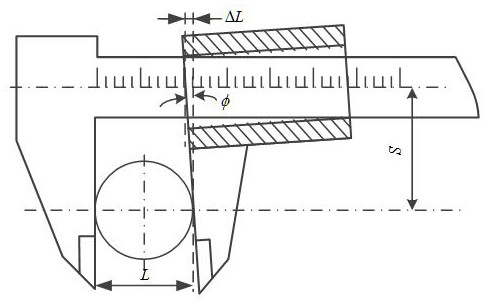

Vernier caliper capable of effectively reducing Abbe error and measuring method

A vernier caliper and Abbe error technology, which is applied in the field of vernier calipers, can solve the problems of low measurement accuracy and large Abbe error, and achieve the effects of improving measurement accuracy, reducing Abbe error, and eliminating tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

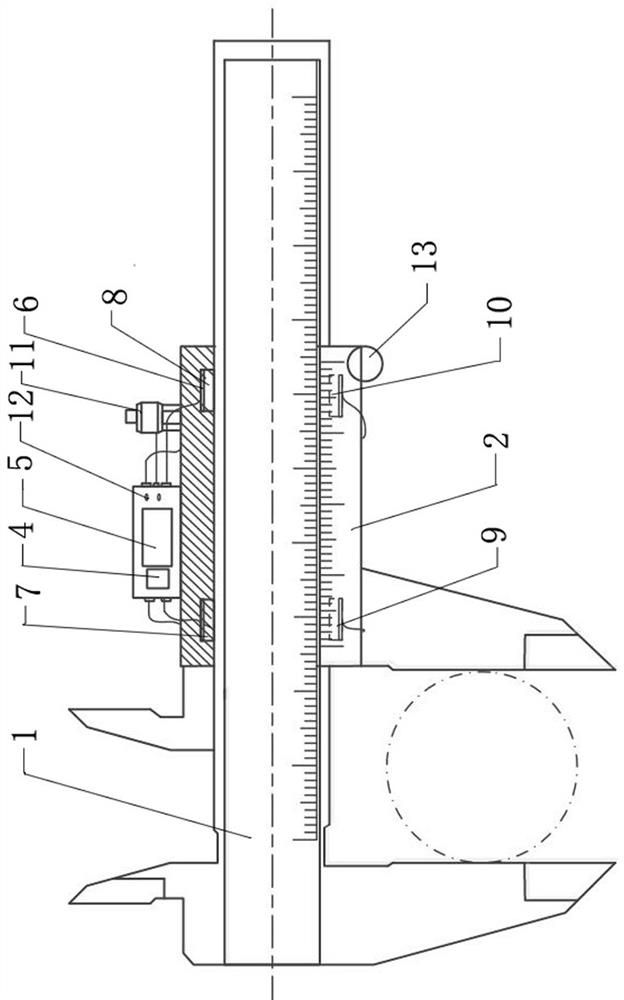

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

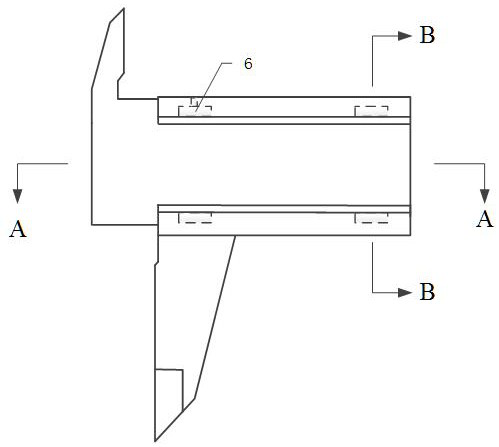

[0033] Such as Figure 2 to Figure 5 As shown, the vernier caliper of the present invention that can effectively reduce the Abbe error includes a main ruler 1 and a vernier ruler 2. The upper and lower ends of the front side of the vernier ruler 2 are formed with flanges to form a main ruler accommodating groove 3. The main ruler 1 is set in the main scale accommodating groove 3 and the vernier scale 2 is slidably connected with the main scale 1. The above-mentioned structure is a conventional structure of the existing vernier caliper and will not be repeated here.

[0034] In the present invention, pressure sensing devices are arranged symmetrically along the front and rear directions in the main ruler accommodating grooves 3 at the upper and lower ends, and the pressure sensing devices are used to collect the pressure signals generated by the main ruler 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com