XYY precision positioning platform calibration method

A calibration method, precise positioning technology, applied in the direction of machine/stand, supporting machine, photolithography process exposure device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

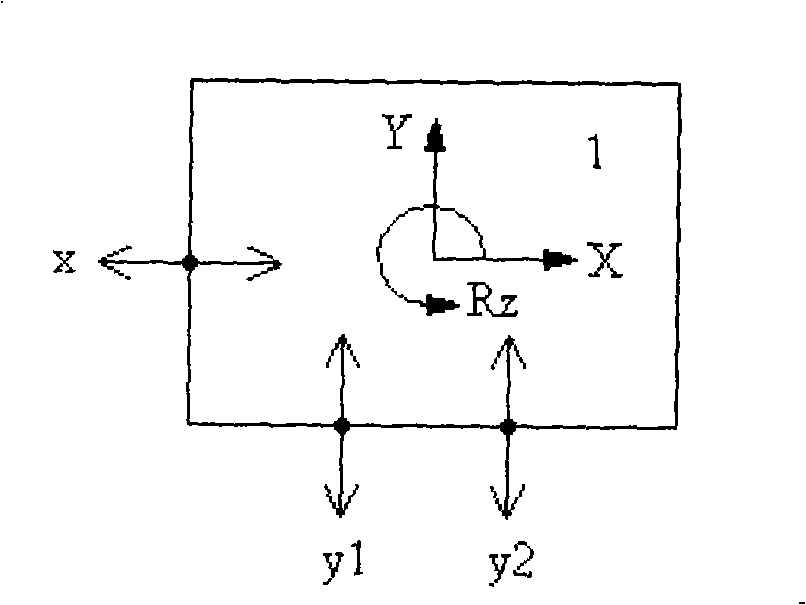

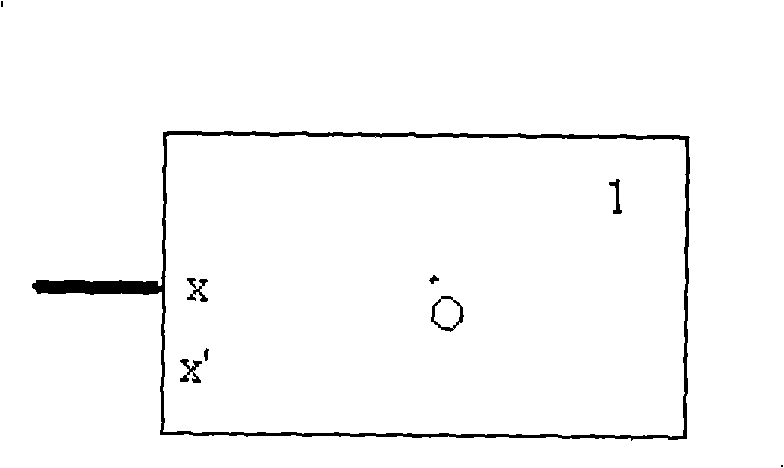

[0072] The calibration method of the XYY precision positioning platform of the present invention will be described in detail below in conjunction with the accompanying drawings.

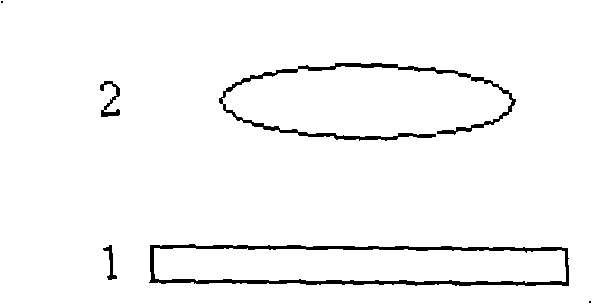

[0073] image 3 It is an arrangement method of the XYY platform in the lithography machine. Above the platform 1, there is a position sensor 2, which can detect the position of the platform 1. Since the position sensor 2 is independent of the platform 1, it can accurately detect the position of the platform 1 regardless of whether the platform 1 is calibrated or not. In other embodiments of the present invention, the position sensor 2 can also be installed on the side or under the platform 1 , as long as it is independent from the platform 1 .

[0074] Calibration is divided into three steps, and the order cannot be reversed. The details are as follows:

[0075] Step 1: Actuator Calibration

[0076] see Figure 4 , where F is the control value from the controller. In order to calibrate the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com