Patents

Literature

38results about How to "Realize fully automatic calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

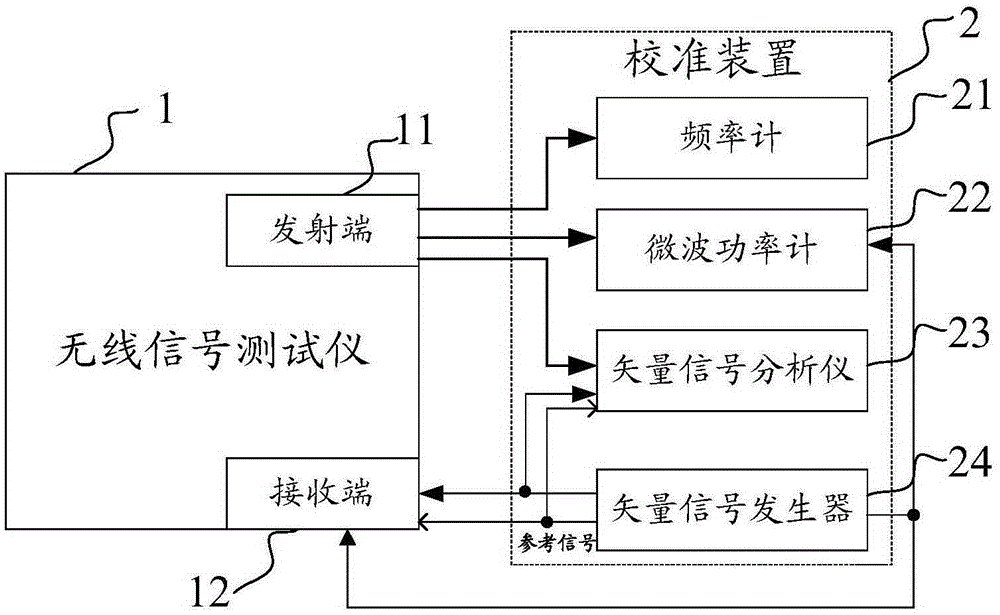

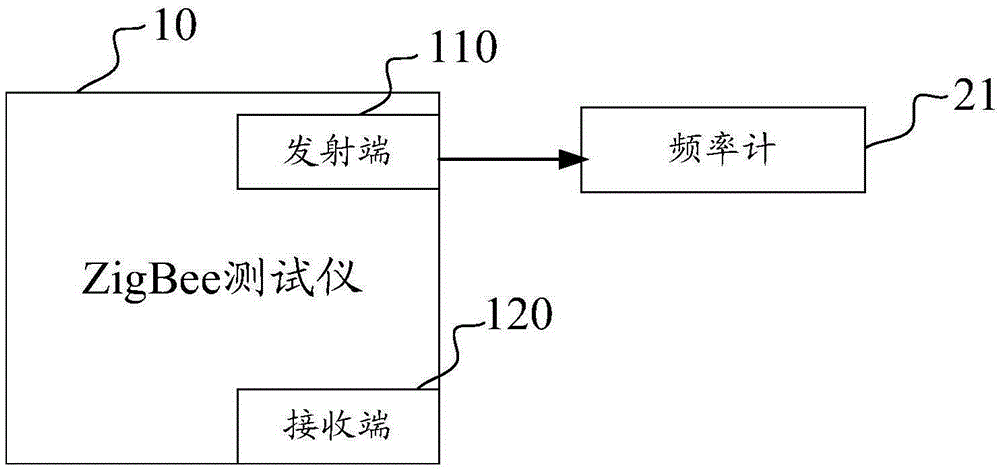

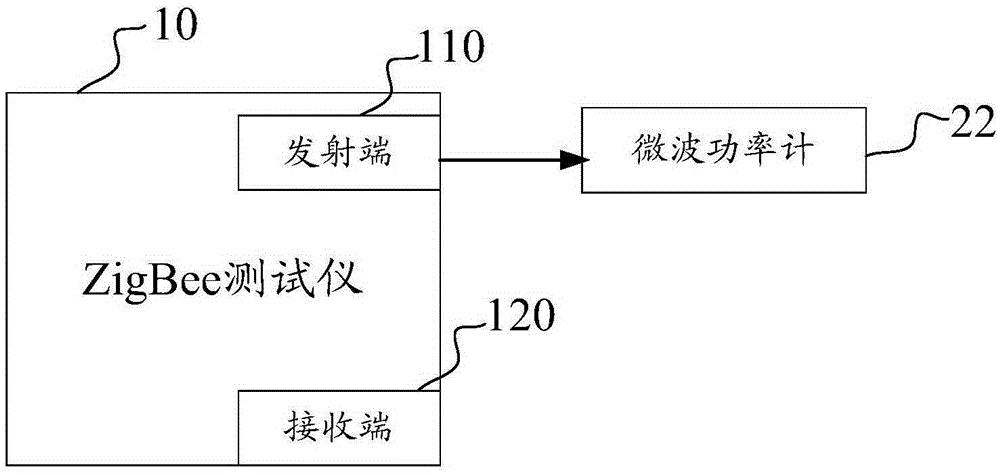

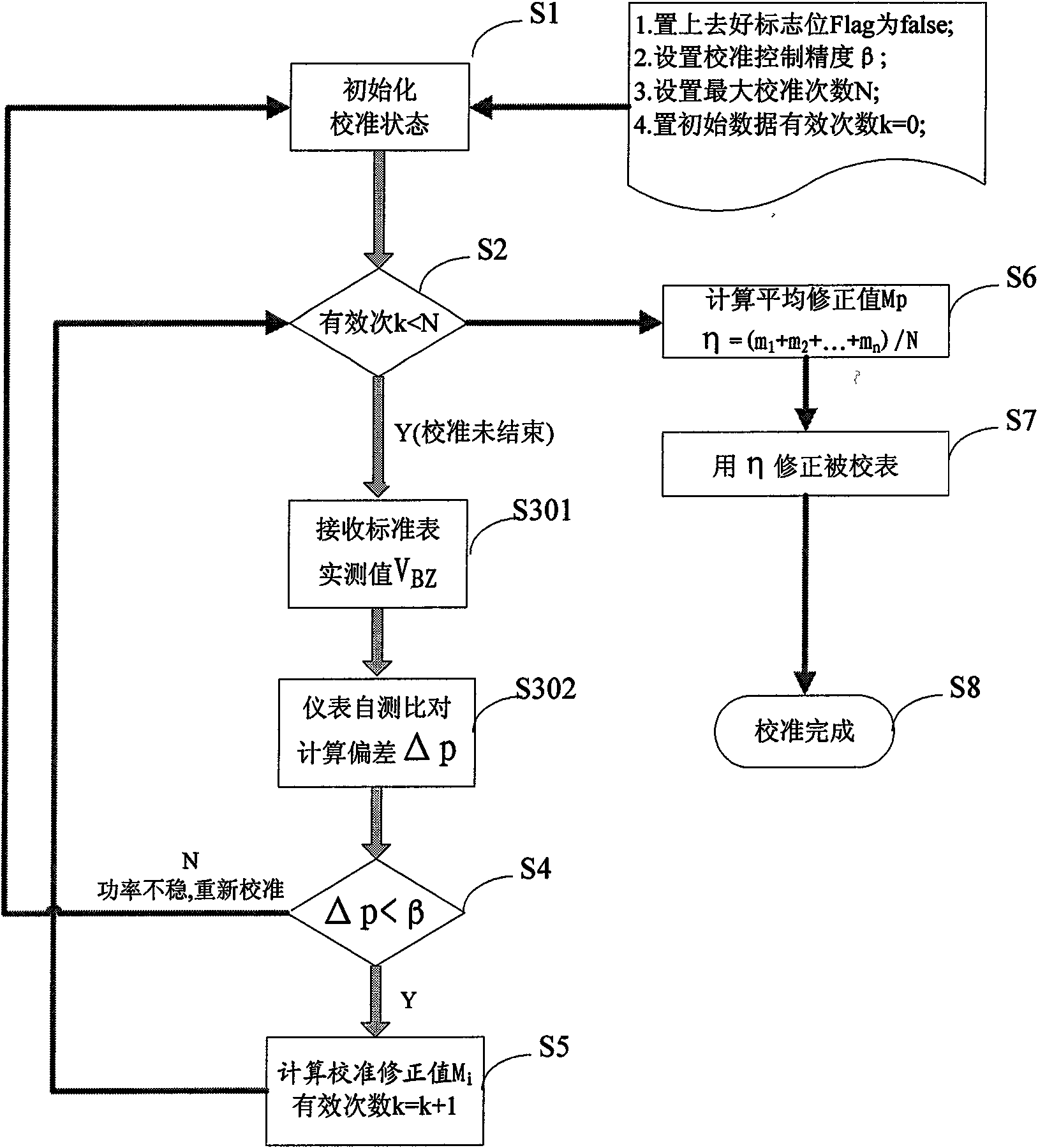

Wireless signal tester calibration device and method, and automatic testing system and method

InactiveCN105262551ARealize fully automatic calibrationGuaranteed reliabilityTransmitters monitoringReceivers monitoringTester deviceEngineering

The invention provides a wireless signal tester calibration device and a method. A frequency meter is used for calibration of an output frequency of output signals of the wireless signal tester; a microwave power meter is used for calibration of output power of output signals of the wireless signal tester; a vector signal analyzer is used for EVM calibration of output signals of the wireless signal tester; a vector signal transmitter and the microwave power meter are used for calibration of power measurement of the wireless signal tester; the vector signal transmitter and the vector signal analyzer are used for calibration of EVM measurement of the wireless signal tester; and thus, reliability of performance test on the corresponding wireless transmitting and receiving equipment by using the wireless signal tester can be ensured. The invention also provides an automatic testing system and a method. The calibration device of the invention can be used for carrying out automatic calibration on the wireless signal tester, and the wireless signal tester after calibration is used for automatically testing to-be-tested wireless equipment.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

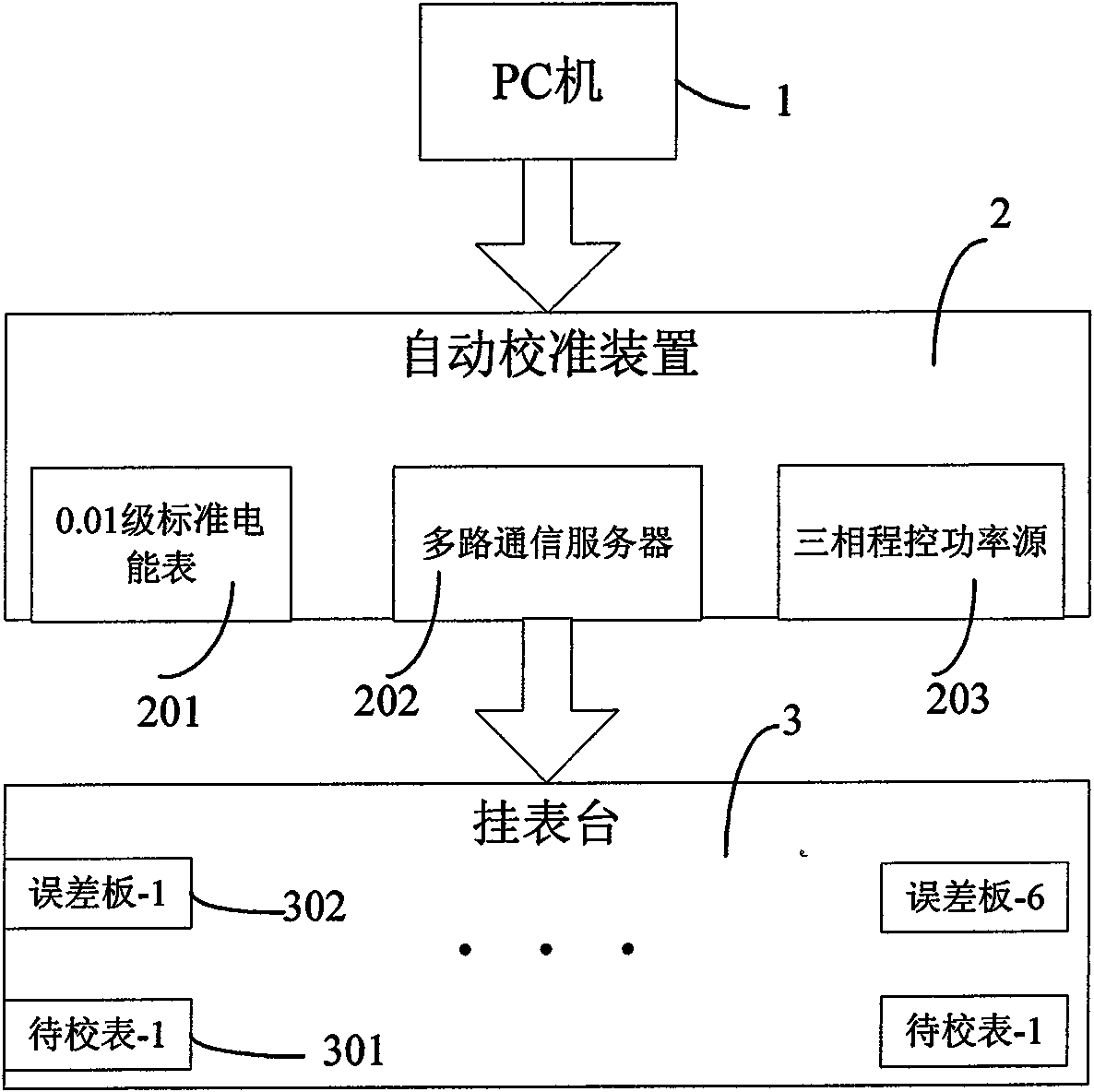

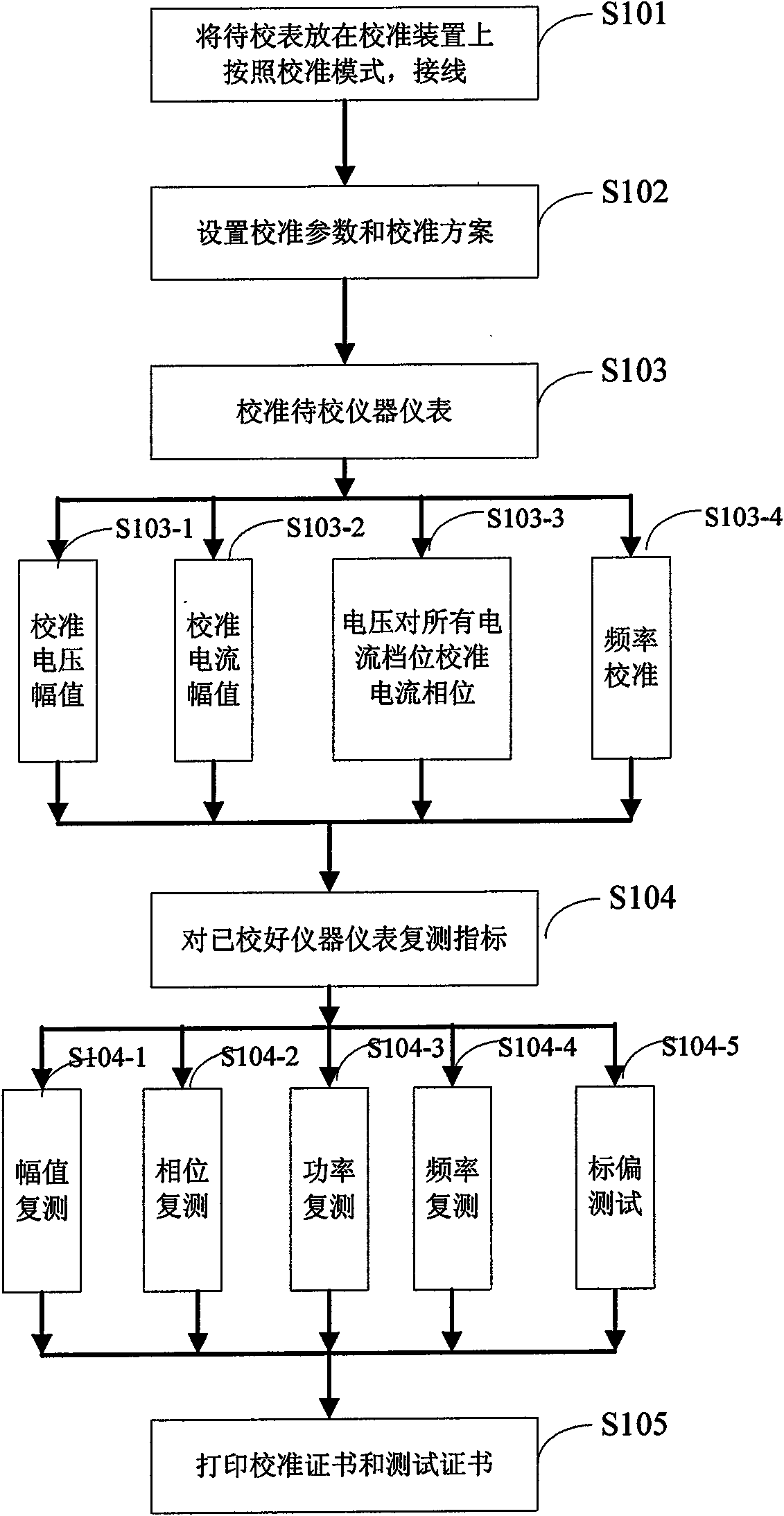

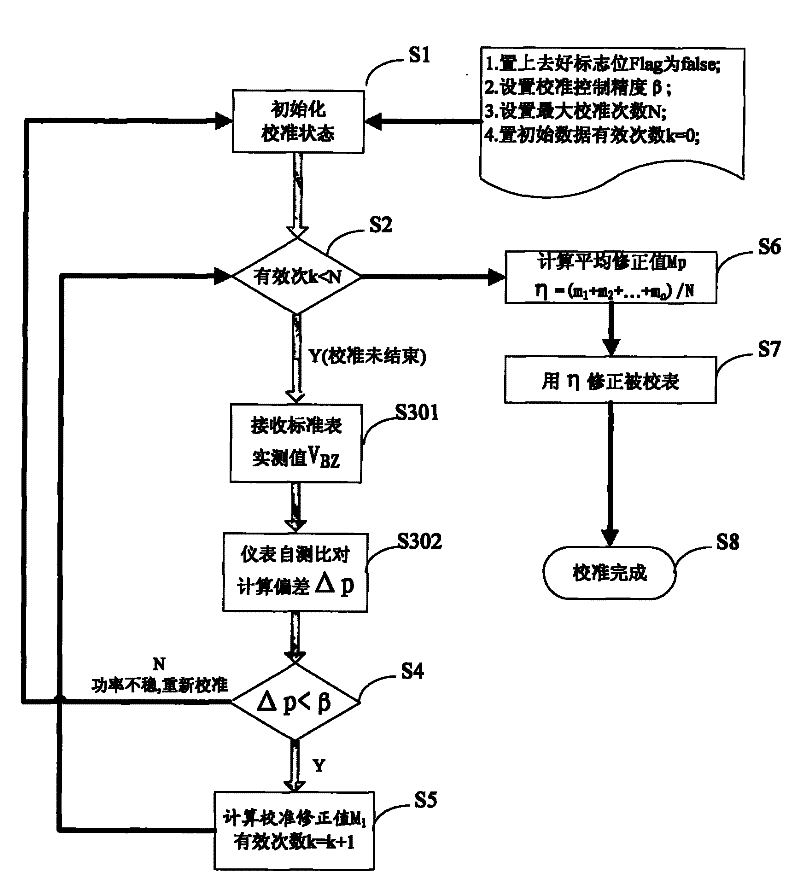

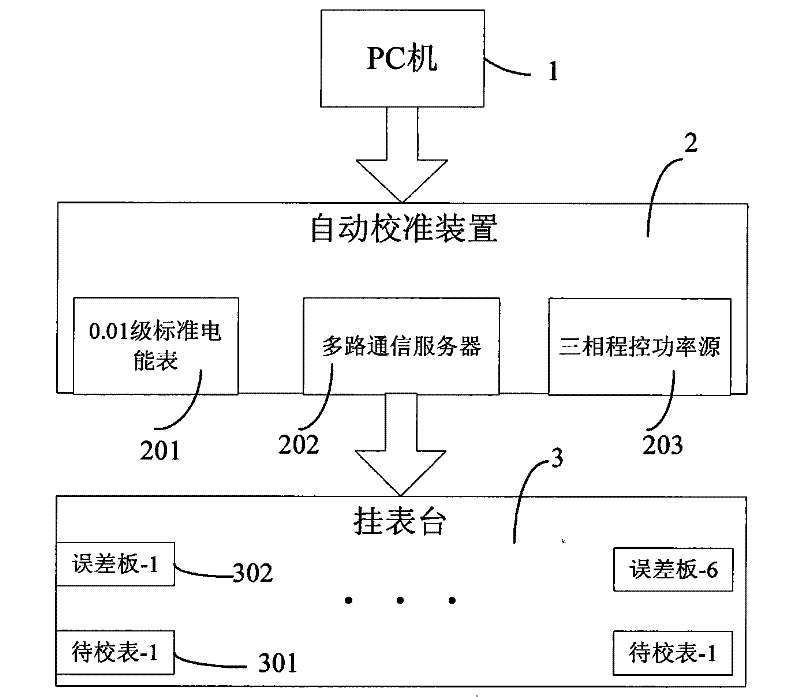

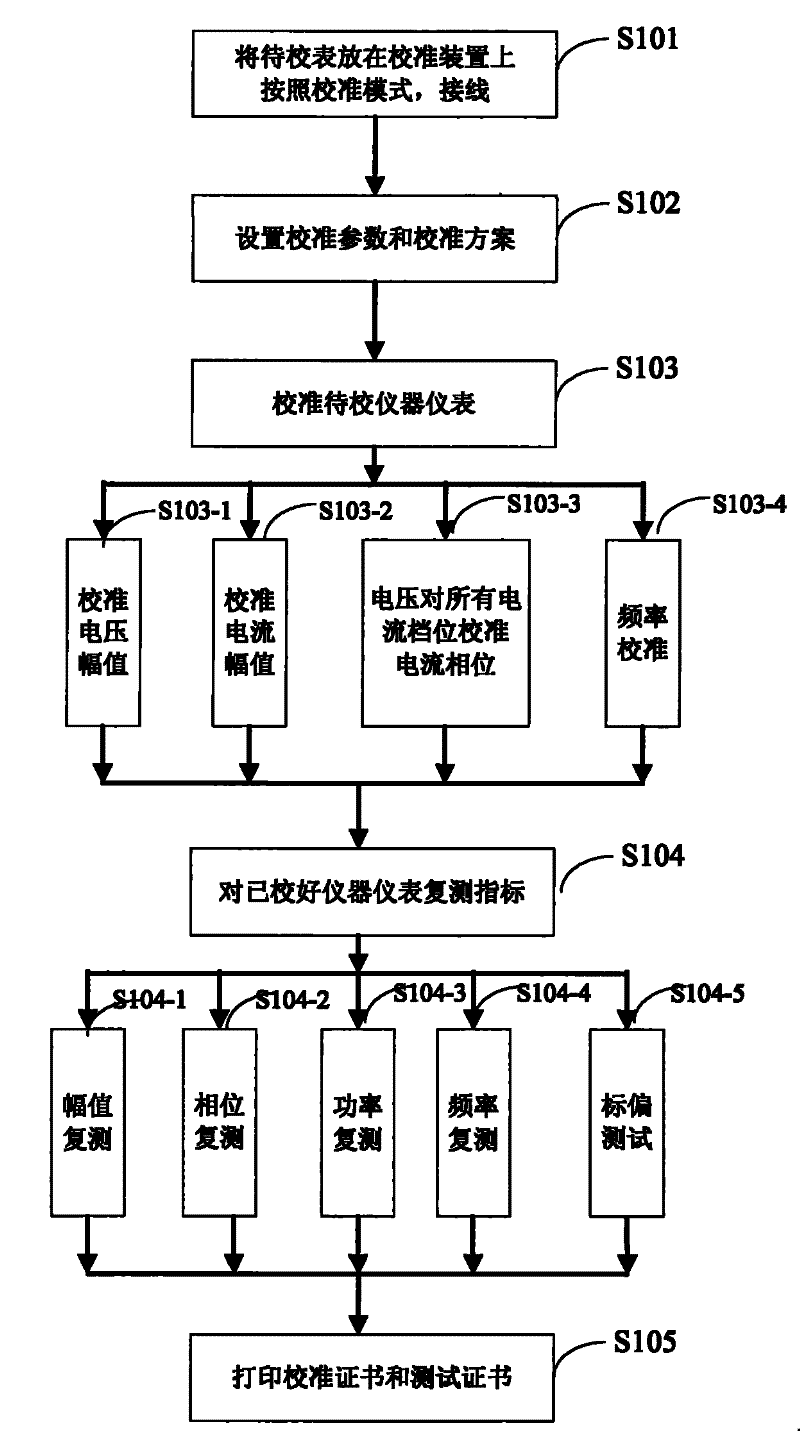

Method and system for automatically calibrating electrical instrument

InactiveCN101592717AShorten the production cycleReduce workloadElectrical measurementsEngineeringElectric power

The invention provides a method and a system for automatically calibrating an electrical instrument. The system comprises a PC, an automatic calibration device controlled by the PC and an instrument hanging table for fixing the instrument to be calibrated. The PC sets a calibration proposal, controls the calibration device to calibrate calibrated instruments synchronously, and controls the calibration device to automatically retest the amplitude, phase, power, frequency and electrical error of the calibrated instrument, automatically store test data and generate test report after the calibration is finished. The method and the system solve the problem of the prior art of low instrument calibration precision and complex calibration process, realize automatic calibration and retest of the high-precision electrical instrument, ensure calibration precision and improve production efficiency.

