A system and method for automatic calibration of optical fiber gauge factor

An automatic calibration system and optical fiber strain technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of large error in calibration results of optical fiber strain coefficient, poor precision, cumbersome manual operation steps, etc., to improve accuracy and Effect of Gage Factor Calibration Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

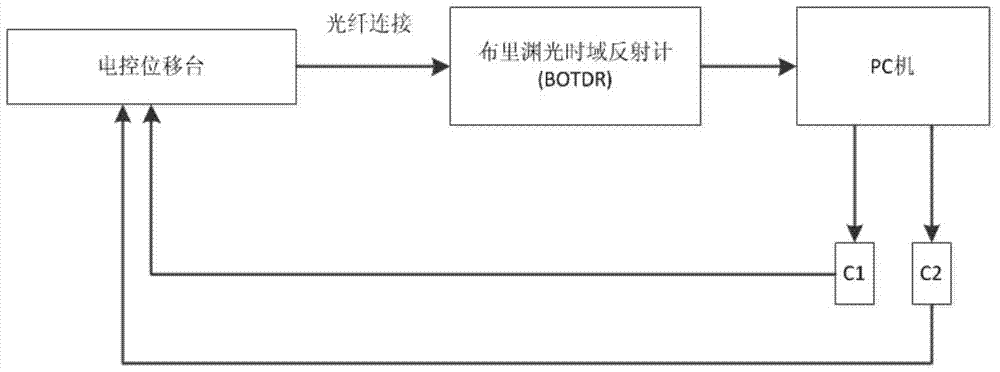

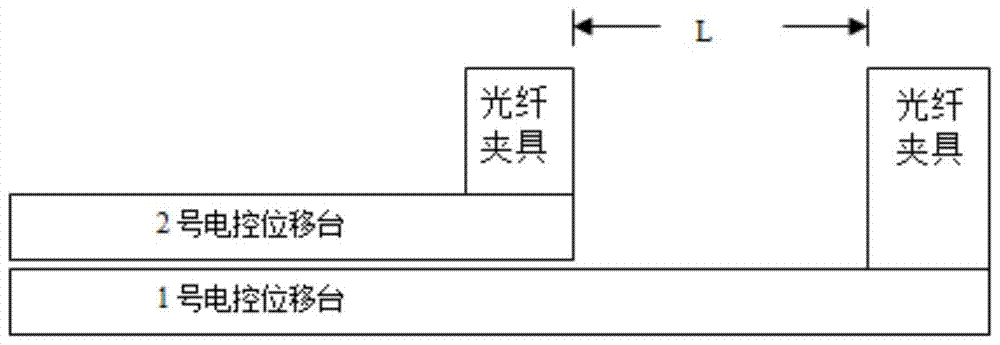

[0048] In the automatic calibration method of optical fiber strain coefficient proposed by the present invention, devices such as computer-controlled electronically controlled displacement stage, dual-frequency laser interference device, Brillouin optical time domain reflectometer and the like are used to complete the automatic calibration of optical fiber strain coefficient. The device is connected as figure 1 shown. The movement of the electronically controlled displacement stage is used to generate strain on the optical fiber, and the original length and displacement length of the optical fiber are measured by a dual-frequency laser interferometry device, and the displacement length of the displacement stage is corrected twice in combination with the grating ruler.

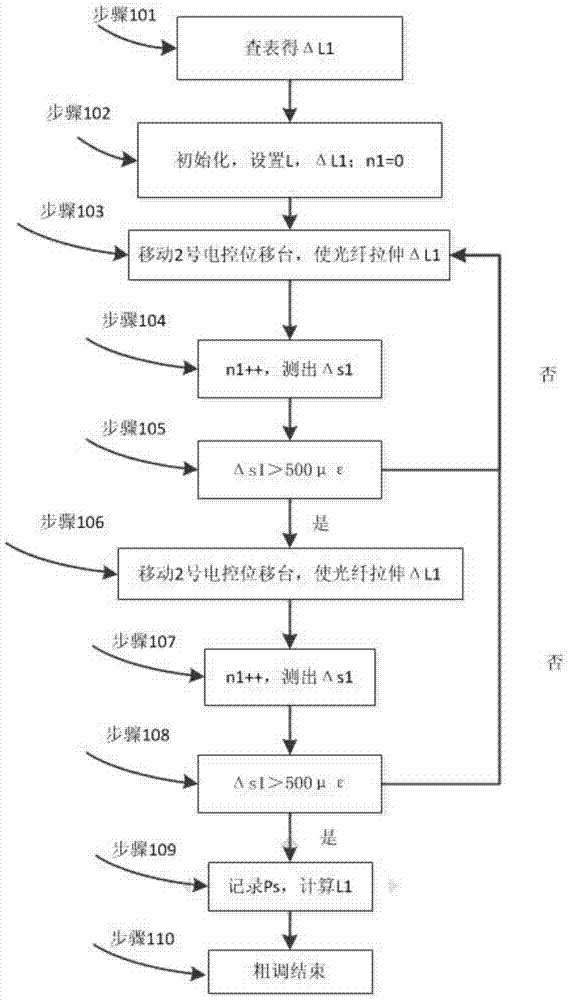

[0049] This method will automatically read the central frequency shift distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com