Construction method of large space building

A construction method and building technology, applied in building structure, processing of building materials, construction, etc., can solve problems such as lengthening construction period, increasing manufacturing cost, and reducing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0030] In the method for constructing a large-space building according to the present embodiment, the large-space structure 1 used as a hangar of an aircraft will be described as a large-space building.

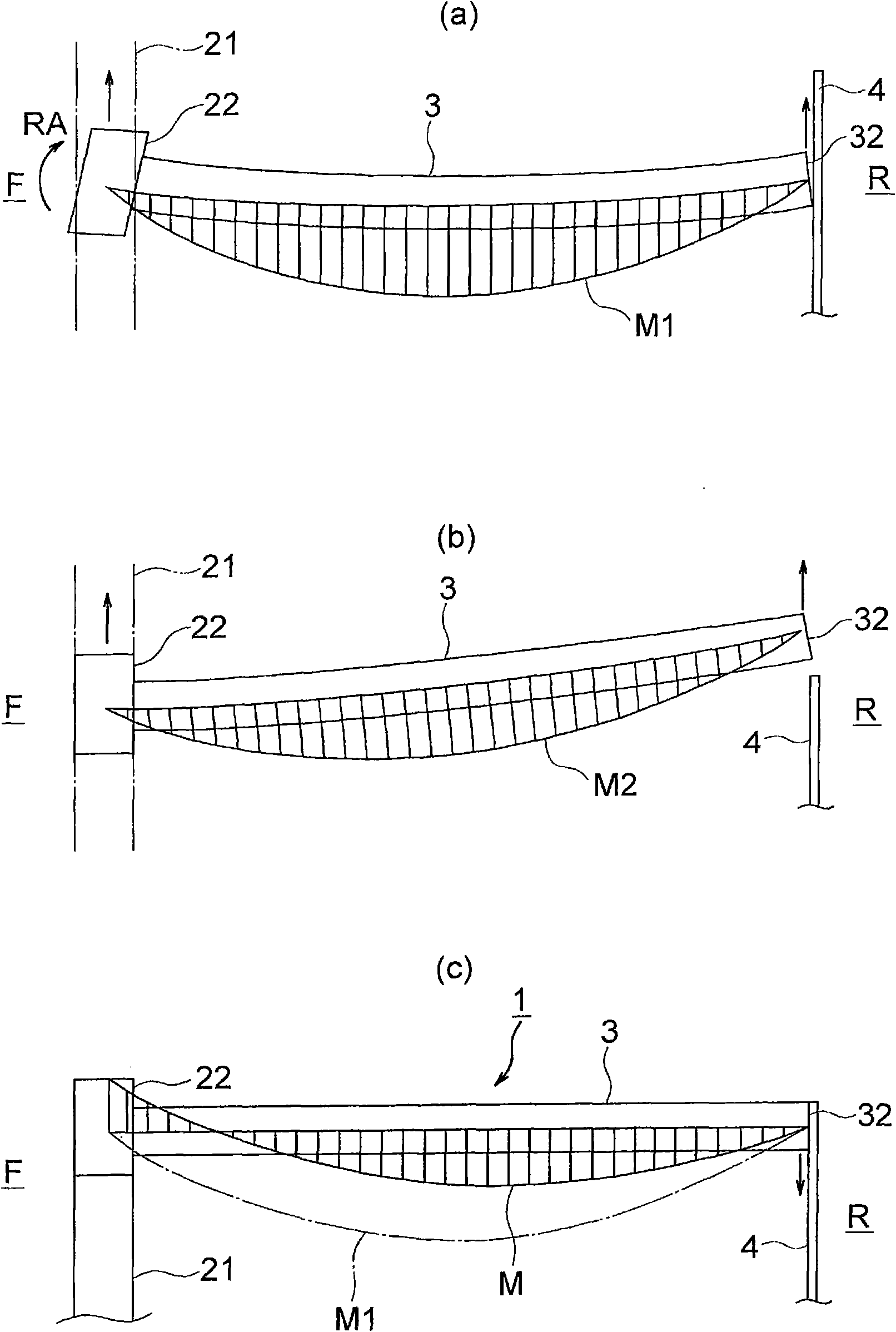

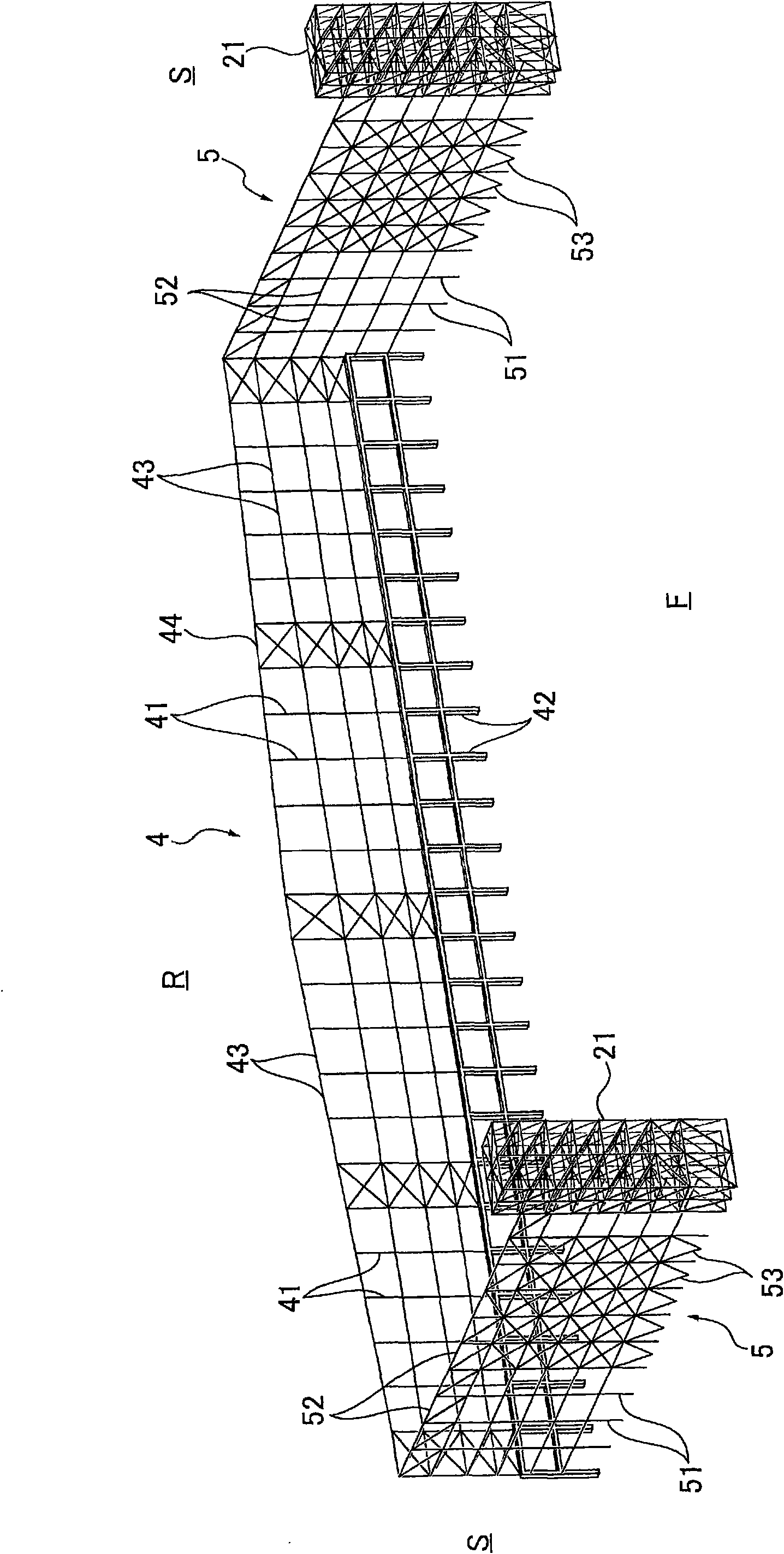

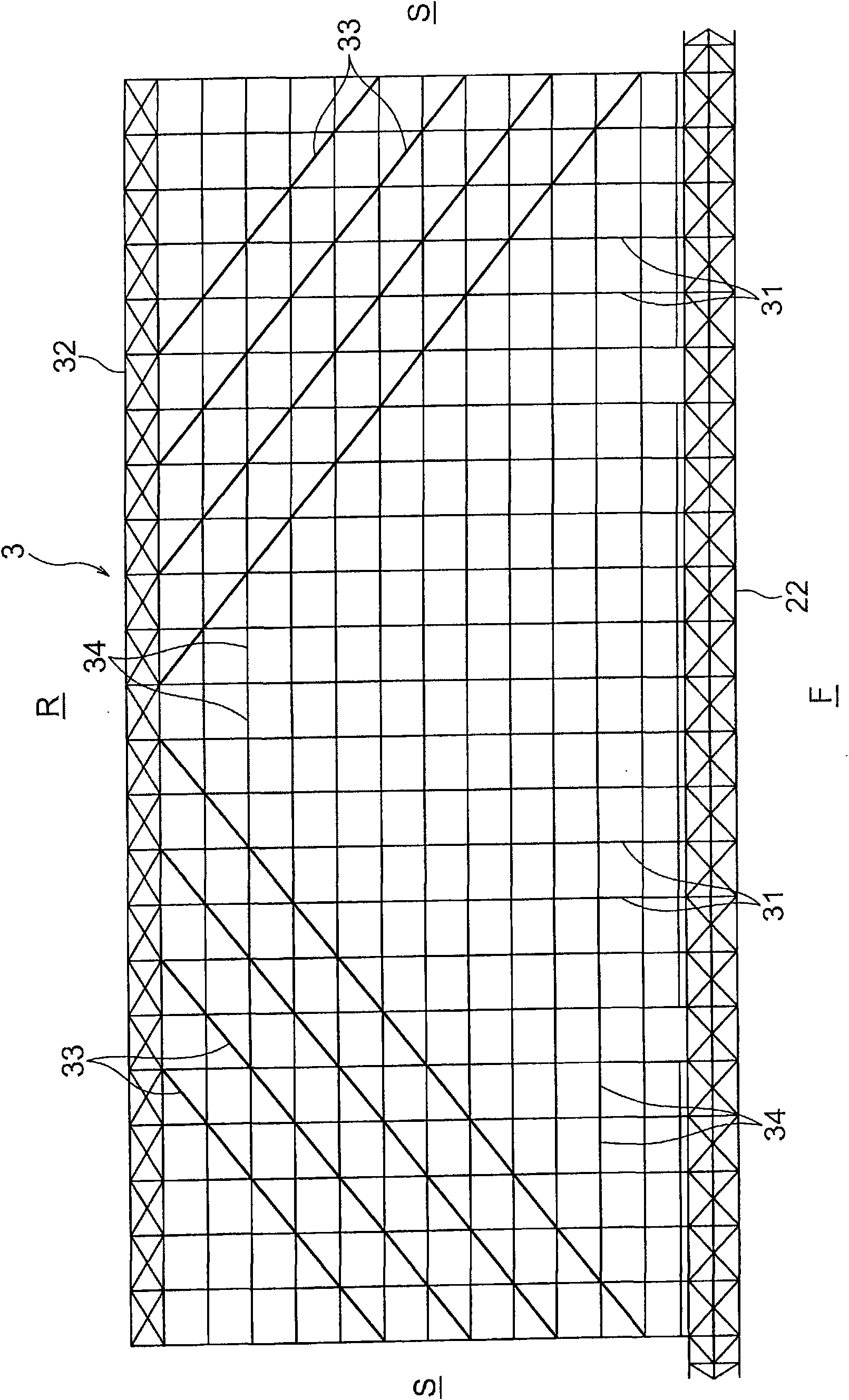

[0031] First, refer to figure 2 , image 3 , Figure 8 The overall configuration of the large space frame 1 will be described.

[0032] The large space frame 1 is mainly composed of Figure 8 The "door" shaped truss 2 constituting the front F side shown in (a), such as figure 2 Shown as the rear part 4 of the rear support part, the side parts 5, 5 as the side support parts connected to the both sides of the rear part 4, and the rear part 4 and the side parts 5, 5 such as image 3 The shown roof frame 3 is formed.

[0033] The "gate" shaped trusses 2 as Figure 8 As shown in (a), it is a planar truss constructed by combining steel materials such as H-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com