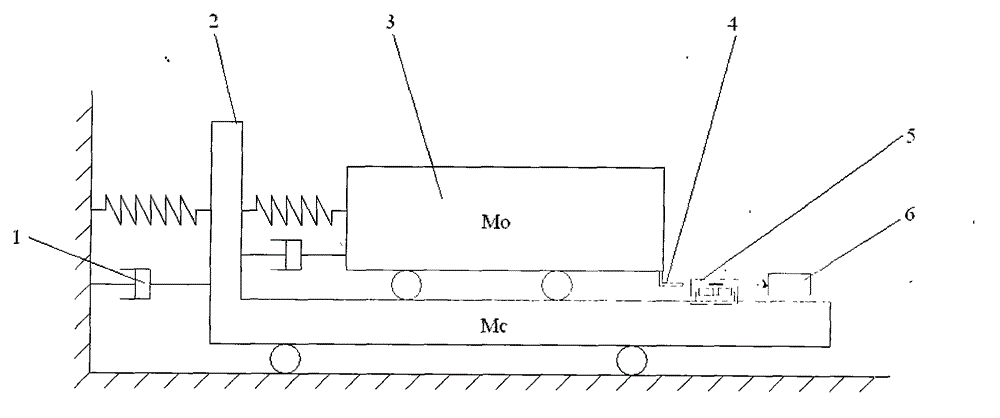

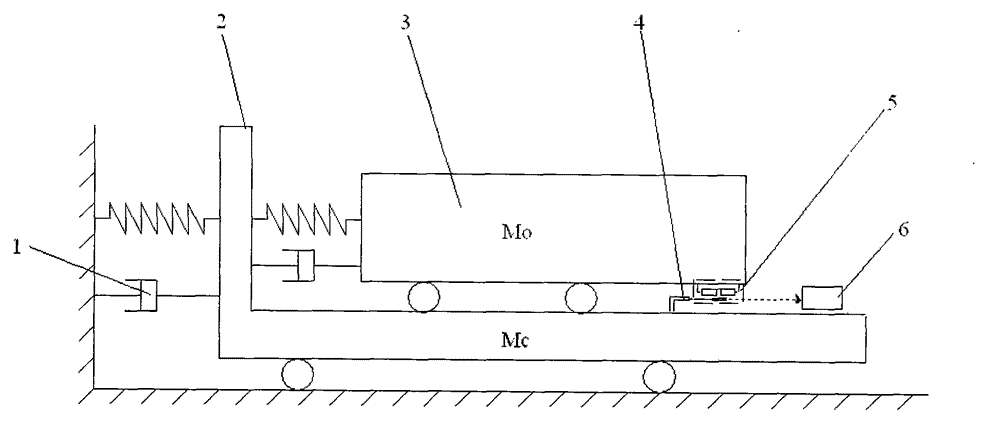

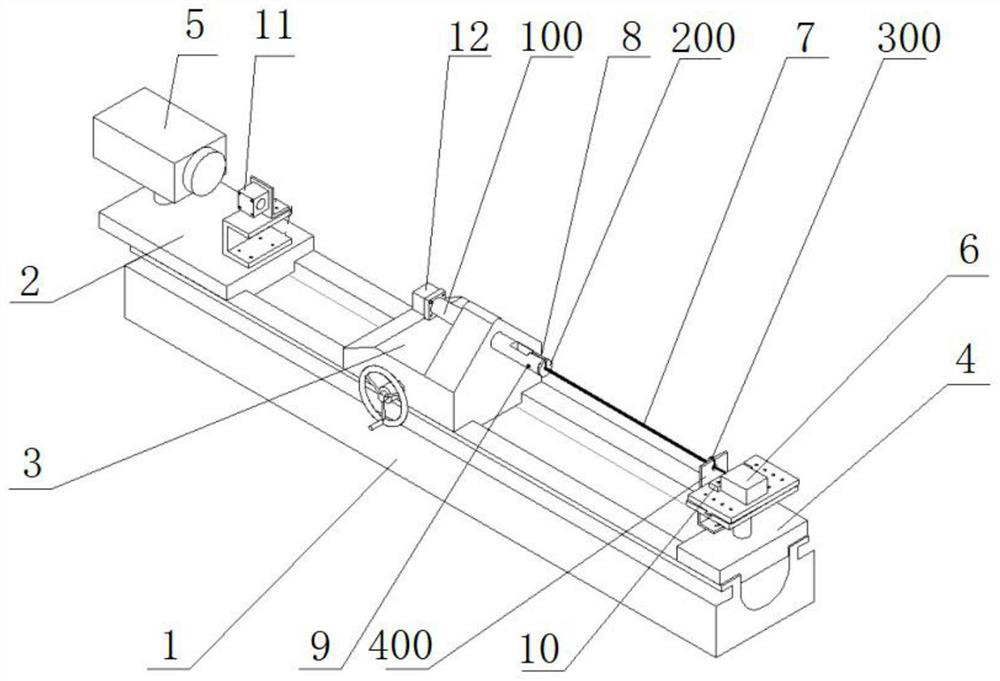

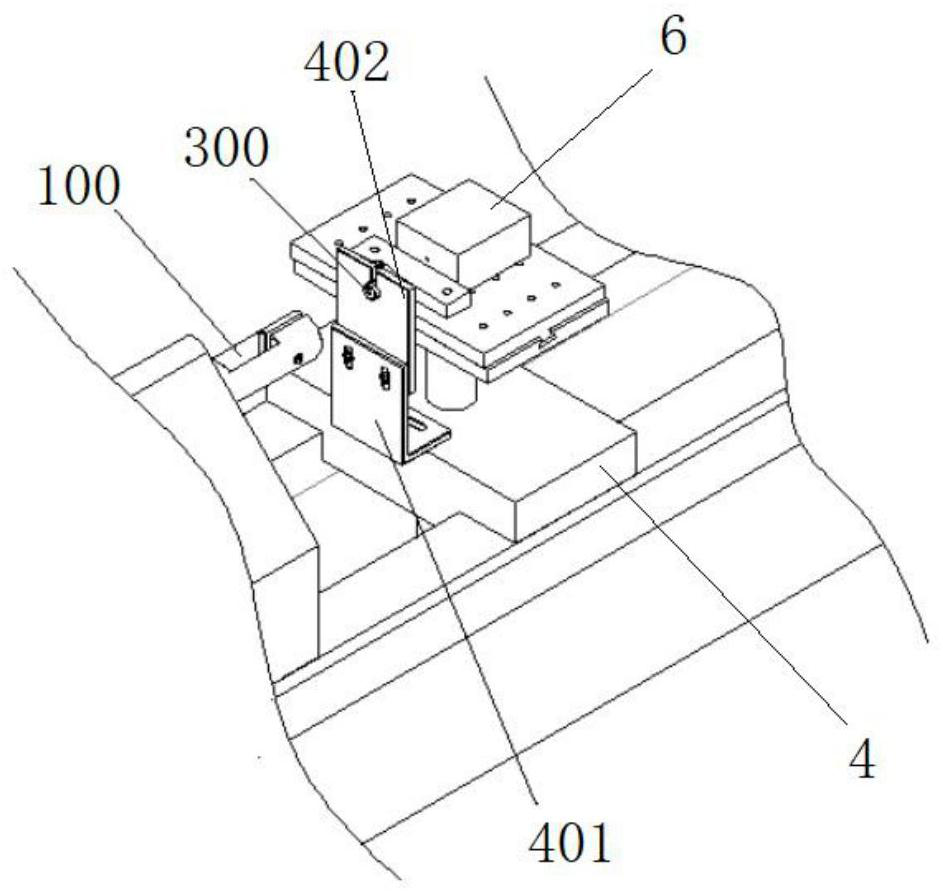

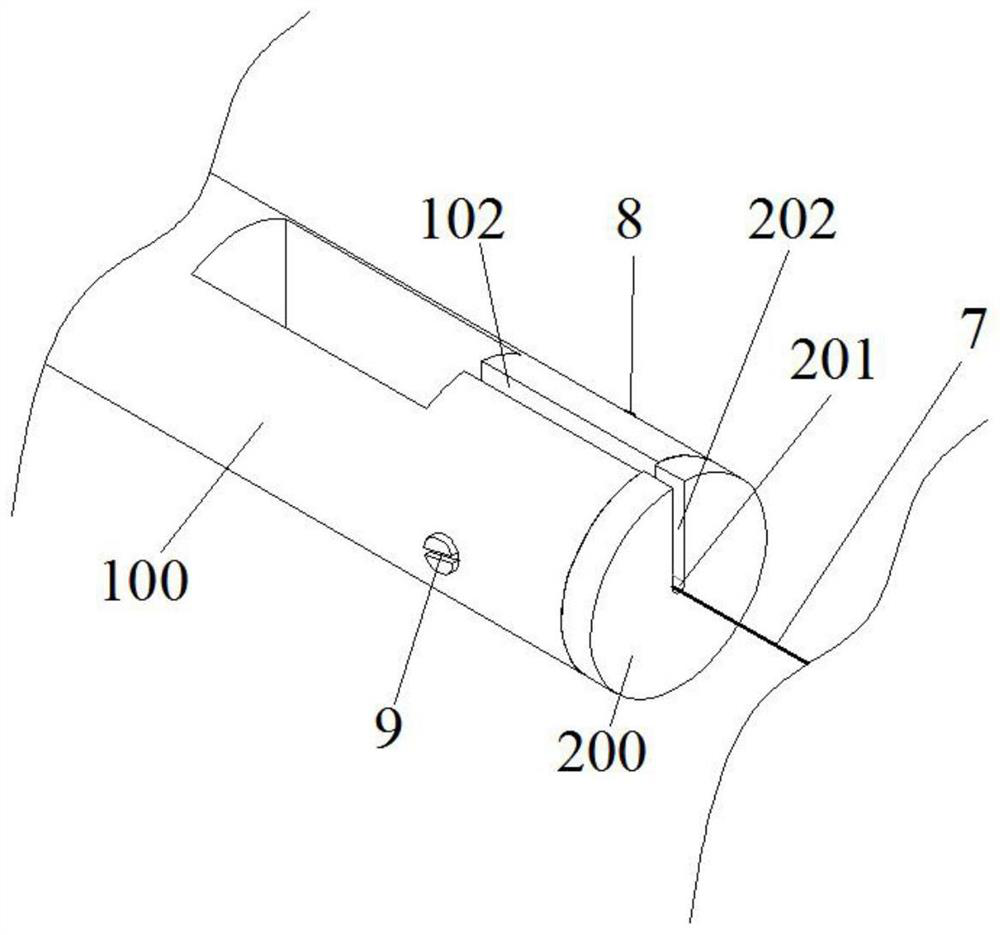

Stay wire type displacement sensor calibration device and calibration method

ActiveCN111288947AHigh degree of integrationEasy to operateMeasurement devicesMechanical engineeringTransducer calibration