Owner:SHENZHEN CLOU ELECTRONICS

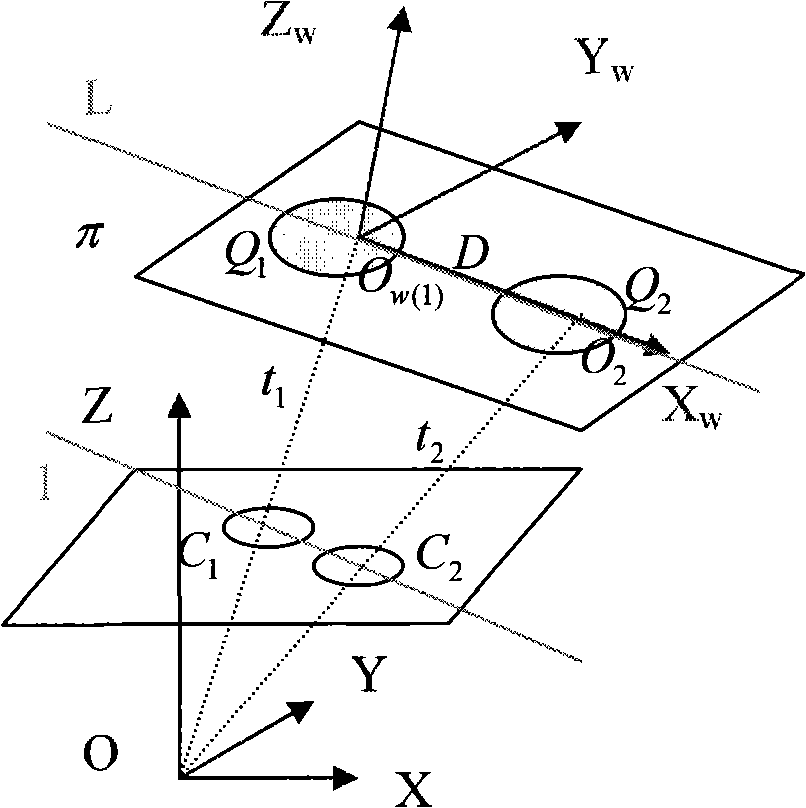

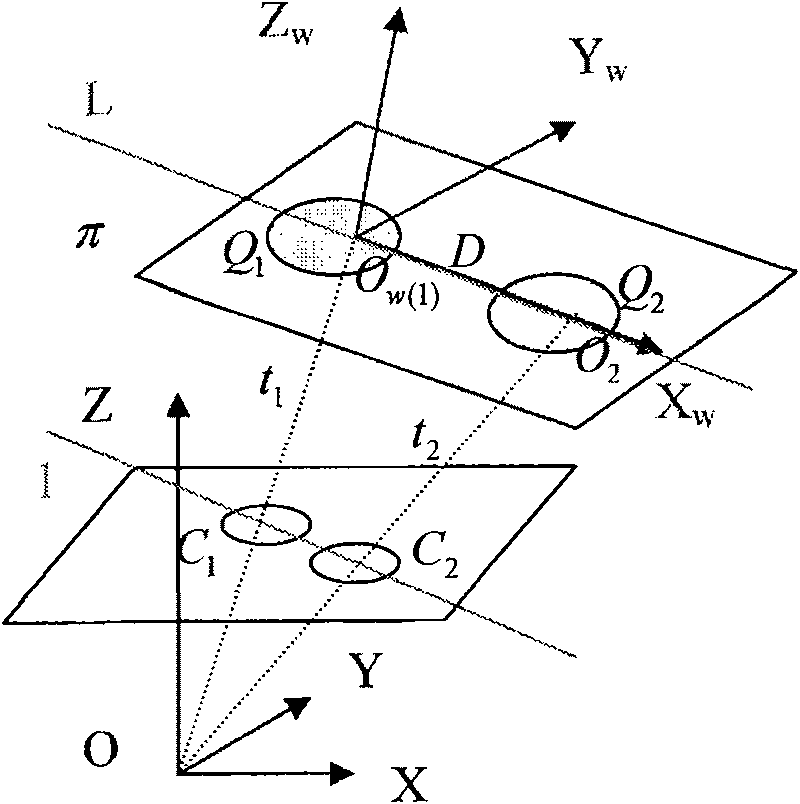

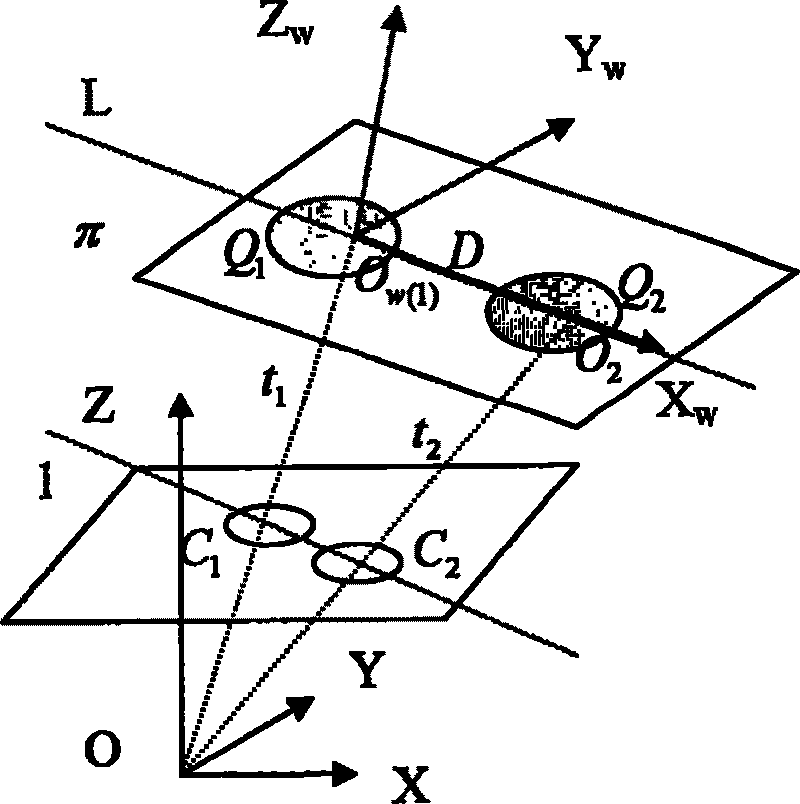

Method for positioning video camera using two arbitrary coplane circles

InactiveCN101329764AEasy CalibrationRealize fully automatic calibrationImage analysisAutonomous Navigation SystemEllipse

The invention relates to a method for calibrating a camera by any two coplanar circles, and two non-concyclic centre coplanar circles are used as the calibration objects. A clear image is taken by the camera for the calibration objects, to define the equations of two elliptical shadows in the images and solve the coordinates of the image points of the focoids. The image point coordinates of the focoids and the shadow equations of absolute secondary curves are utilized to define the focal distance of the camera; a world coordinate system is set up, with the center of any of the two circles as the origin, and Z axis is parallel with the normal direction of the plane of the two circles. A rotation matrix is defined according to the relation between blanking points, blanking lines and the elliptical shadows; the solved position, of the world coordinate system, under the camera coordinate system is the right translation vector. The method of the invention can easily and conveniently define all variable parameters every time when the camera is calibrated, can realize the wholly automatic calibration, reduce calculation errors arisen by human intervention, and is particularly suitable for non-contact industrial inspection and the vision-based independent navigation system.

Owner:SHANGHAI JIAO TONG UNIV

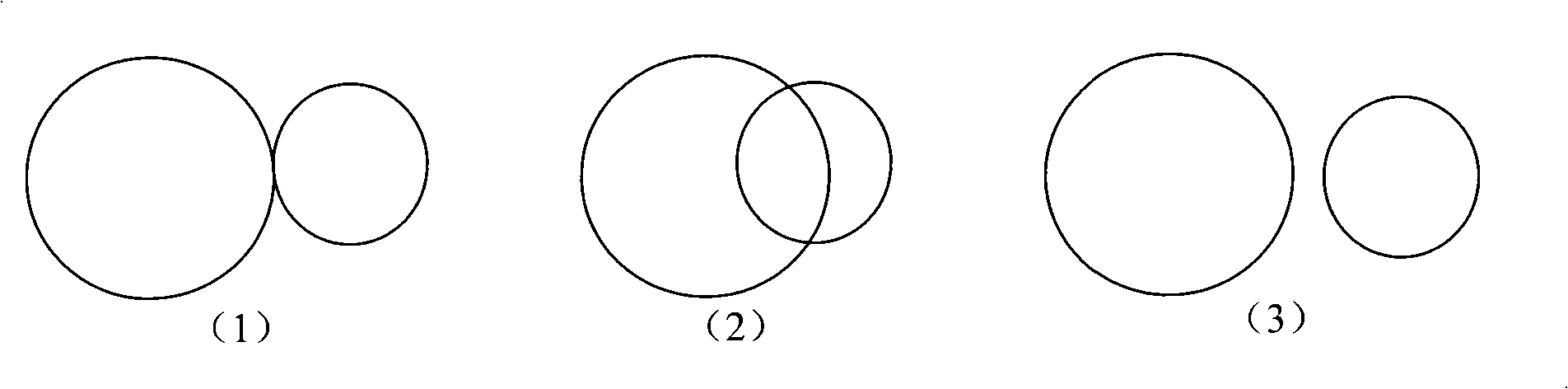

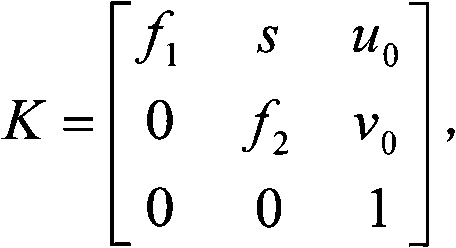

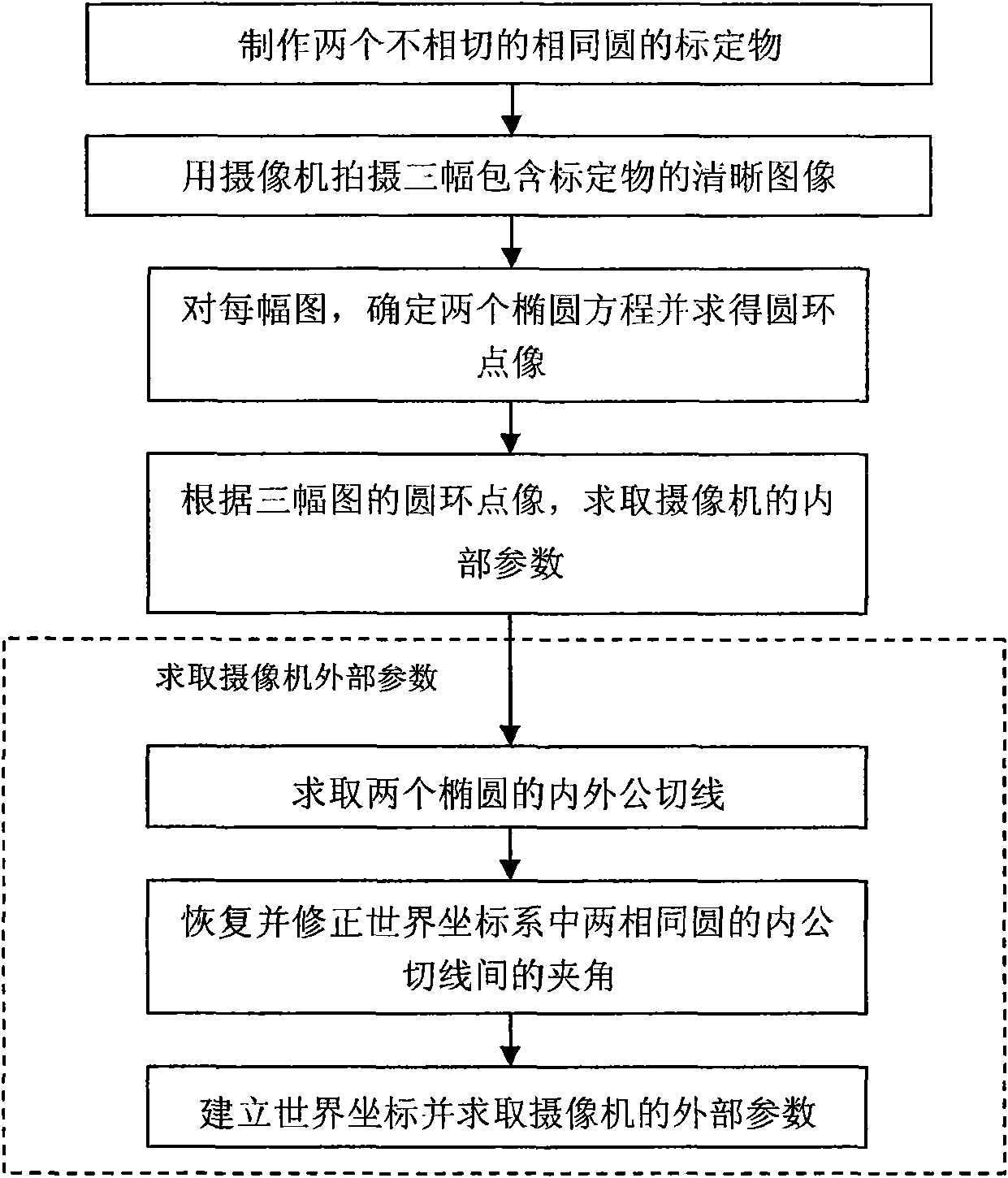

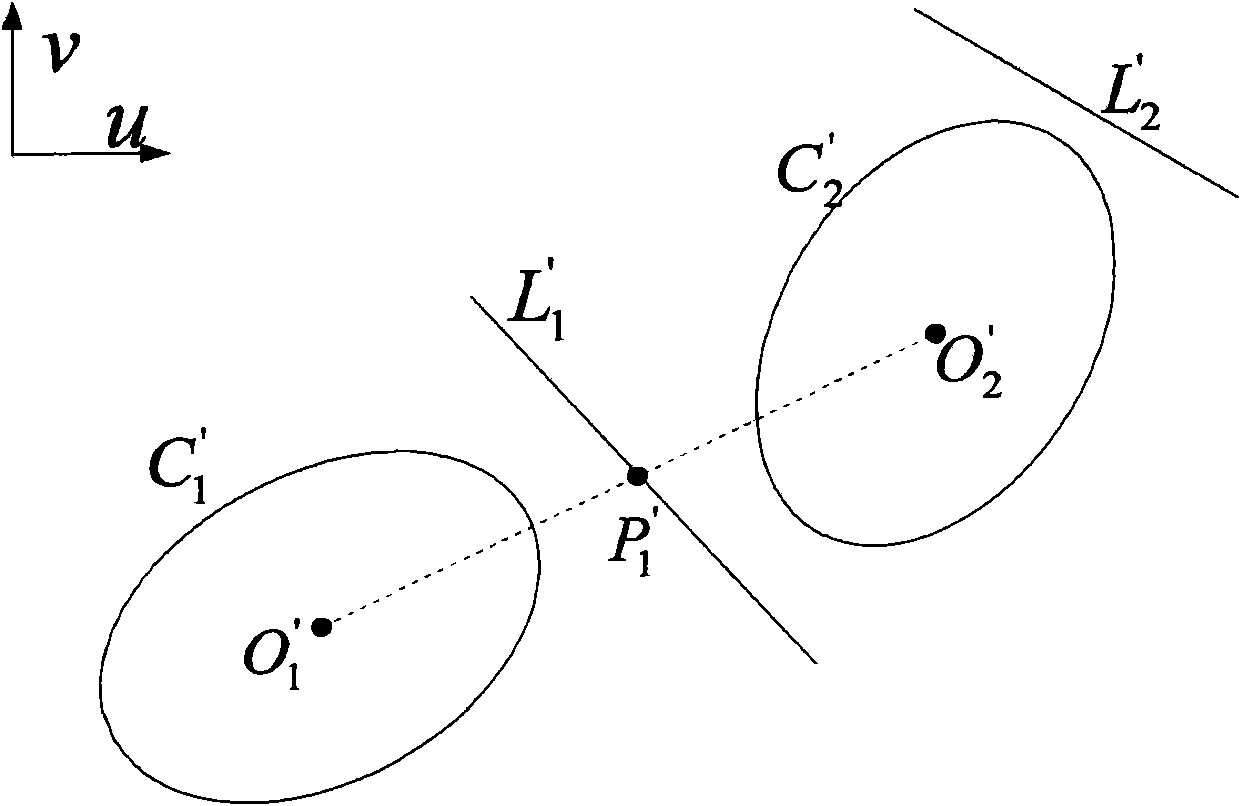

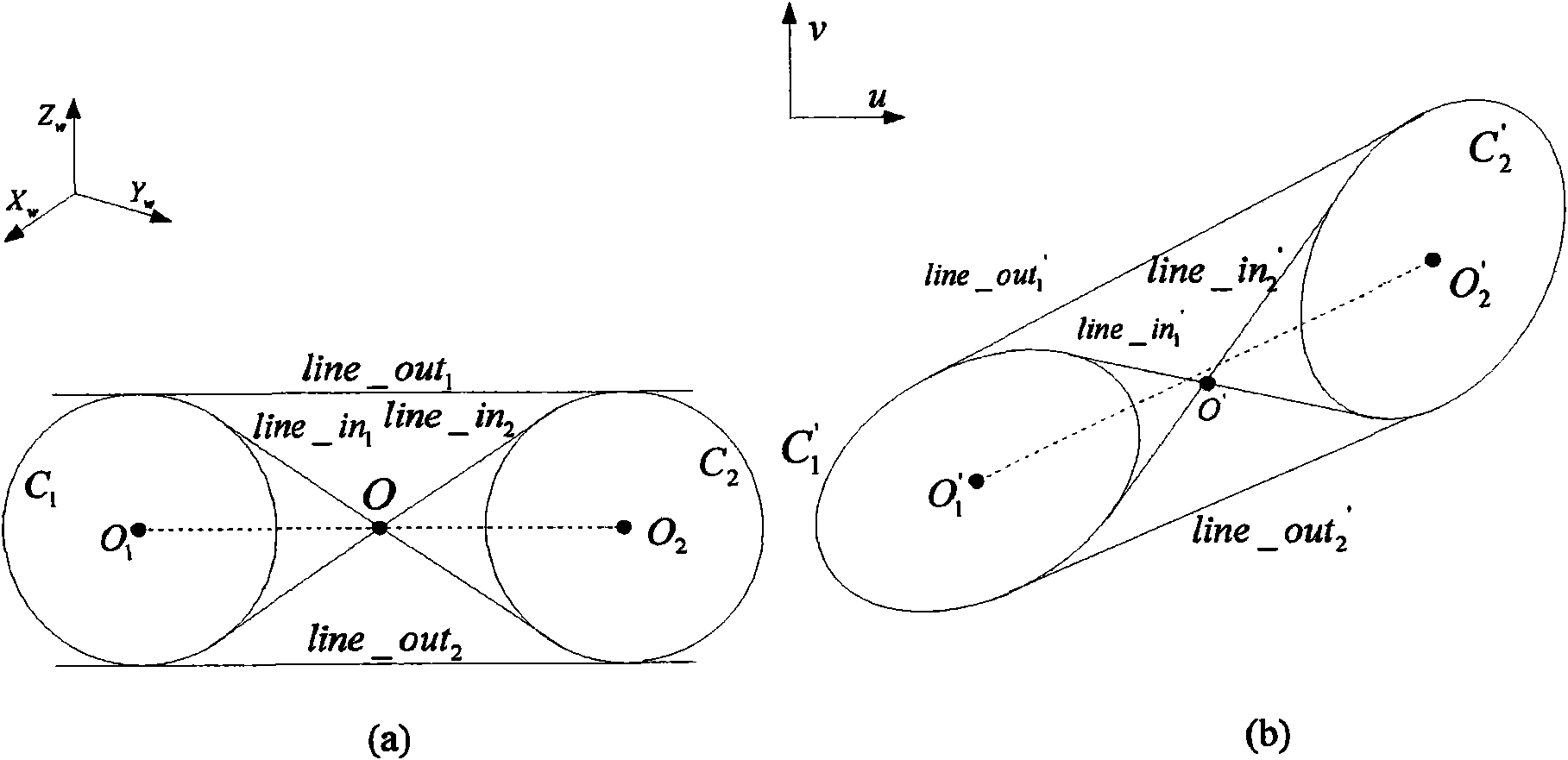

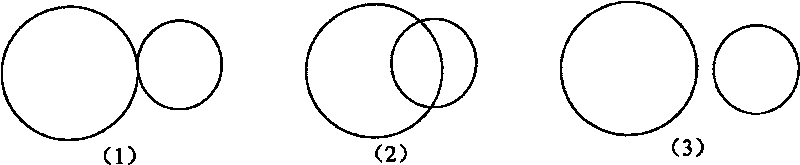

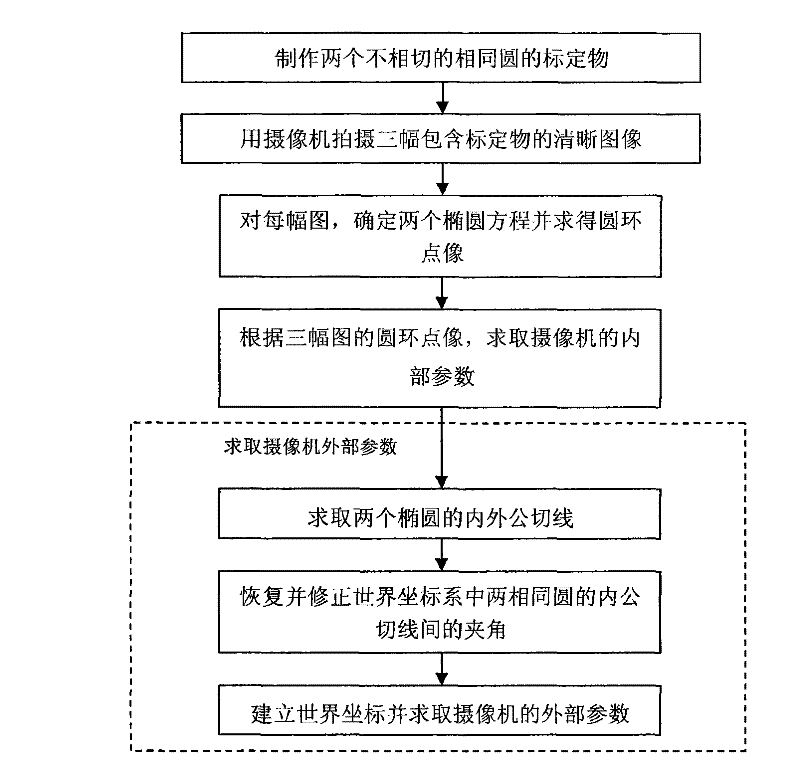

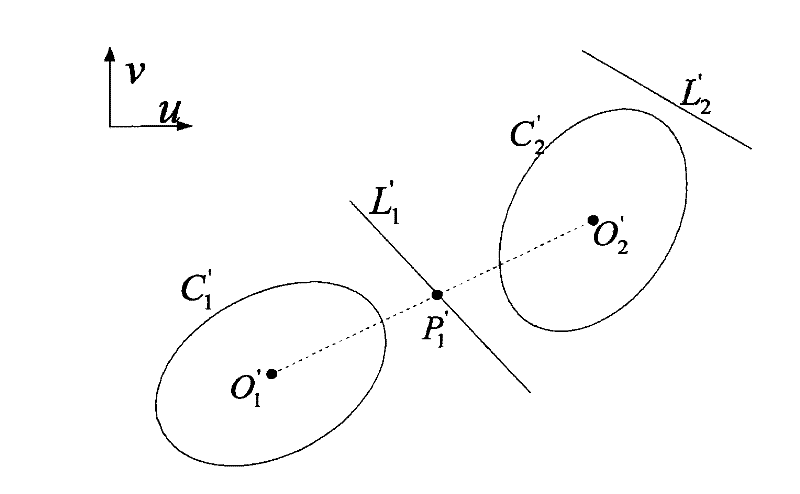

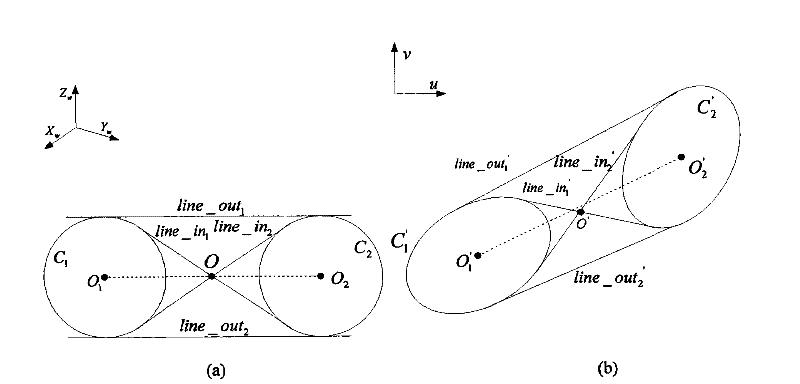

Method for calibrating camera by adopting two same circles

The invention relates to a method for calibrating a camera by adopting two same circles, which comprises the following steps: utilizing two non-tangent same circles as a calibration object, using the camera to shoot the calibration object from three angles to obtain three clear pictures, determining the equation of two elliptical images in each picture and obtaining coordinates of a pair of circle point images in each picture; determining internal parameters of the camera by utilizing the coordinates of the circle point images in the three pictures and the projection equation of an absolute secondary curve; obtaining internal common tangents and external common tangents of the two elliptical images in each picture; recovering and correcting an included angle between the internal common tangents of the two same circles in a world coordinate system; and finally obtaining external parameters of the camera according to established world coordinates of the internal common tangents and the external common tangents of the two same circles and image coordinates of the projection thereof. The invention can simply and accurately obtain the internal parameters and the external parameters of the camera and realize automatic calibration and also can be widely applied to non-contract type industrial detection and vision-based self-contained navigation systems.

