High-precision radius of curvature testing device and method

A technology of radius of curvature and testing equipment, which is applied in the direction of measuring equipment, electrical equipment, instruments, etc., can solve the problems of easy scratches on the surface of the tested optical components, difficult detection uncertainty, etc., to reduce the error of the non-sensing area, Avoid being scratched and reduce the effect of empty stroke error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

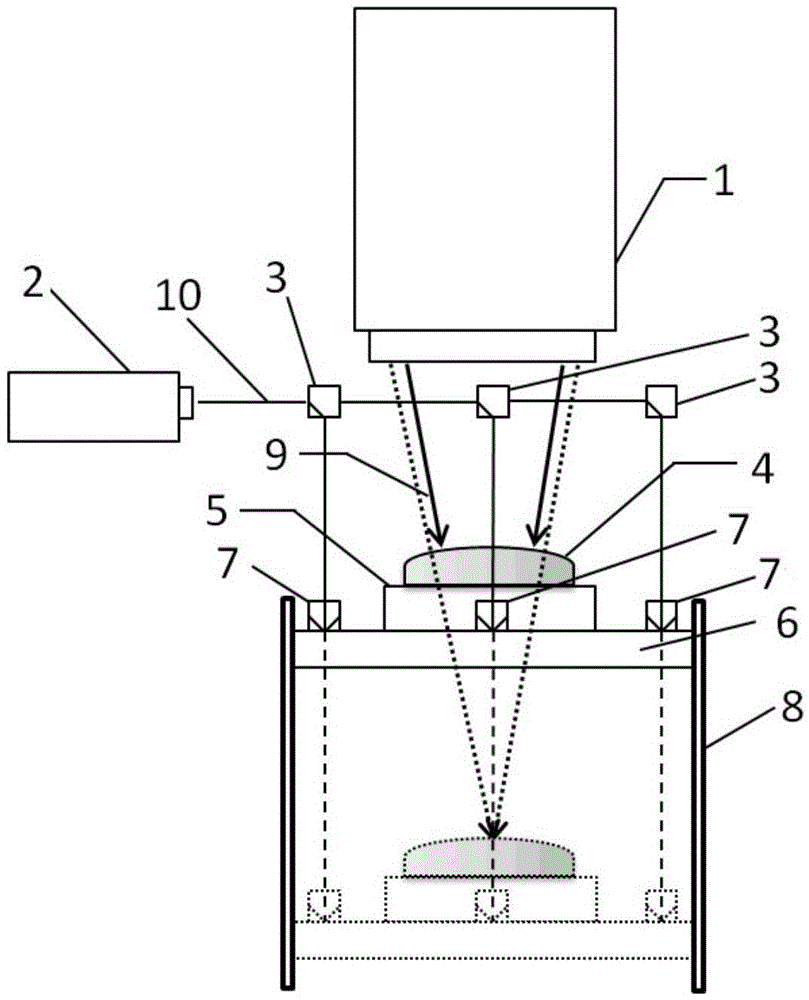

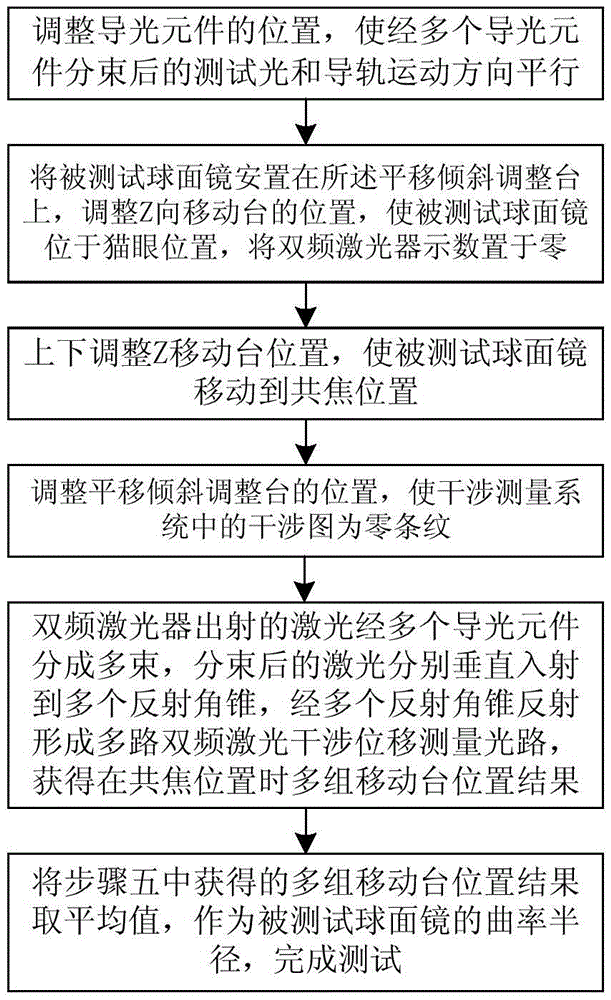

[0023] See attached figure 1 , a high-precision curvature radius testing device of the present invention includes an interferometric system 1, a dual-frequency laser 2, a light guide element 3, a translation tilt adjustment table 5, a Z-direction mobile table 6, a reflection pyramid 7 and a guide rail 8;

[0024] The translation and inclination adjustment table 5 is arranged on the Z-direction mobile table 6, and any two opposite side walls of the Z-direction mobile table 6 slide up and down in cooperation with the guide rail 8, and the tested spherical mirror 4 is arranged on the translation table 6. On the tilt adjustment table 5, three reflective pyramids 7 are uniformly arranged on the upper surface of the Z-direction mobile platform 6, and a light guide element 3 is arranged at a vertical position above each reflective pyramid 7, and the light radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com