The invention discloses a stay wire type displacement sensor calibration device and a calibration method. The stay wire type displacement sensor calibration device comprises a linear guide rail, and alaser interferometer sliding table, a main shaft sliding table and a stay wire type displacement sensor sliding table which are sequentially arranged on the linear guide rail in a sliding manner, wherein a laser interferometer is arranged on the laser interferometer sliding table; a main shaft is arranged on the main shaft sliding table; a calibrated stay wire type displacement sensor is arrangedon the stay wire type displacement sensor sliding table. The stay wire type displacement sensor calibration device further comprises a first induction line calibration fine adjustment sleeve, a second induction line calibration fine adjustment sleeve, an induction line calibration fine adjustment plate and an induction line fixing element used for fixing the starting end of an induction line of the stay wire type displacement sensor. The stay wire type displacement sensor calibration device aims at solving the technical problems that the clamping is inconvenient, the measuring range is small,large Abbe errors are prone to be caused and the safety is poor due to a calibration scheme of a linear displacement sensor in the prior art.

Owner:HUNAN INST OF METROLOGY & TEST

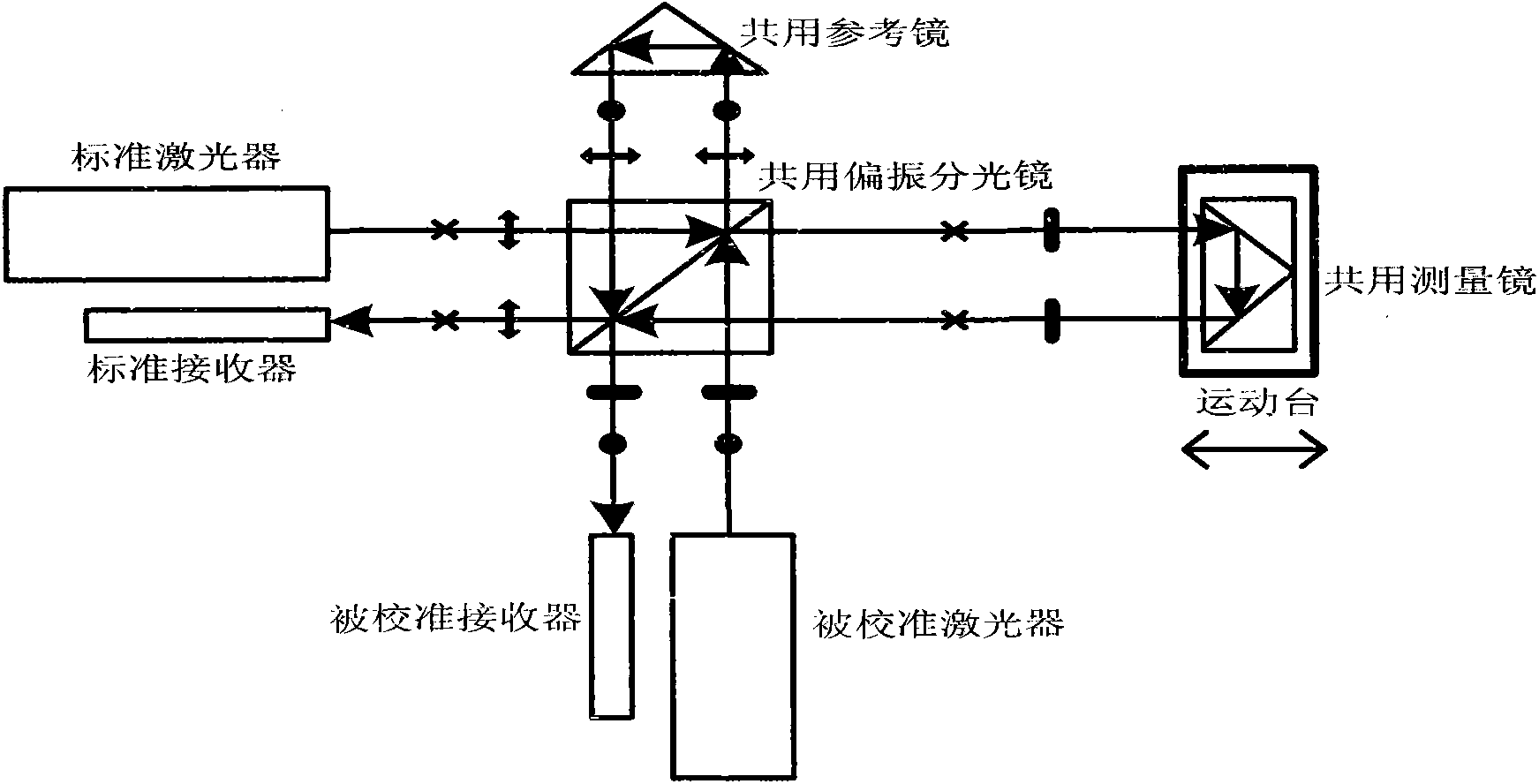

Angular displacement laser interferometer calibration method and device based on two standard optical axes

The invention provides an angular displacement laser interferometer calibration method and an angular displacement laser interferometer calibration device based on two standard optical axes, and belongs to the technical field of laser measurement. Two measuring light beams of a laser interferometer to be calibrated pass through a middle through hole of a two-axis hollow laser interference mirror group, and are parallelly arranged in the center position of two parallel standard measuring light beams; in a line segment region formed by the two standard measuring light beams at the plane projection points, the differences of environment interference degrees of the two standard measuring light beams and the two measuring light beams of the laser interferometer to be calibrated are very small, and the air refractive index average value of the standard measuring light beams is approximate to the air refractive index value of the measuring light beams of the laser interferometer to be calibrated.