Owner:NANTONG YIXUAN IND DESIGN CO LTD +1

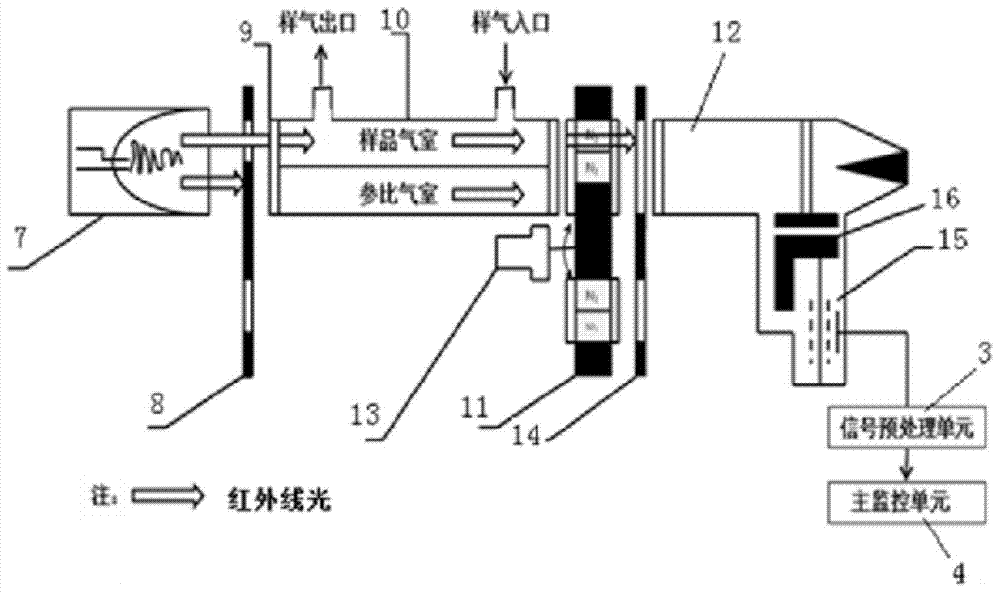

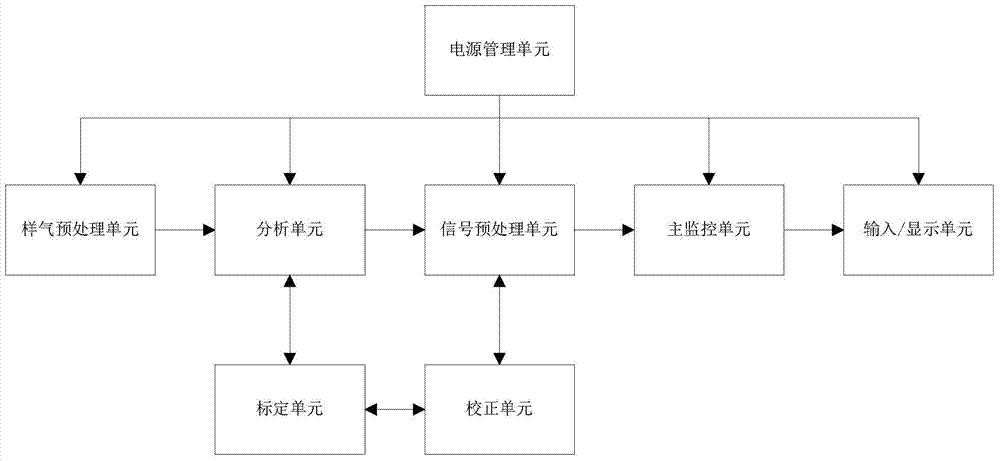

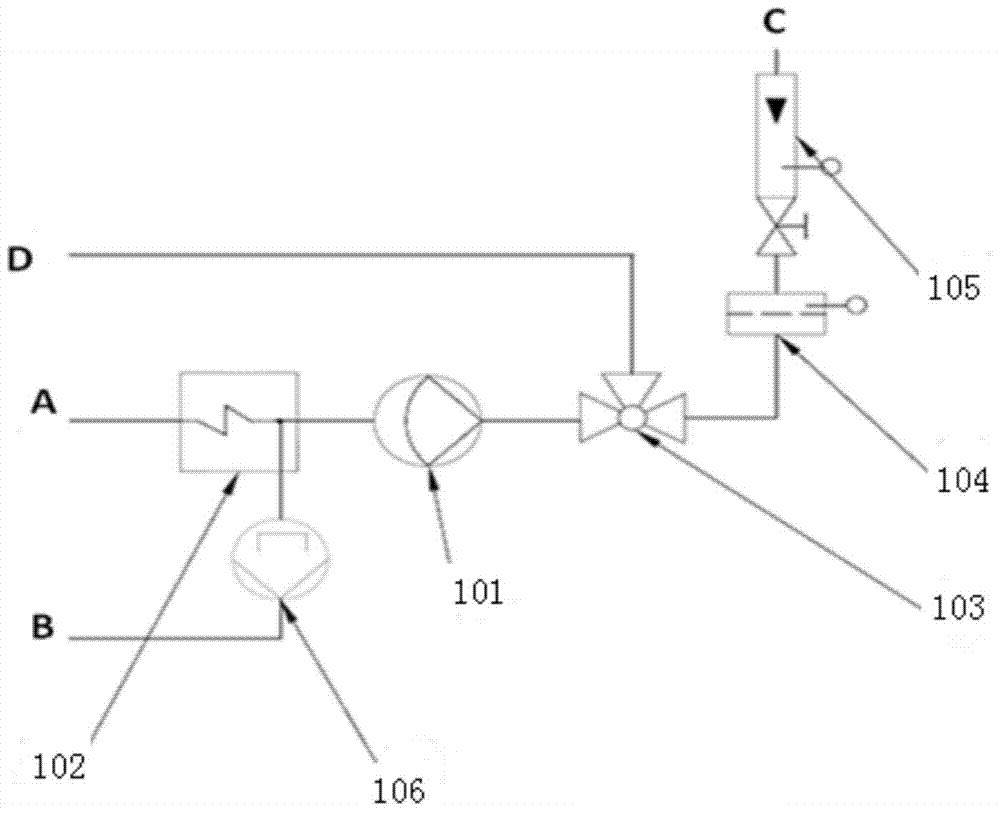

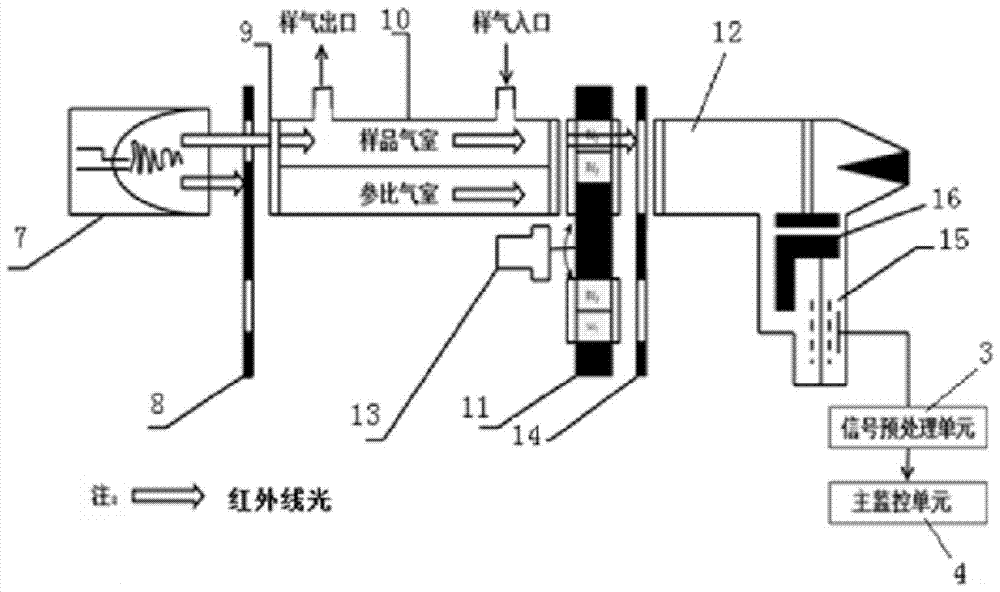

Portable infrared gas analyzer with automatic range calibration and calibration method

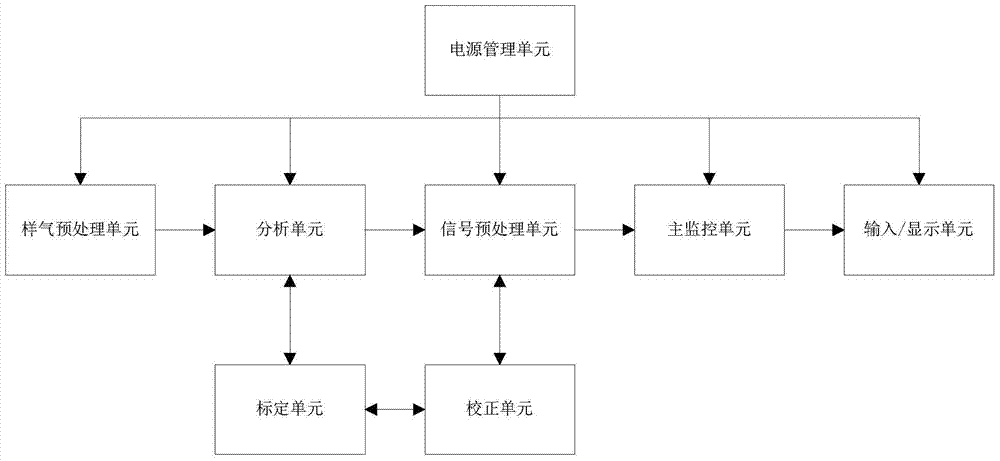

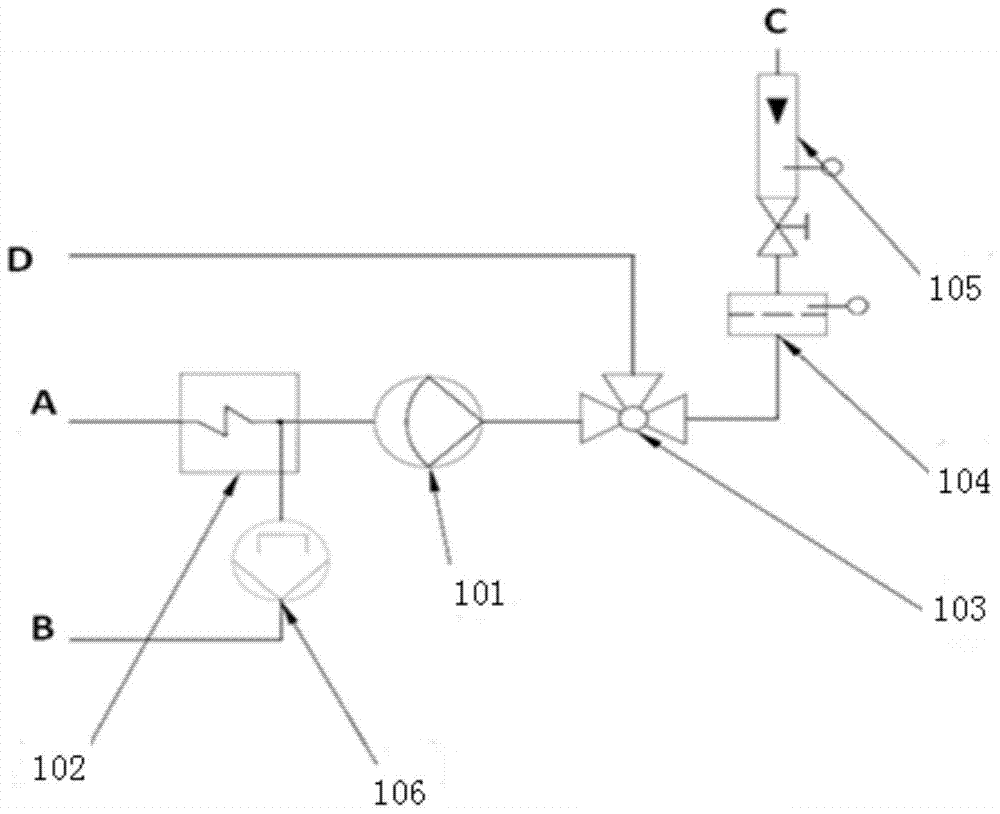

InactiveCN104764693ARealize fully automatic calibrationGuaranteed measurement accuracyMaterial analysis by optical meansInfraredGas chamber

The invention provides a portable infrared gas analyzer with automatic range calibration, comprising a pretreatment unit, an analysis unit, a master monitoring unit, a standardization unit and a correction unit. The analysis unit comprises a light source, an absorbing gas chamber and a receiving gas chamber, the light source generates infrared light and the infrared light irradiates the interior of the absorbing gas chamber, the standardization unit performs zero correction and range standardization and transmits standardized gas into the receiving gas chamber, and the correction unit automatically corrects a sample gas concentration measurement adapter pipe by calculating offset increment caused by actual environment variation. The portable infrared gas analyzer can automatically correct measurement results, not only overcomes the influence of measurement environments on measurement and ensures system measurement precision, but also can analyze gas for long time without an extra pretreatment unit, has a cost-saving effect and is convenient to carry.

Owner:CHONGQING TECH & BUSINESS UNIV

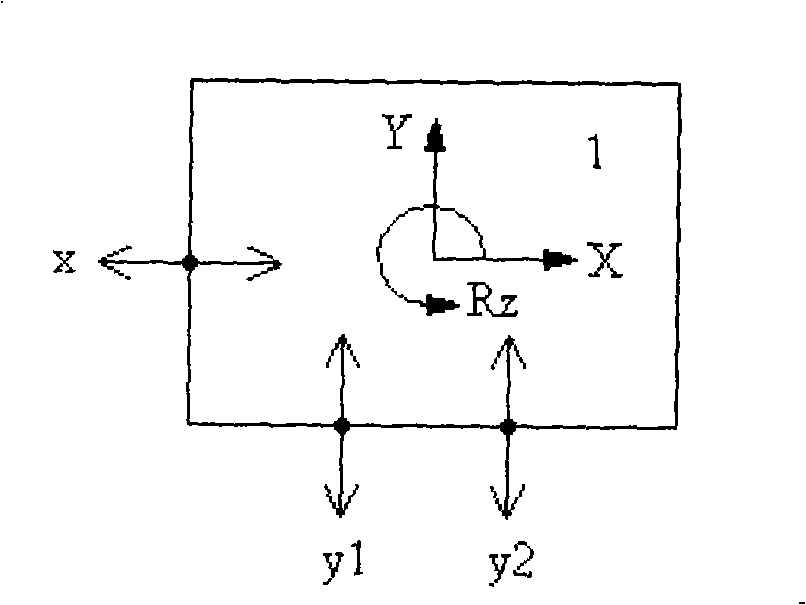

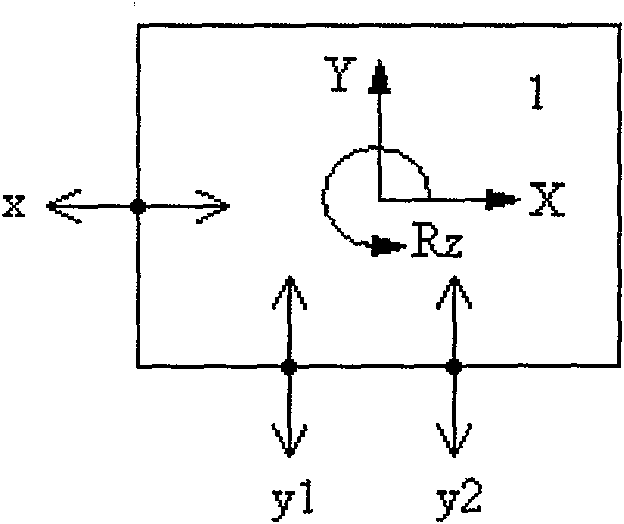

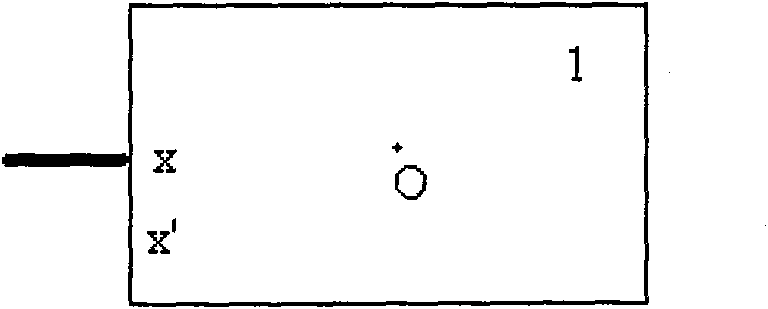

XYY precision positioning platform calibration method

ActiveCN101260967ASimplify the decoupling processImprove calibration accuracyStands/trestlesPhotomechanical exposure apparatusActuatorFully automatic

The invention provides a calibration method for an XYY precision positioning platform. The method is used for completely solving the problems of executor calibration, decoupling and telescopic sensor calibration in single flow. The method is realized by arranging a separated position sensor at the external of the XYY precision positioning platform and orderly accomplishing the executor calibration, the telescopic sensor calibration and decoupling matrix calibration. The method sufficiently uses the position sensor which is independent of the platform. The position sensor is not only used for decoupling, but also used for the executor calibration and the telescopic sensor calibration. Besides, with the superposition property of matrix operation, the decoupling process can be simplified. The calibration method is high in precision, fast in speed, and capable of realizing fully automatic calibration. For lithography tools, the calibration method can be realized by using the prior devices in the lithography tools without arranging extra special devices.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

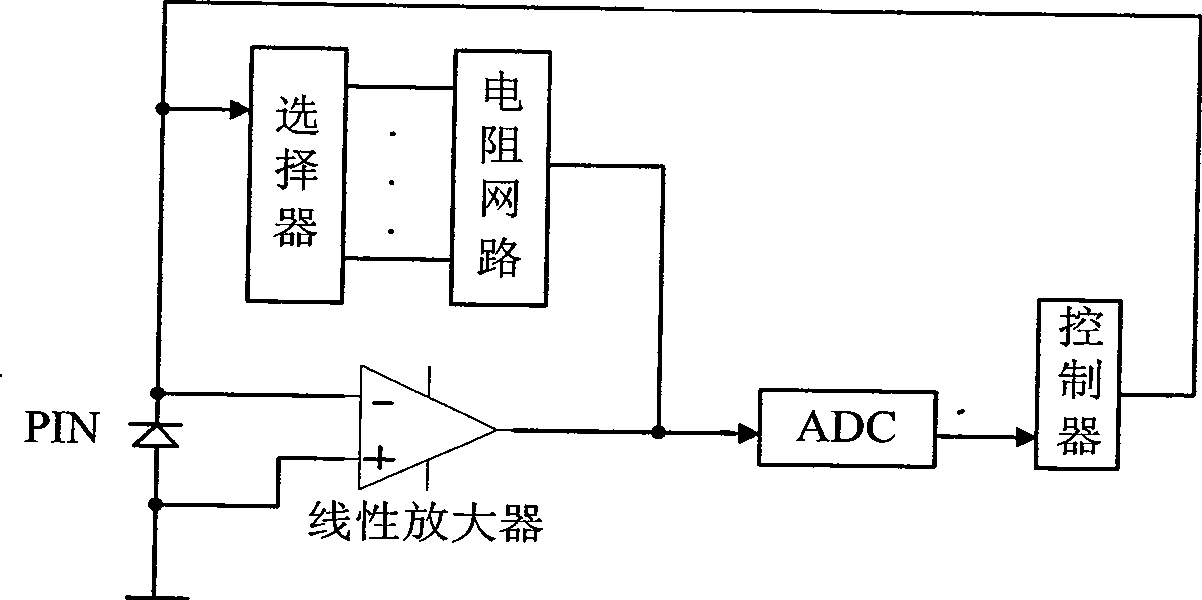

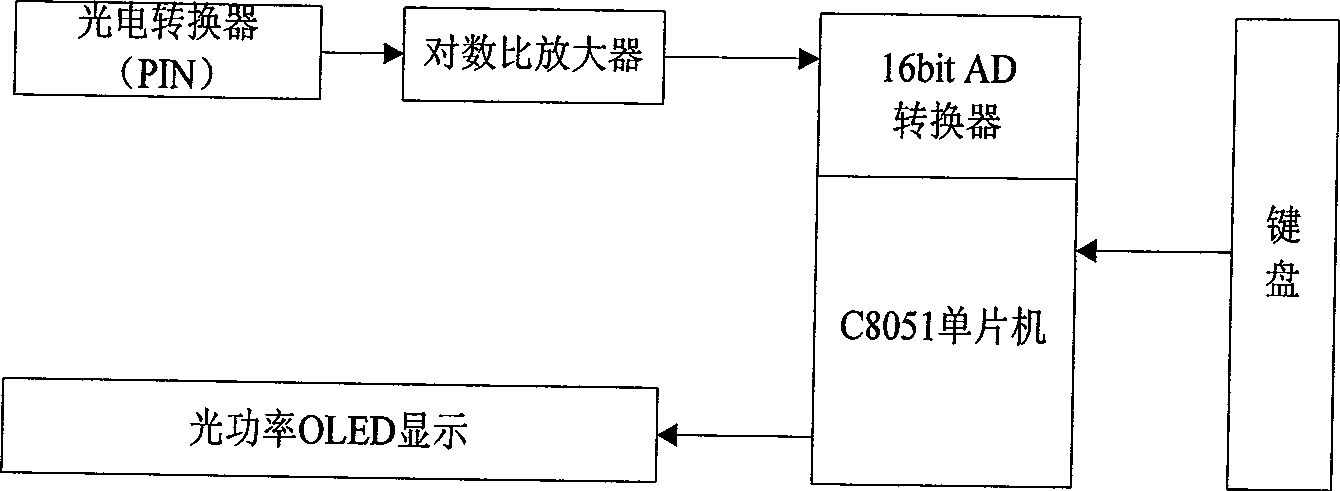

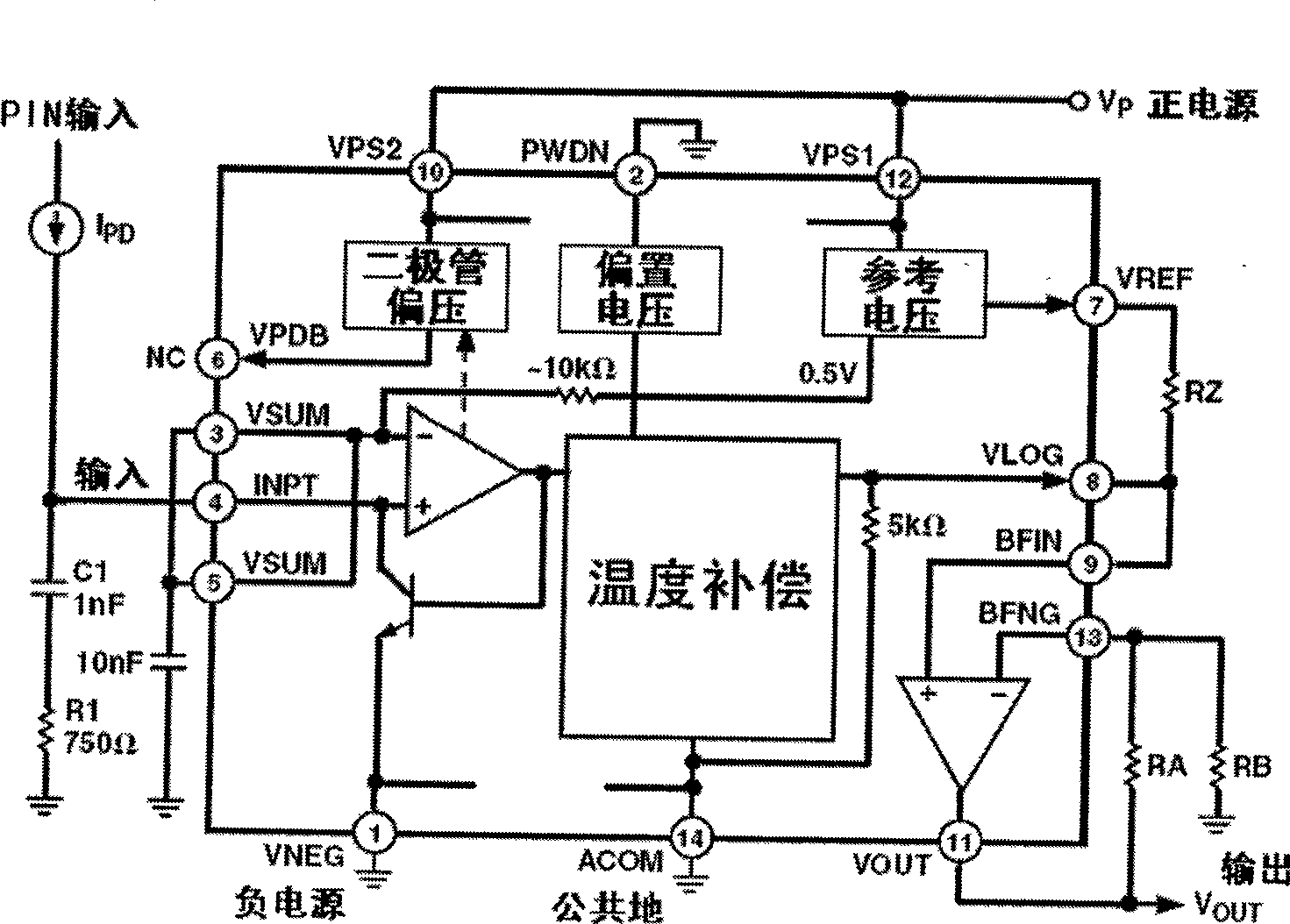

Optical power measurement method

InactiveCN101451885ALarge dynamic rangeEasy CalibrationPhotometry using electric radiation detectorsOptical power meterPhotoelectric conversion

The invention discloses a light power measuring method with a log ratio amplifying circuit combined with software. Measuring process is: constructing light power calculating formula P=K<3>beta+C<3> according to the log ratio amplifying circuit in the measuring system; configuring an AD converter according to wavelength of measured light source; connecting the measured light source with the light end, picking a signal received at the light end, the AD converter reading in data N times circularly after photoelectric conversion and log amplification, solving an average value beta of N conversion values; judging whether value of beta exceeds measuring range, if so, measurement is over; if not, dividing the light source measured according to power of the standard light source; comparing beta value with an edge value of the standard light source, selecting corresponding K<3> and C<3> according to location where beta is; introducing determined beta, K<3> and C<3> values to the light power calculating formula to obtain a power value P of the measured signal. The invention, compared with current power measuring method, is simple in process, large in dynamic range, and high in precision for light power measurement of optical fiber communication.

