Method for Measuring the Diameter of Czochralski Single Crystal

A diameter measurement, single crystal technology, applied in the direction of single crystal growth, chemical instruments and methods, self-melt pulling method, etc., can solve the problem of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

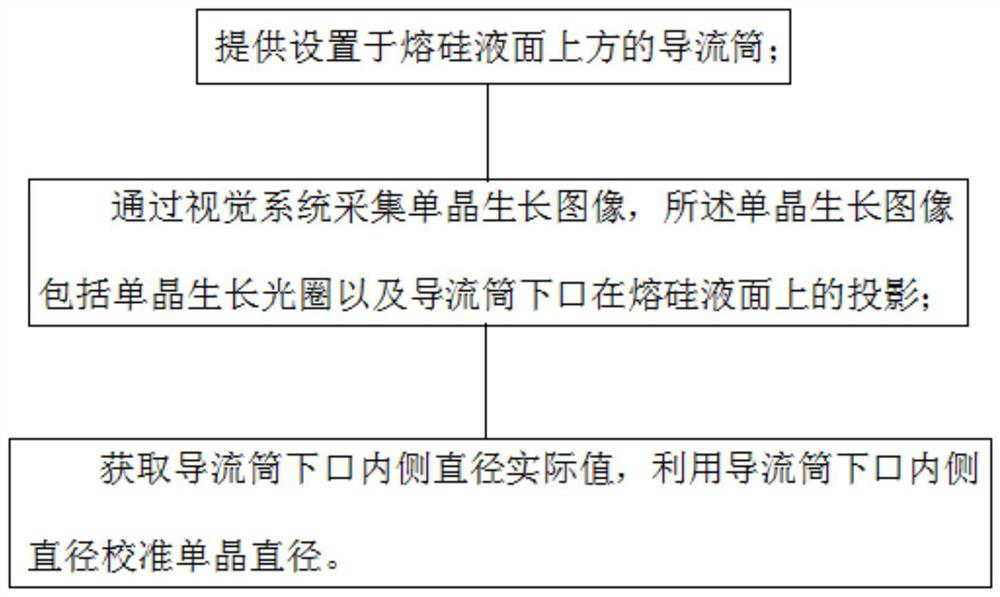

Method used

Image

Examples

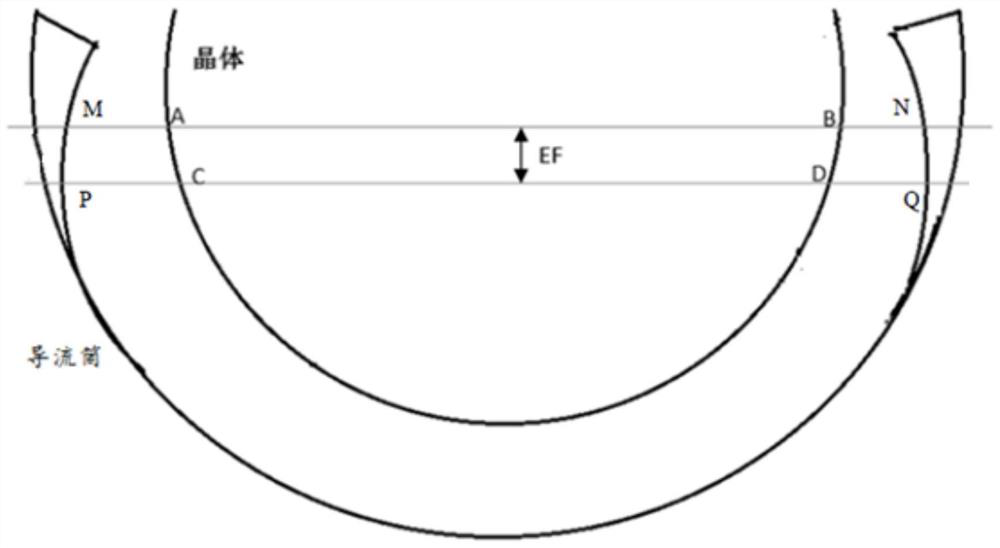

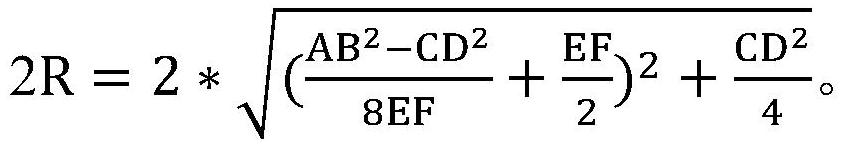

Embodiment 1

[0040] The single crystal furnace platform described in this embodiment is equipped with a vision system and an industrial computer. The vision system includes at least a CCD camera, and the CCD camera preferably has high measurement accuracy, preferably, the resolution is not lower than 2 million pixels. The CCD camera is fixed on the observation window on the side of the single crystal furnace, adjust the angle and object distance of the CCD camera so that the diameter of the single crystal (rod) and the crucible are all within the field of view of the single crystal growth image, and adjust the focal length of the CCD camera (camera) to make the diameter of the single crystal in the image And the inner projection (reflection) of the lower opening of the crucible and the draft tube is clearly visible. The single crystal growth image collected by the vision system in real time is input to the industrial computer through the circuit, and the single crystal growth image is proc...

Embodiment 2

[0072] Using the single crystal diameter measurement method described in Example 1, taking a 26-inch thermal field Czochralski single crystal with a diameter of 215 mm as an example, the single crystal diameter measurement method will be further described in combination with actual operation steps.

[0073] The first step is to provide a draft tube arranged above the liquid surface of molten silicon.

[0074] In this embodiment, a 26-inch thermal field is used, and the actual value 2r of the inside diameter of the lower opening of the guide tube is 270mm.

[0075] In the second step, the single crystal growth image is collected by the vision system. The single crystal growth image includes the single crystal growth aperture and the projection of the inner side of the lower opening of the draft tube on the molten silicon surface.

[0076] Adjust the object distance and angle of the camera so that the inner projections of the crucible and the lower opening of the draft tube are ...

Embodiment 3

[0103] For the case where the diameter of the single crystal is of other sizes, the actual value of the inner diameter of the lower opening of the draft tube described in Embodiments 1 and 2 remains unchanged under the condition that the guide tube in the single crystal furnace platform remains unchanged, and it is only necessary to obtain The measurement pixel AB of the first measurement line of the crystal diameter and the measurement pixel CD of the second measurement line of the crystal diameter, the measurement pixel MN of the first measurement line of the flow guide tube diameter and the measurement pixel PQ of the second measurement line of the flow guide tube are calculated respectively The actual value of the diameter of the single crystal can be obtained according to the proportional relationship of the single crystal diameter 2R and the diameter pixel 2R′ of the draft tube in the single crystal growth image. For the same image interface, under the premise that the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com