Owner:HARBIN INST OF TECH

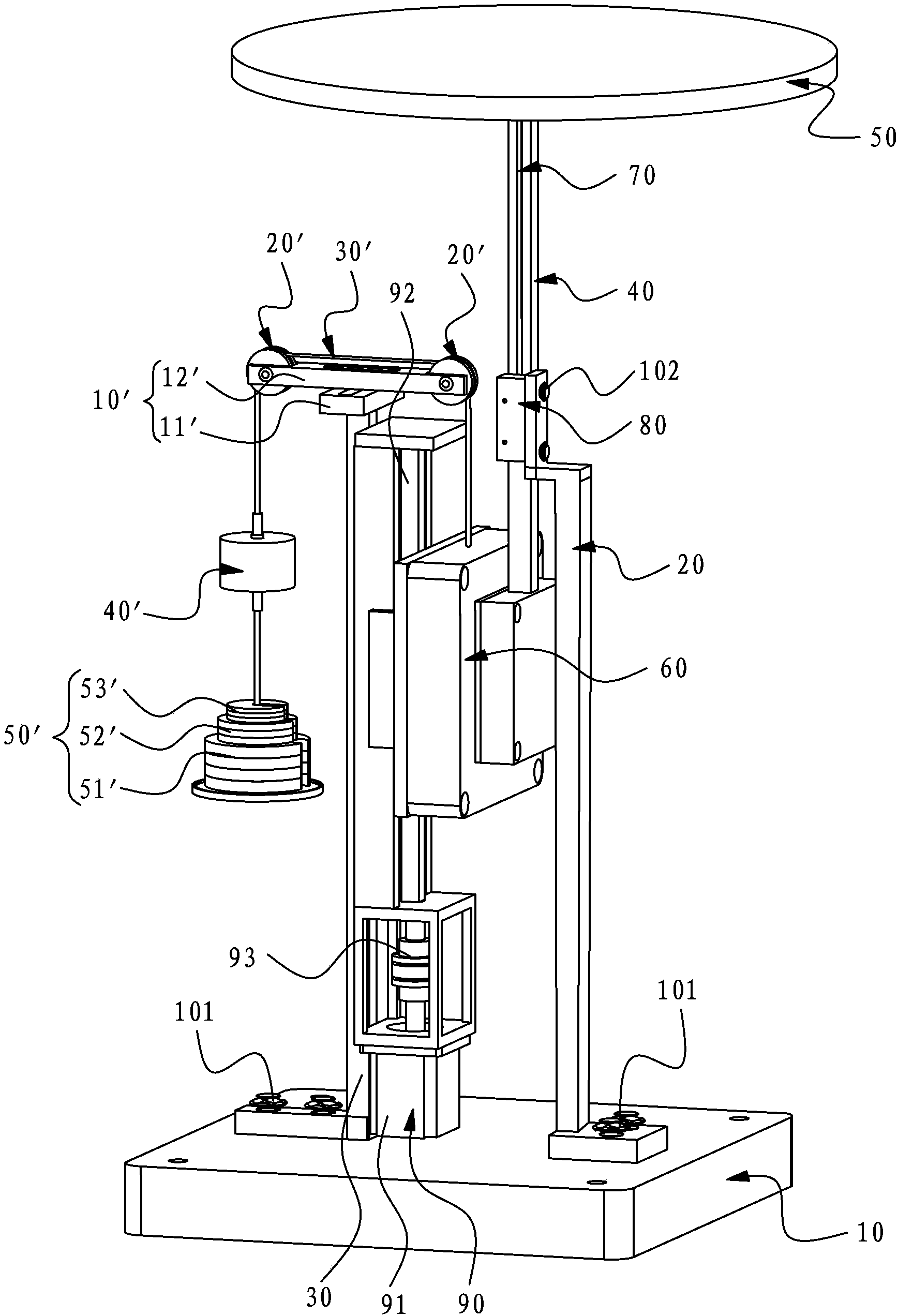

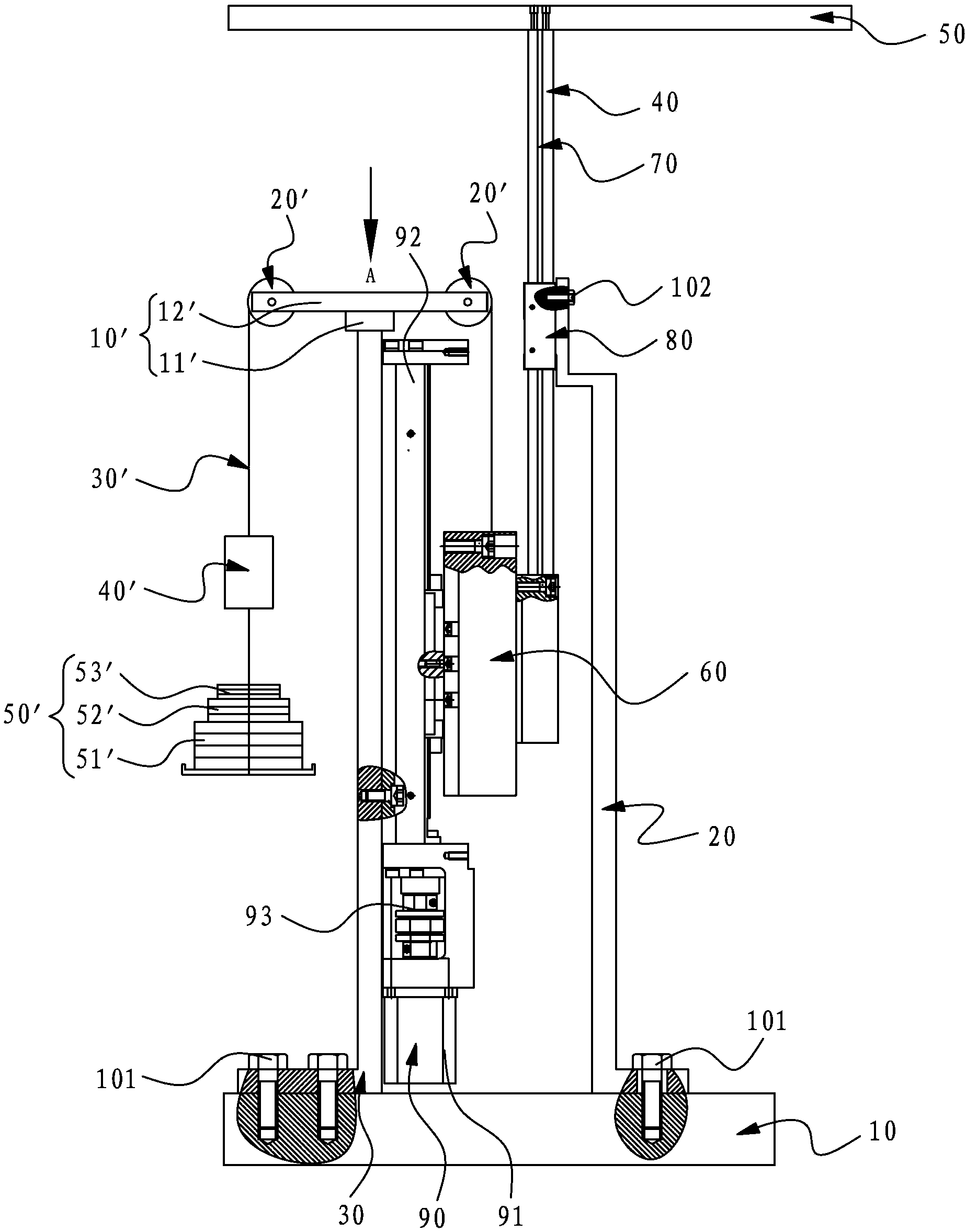

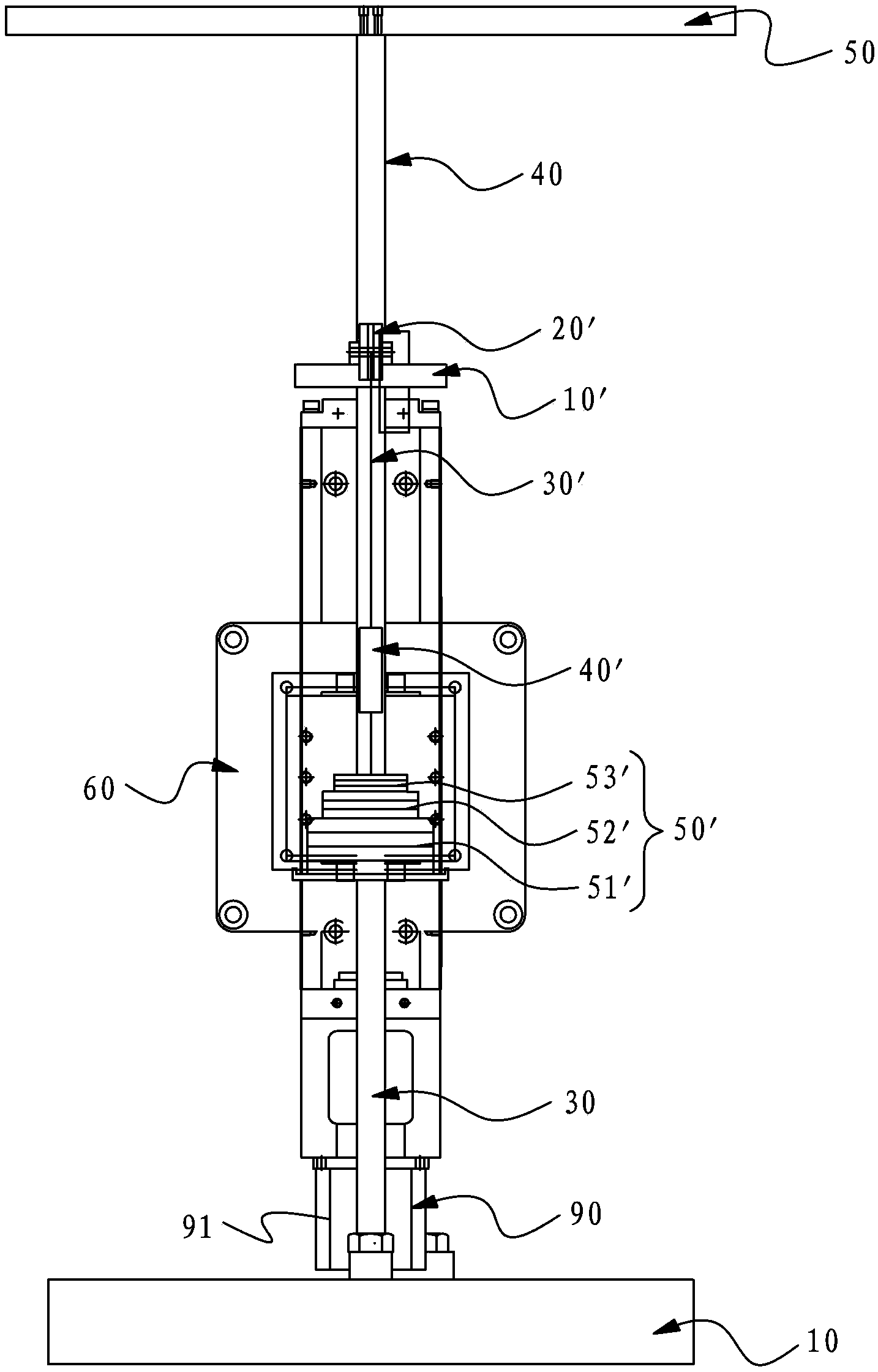

Large-stroke high-precision Z-axis worktable with novel structure

ActiveCN103506855AAbbe's error is smallSimple structureMeasurement/indication equipmentsCounterweightsMicro nanoGrating

The invention discloses a large-stroke high-precision Z-axis worktable with a novel structure. The worktable comprises a base, a first support, a second support, a movable supporting rod, a worktable body and a precise movable positioning table. The first support and the second support are arranged on the base, the movable supporting rod is arranged on the first support in an upward and downward movable mode, the movable supporting rod is fixedly provided with a grating ruler extending vertically, the first support is provided with a grating reading head, the precise movable positioning table is arranged on the second support in an upward and downward movable mode, the lower end of the movable supporting rod is fixedly connected with the precise movable positioning table, and a drive device is arranged on the precise movable positioning table. Due to the fact that the center of the worktable body, the center of the grating ruler, the center of the grating reading head and the center of the precise movable positioning table are located on the same line, zero abbe errors of a system can be achieved theoretically, abbe errors of the system are reduced to the largest extent, and micro-nano measuring and micro-nano processing requirements can be met.