Owner:XIDIAN UNIV

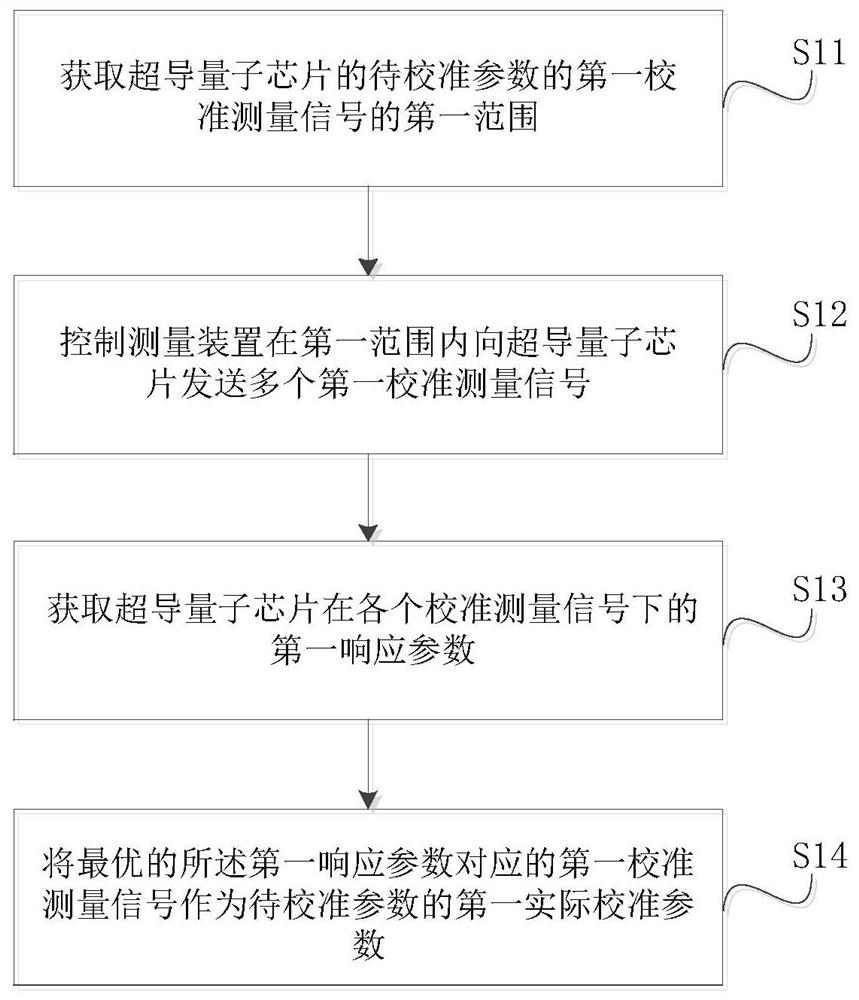

Automatic calibration method for superconducting quantum chip parameter and related assembly

ActiveCN111722084ACalibration time is shortReduce repetitive workElectronic circuit testingEngineeringReal-time computing

The invention discloses an automatic calibration method for a superconducting quantum chip parameter. In the method, the method comprises the following steps: acquiring a first range of a first calibration measurement signal of a to-be-calibrated parameter of a superconducting quantum chip and controlling a measurement device to send a plurality of first calibration measurement signals to the superconducting quantum chip in a first range; acquiring a first response parameter of the superconducting quantum chip under each calibration measurement signal; and finally, taking the first calibrationmeasurement signals corresponding to the optimal first response parameters as first actual calibration parameters of the to-be-calibrated parameter. According to the method, the problems of low calibration efficiency and the like caused by manual calibration are effectively solved, full-automatic calibration of the parameters of the chip is realized, and the method has the advantages of short calibration time, less repetitive work, labor cost saving and high calibration efficiency. The invention also discloses an automatic calibration device for a superconducting quantum chip parameter, an automatic calibration system for a superconducting quantum chip parameter and a readable storage medium. The automatic calibration device and the automatic calibration system have the same beneficial effects as the automatic calibration method.

Owner:INSPUR GROUP CO LTD

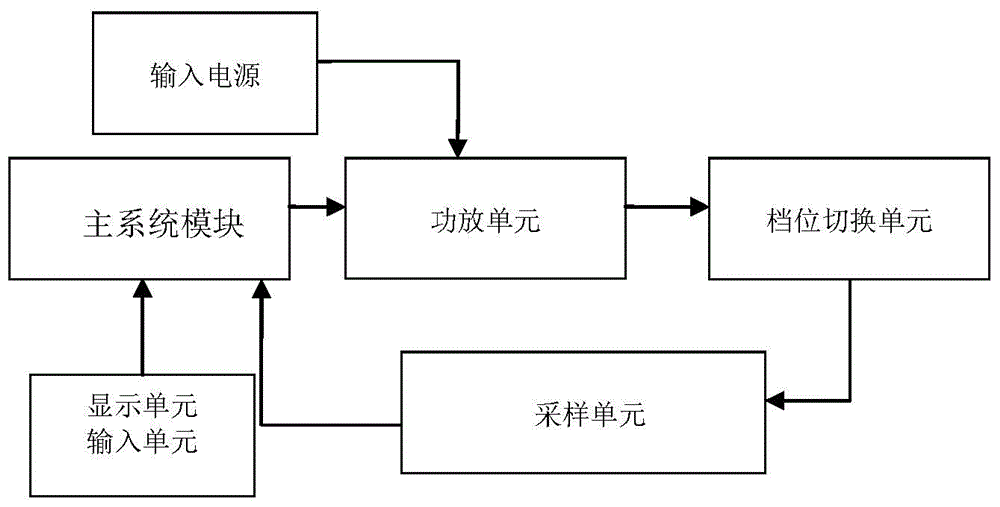

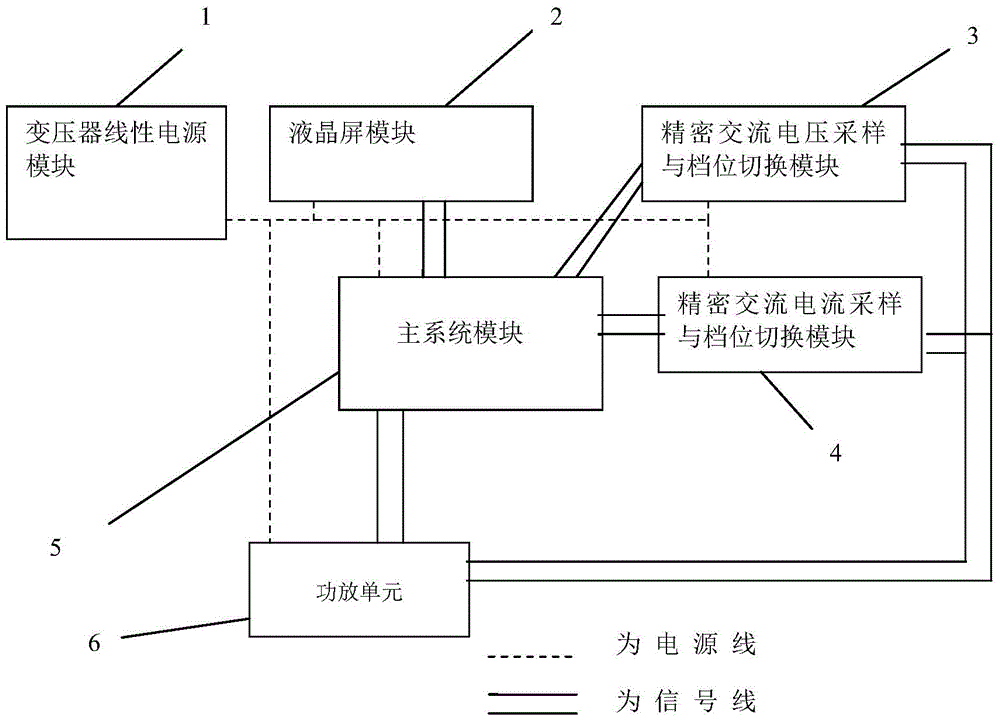

Transformer load box calibration device

InactiveCN104316892AReduce volumeAvoid mutual interferenceElectrical measurementsTransformerComputer module

The invention provides a transformer load box calibration device. The transformer load box calibration device comprises an input power supply, a power amplifier unit, a gear switching unit, a sampling unit and a main system module; the input power supply is connected with the power amplifier unit; an input end of the power amplifier unit is connected with the main system module; an output end of the power amplifier unit is connected with an input end of the gear switching unit; an output end of the gear switching unit is connected with an input end of the sampling unit; an output end of the sampling unit is connected with an input end of the main system module. The transformer load box calibration device is designed in an integrated mode, the operation is convenient, the size is small, and the use requirements of the industrial field are met.

Owner:INNER MONGOLIA POWER GRP

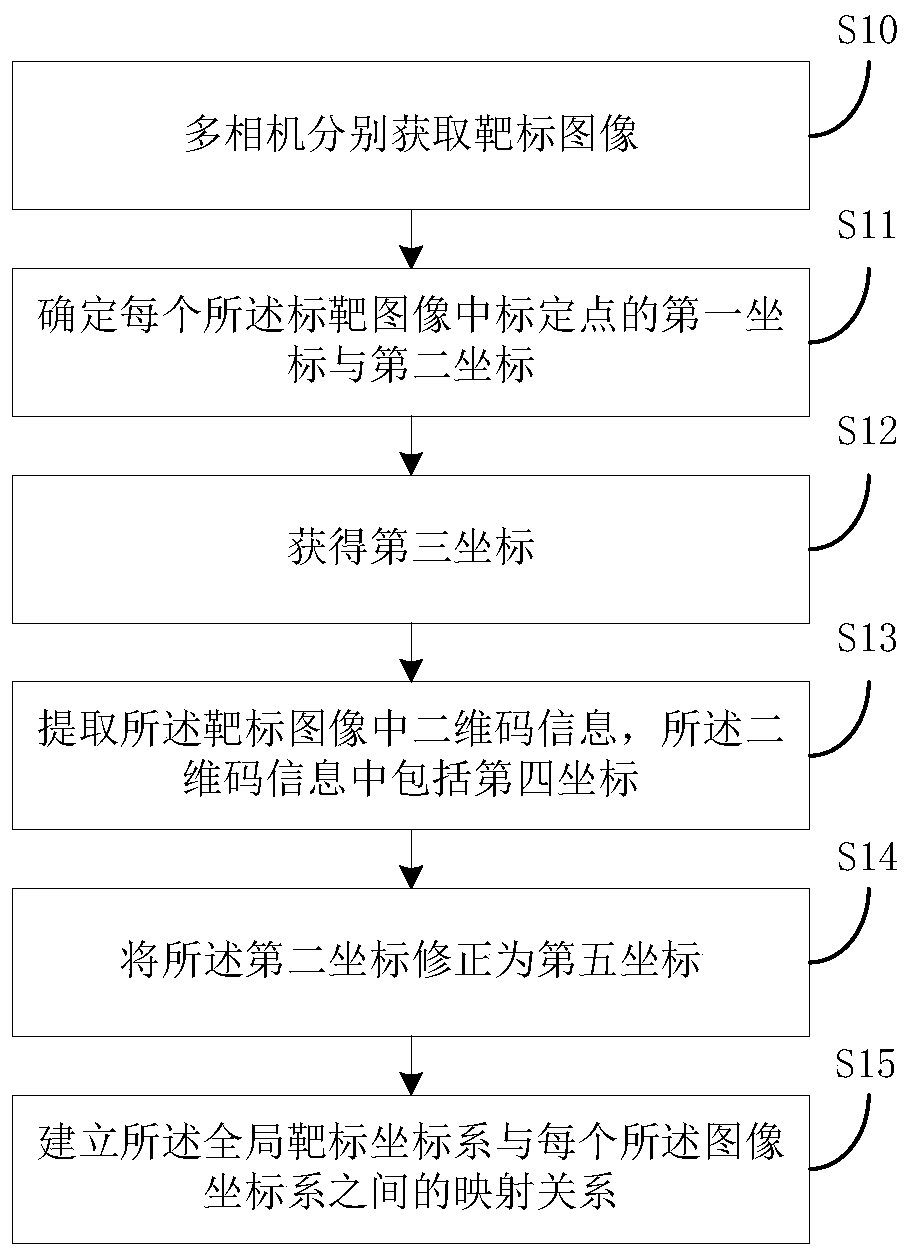

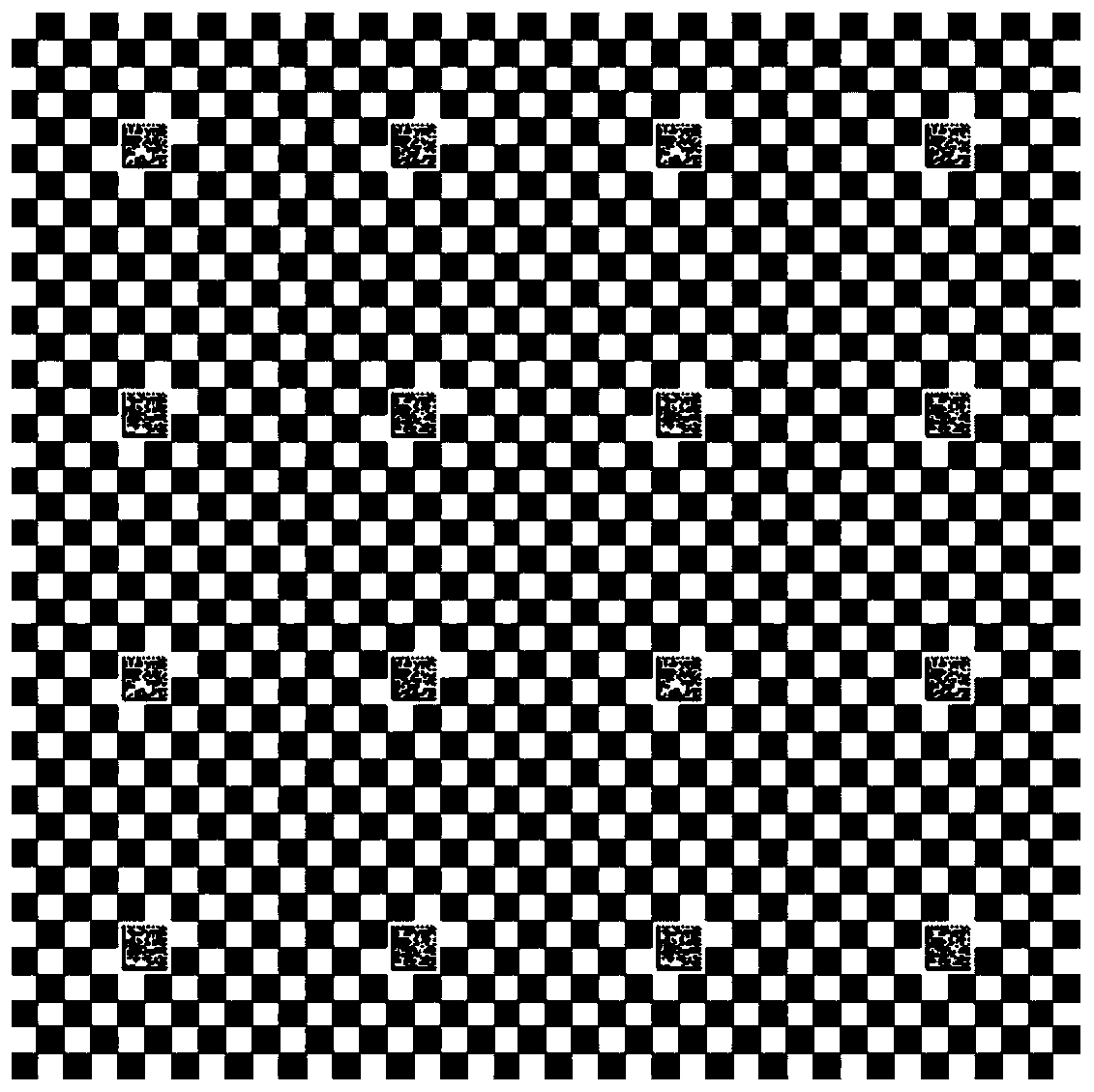

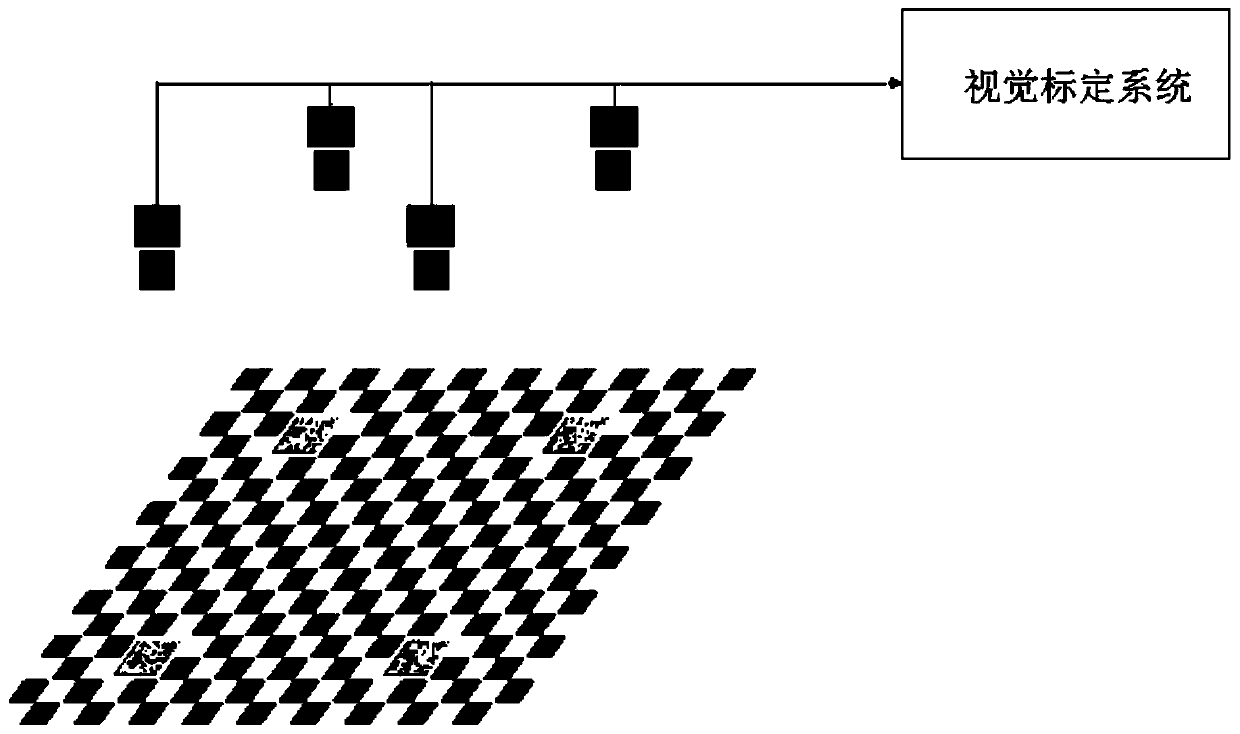

Visual calibration method and system

ActiveCN110415304ARealize fully automatic calibrationAchieve calibrationImage analysisRecord carriers used with machinesMulti cameraVisual perception

The embodiment of the invention discloses a visual calibration method and system. The method comprises the steps that multiple cameras obtain target images respectively, first coordinates and second coordinates, namely coordinates of calibration points in an image coordinate system and coordinates of the index fixed points in a local target coordinate system, of the calibration points in each target image are determined, third coordinates are obtained, and the third coordinates refer to coordinates of two-dimensional codes in the target images in the image coordinate system; two-dimensional code information in the target image is extracted, the two-dimensional code information comprises fourth coordinates, the fourth coordinates refer to coordinates of the current two-dimensional code in aglobal target coordinate system, the second coordinates are corrected into fifth coordinates, and the fifth coordinates indicate coordinates of a fixed point in the global target coordinate system; and establishing a mapping relationship between the global target coordinate system and each image coordinate system according to the first coordinate and the fifth coordinate. A target with a two-dimensional code is utilized, local target coordinates of a calibration point are automatically corrected into global target coordinates through two-dimensional code information, and full-automatic calibration of the multi-camera vision system is achieved.

Owner:北京博视智动技术有限公司

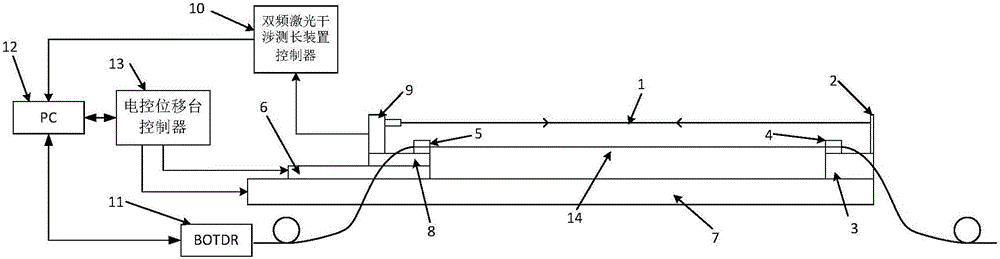

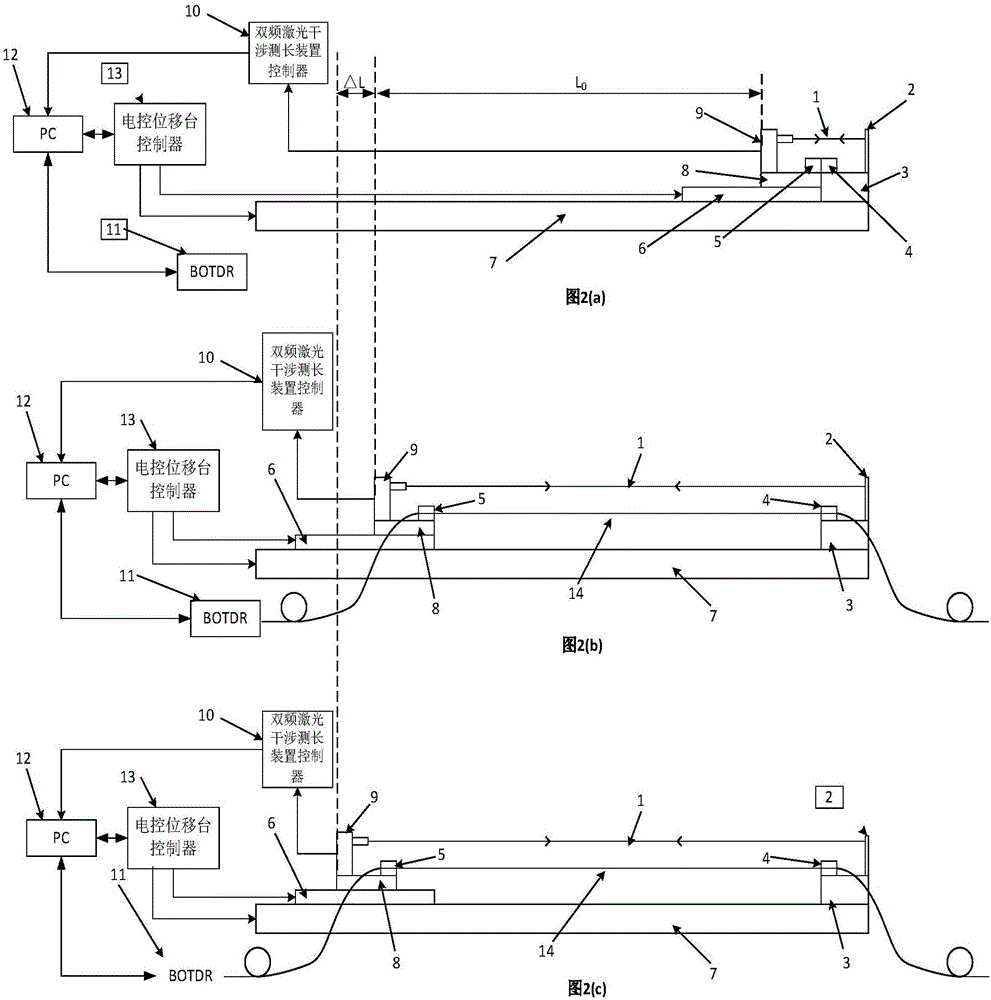

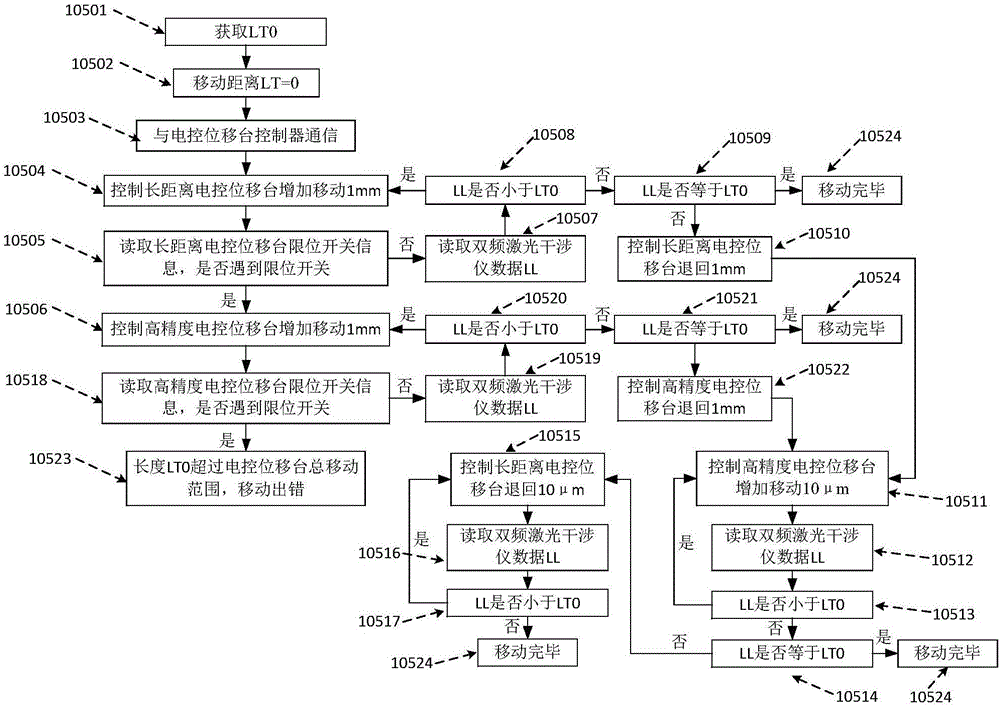

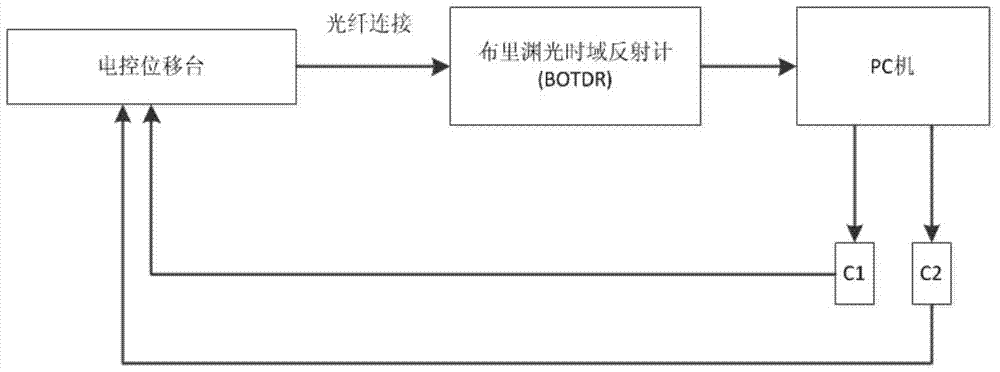

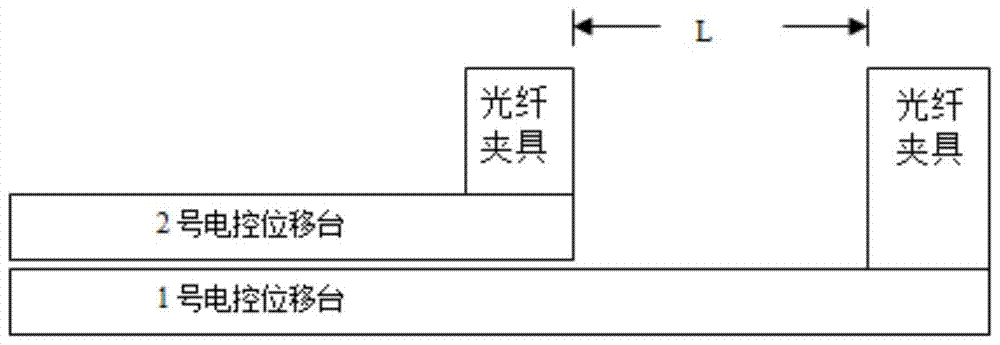

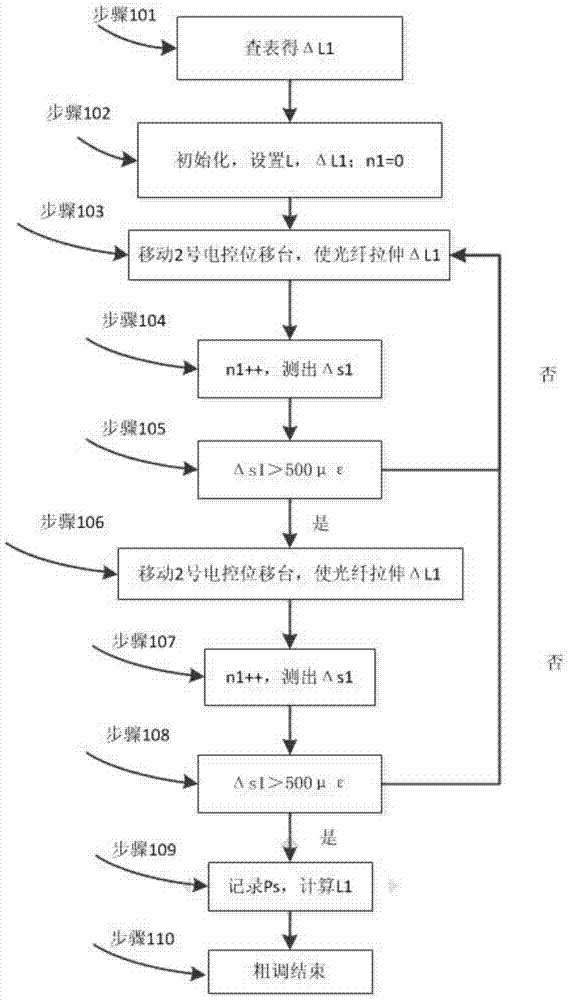

Optical fiber strain coefficient automatic calibration method

ActiveCN106482658ARealize fully automatic calibrationImprove calibration efficiencyUsing optical meansArray data structureRefractive index

