Micro-displacement measurement method and sensing device for dual-workpiece platforms of photoetching machine

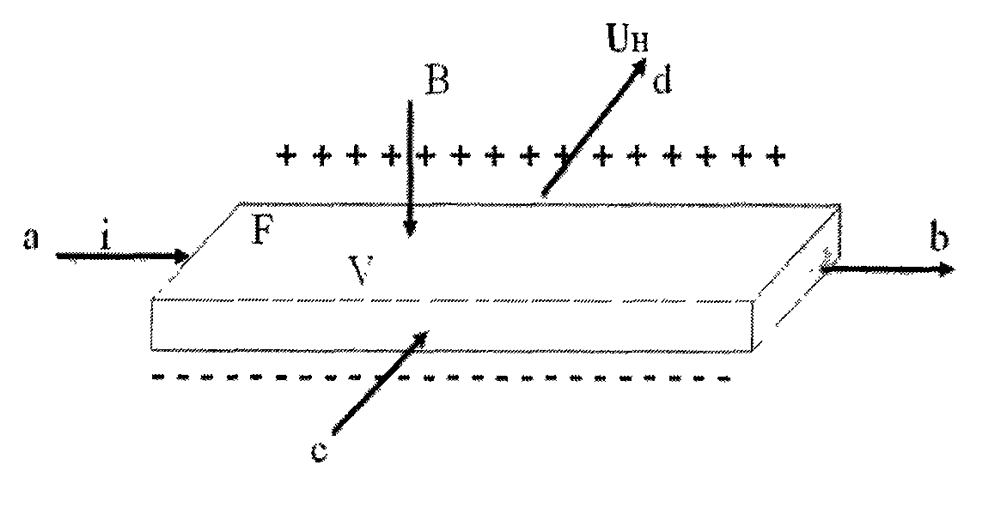

A technology of micro-displacement sensor and double workpiece table, which is applied in measuring device, electric device, exposure device of photoplate making process, etc., to achieve the effect of precise positioning, fast response speed and excellent linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

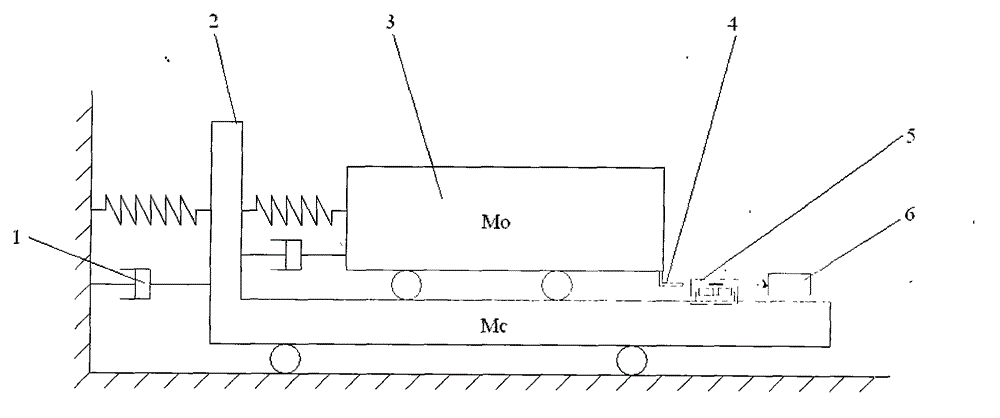

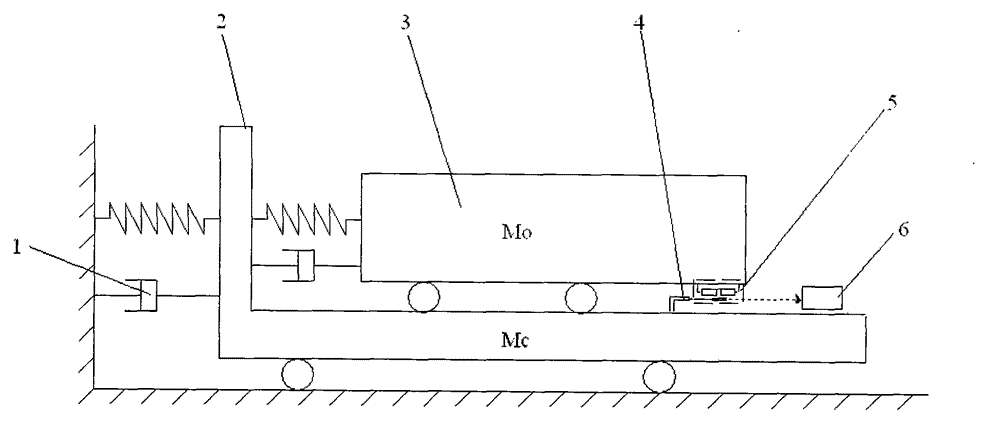

[0021] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0022] see figure 2 with image 3 , a micro-displacement measurement sensing device for double worktables of lithography machine, including double worktable 1 of lithography machine, double worktable macro motion mechanism 2, double work table micro motion mechanism 3 Hall connection Frame 4, Hall micro-displacement sensor 5 and external detection circuit 6; Described Hall micro-displacement sensor 5 is made up of mover permanent magnet group base 7, permanent magnet group 8 and stator gallium arsenide Hall element 9, wherein The mover permanent magnet group base 7 is fixed on the double-workpiece macro-motion mechanism 2 or the double-workpiece micro-motion mechanism 3, and the permanent magnet group 8 is fixed on the mover permanent magnet group base 7 in parallel and horizontally. Stator gallium arsenide Hall element 9 is installed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com