Owner:HUAQIAO UNIVERSITY

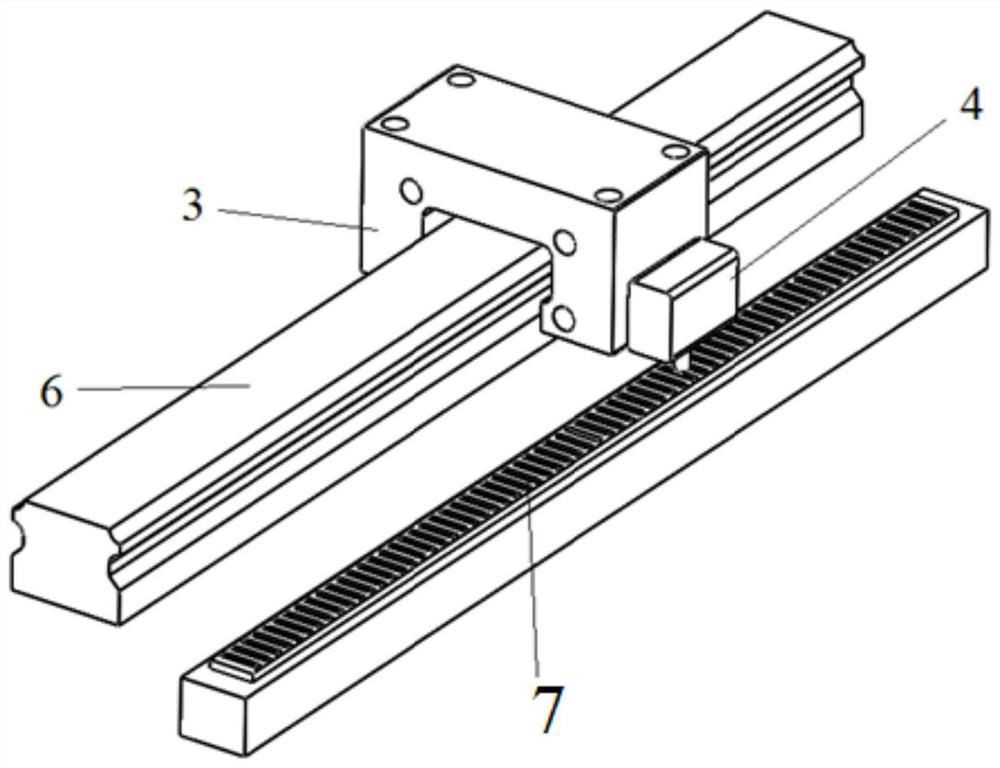

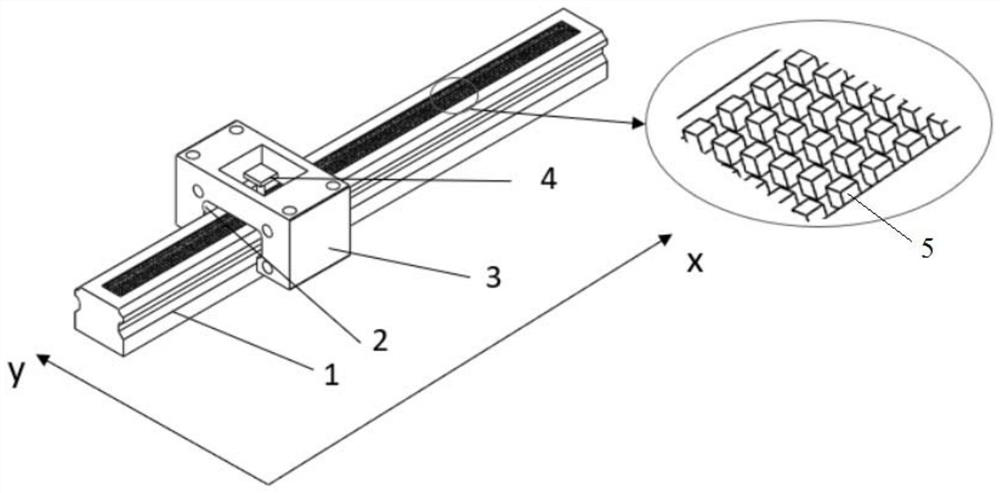

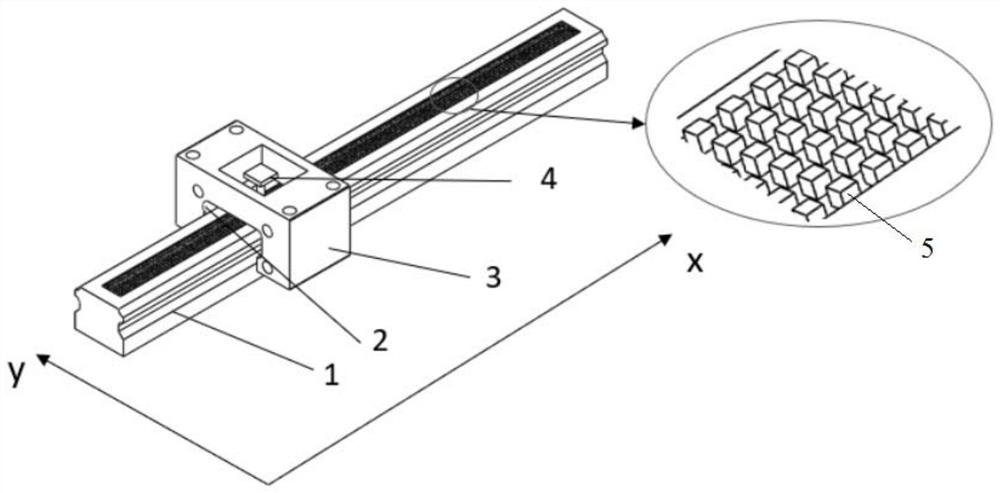

Device and method for synchronous in-situ measurement of linear displacement and straightness of guide rail

ActiveCN111735393AAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronous in-situ measurement of linear displacement and straightness of a guide rail. For an integrated two-dimensional grating and guide rail, a two-dimensional grating is etched on the upper surface of a linear guide rail, and a reading head is embedded in a sliding block. The specific measurement method comprises the steps that when the sliding block moves on the guide rail, the reading head outputs two pairs of orthogonal sine and cosine signals at the same time, the sine and cosine signals are transmitted to an upper computer through anacquisition card after being subjected to filtering and analog-digital conversion, and displacement and straightness are solved on the upper computer through a method of counting edges through high-frequency pulses, wherein the linear displacement of the guide rail is solved through orthogonal signals generated by the grid lines perpendicular to the x axis, and the straightness of the guide railis solved through orthogonal signals generated by the grid lines perpendicular to the y axis. The method has the advantages of small guide rail pair mounting size, high positioning precision, multi-parameter synchronous in-place measurement and the like, and a new method is provided for displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

Large gear grinding machine grinding wheel rack rotation device and rotation control method thereof

ActiveCN104889502AImprove support rigidityIncrease rotation speedGear-cutting machinesGear teethGear grindingGrating

The invention provides a large gear grinding machine grinding wheel rack rotation device and a rotation control method thereof. The device comprises a rotation cylinder, a rotation seat, a spindle, a dual-lead clearance elimination worm gear, a circular grating, a grinding wheel rack, a clamping mechanism and an unloading mechanism. the spindle and the rotation seat are fixed firmly through bolts, the rotation cylinder is supported on the spindle through a group of rolling bearings, the grinding wheel frame is directly connected with the rotation cylinder and is rotated by the driving of the dual-lead clearance elimination worm gear, the rotation position is controlled by the circular grating, and the grinding wheel rack can be locked on the rotation seat through the clamping mechanism. By means of the device and the method, the requirements for high rigid support, stable and flexible moving and accurate location of large gear grinding machine grinding wheel racks can be met.

Owner:秦川机床工具集团股份公司

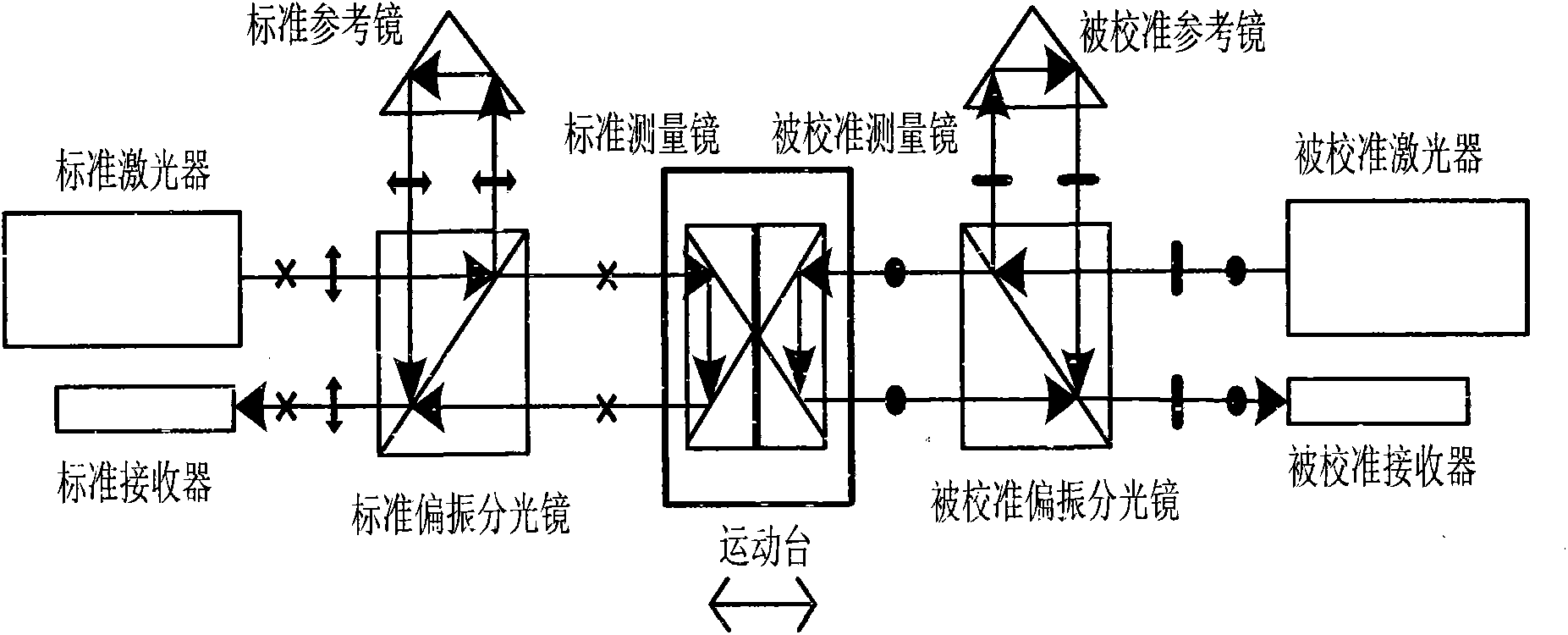

Linear displacement laser interferometer calibration method and device based on three standard optical axes

ActiveCN103499279AGood effectShort vertical distanceUsing optical meansIsoetes triquetraOptical axis

The invention provides a linear displacement laser interferometer calibration method and a linear displacement laser interferometer calibration device based on three standard optical axes, and belongs to the technical field of laser measurement. A measuring light beam of a laser interferometer to be calibrated passes through a middle through hole of a three-axis hollow laser interference mirror group, and is parallelly arranged in the center position of three parallel standard measuring light beams distributed in a regular triangular prism side edge form; in a plane vertical to the three standard measuring light beams, in an equilateral triangle region formed by the three standard measuring light beams at plane projection points, the differences of environment interference degrees of the three standard measuring light beams and the measuring light beam of the laser interferometer to be calibrated are very small, and the air refractive index average value of the three standard measuring light beams is approximate to the air refractive index value of the measuring light beam of the laser interferometer to be calibrated.