The present invention discloses an optical fiber strain coefficient automatic calibration method. The method includes the following steps that: the length of an optical fiber strain region is inputted, a measured optical fiber is tensioned and is fixed between a first fixture and a second fixture according to a set distance; an optical fiber length and an optical fiber refractive index are inputted; a main control computer starts automatic calibration; a Brillouin optical time domain reflectometer is adopted to test optical fiber strain distribution so as to find out an optical fiber length corresponding to the optical fiber strain region; the Brillouin optical time domain reflectometer is adopted to test optical fiber strain distribution so as to find out an acting area length of the measured optical fiber; a calibration stepping distance is determined according to the acting area length of the measured optical fiber; the Brillouin optical time domain reflectometer is adopted to test optical fiber strain distribution so as to read Brillouin frequency shift data corresponding to the optical fiber length corresponding to the optical fiber strain region, and movement is carried out, and N times of testing is carried out, wherein N is a natural number greater than or equal to 1, the data array of the corresponding optical fiber length and a Brillouin frequency shift data array corresponding to the optical fiber length are obtained; and the data are linearly fitted, so that the strain coefficient FCS of the measured optical fiber can be obtained.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

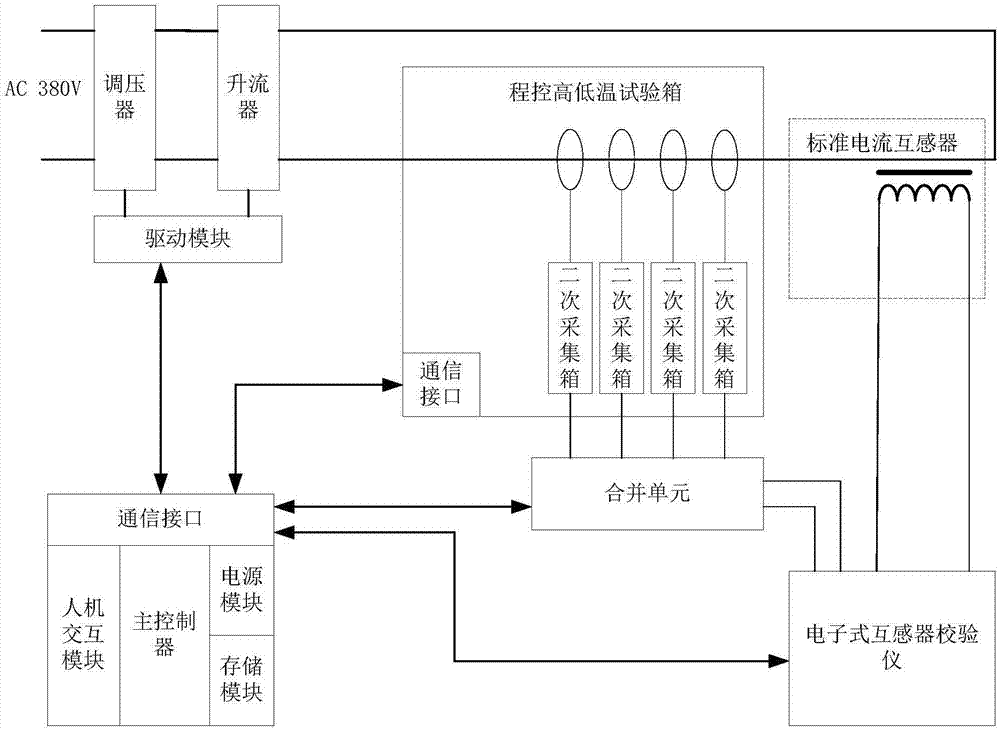

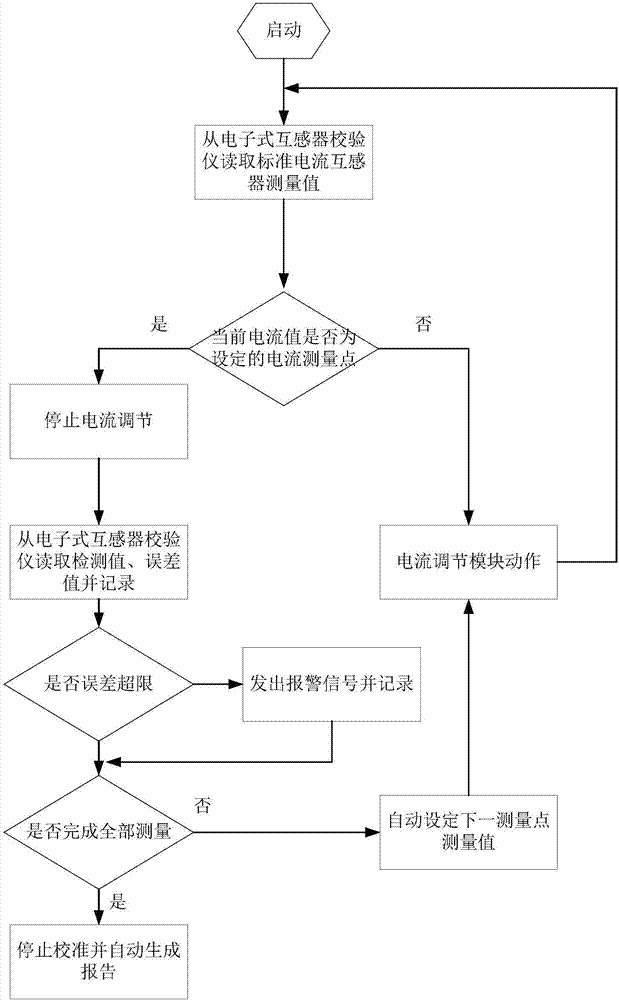

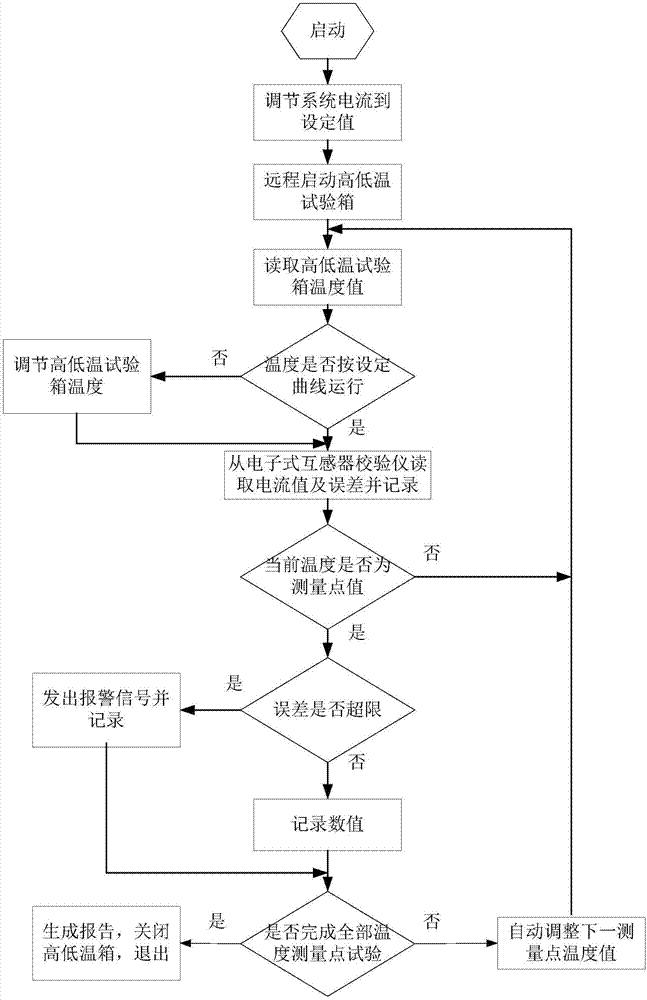

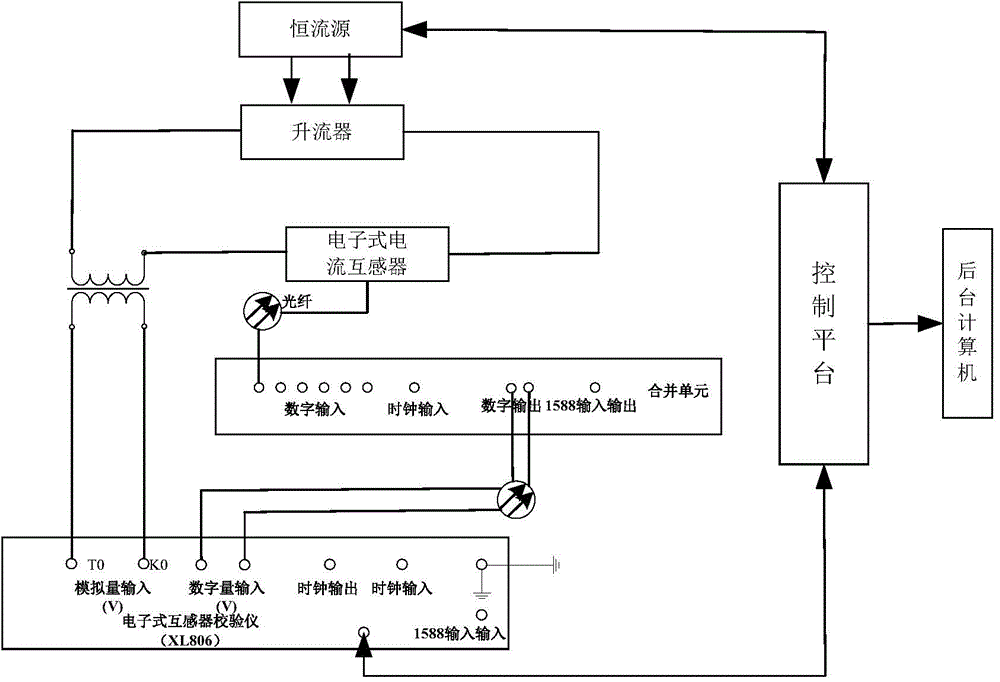

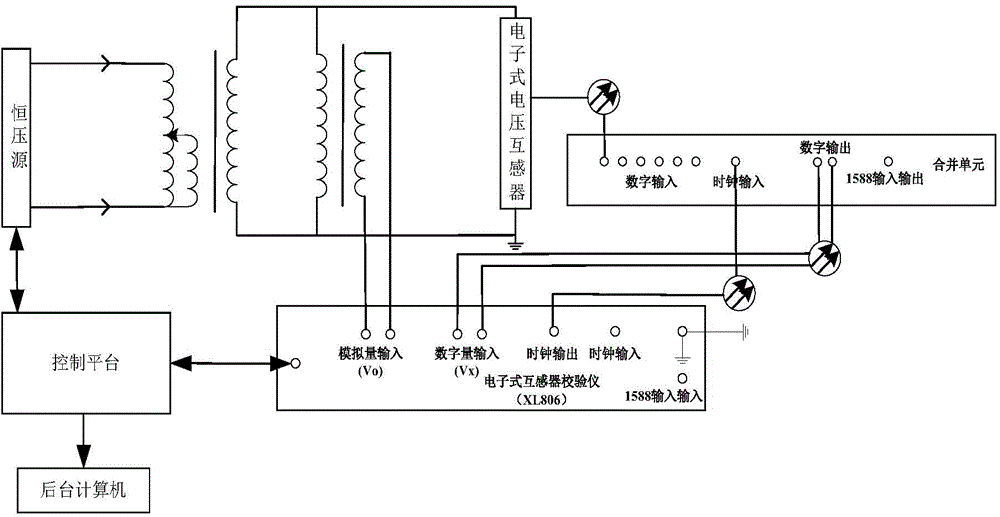

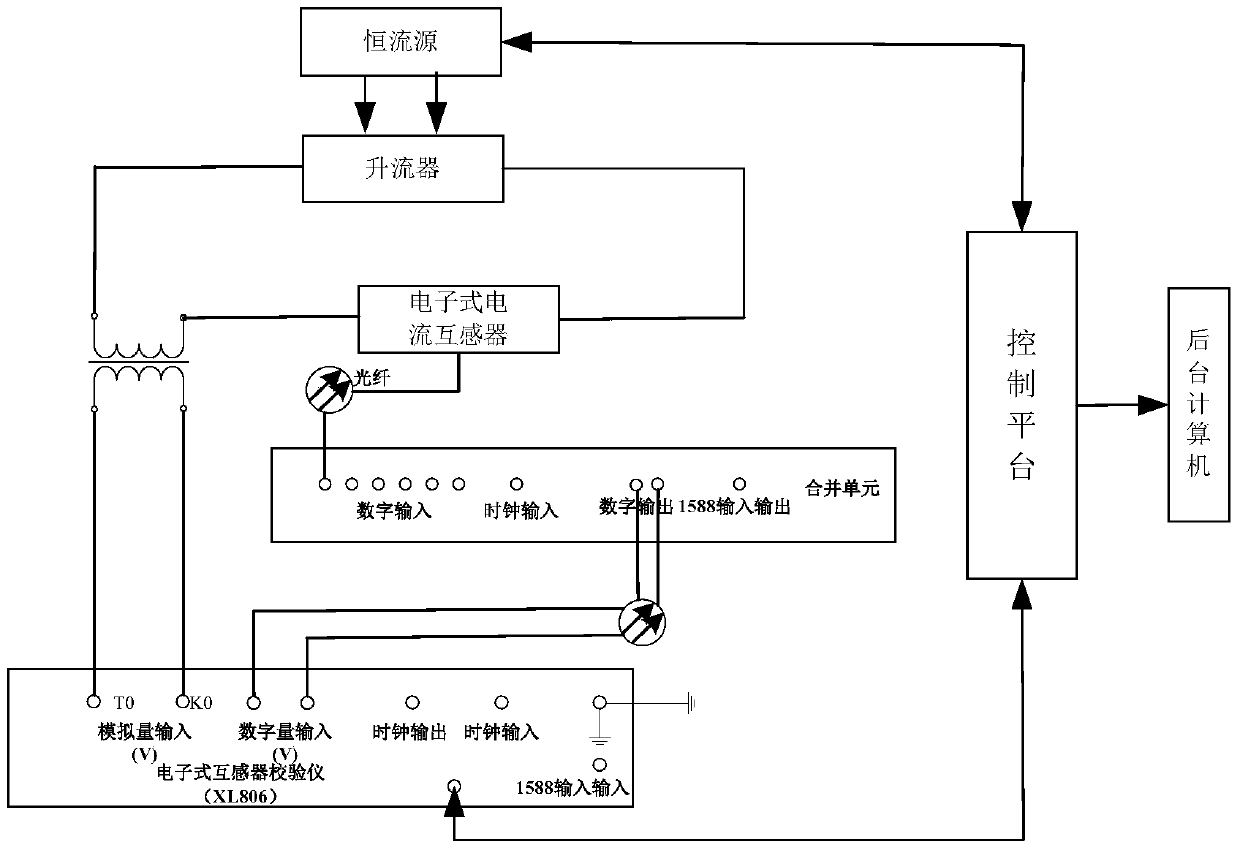

System and device for verifying electronic current transformer

InactiveCN107064849ARealize fully automatic calibrationHigh precisionElectrical measurementsEngineeringElectronic current

The invention relates to a system and device for verifying an electronic current transformer. The system is provided with a standard current transformer, a control processing part, a to-be-detected electronic current transformer, and a temperature adjustment device which is used for adjusting the temperature of a detection environment of the to-be-detected electronic current transformer. The control processing part enables the current signals, detected under different detection environment temperatures, of the electronic current transformer to be compared with a standard current signal, and carries out the corresponding processing of the comparison result, so as to achieve the verification of the electronic current transformer. The system can achieve the full-automatic verification of the detection precision during the batch production and verification of related electronic current transformers, and effectively improves the verification precision and efficiency. Moreover, the detection precision obtained through verification is closer to the actual detection precision, so the system is higher in verification reliability, and is higher in reliability of detection precision.

Owner:PINGGAO GRP +1

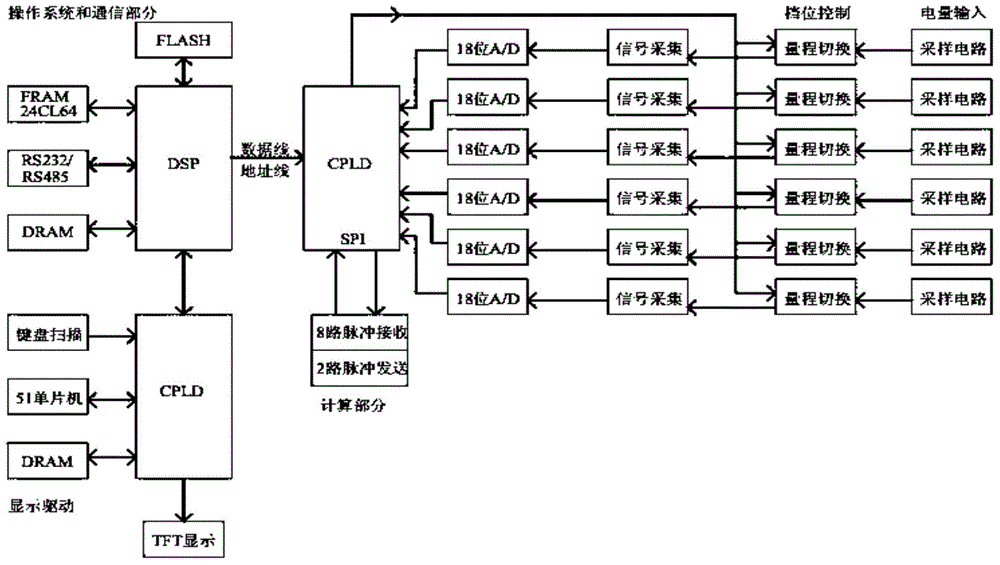

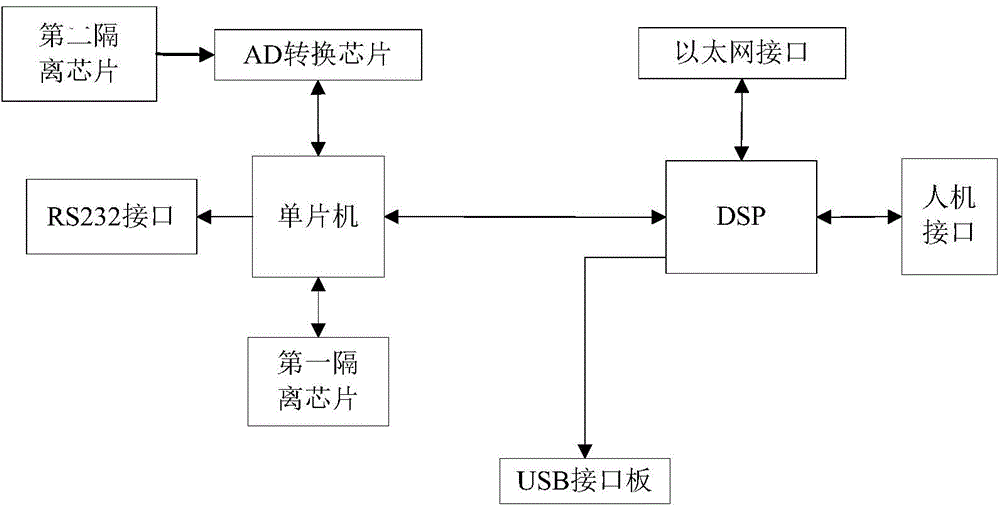

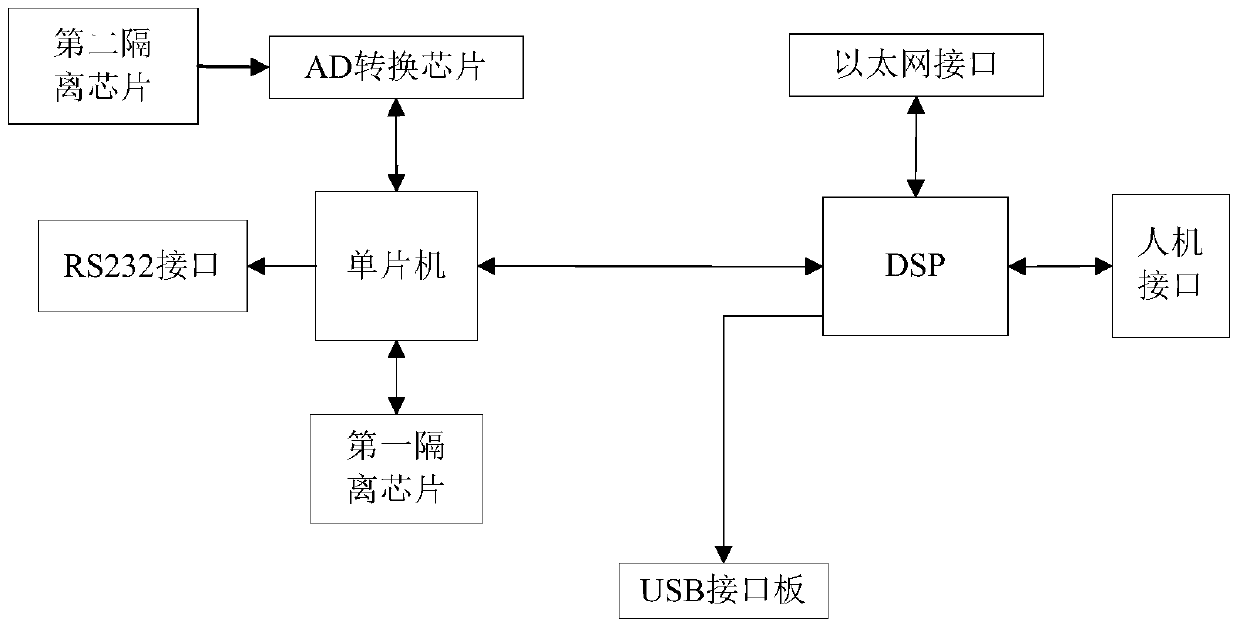

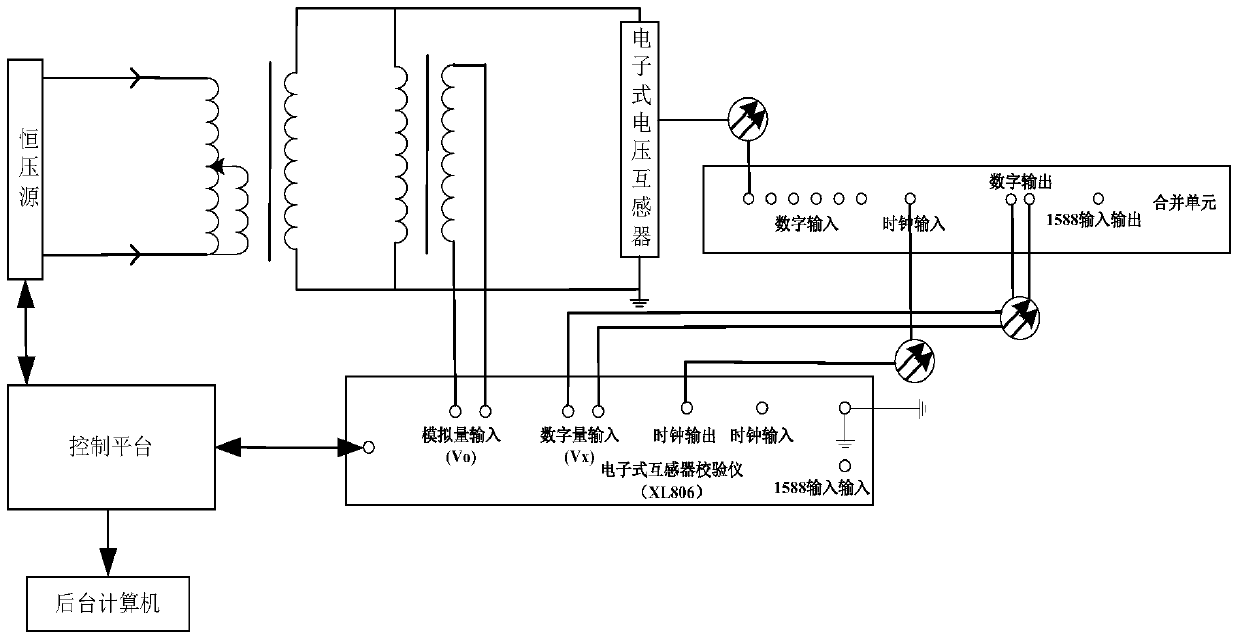

Electronic transformer full-automatic debugging system

ActiveCN104090256ARealize fully automatic calibrationReal-time temperature monitoringElectrical measurementsMicrocontrollerMicrocomputer

Provided is an electronic transformer full-automatic debugging system. The input end of a standard transformer and the input end of a detected electronic transformer are simultaneously connected to the output end of a standard source, the output end of the standard transformer is connected to the analog quantity input end of an electronic transformer calibrator, the output end of the detected electronic transformer is connected to the digital input end of a merging unit through an optical fiber, and the digital output end of the merging unit is connected to the digital quantity input end of the electronic transformer calibrator through an optical fiber. The electronic transformer full-automatic debugging system comprises a control platform. The control platform comprises a DSP chip and a single-chip microcomputer which are connected. The DSP chip is connected with an Ethernet interface and a USB interface board. The Ethernet interface is connected with the electronic transformer calibrator, and the USB interface board is connected with a background computer. The single-chip microcomputer is connected with an RS232 interface which is connected with the control end of the standard source. By means of the electronic transformer full-automatic debugging system, calibration accuracy and calibration efficiency are improved, and the calibration security risk is greatly reduced.

