Two-dimensional absolute coding three-freedom moving platform measuring system

An absolute coding and motion platform technology, applied in the field of two-dimensional absolute coding three-degree-of-freedom motion platform measurement system, can solve problems such as measurement errors, achieve the effect of increasing the range, strong real-time performance, and improving system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

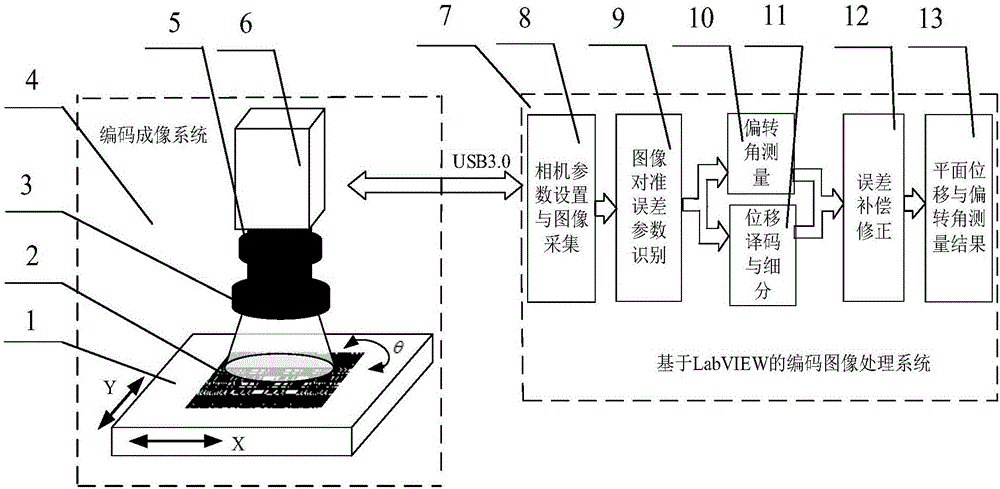

[0028] refer to figure 1 , two-dimensional absolute coding three-degree-of-freedom measurement method and system, including two-dimensional absolute position coding plate 2, coding imaging camera 4 and coding image processing system 7 based on LabVIEW. The data communication between the coded imaging camera 4 and the coded image processing system 7 based on LabVIEW is realized through the USB3.0 data line 13 . The two-dimensional absolute position encoding board 2 uses a pseudo-random m-sequence to perform two-dimensional absolute position encoding, and each different position on the two-dimensional absolute position encoding board corresponds to a unique two-dimensional encoding sequence; the encoding imaging camera 4 includes a ring lighting source 3, three Degree of freedom motion platform 1, focusable imaging lens 5, industrial camera 6; coded image processing system 7 based on LabVIEW includes: camera parameter setting and image acquisition module 8, image alignment error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com