Owner:HARBIN INST OF TECH

Large-dip-angle free-form surface measuring method and device based on reference plane comparison measurement

ActiveCN110954019AAchieve nanometer precision measurementsAbbe's error is smallUsing optical meansMechanical measuring arrangementsEngineeringOptical flat

The invention discloses a large-dip-angle free-form surface measurement method and device based on reference plane comparison measurement, and belongs to the technical field of optical precision detection. A high-precision horizontal plane optical flat is used as the reference standard of an X-Y plane so that the straightness errors of the two guide rails in the height direction are removed. Meanwhile the plane optical plane is used for monitoring the transverse micro-displacement of the X guide rail and the Y guide rail so that the transverse straightness errors of the two guide rails are removed. A sensor for monitoring a reference plane and a sensor for measuring height information of a free-form surface are coaxially mounted, so that abbe errors caused by inclination of a guide rail and a truss are reduced; straightness errors of the X-direction air floatation guide rail and the Y-direction air floatation guide rail are compensated through the reference datum plane, and dimension reduction error separation of free-form surface high-precision measurement is achieved. The nano-precision free-form surface sensor provides a high-precision three-dimensional linear positioning and scanning measurement means for free-form surface detection by utilizing an air floatation rotating shaft to widen the test range and combining a macro-micro cross-scale nano-precision undisturbed driving and positioning method of a residual air recovery type air floatation guide rail.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Clamping mechanism for vibrating wire strain sensor calibration device

PendingCN109357606ARealize fully automatic calibrationImprove measurement accuracyMechanical solid deformation measurementsVibrating wireEngineering

The invention discloses a clamping mechanism for a vibrating wire strain sensor calibration device, comprising left and right clamps. The left clamp comprises a left slider, which is provided with a left smooth punch hole for passing through the guide slide, and a left threaded punch hole for screwing the power screw. A left clamping head is fixed on the top of the left slider. The right clamp comprises a right slider, which is provides with a right smooth punch hole for passing through the guide slide, and a right smooth punch hole for passing through the power screw. A right clamping head isfixed at the top of the right slider. The left and right displacement sensors simultaneously detect the sliding amount of the left and right ends of the vibrating wire strain sensor, which improves the measurement accuracy and also detects the stress change in real time.

Owner:HENAN PROVINCE INST OF METROLOGY

Method and device for calibrating return compensation type double-optical-axis angular displacement laser interferometer

ActiveCN103528502AAbbe's error is smallLittle differenceUsing optical meansOptical axisRefractive index

A method and a device for calibrating a return compensation type double-optical-axis angular displacement laser interferometer belong to the technical field of laser measurement. Two measurement light beams of the calibrated laser interferometer penetrate through a middle through hole of a double-axis hollow laser interferoscope group; the two measurement light beams of the calibrated laser interferometer are arranged in the middle positions of two parallel standard measurement light beams in parallel; the perpendicular distance between the standard measurement light beams and the measurement light beams of the calibrated laser interferometer is very small, and the air refractive index of the standard measurement light beams is extremely close to that of the measurement light beams of the calibrated laser interferometer; an average derived displacement is measured by a micro-motion device according to two light beam position detectors to carry out return compensation on the derived displacement of a target reflector in real time, so that the incidence positions of the measurement light beams on the reflecting surface of the target reflector do not vary.

Owner:HARBIN INST OF TECH

Two-dimensional laser optical path gear measurement device

InactiveCN107525464ARealize measurementMeasuring chain shortenedUsing optical meansLinear motionMeasurement device

The invention discloses a two-dimensional laser optical path gear measurement device. The device comprises a main motion shaft system, an optical path tracking and adjustment shaft system, and a laser interferometry system. The main motion shaft system comprises a rotary table and three linear motion shaft systems, moves along a measurement planning path, and executes various operations in the whole measurement process. Three linear motion shafts of the optical path tracking and adjustment shaft system make synchronous movement with the main motion shaft system, thereby guaranteeing that a laser optical path is not cut off and is in a collimation state. The laser interferometry system has X and Z two-dimensional laser wavelength measurement optical paths, is disposed nearby a gear tested point, and can directly measure a plurality of error items of a gear. The device is short in measurement chain, is high in measurement precision, is high in flexibility, and can meet the requirements of direct tracing measurement of gear errors.

Owner:NAT INST OF METROLOGY CHINA

Two-dimensional laser optical path gear measuring device

InactiveCN107525464BRealize measurementMeasuring chain shortenedUsing optical meansLinear motionEngineering

Owner:NAT INST OF METROLOGY CHINA

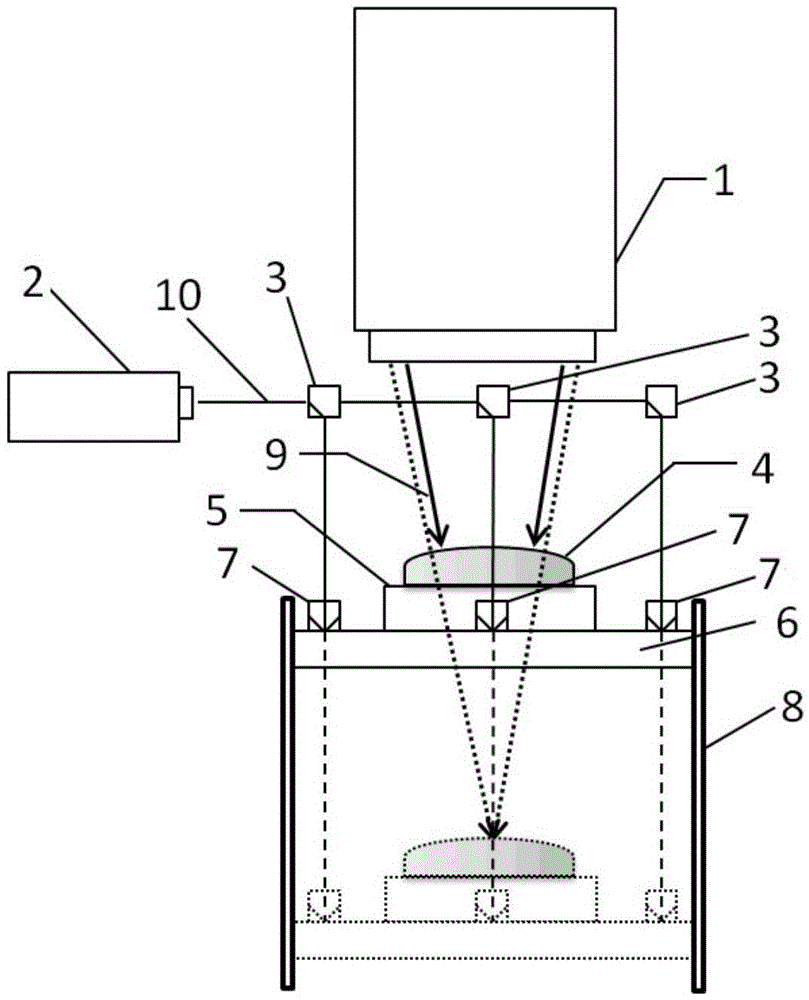

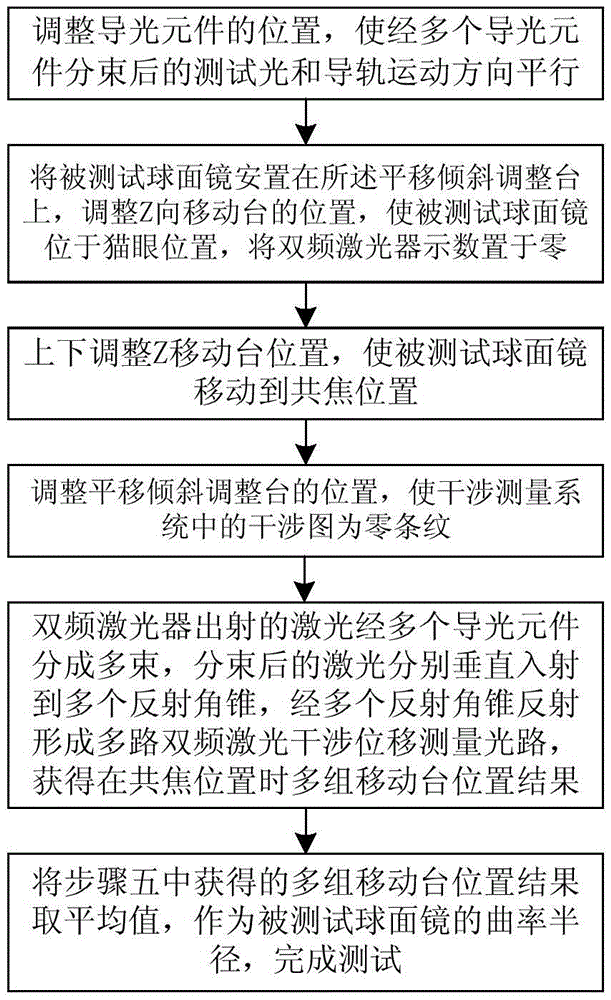

High-precision radius of curvature testing device and method

InactiveCN105571481AAvoid the problem of being scratchedSimple structureUsing electrical meansDual frequencyBeam splitting