Owner:STATE GRID CORP OF CHINA +1

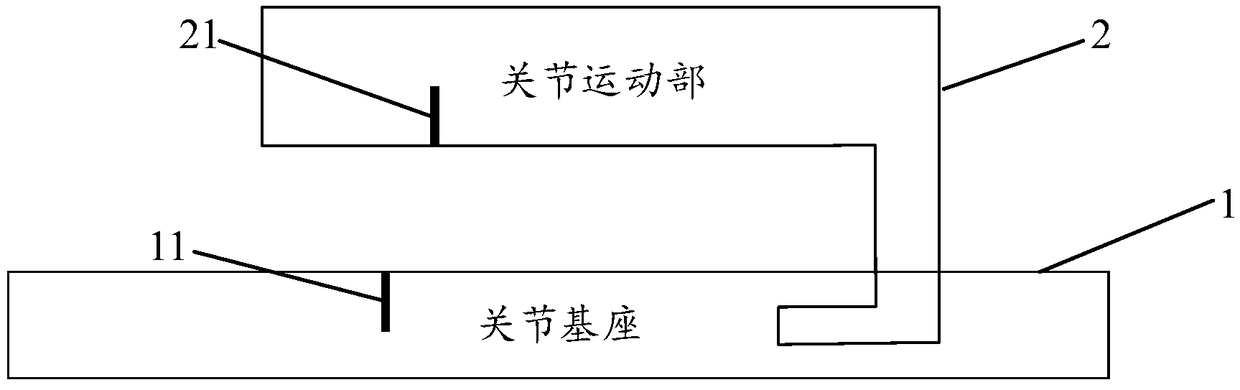

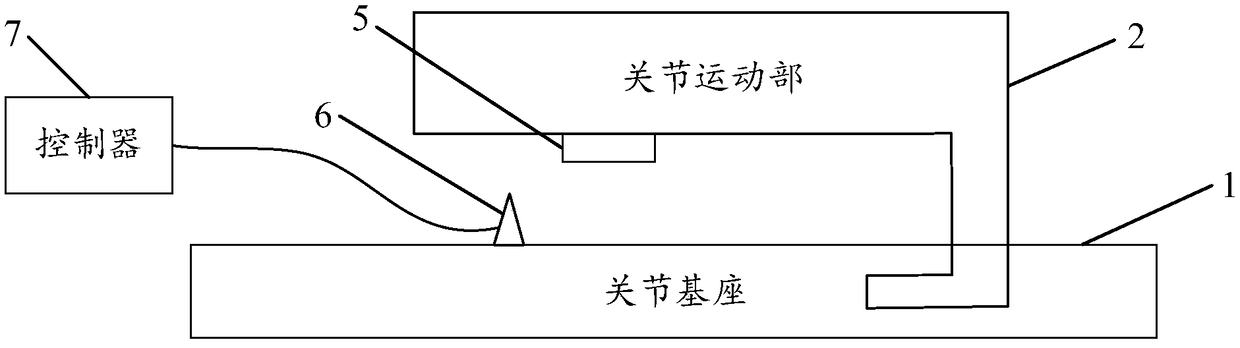

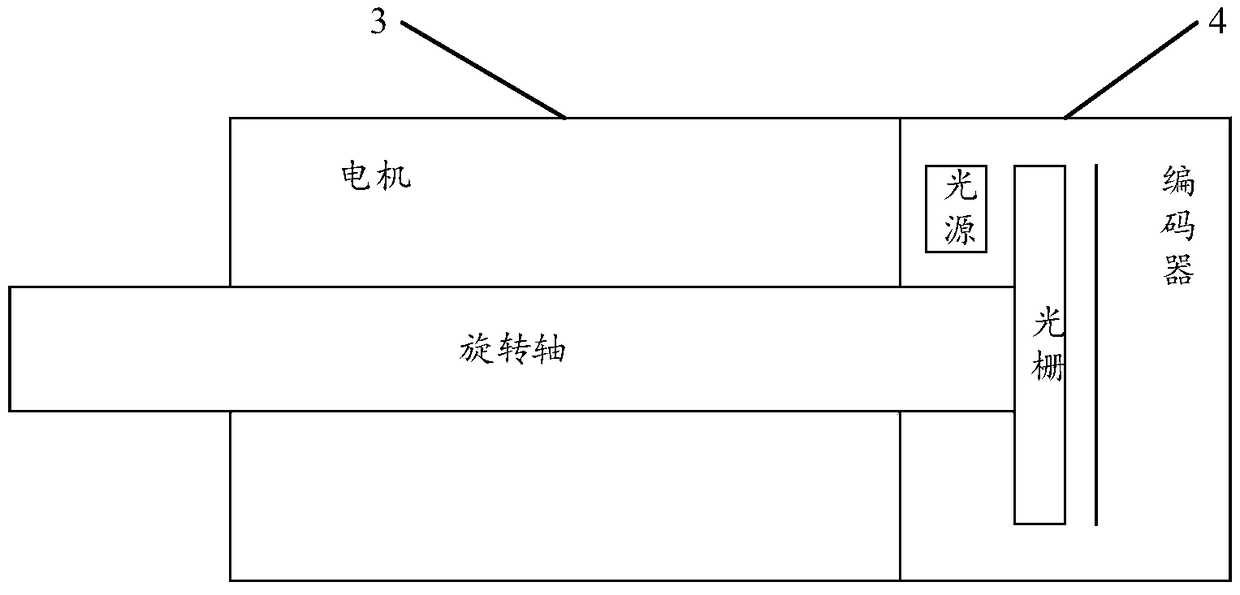

Original point calibration system and method

ActiveCN109483549ASave manpower and timeImprove calibration accuracyProgramme-controlled manipulatorAutomationControl theory

The invention provides an original point calibration system applied to automation equipment. The automation equipment comprises a joint base, a joint moving portion, and a motor used for driving the joint moving portion to move. The original point calibration system comprises an encoder, a calibration component, an original point sensor and a controller, wherein the encoder is mounted on the motorand used for recording the position of the joint moving portion; when the joint moving portion moves relative to the joint base until the calibration component is aligned with the original point sensor, the original point sensor outputs a trigger signal; and the controller is connected with the original point sensor and the encoder and used for receiving the trigger signal output by the originalpoint sensor, obtaining an encoder value of the encoder at the very moment when starting receiving the trigger signal, and determining an encoder value corresponding to an original point according tothe obtained encoder value. The system is used for achieving full-automatic original point calibration of the automation equipment including robots and the like, for improving the calibration precision and for reducing errors.

Owner:合肥欣奕华智能机器股份有限公司

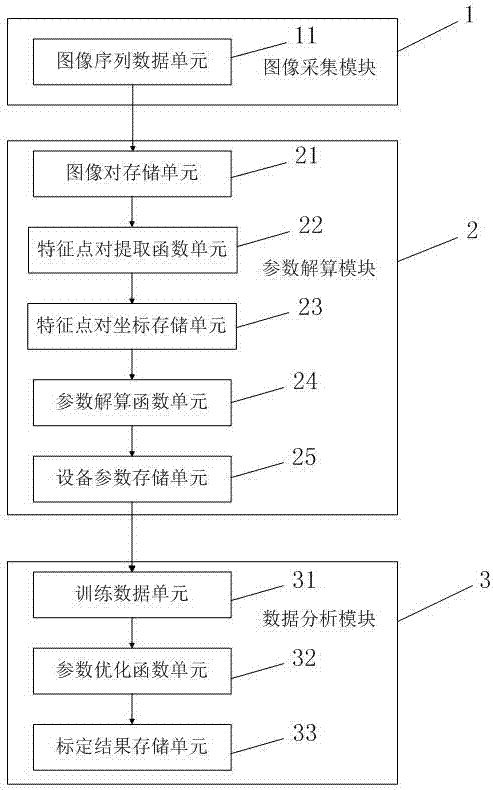

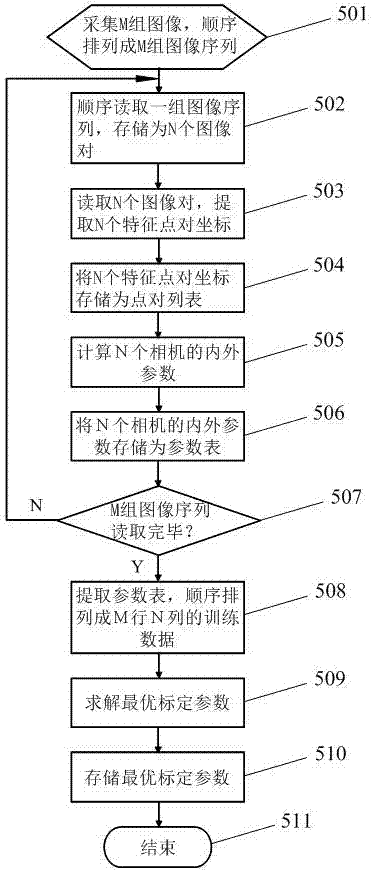

Calibration system and calibration method for parameters of panoramic photographing equipment

PendingCN106991701ARealize fully automatic calibrationReduce dependenceImage enhancementImage analysisComputer graphics (images)Image acquisition

The invention discloses a calibration system and a calibration method for a parameters of panoramic photographing equipment. The calibration system comprises the components of an image acquisition module, a parameter estimating module which is connected with the image acquisition module, and a data analyzing module which is connected with the parameter estimating module. The image acquisition module is used for transmitting an instruction for making N cameras of the panoramic photographing equipment synchronously and continuously acquire M sets of images and performs storage. The parameter estimating module is used for successively reading the M sets of image from the image acquisition module and processing, thereby obtaining M corresponding equipment parameter and storing. The data analyzing module is used for performing data analysis on M corresponding equipment parameters, thereby obtaining optimal solutions of a calibration parameter and performing storage. The calibration system and the calibration method have advantages of realizing full-automatic calibration to the parameters of the panoramic photographing equipment, greatly simplifying a parameter calibration operation process, reducing dependence to calibration equipment, and realizing high meaning in improving flexibility and robustness of equipment and improving panoramic splicing accuracy.

Owner:SHENZHEN PISOFTTECH TECH CO LTD

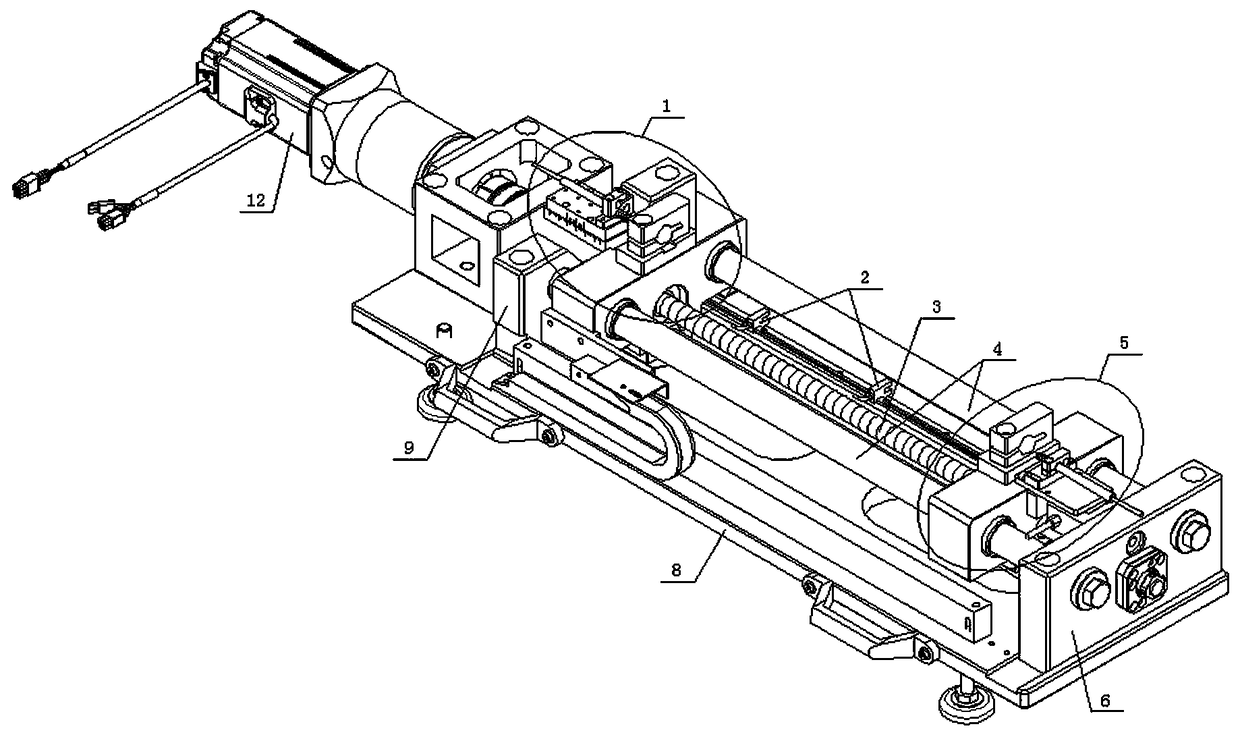

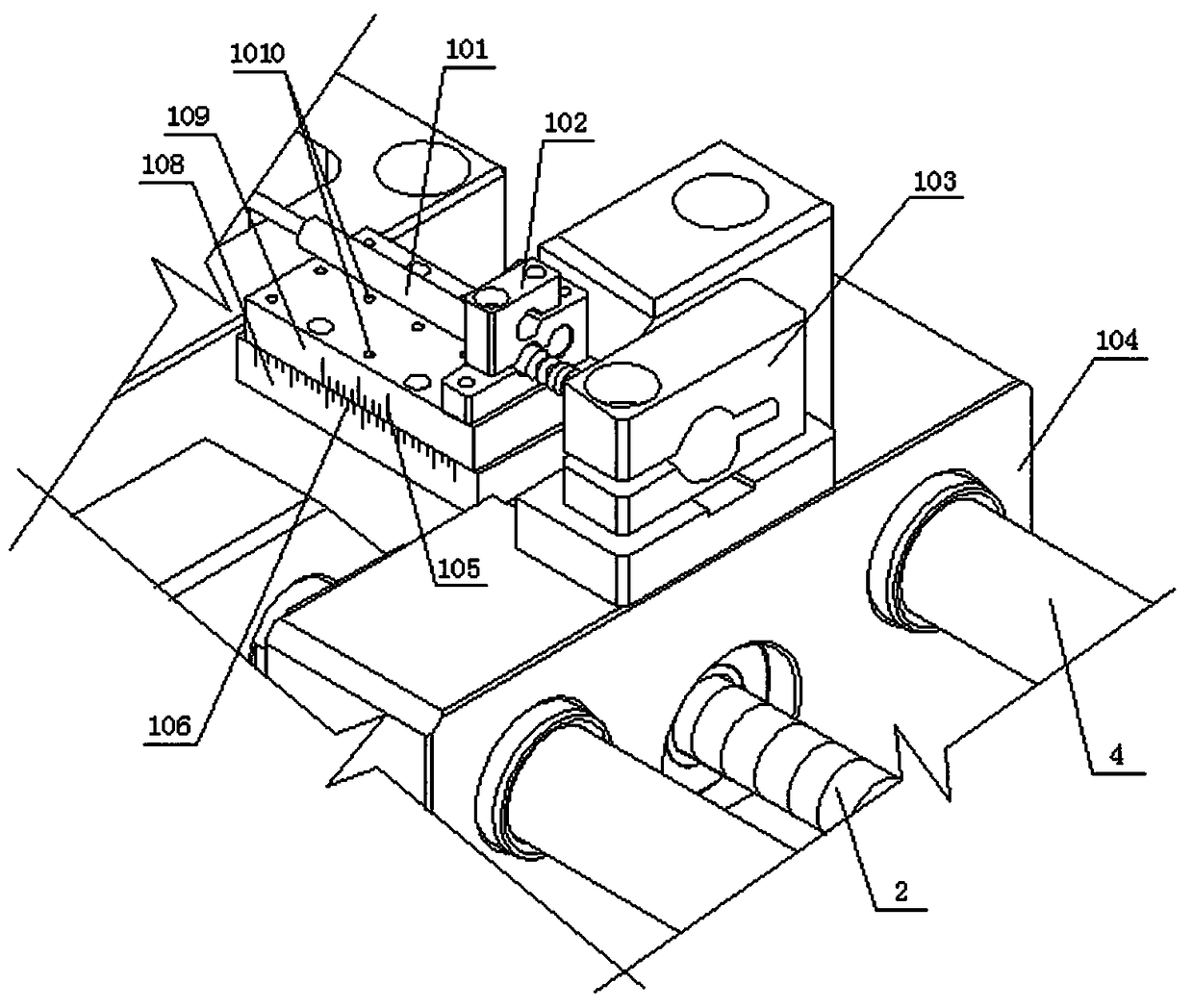

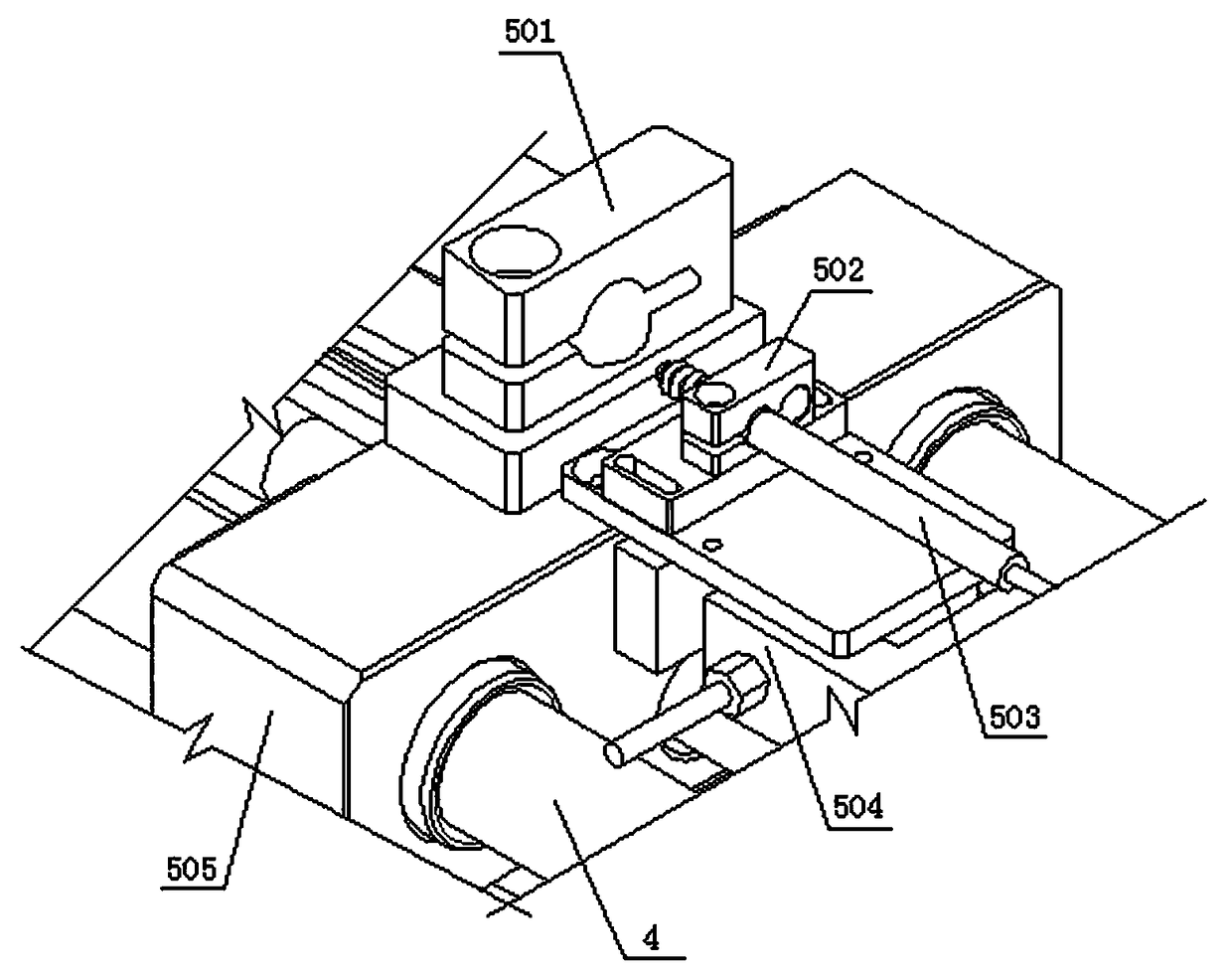

Clamping mechanism for vibrating wire strain sensor calibration device

PendingCN109357606ARealize fully automatic calibrationImprove measurement accuracyMechanical solid deformation measurementsVibrating wireEngineering

The invention discloses a clamping mechanism for a vibrating wire strain sensor calibration device, comprising left and right clamps. The left clamp comprises a left slider, which is provided with a left smooth punch hole for passing through the guide slide, and a left threaded punch hole for screwing the power screw. A left clamping head is fixed on the top of the left slider. The right clamp comprises a right slider, which is provides with a right smooth punch hole for passing through the guide slide, and a right smooth punch hole for passing through the power screw. A right clamping head isfixed at the top of the right slider. The left and right displacement sensors simultaneously detect the sliding amount of the left and right ends of the vibrating wire strain sensor, which improves the measurement accuracy and also detects the stress change in real time.

