External calibration source for infrared radiometer in vacuum low-temperature environment and temperature control system

A technology of vacuum low temperature and infrared radiation, applied in the field of calibration and calibration, infrared radiation measurement, can solve the problems of inability to achieve high-precision on-orbit calibration, inaccurate measurement values, and narrow calibration temperature range, so as to ensure accurate measurement Sexuality, accurate value, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

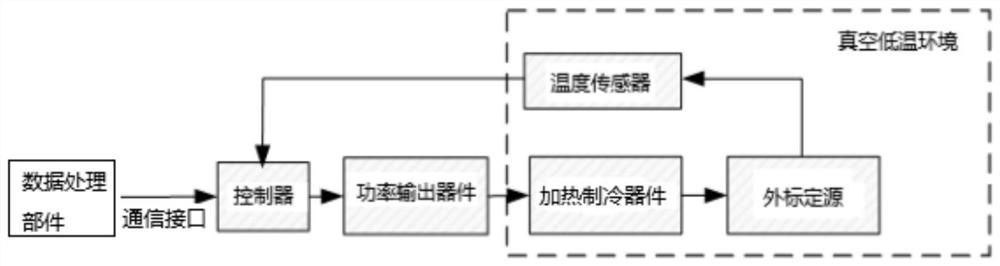

[0025] The vacuum low-temperature environment of the present invention is the environment in a liquid nitrogen refrigeration vacuum chamber, and the temperature of the inner wall of the vacuum chamber is 77K.

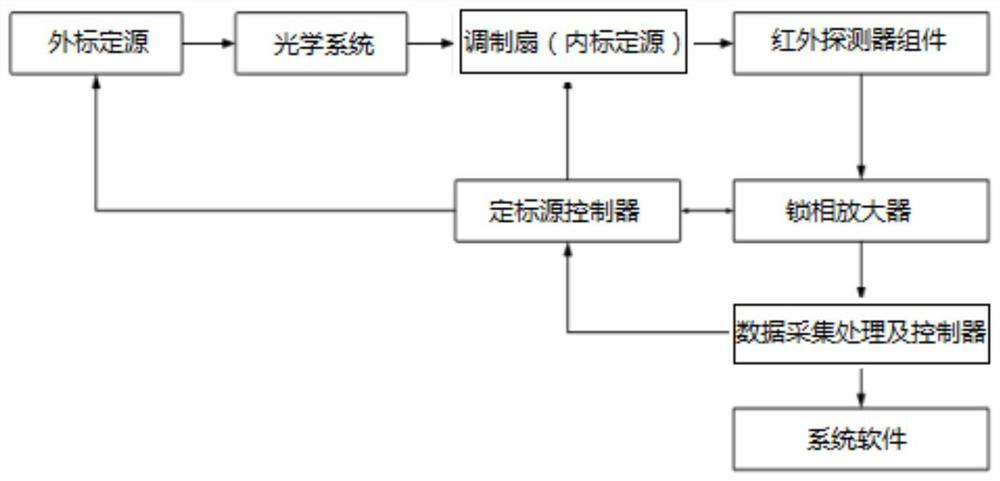

[0026] The infrared radiometer is composed of the following main components: optical system, internal calibration source, external calibration source, infrared detector assembly, lock-in amplifier, calibration source controller, data acquisition processing and controller. Such as figure 1 shown.

[0027] The internal calibration source and the external calibration source are used for calibration of the infrared radiometer, and the external calibration source is a vacuum standard blackbody; the internal calibration source is a moving vacuum standard blackbody integrated with the modulation fan;

[0028] The optical system is used to collect target light;

[0029] The modulation fan is placed between the optical system and the infrared detector assembly to modulate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com