The invention belongs to the technical field of optical element geometrical parameter measurement, relates to a high-precision radius of curvature testing device and method, and aims to solve the problem existing in the prior art that a surface of a tested optical element is easy to scratch and submicron-grade detection of uncertainty is difficult to reach. A translation inclination adjusting table is arranged on a Z-direction moving table, any two opposite side walls of the Z-direction moving table are matched with guide rails and slide up and down, a tested spherical mirror is arranged on the translation inclination adjusting table, an upper surface of the Z-direction moving table is uniformly provided with a plurality of reflection pyramids, an upper side vertical position of each reflection pyramid is provided with a light guiding element, light radiated by an interference measurement system is reflected by the tested spherical mirror to form an interference measurement optical path, the interference measurement optical path passes through the interference measurement system and an interferogram is to obtained, laser emitted by a dual-frequency laser is split into multiple beams through the plurality of light guiding elements, laser after beam splitting is vertically incident to the plurality of reflection pyramids, and after reflection by the plurality of reflection pyramids, a dual-frequency laser interference displacement measurement optical path is formed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

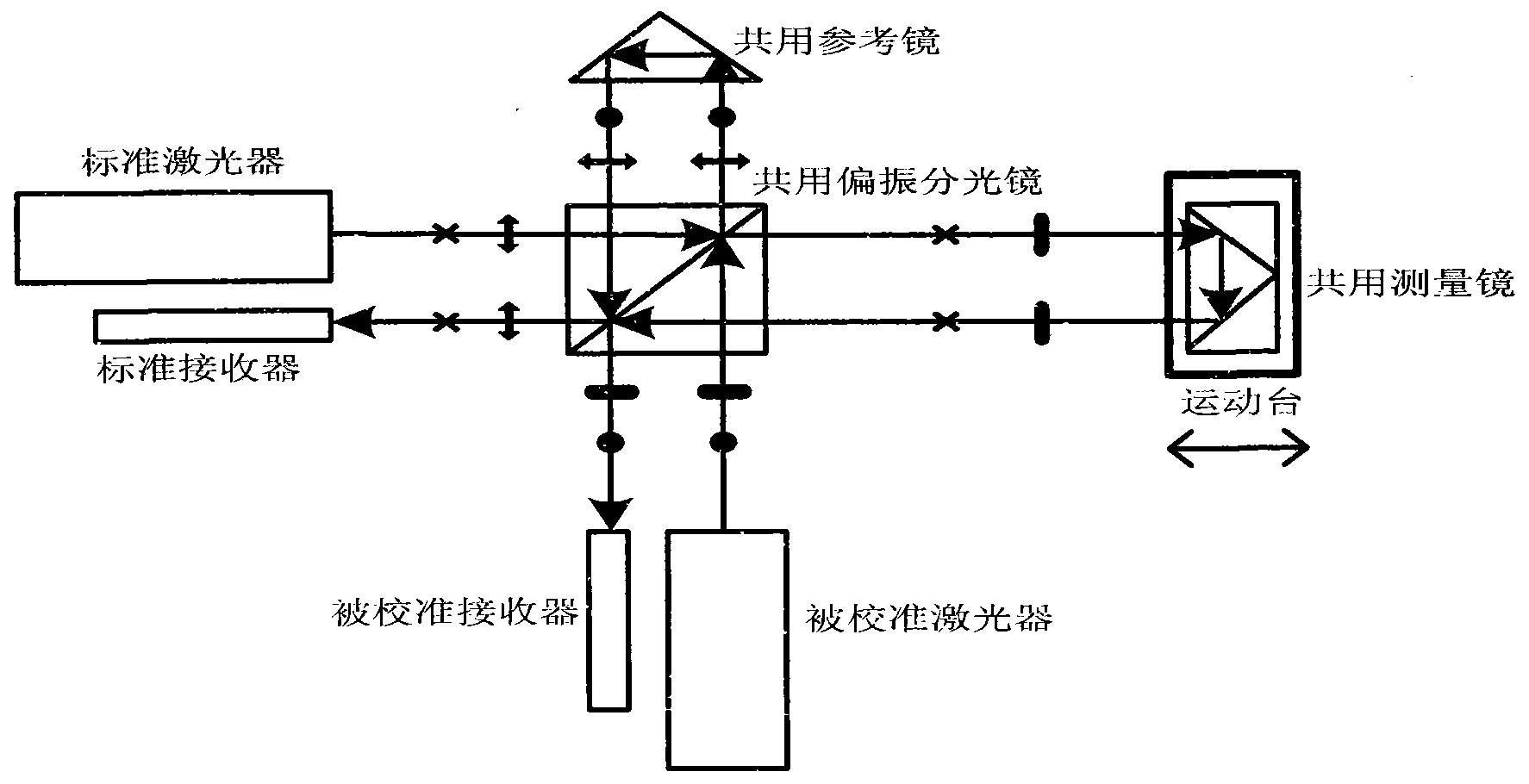

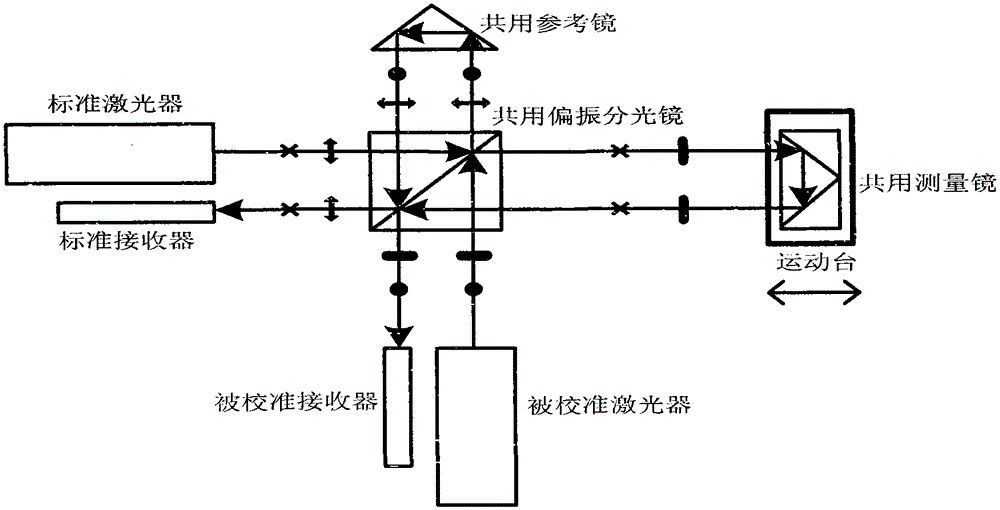

Linear displacement laser interferometer calibration method and device based on two-standard-optical-axis air bath

ActiveCN103499287AAbbe's error is smallShort vertical distanceUsing optical meansLaser interferenceLinear displacement

The invention provides a linear displacement laser interferometer calibration method and a linear displacement laser interferometer calibration device based on a two-standard-optical-axis air bath, and belongs to the technical field of laser measurement. A measuring light beam of a laser interferometer to be calibrated passes through a middle through hole of a two-axis hollow laser interference mirror group, and is parallelly arranged in the center position of two parallel standard measuring light beams; the vertical distance from the standard measuring light beams to the measuring light beam of the laser interferometer to be calibrated is very small, the differences of environment interference degrees of the two standard measuring light beams and the measuring light beam of the laser interferometer to be calibrated are very small, and the air refractive index average value of the two standard measuring light beams is approximate to the air refractive index value of the measuring light beam of the laser interferometer to be calibrated; through the stable air bath environment formed by an air bath device, the air temperature, the humidity and the air pressure are approximate to uniform distribution, so the air refractive index average value of the two standard measuring light beams is more approximate to the air refractive index value of the measuring light beam of the laser interferometer to be calibrated.

Owner:HARBIN INST OF TECH

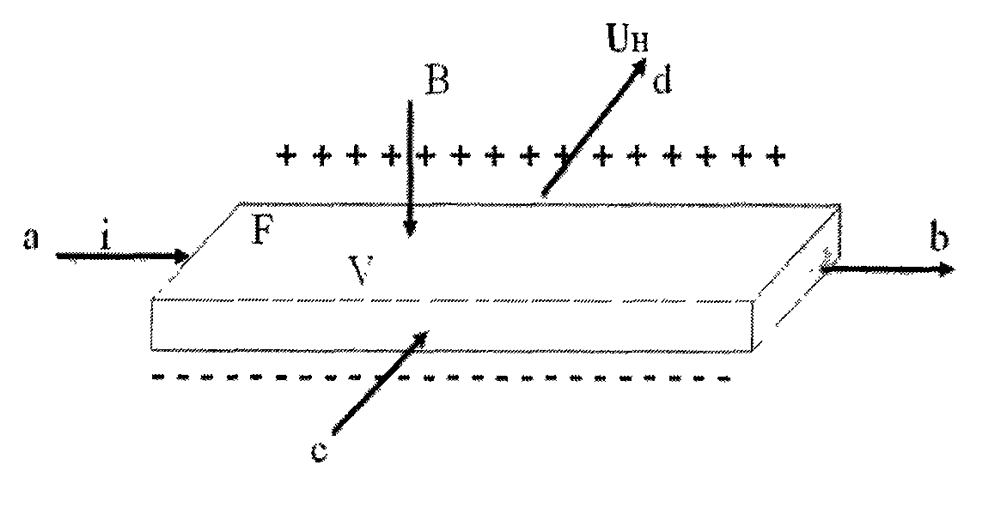

Micro-displacement measurement method and sensing device for dual-workpiece platforms of photoetching machine

InactiveCN102880015AEasy to installImprove linearityUsing electrical meansPhotomechanical exposure apparatusRelative displacementThree dimensional measurement

The invention discloses a micro-displacement measurement method and a sensing device for dual-workpiece platforms of a photoetching machine and belongs to technologies of integrated circuit (IC) manufacturing, ultra precise measurement and ultra precise processing. The measurement method comprises that output Hall voltage signals of a Hall micro-displacement sensor are changed linearly along with the relative displacement of macro and micro dual-workpiece platforms, and an external detection circuit processes and synthesizes output signals of the Hall sensor to finish measurement. The device solves the problems of high-speed high-precision relative position detection of special positions such as a Chuck platform and a mask platform of a photoetching macro and micro dual driving mechanism, the device has the advantages of being free from contacts, good in linearity, high in integration level and high in portable capability, one-dimensional measurement, two-dimensional measurement or three-dimensional measurement can be achieved, and the environmental requirements of a photoetching system can be met.