Owner:HENAN PROVINCE INST OF METROLOGY

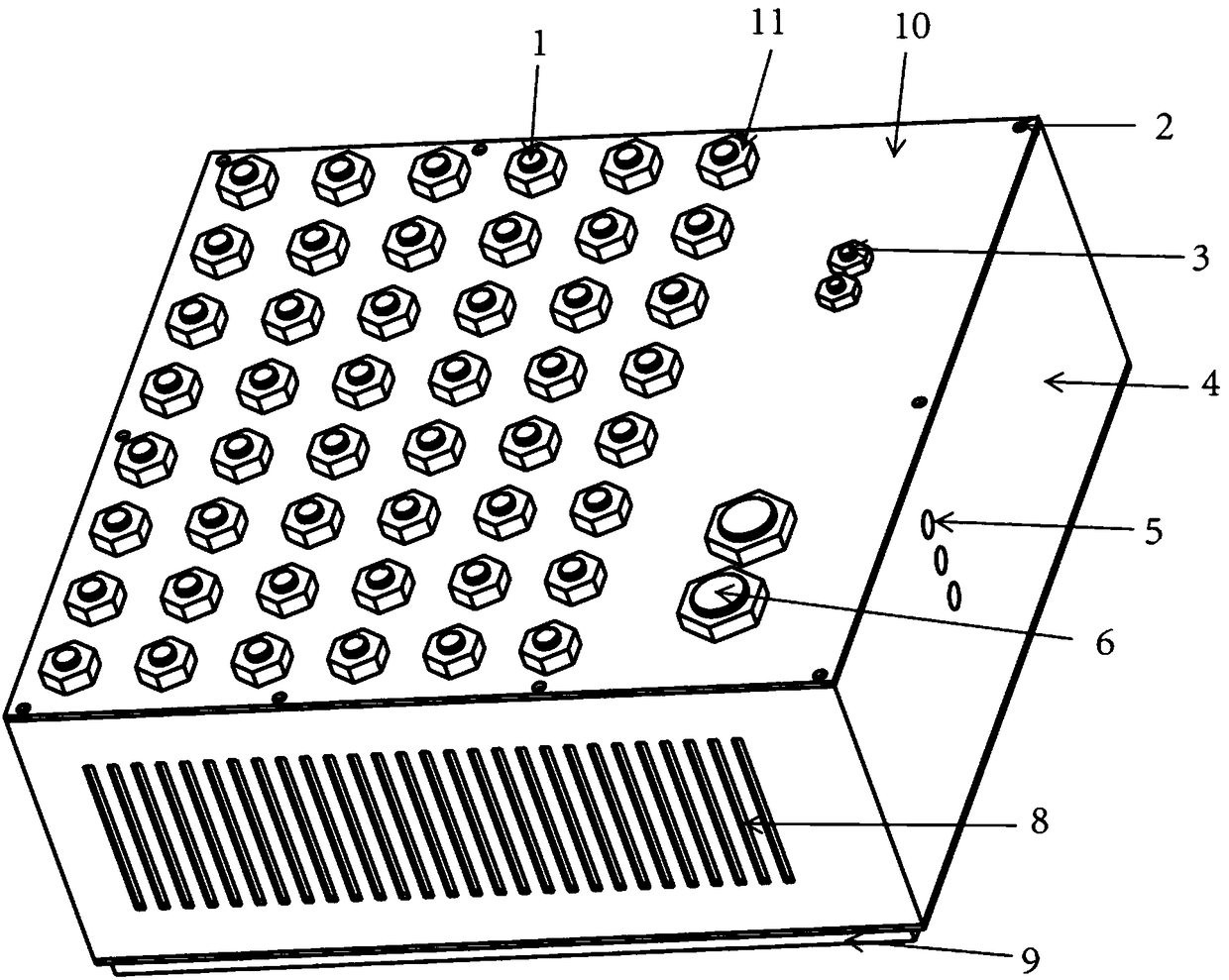

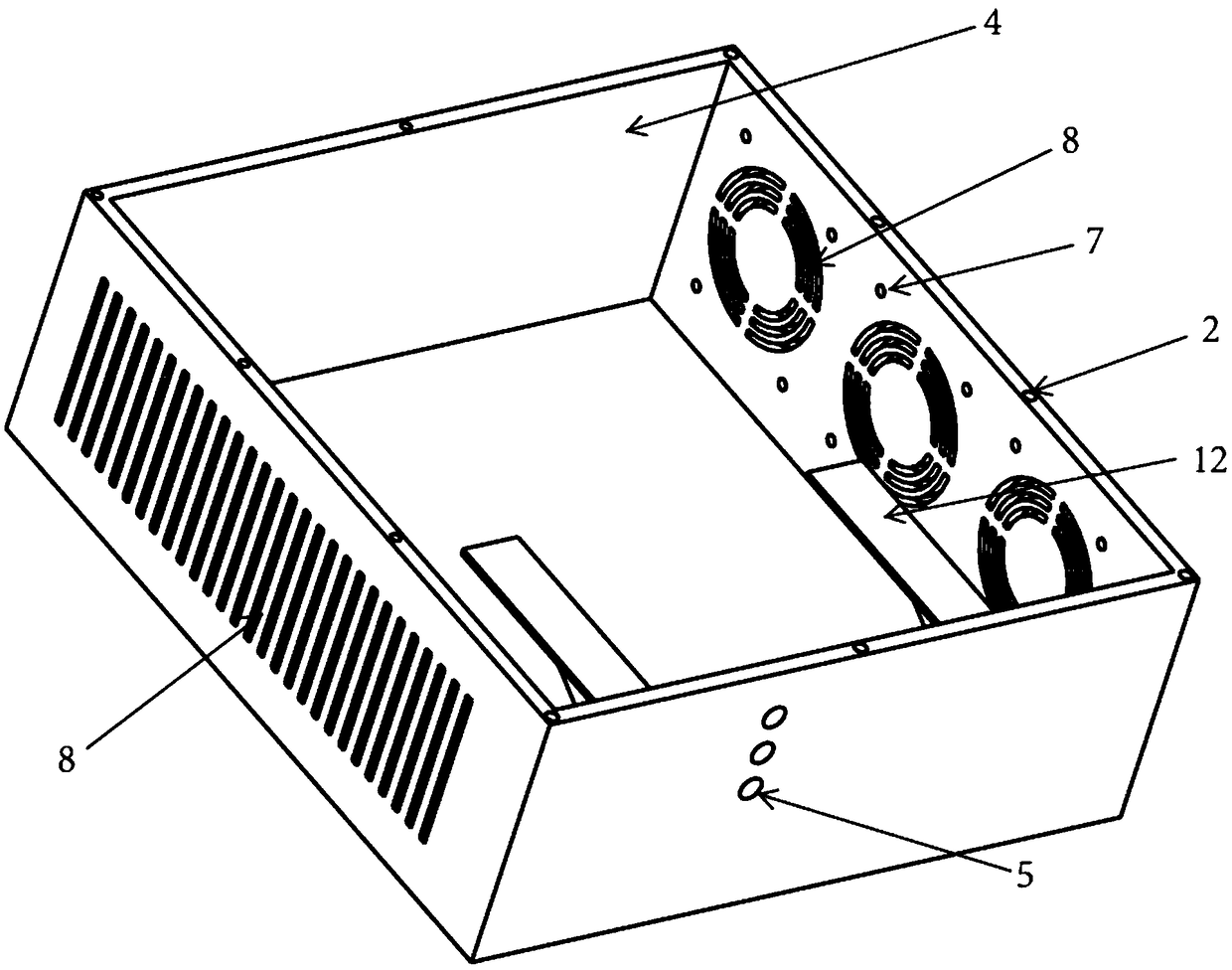

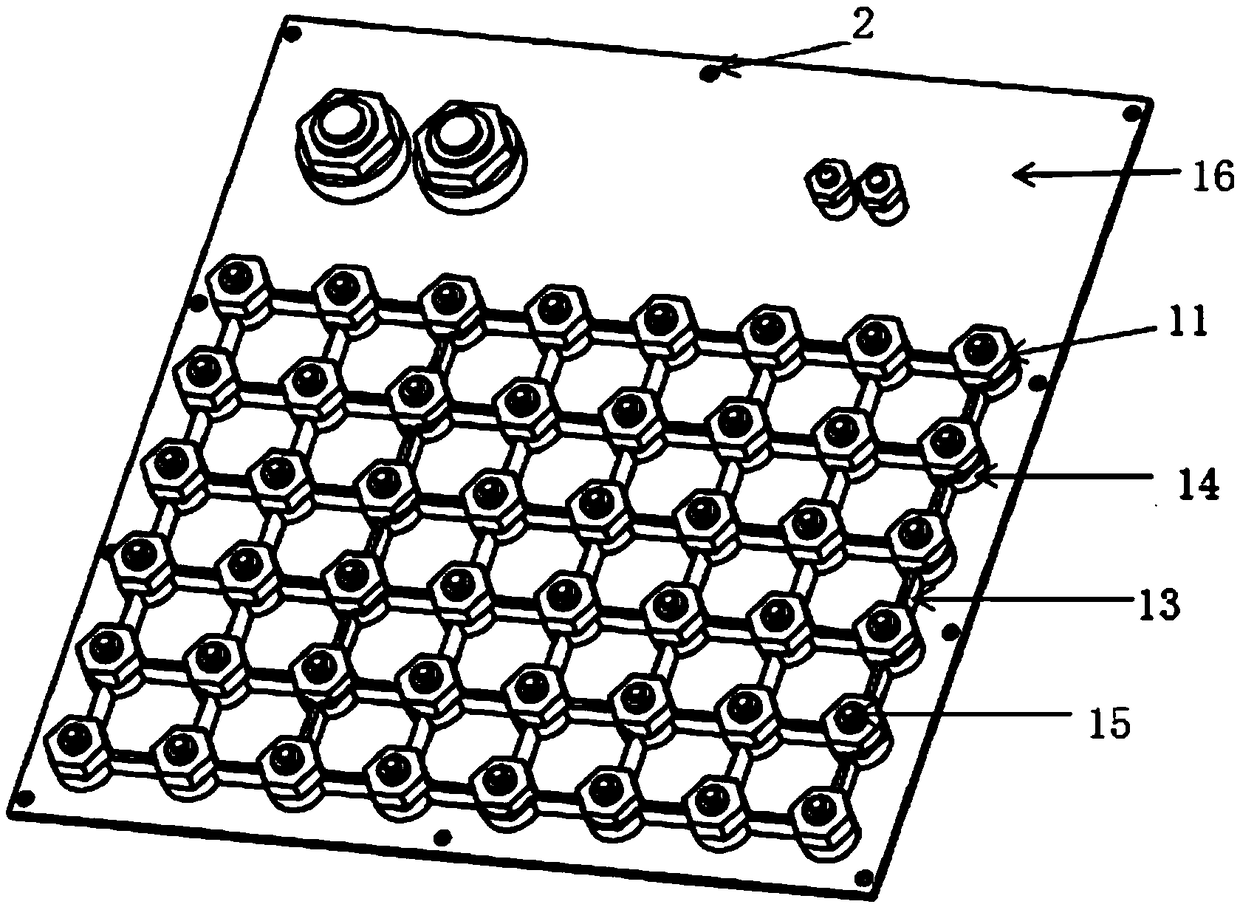

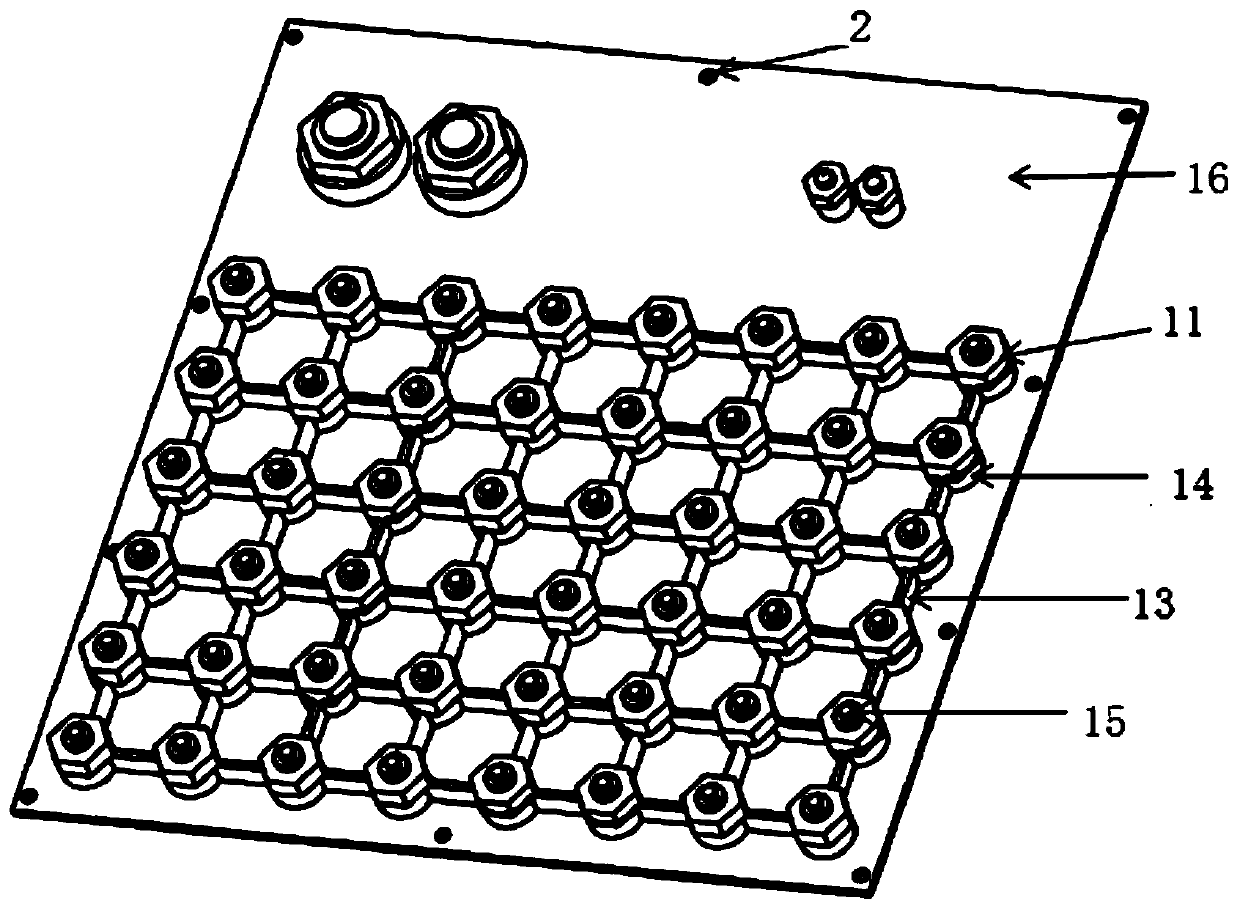

Calibration tooling for automatic calibration system for formation and capacity grading testing power supply

The invention discloses a calibration tooling for an automatic calibration system for a formation and capacity grading testing power supply. The calibration tooling comprises an upper top plate, a lower bottom plate and a side plate frame; a plurality of probes are arranged on the upper top plate and the lower bottom plate; probe points are arranged on the tops of the probes; the probes on the upper top plate and the lower bottom plate are in one-to-one correspondence; the probes are fixed by bolt and nut sets; and bolts are of a hollow structure and used for wrapping the probes. The probes ofthe calibration tooling of the invention are simple in structure and reasonable in design, are compatible with various specifications of test power supplies, and can be combined with the automatic calibration system to sample the current and voltage of the test power supply.

Owner:元山(济南)电子科技有限公司

Method and system for automatically calibrating electrical instrument

InactiveCN101592717BShorten the production cycleReduce workloadElectrical measurementsEngineeringElectric power

Owner:SHENZHEN CLOU ELECTRONICS

Method for positioning video camera using two arbitrary coplane circles

InactiveCN101329764BEasy CalibrationRealize fully automatic calibrationImage analysisAutonomous Navigation SystemEllipse

The invention relates to a method for calibrating a camera by any two coplanar circles, and two non-concyclic centre coplanar circles are used as the calibration objects. A clear image is taken by thecamera for the calibration objects, to define the equations of two elliptical shadows in the images and solve the coordinates of the image points of the focoids. The image point coordinates of the focoids and the shadow equations of absolute secondary curves are utilized to define the focal distance of the camera; a world coordinate system is set up, with the center of any of the two circles as the origin, and Z axis is parallel with the normal direction of the plane of the two circles. A rotation matrix is defined according to the relation between blanking points, blanking lines and the elliptical shadows; the solved position, of the world coordinate system, under the camera coordinate system is the right translation vector. The method of the invention can easily and conveniently defineall variable parameters every time when the camera is calibrated, can realize the wholly automatic calibration, reduce calculation errors arisen by human intervention, and is particularly suitable fornon-contact industrial inspection and the vision-based independent navigation system.

Owner:SHANGHAI JIAO TONG UNIV

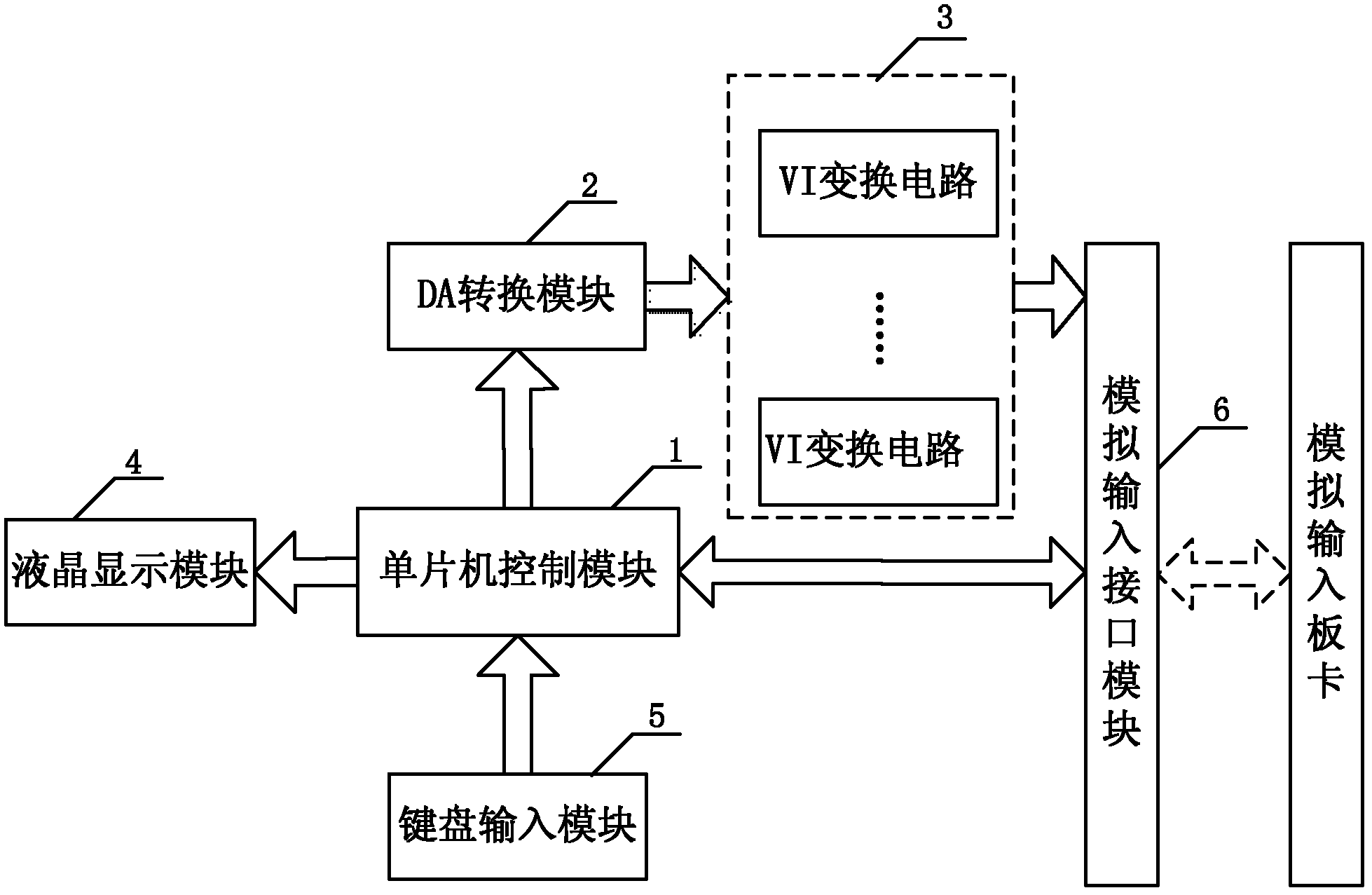

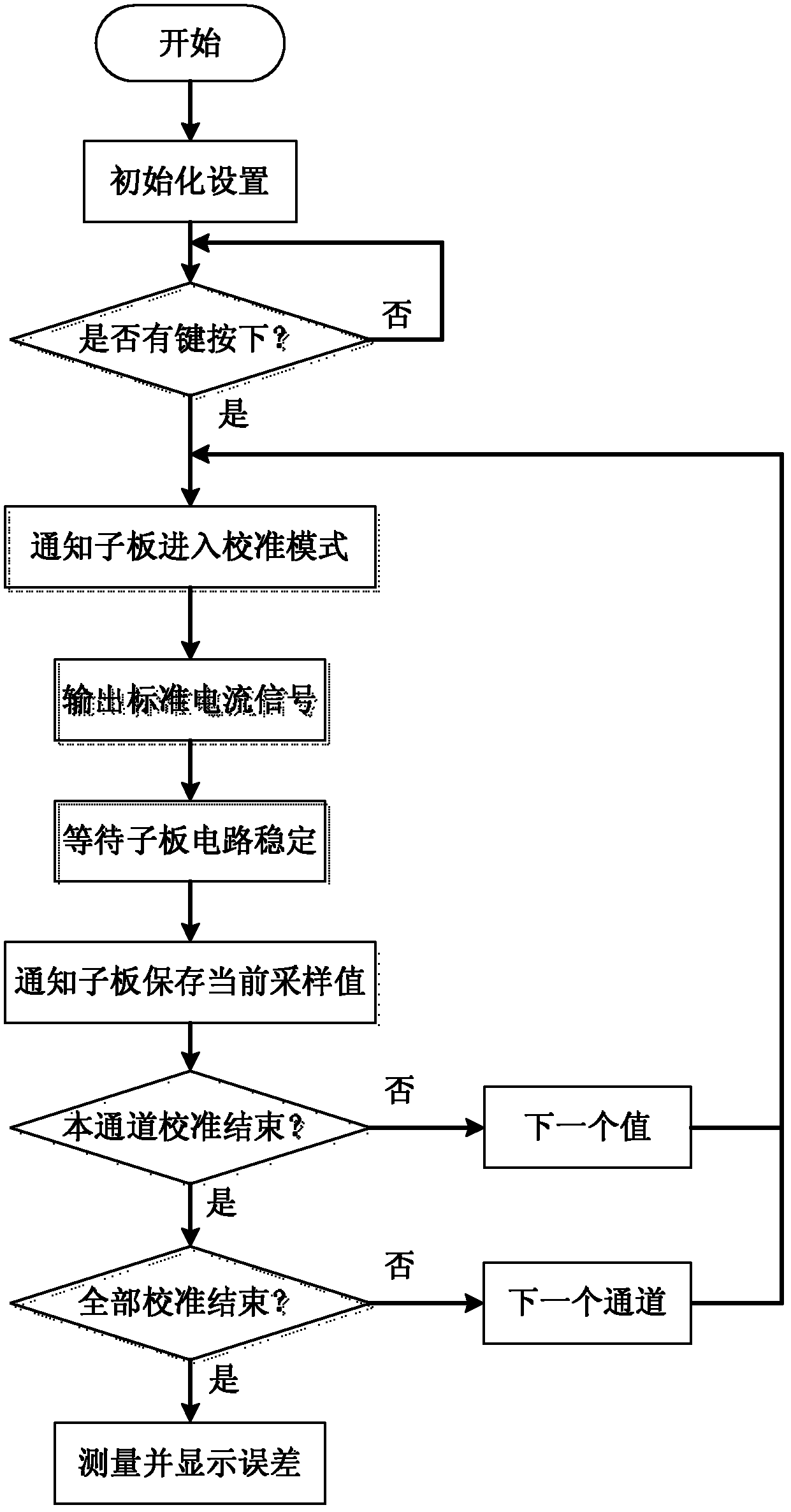

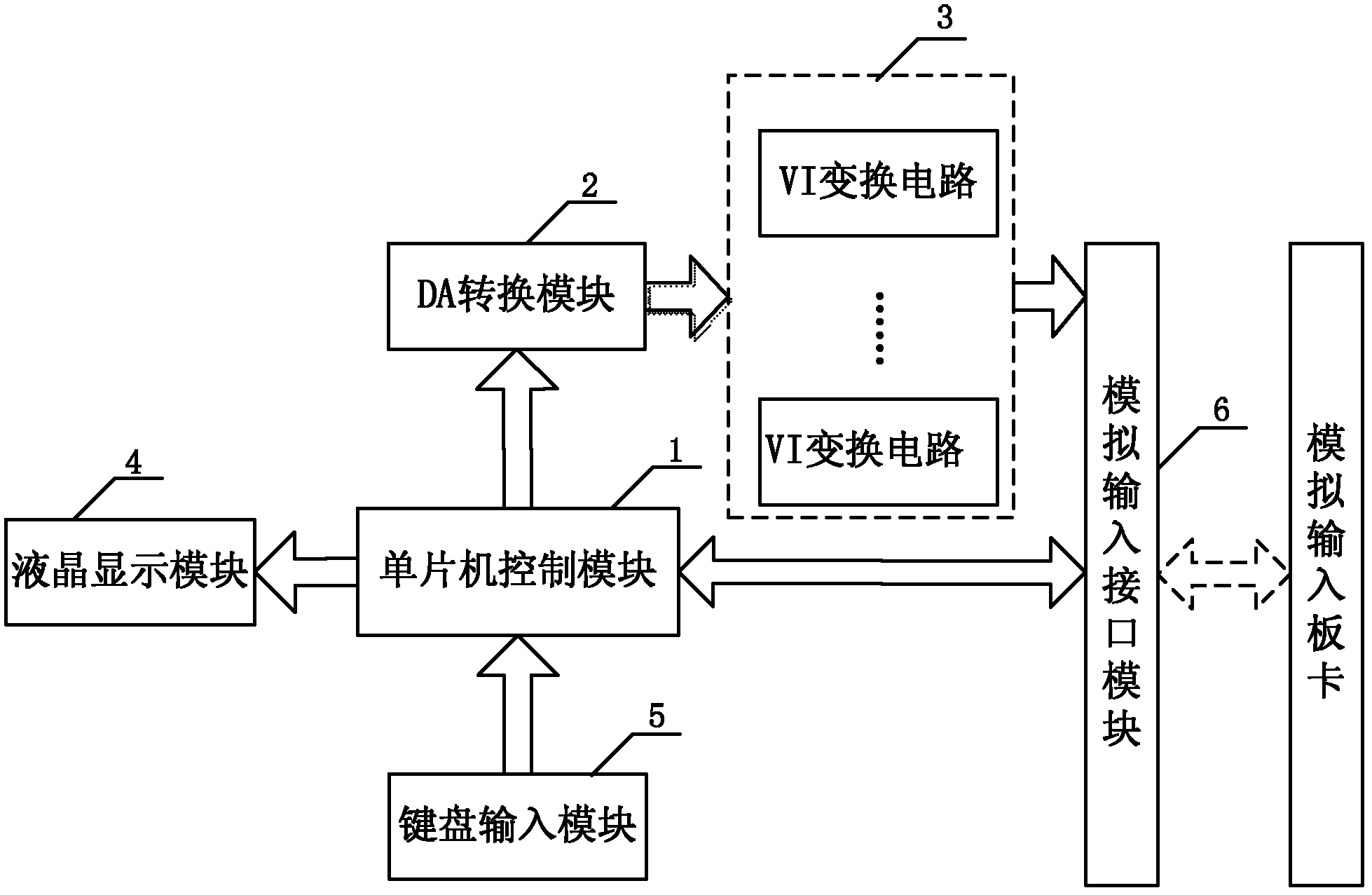

Device and method for automatic calibrating in water treatment analog data collecting system

ActiveCN102495386AAvoid shunt effectBoard error is smallElectrical measurementsIntegrated circuitData exchange

The invention belongs to the field of industrial process control, and particularly relates to a device and a method for automatic calibrating in a water treatment analog data collecting system, which solves the problems that the existing calibrating method for the water treatment analog data collecting system has big error, can't meet industrial standard, is complicated to operate, and is poorly universal. The automatic calibrating device includes a single chip control module, a DA conversion module, a VI transformation module, an LCD module, a keyboard input module and an analog input interface module. The calibrating method based on the device is that: the single chip control module controls the DA conversion module and the VI transformation module to form a standard current signal for the analog input interface module, the analog input interface module completes the communication between a to-be-calibrated analog input integrated circuit board and the single chip control module, soas to perform the data exchange between the analog input integrated circuit board and the single chip control module, the analog input integrated circuit board is calibrated under the control of the single chip control module as per the industrial standard current signal provided by the single chip control module, and the calibration error coefficient is stored.

