A hand-eye calibration system and calibration method for line structured light sensor

A structured light sensor and line structured light technology, applied in the field of visual calibration, can solve the problems of difficult to control the line structured light to accurately scan to the same fixed point, low positioning accuracy of fixed point, difficult end tool tip, etc., to improve the accuracy of hand-eye calibration , The calibration process is simple and efficient, and the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

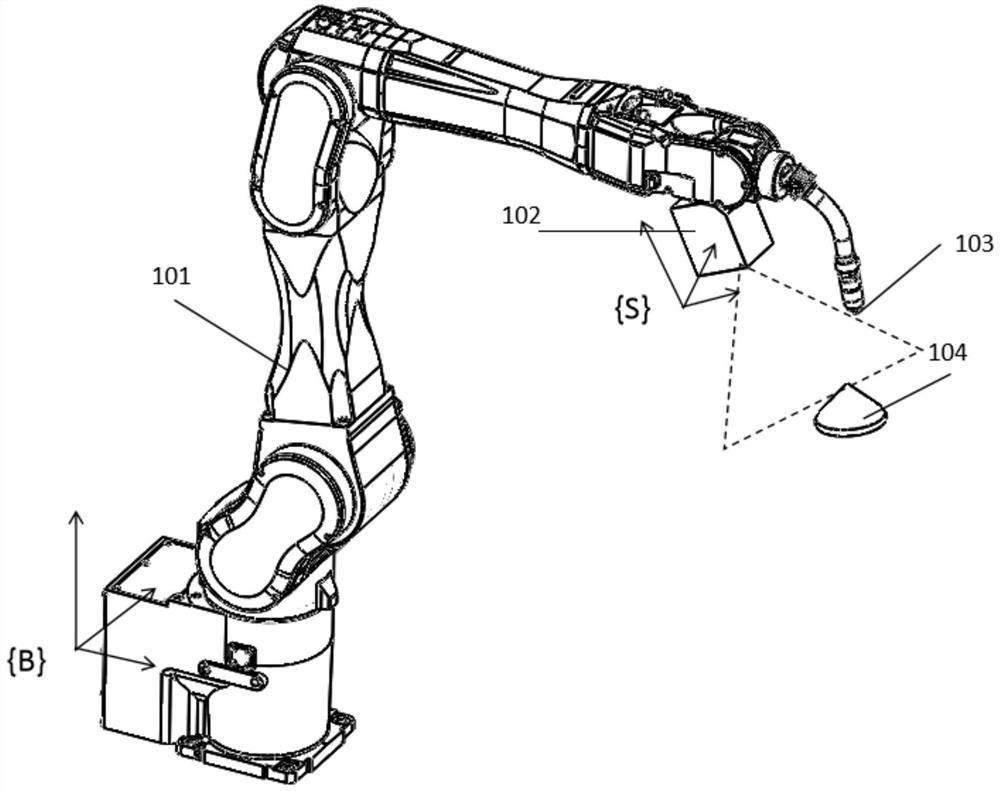

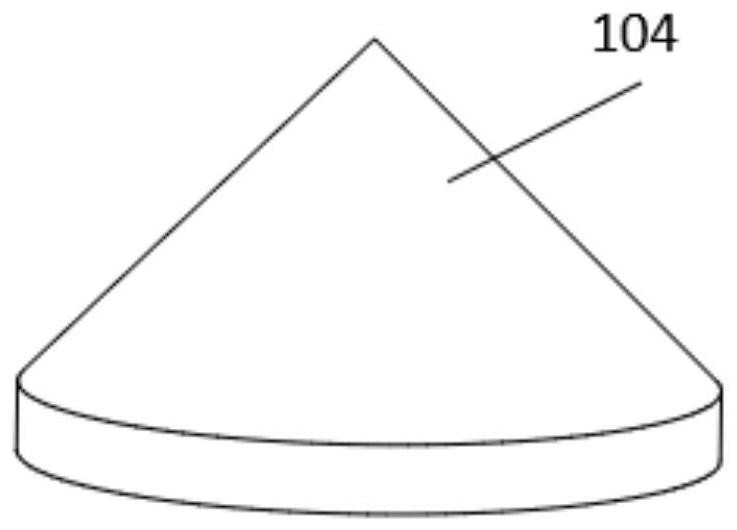

[0058] Such as figure 1 As shown, on the one hand, this embodiment provides a hand-eye calibration system for a line structured light sensor, including a six-axis robot 101, a line structured light sensor 102, an end tool 103 and a tapered target 104, the end tool 103 is provided at the end of the action part of the robot 101 as a tool for performing specific work.

[0059] The line structured light sensor 102 is selected as a laser seam tracking sensor.

[0060] The coordinate system of the robot 101 (equivalent to the world coordinate system) is {B}, and its coordinate origin is located at the center of the base of the robot 101; the coordinate system of the line structured light sensor 102 is {S}, and its coordinate origin is located inside the sensor, which has been calibrated by the manufacturer before leaving the factory . The purpose of hand-eye calibration is to obtain a transformation matrix, so as to transform the weld seam coordinates measured by the seam tracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com