Owner:HARBIN INST OF TECH

Freeform surface measurement method and device based on datum plane comparison measurement

ActiveCN110057337BImproved scan detection accuracyAbbe's error is smallUsing optical meansEngineeringSurface measurement

The invention discloses a method and a device for measuring a free-form surface based on reference plane comparative measurement, and belongs to the technical field of optical precision detection. Themethod uses the high-precision plane flat crystal as a reference plane of an X-Y surface, utilizes the high-precision height measurement sensor and the free-form surface measurement sensor which arecoaxially installed to detect the high-precision plane flat crystal and the surface height information of the measured free-form surface respectively, utilizes the high-precision height measurement sensor to acquire the surface height information of the high-precision plane flat crystal to monitor and compensate the straightness error of an X-direction air-floatation guide rail and a Y-direction air-floatation guide rail, performs dimension reduction error separation on the surface appearance of the free-form surface, and realizes the nanometer precision detection of the appearance of the free-form surface. The method and the device for measuring the free-form surface based on reference plane comparative measurement can realize the detection of the free-form surface, provide high-precisionthree-dimensional linear positioning and scanning measurement, inhibit the influence of the straightness error of the movement of the X-direction guide rail and the Y-direction guide rail on the measurement of the free-form surface, reduce the influence of the Abbe error of the Z axis on the measurement, and realize the large-range and nanometer precision measurement of the free-form surface.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Linear displacement laser interferometer calibrating method and device based on four-standard light-axis gas bath

The invention discloses a linear displacement laser interferometer calibrating method and device based on a four-standard light-axis gas bath, and belongs to the technical field of laser measurement. Measuring light beams of a calibrated laser interferometer pass through the middle through hole of a four-axle hollow laser interference mirror group; the measuring light beams of the calibrated laser interferometer are arranged in parallel in the centers of four parallel standard measuring light beams which are distributed in the forms of lateral edges of a regular quadrangular prism; the vertical distances between the standard measuring light beams and the measuring light beams of the calibrated laser interferometer are very small; the difference between the environment interference degrees of four standard measuring light beams and the measuring beams of the calibrated laser interferometer is very small; the average value of the refractive indexes of the four standard measuring light beams is close to the air refractive index values of the measuring light beams of the calibrated laser interferometer; a stable gas bath environment is formed by a gas bath device, so that the air temperature, moisture and air pressure are uniformly distributed approximately, and the average value of the air refractive indexes of the standard measuring light beams are even closer to the air refractive index values of the measuring light beams of the calibrated laser interferometer.

Owner:HARBIN INST OF TECH

Cam measuring device and cam measuring method based on laser interference principle

PendingCN111895910ARealize measurementStrong independenceUsing optical meansBeam splitterPlane mirror

The invention discloses a cam measuring device and cam measuring method based on a laser interference principle. The cam measuring device comprises a micrometer probe, an XZ-axis movement device and alaser device. The micrometer probe is installed on the XZ-axis movement device and moves along the X axis or the Z axis. A measuring ball of the micrometer probe is contacted with the surface of a cam; the laser device emits laser interference length measurement double light paths, and a laser beam is divided into an X light path and a Z light path through a spectroscope; the X light path is received by a pyramid mirror I after being reflected by a plane mirror, and the reflected X light path received by the pyramid mirror I is parallel to the axial direction of a measuring rod; the Z light path is received by a pyramid mirror II, and the reflected Z light path received by the pyramid mirror II is perpendicular to the axial direction of the measuring rod; and the pyramid mirror I and thepyramid mirror II are both arranged on a measuring rod of the micrometer probe. Laser interference length measurement is adopted as a measurement standard, grating ruler length measurement is replaced, abbe errors in the measurement process are greatly reduced, and arrangement of a light path is suitable for measurement of various cams.