Owner:NAT ENG RES CENT OF URBAN WATER RESOURCE

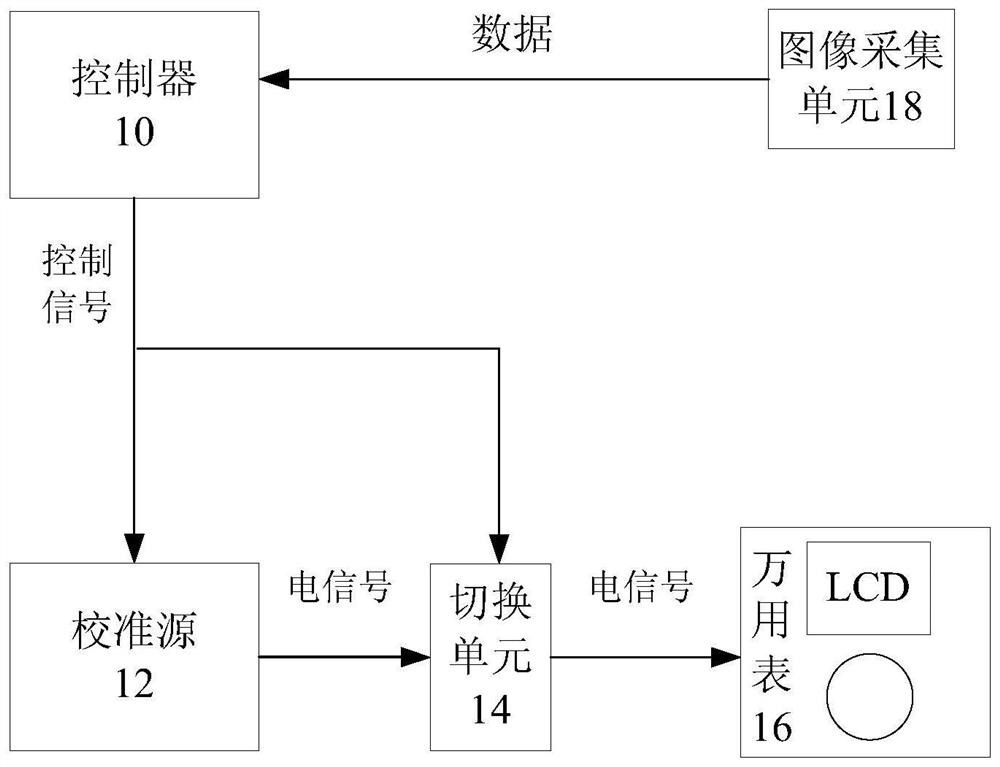

Automatic calibration device for digital multimeter

InactiveCN112415455ARealize fully automatic calibrationWith automatic reading functionElectrical measurementsComputer hardwareEngineering

The invention relates to the technical field of electrical metering, and discloses an automatic calibration device for a digital universal meter. The device comprises a controller, a calibration source, a switching unit and an image acquisition unit, wherein the controller is used for outputting a first instruction for controlling the calibration source to generate a standard signal and a second instruction for controlling the switching unit to switch between different paths of the digital multimeter; the calibration source is used for generating a corresponding standard signal according to the first instruction; the switching unit is used for switching to the corresponding path according to the second instruction and transmitting the standard signal generated by the calibration source tothe switched path so as to enable the digital multimeter to execute measurement; the image acquisition unit is connected with the controller and is used for acquiring a reading image of the digital multimeter and outputting the reading image to the controller; and the controller is also used for identifying the reading image to obtain the reading of the digital multimeter, calculating an error according to the obtained reading, and judging whether the digital multimeter is out of tolerance or not according to the calculated error. Therefore, full-automatic calibration of the digital multimetercan be realized.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

A system and method for automatic calibration of optical fiber gauge factor

ActiveCN105333834BRealize fully automatic calibrationImprove accuracyUsing optical meansTime-domain reflectometerRecognition algorithm

The invention discloses a system and method for automatic calibration of an optical fiber strain coefficient. By reading a center frequency shift distribution curve tested by a Brillouin light time domain reflectometer, according to an estimated value of the original length of an optical fiber, the automatic identification of a strain area is finished by changing displacement lengths at large intervals by means of a strain area recognition algorithm; after the strain area is recognized, the displacement lengths are changed sequentially from large to small, so that the optical fiber sequentially generates strain from large to small, a theoretical strain value of the optical fiber and an actual Brillouin spectrum frequent shift value are calculated by utilizing an optical fiber strain coefficient analytical algorithm, and all-automatic calibration of the optical fiber strain coefficient is achieved. According to the system and method for automatic calibration of the optical fiber strain coefficient, the all-automatic calibration of the optical fiber strain coefficient can be achieved, and the strain coefficient calibration accuracy and strain coefficient calibration efficiency are improved effectively.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

XYY precision positioning platform calibration method

ActiveCN101260967BSimplify the decoupling processImprove calibration accuracyCalibration apparatusStands/trestlesActuatorFully automatic

The invention provides a calibration method for an XYY precision positioning platform. The method is used for completely solving the problems of executor calibration, decoupling and telescopic sensor calibration in single flow. The method is realized by arranging a separated position sensor at the external of the XYY precision positioning platform and orderly accomplishing the executor calibration, the telescopic sensor calibration and decoupling matrix calibration. The method sufficiently uses the position sensor which is independent of the platform. The position sensor is not only used for decoupling, but also used for the executor calibration and the telescopic sensor calibration. Besides, with the superposition property of matrix operation, the decoupling process can be simplified. The calibration method is high in precision, fast in speed, and capable of realizing fully automatic calibration. For lithography tools, the calibration method can be realized by using the prior devicesin the lithography tools without arranging extra special devices.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

A calibration tool for automatic calibration system of chemical composition and volume test power supply

ActiveCN108614232BSimple structureReasonable designElectrical measurementsTest powerChemical composition

The invention discloses a calibration tooling for an automatic calibration system for a formation and capacity grading testing power supply. The calibration tooling comprises an upper top plate, a lower bottom plate and a side plate frame; a plurality of probes are arranged on the upper top plate and the lower bottom plate; probe points are arranged on the tops of the probes; the probes on the upper top plate and the lower bottom plate are in one-to-one correspondence; the probes are fixed by bolt and nut sets; and bolts are of a hollow structure and used for wrapping the probes. The probes ofthe calibration tooling of the invention are simple in structure and reasonable in design, are compatible with various specifications of test power supplies, and can be combined with the automatic calibration system to sample the current and voltage of the test power supply.

Owner:元山(济南)电子科技有限公司

Electronic transformer automatic debugging system

ActiveCN104090256BRealize fully automatic calibrationReal-time temperature monitoringElectrical measurementsMicrocomputerMicrocontroller

Owner:STATE GRID CORP OF CHINA +1

Portable infrared gas analyzer with automatic range calibration and calibration method

InactiveCN104764693BRealize fully automatic calibrationGuaranteed measurement accuracyMaterial analysis by optical meansInfraredCalibration gas

The portable infrared gas analyzer with automatic range calibration provided by the present invention includes a preprocessing unit, an analysis unit, a main monitoring unit, a calibration unit and a correction unit, and the analysis unit includes a light source, an absorbing gas chamber and a receiving gas chamber, and the The light source generates infrared light and injects it into the absorbing gas chamber. The calibration unit performs zero point calibration and range calibration and sends the calibrated gas into the receiving gas chamber. The calibration unit calculates the deviation caused by the actual environmental change The measurement connection of the sample gas concentration can be automatically corrected by shifting increments; the invention can automatically correct the measurement results, which not only overcomes the influence of the measurement environment on the measurement, but also ensures the measurement accuracy of the system. It can be analyzed for a long time, saving cost and easy to carry.

Owner:CHONGQING TECH & BUSINESS UNIV

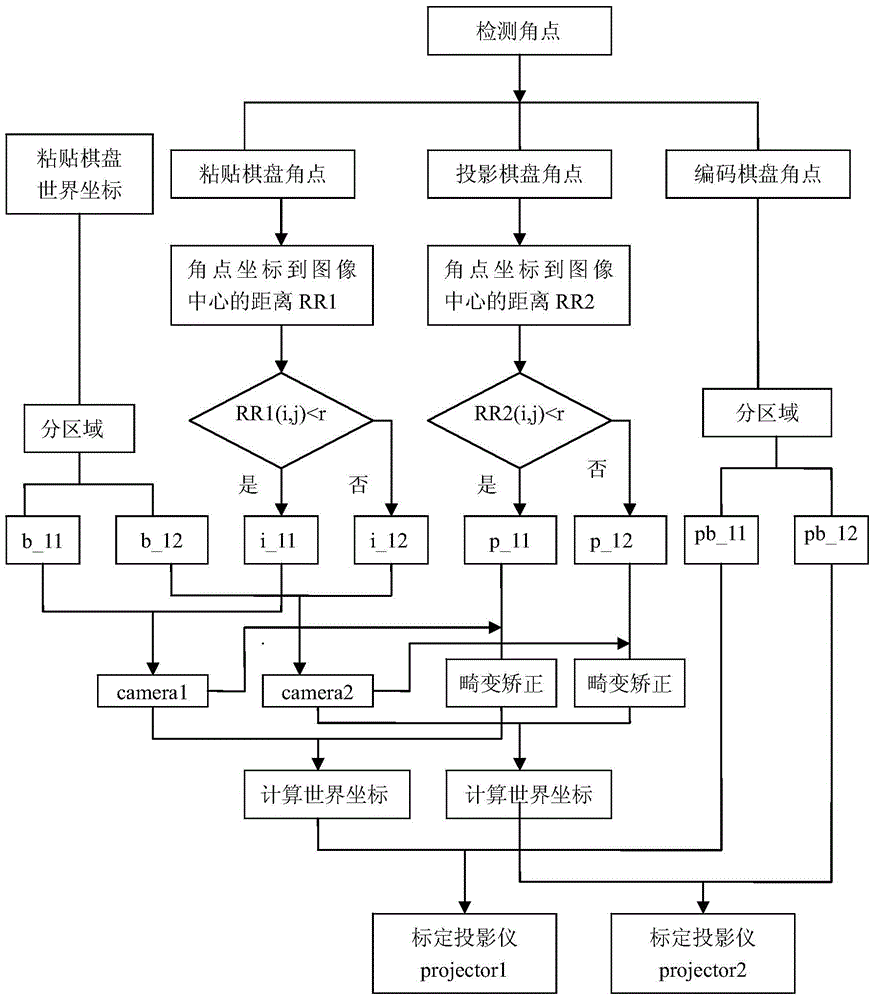

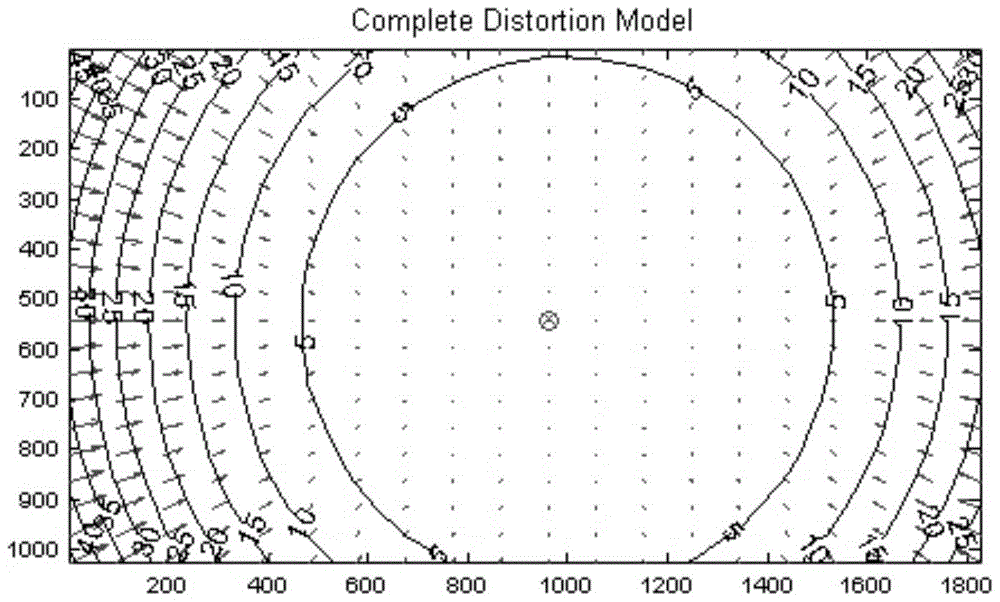

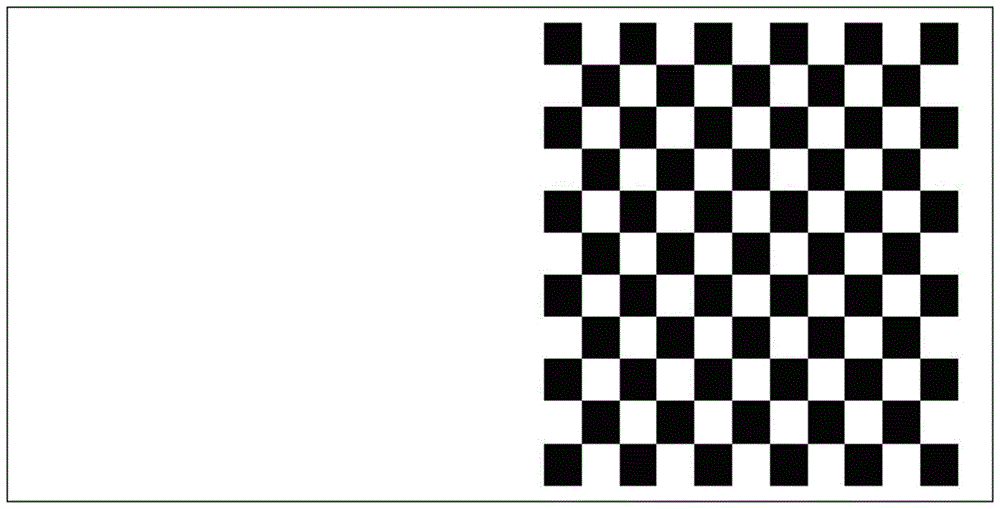

Projector Calibration Method Based on Lens Distortion Law

The invention discloses a projector area calibration method by utilizing concentric circular rings on the basis of a lens distortion rule, and solves a problem of low calibration precision when a field of view is enlarged at present while a problem of insufficient optical lens distortion processing is solved. The method comprises the following steps: firstly, projecting a specially-designed checkerboard image onto a plane calibration board by utilizing a DLP (Digital Light Processing) projector, and capturing a calibration object image which contains a pasting checkerboard and a projection checkerboard by a CCD (Charge Coupled Device) camera; changing the position of the plane calibration board for multiple times to obtain multiple pairs of calibration object images; according to the lens distortion rule, taking the center of each calibration image as a center of a circle, calculating distance between each angle point to the center of a circle, and comparing the distance with a given radius value to divide the concentric circular ring areas; on the basis of each concentric circular ring, calibrating a camera, carrying out distortion correction to the data of the projection checkerboard by utilizing calibration parameters so as to calibrate the projector to obtain the internal and external parameters of the projector of a corresponding area; and repeating the above operations to the circular ring areas to finish the calibration of the projector.

Owner:NANJING UNIV OF POSTS & TELECOMM

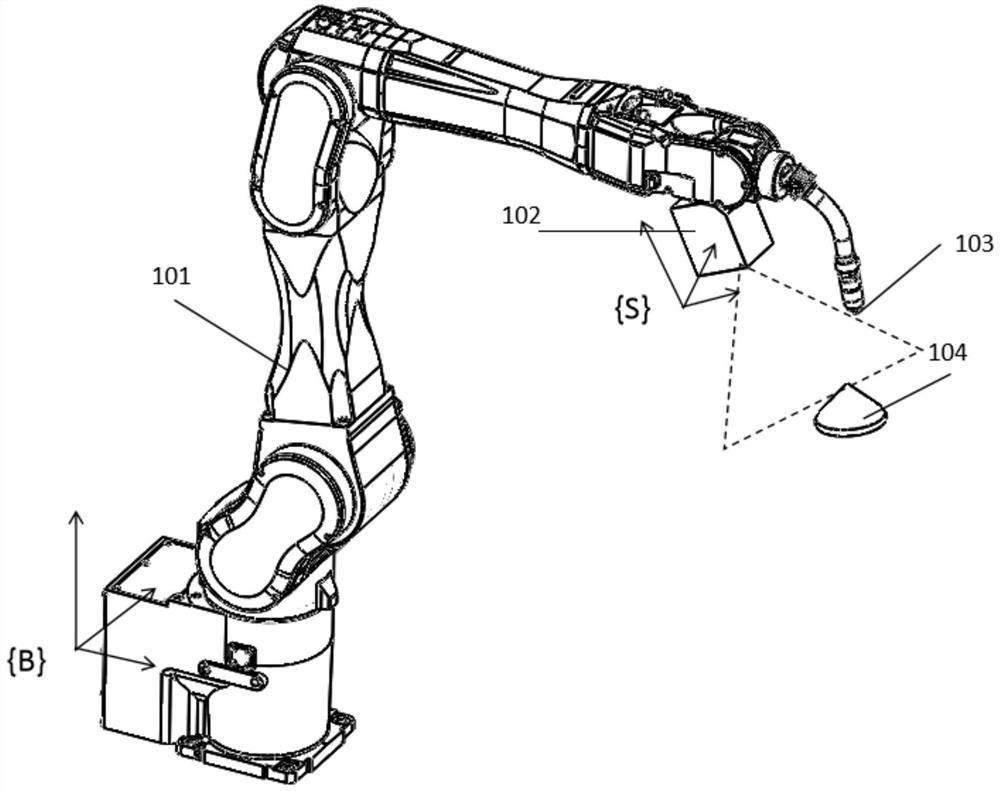

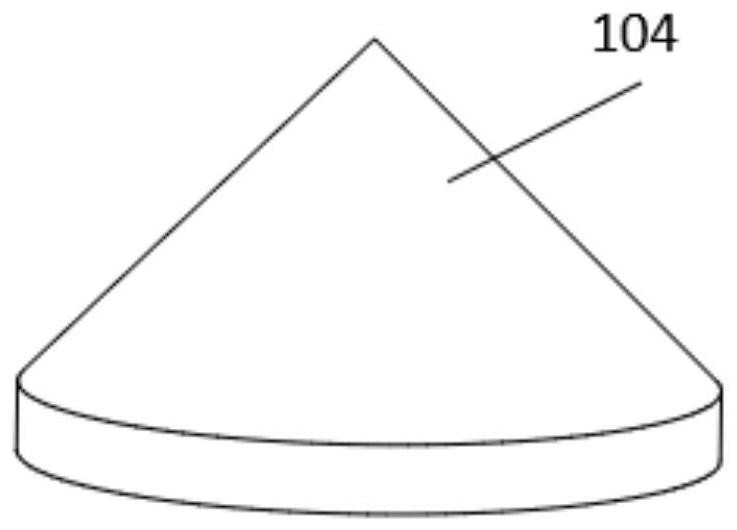

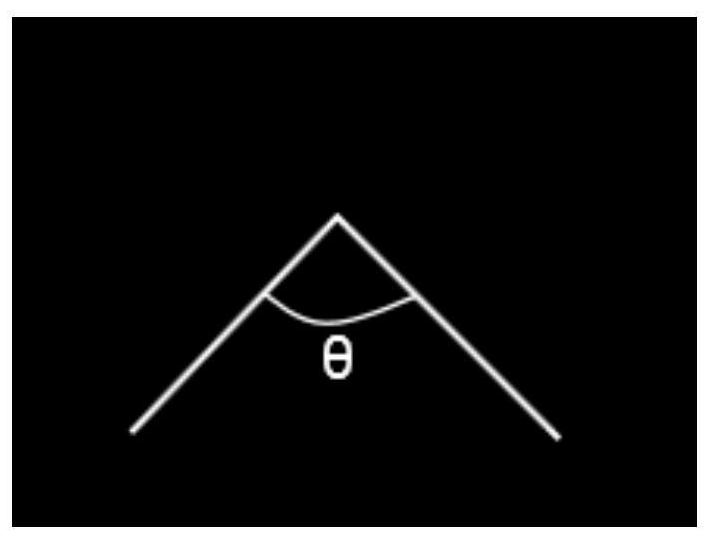

A hand-eye calibration system and calibration method for line structured light sensor

ActiveCN110906863BEasy alignmentImprove alignment accuracyUsing optical meansEngineeringLeast squares

Owner:成都绝影智能科技有限公司

Method of Camera Calibration Using Two Same Circles

InactiveCN101621711BEasy to getEasy accessImage analysisTelevision systemsAutonomous Navigation SystemEllipse

The invention relates to a method for camera calibration using two identical circles, using two non-tangent identical circles as calibration objects, using a camera to photograph the calibration objects from three different angles to obtain three clear images, and determining each The equations of the two elliptical images in the figure, and find the coordinates of a pair of circular point images in each figure. The internal parameters of the camera are determined by using the coordinates of the circular point images of the three images and the projection equation of the absolute conic curve. For each image, find the inner and outer common tangents of two ellipse images; recover and correct the angle between the inner and outer common tangents of two identical circles in the world coordinate system; according to the established world coordinates of the inner and outer common tangents of two identical circles and its projected image coordinates to obtain the external parameters of the camera. The invention can obtain the internal and external parameters of the camera simply and accurately, and can realize automatic calibration. The invention can be widely used in non-contact industrial detection and vision-based autonomous navigation systems.

Owner:NANTONG YIXUAN IND DESIGN CO LTD +1

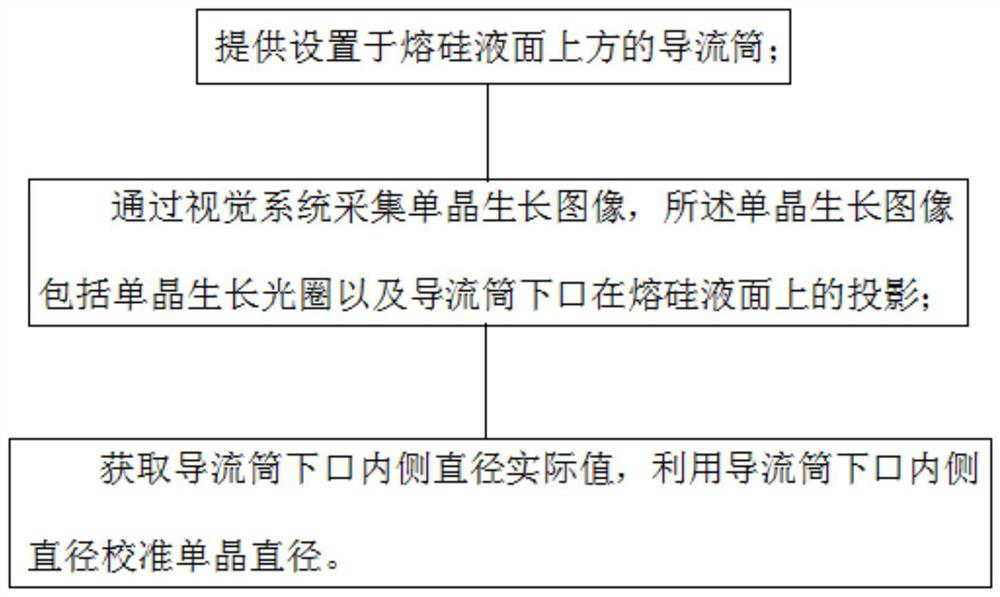

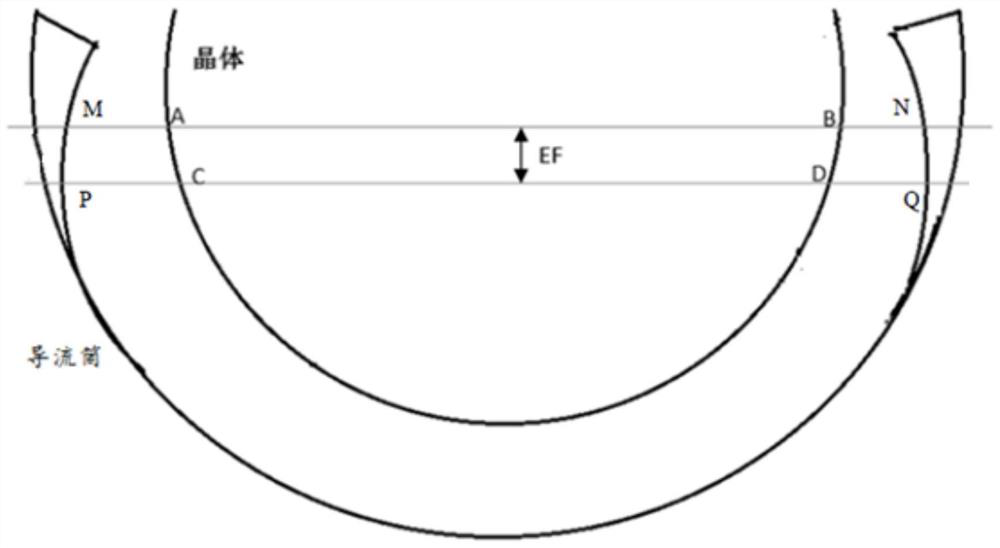

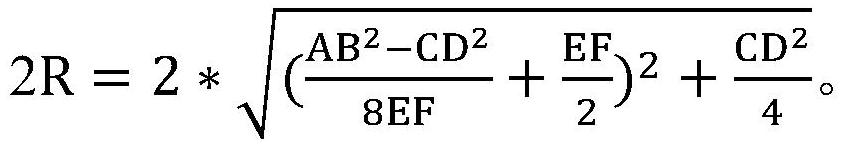

Method for Measuring the Diameter of Czochralski Single Crystal

ActiveCN110528070BRealize real-time calibrationAvoid defectsBy pulling from meltSingle crystalSingle crystal growth

Owner:LONGI GREEN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com