Owner:NAT INST OF METROLOGY CHINA

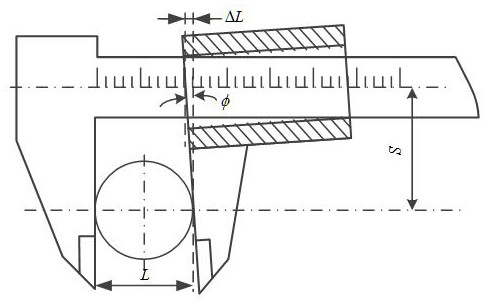

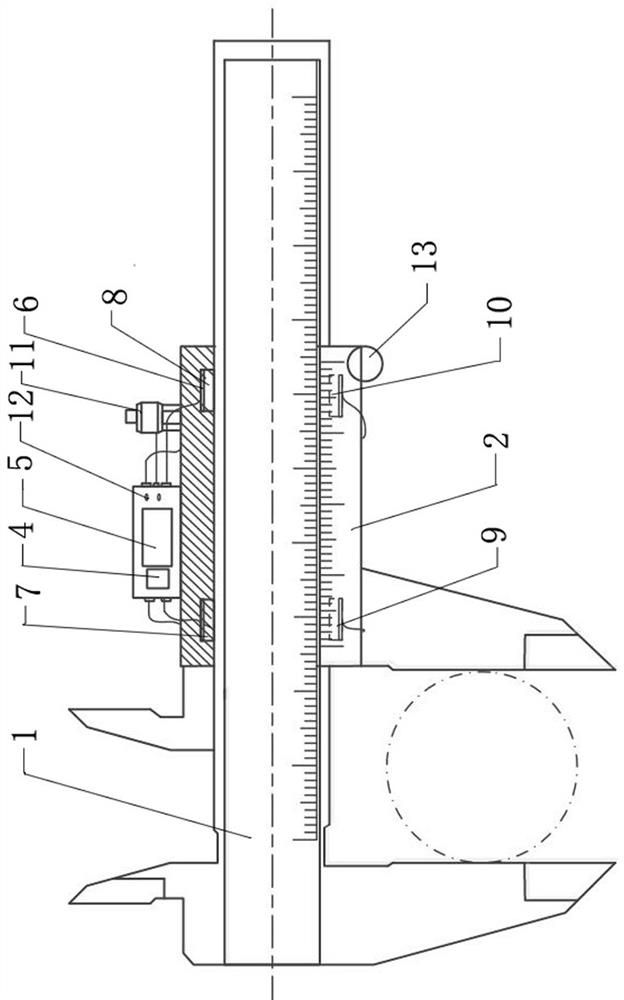

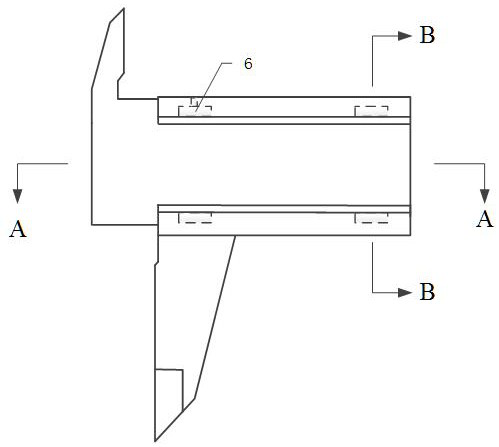

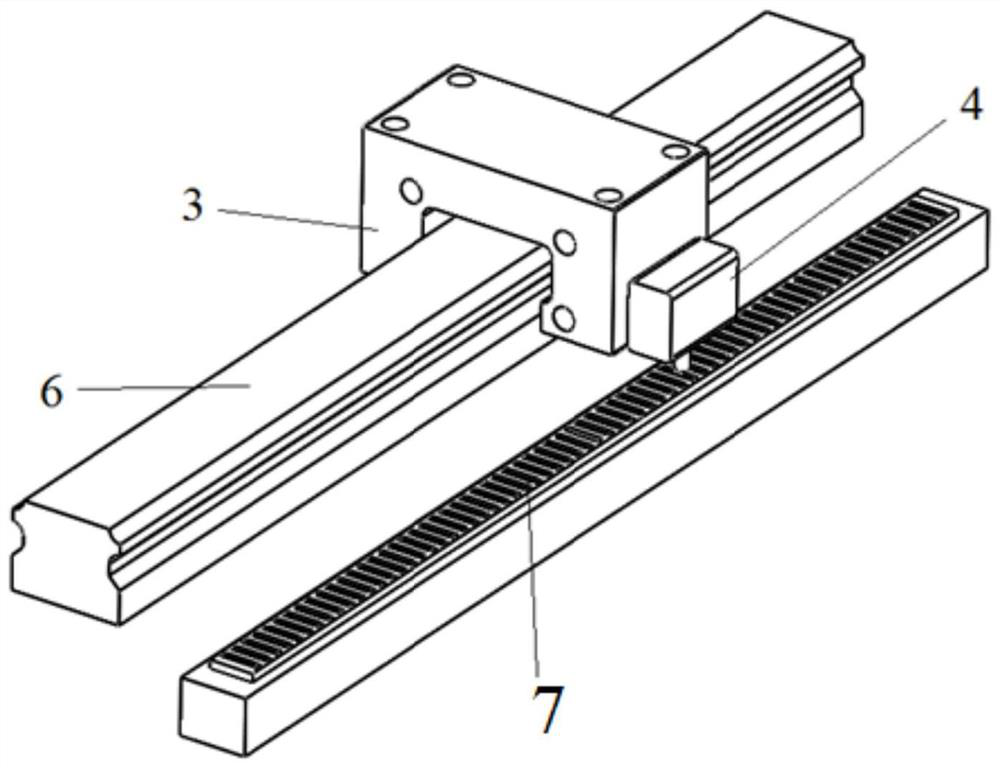

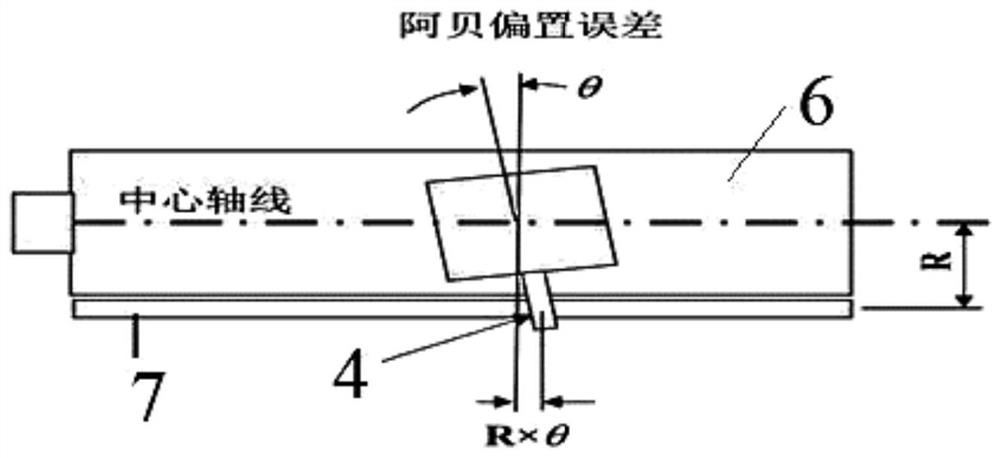

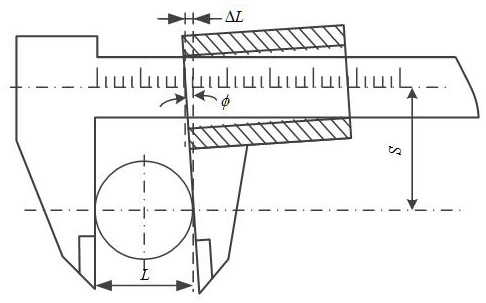

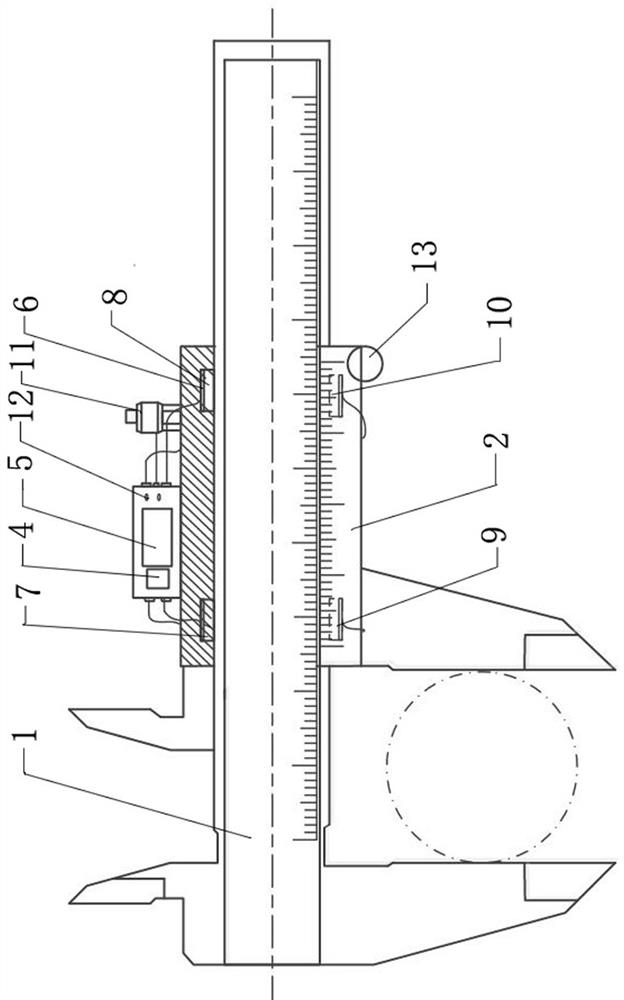

Vernier caliper capable of effectively reducing Abbe error and measuring method

ActiveCN112857165AReduce or eliminate tiltGuaranteed parallelSlide gaugesApparatus for force/torque/work measurementVernier scaleDisplay device

The invention provides a vernier caliper capable of effectively reducing the Abbe error and a measuring method. The vernier caliper comprises main rulers and a vernier scale, the upper end and the lower end of the front side face of the vernier scale are each provided with a flange to form a main ruler containing groove, the main rulers are arranged in the main ruler containing grooves, the vernier scale is in sliding connection with the main scale, pressure sensors are symmetrically arranged in the main ruler containing grooves in the upper end and the lower end in the front-back direction, the pressure sensing devices are used for collecting pressure signals generated by the main rulers on the vernier scale, the signal output ends of the pressure sensing devices are connected with the signal input end of a processing module, and the signal output end of the processing module is connected with a display device; and the processing module is used for receiving pressure signals input by the pressure sensing devices, processing the pressure signals and then calculating to obtain a differential pressure signal value for representing the parallelism of the main line of the vernier scale and the main lines of the main rulers. The vernier caliper can solve the problems that an existing vernier caliper is large in Abbe error and low in measurement precision in the using process.

Owner:HENAN POLYTECHNIC UNIV

A device and method for synchronously measuring guide rail line displacement and straightness in situ

ActiveCN111735393BAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronously measuring the line displacement and straightness of a guide rail in situ. The integrated two-dimensional grating guide rail is to etch the two-dimensional grating on the upper surface of the linear guide rail, and the reading head is embedded in the slide block. The specific measurement method is as follows: when the slider moves on the guide rail, the reading head outputs two pairs of orthogonal sinusine and cosine signals at the same time, and after filtering and analog-to-digital conversion, it is transmitted to the host computer through the acquisition card, and the edge is counted by high-frequency pulses. Methods Calculate the displacement and straightness on the host computer; the linear displacement of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the x-axis, and the straightness of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the y-axis. The invention has the advantages of small installation volume of the guide rail pair, high positioning accuracy, multi-parameter synchronous on-site measurement, etc., and provides a new method for the displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

Reset compensation type three-optical-axis linear displacement laser interferometer calibration method and device

ActiveCN103499280BShort vertical distanceAbbe's error is smallUsing optical meansOptical axisRefractive index

Owner:HARBIN INST OF TECH

Calibration device and calibration method for a pull-wire displacement sensor

ActiveCN111288947BHigh degree of integrationEasy to operateMeasurement devicesTransducer calibrationPulley

The invention discloses a cable-type displacement sensor calibration device and a calibration method. The cable-type displacement sensor calibration device includes a linear guide rail, a laser interferometer slide table, a spindle slide table and a spindle slide table slidably arranged on the linear guide rail in sequence. A pull-wire displacement sensor slide, the laser interferometer slide is provided with a laser interferometer, the spindle slide is provided with a spindle, and the pull-wire displacement sensor slide is provided with a calibrated pull-wire displacement sensor, The pull-wire displacement sensor calibration device includes a first induction wire calibration fine-tuning sleeve, a second induction wire calibration fine-tuning sleeve, an induction wire calibration fine-tuning plate and a handle for fixing the starting end of the induction wire of the pull-wire displacement sensor. Induction wire fixing element. The wire displacement sensor calibration device aims to solve the technical problems of inconvenient clamping, small measuring range, large Abbe error and poor safety caused by the calibration scheme of the wire displacement sensor in the prior art.

Owner:HUNAN INST OF METROLOGY & TEST

Four-optical axis compensation and air bath type linear displacement laser interferometer calibration method and device

ActiveCN103528505AAbbe's error is smallGuaranteed accuracyUsing optical meansLaser interferenceLinear displacement

The invention discloses a four-optical axis compensation and air bath type linear displacement laser interferometer calibration method and a four-optical axis compensation and air bath type linear displacement laser interferometer calibration device, and belongs to the technical field of laser measurement. Measurement light beams of a calibrated laser interferometer penetrate through a middle through hole of a four-axis hollow laser interference mirror group, and are arranged in parallel at the central positions of four parallel standard measurement light beams which are distributed as side edges of a regular triangular prism; the standard measurement light beams are at short perpendicular distances away from the measurement light beams of the calibrated laser interferometer, and an average air refractivity value of the four standard measurement light beams is approximate to air refractivity values of the measurement light beams of the calibrated laser interferometer; air temperature, air humidity and air pressure in a stable air bath environment formed by an air bath device are approximately uniformly distributed, so that the average air refractivity value of the four standard measurement light beams is more approximate to the air refractivity values of the measurement light beams of the calibrated laser interferometer; a measurement error caused by the surface appearance of the reflecting surface of a target reflector is compensated into a linear displacement measurement result to ensure the accuracy of a linear displacement measurement value.

Owner:哈尔滨超精密装备工程技术中心有限公司

A vernier caliper capable of effectively reducing Abbe error and its measuring method

ActiveCN112857165BReduce or eliminate tiltGuaranteed parallelSlide gaugesApparatus for force/torque/work measurementVernier scaleDisplay device

The invention discloses a vernier caliper capable of effectively reducing Abbe errors and a measuring method, which comprises a main ruler and a vernier ruler. The upper and lower ends of the front side of the vernier ruler are provided with flanges to form a main ruler accommodating groove, and the main ruler is arranged on the main ruler. The vernier scale is slidingly connected with the main scale in the scale accommodation groove, and pressure sensors are arranged symmetrically along the front and rear directions in the main scale accommodation grooves at the upper and lower ends. The pressure sensing device is used to collect the pressure signal generated by the main scale against the vernier scale. The signal output end of the pressure sensing device is connected to the signal input end of the processing module, and the signal output end of the processing module is connected to a display device; the processing module is used to receive the pressure signal input by the pressure sensing device, and perform signal processing on the pressure signal before calculating The differential pressure signal value used to represent the parallelism between the main line of the vernier scale and the main line of the main scale is obtained. The invention can solve the problems of large Abbe error and low measurement accuracy in the use process of the existing vernier caliper.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com