Meshing line large-specification gear measurement center

A technology of gear measurement and meshing line, which is applied to measurement devices, instruments, etc., can solve the problem of excessive tangential travel of the gear measurement center, and achieve the effects of reducing Abbe error, simple structure of measuring instrument, and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

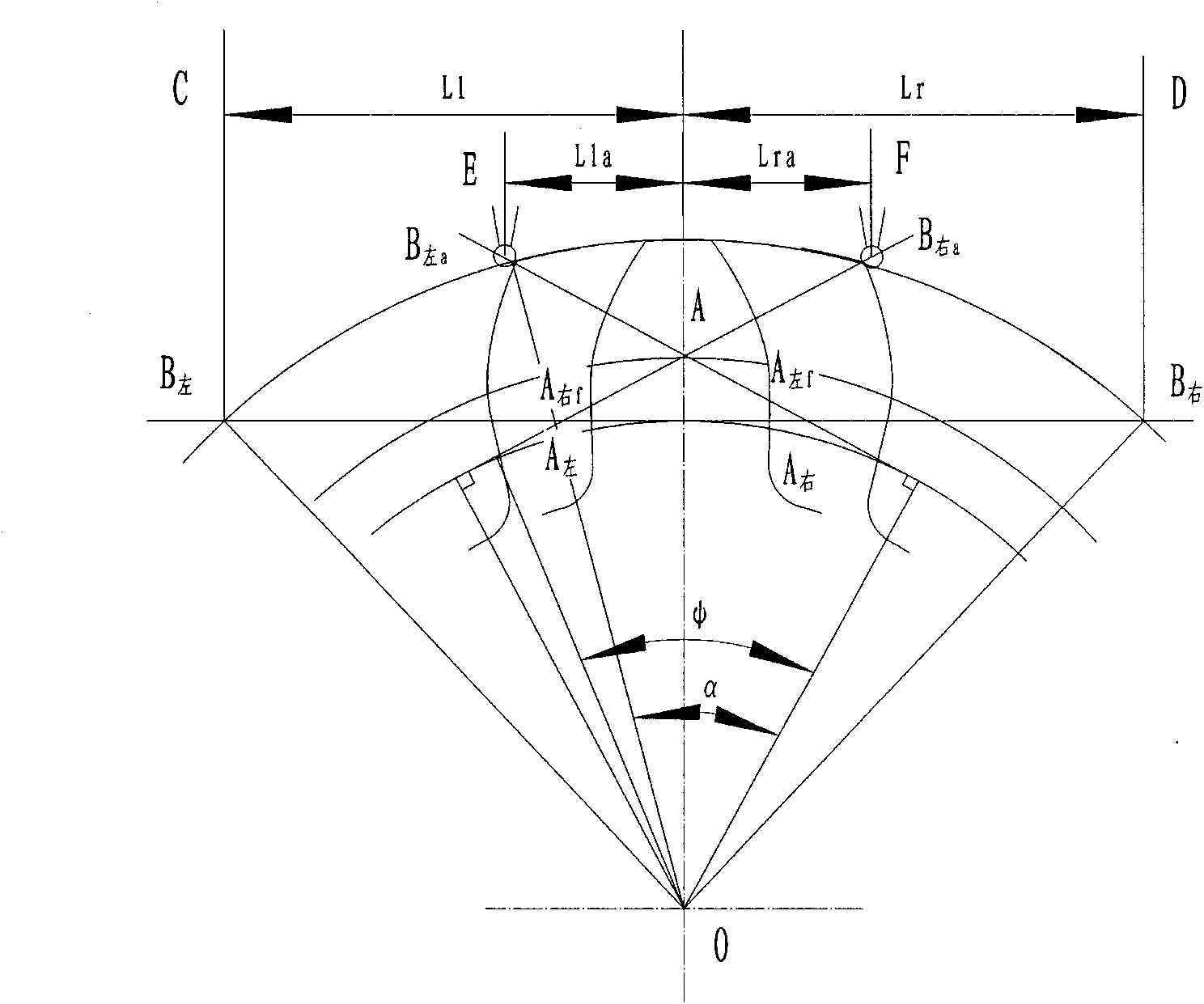

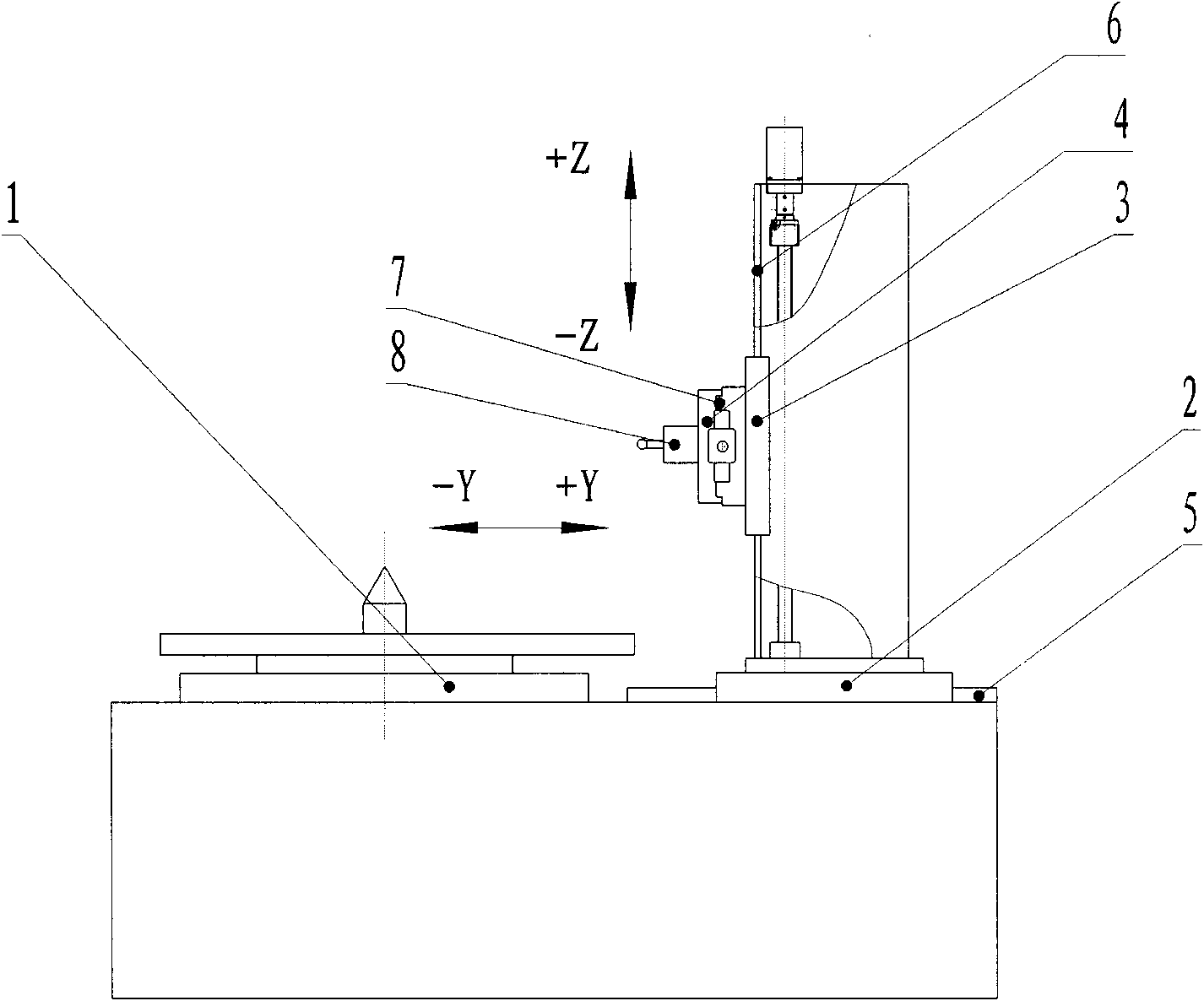

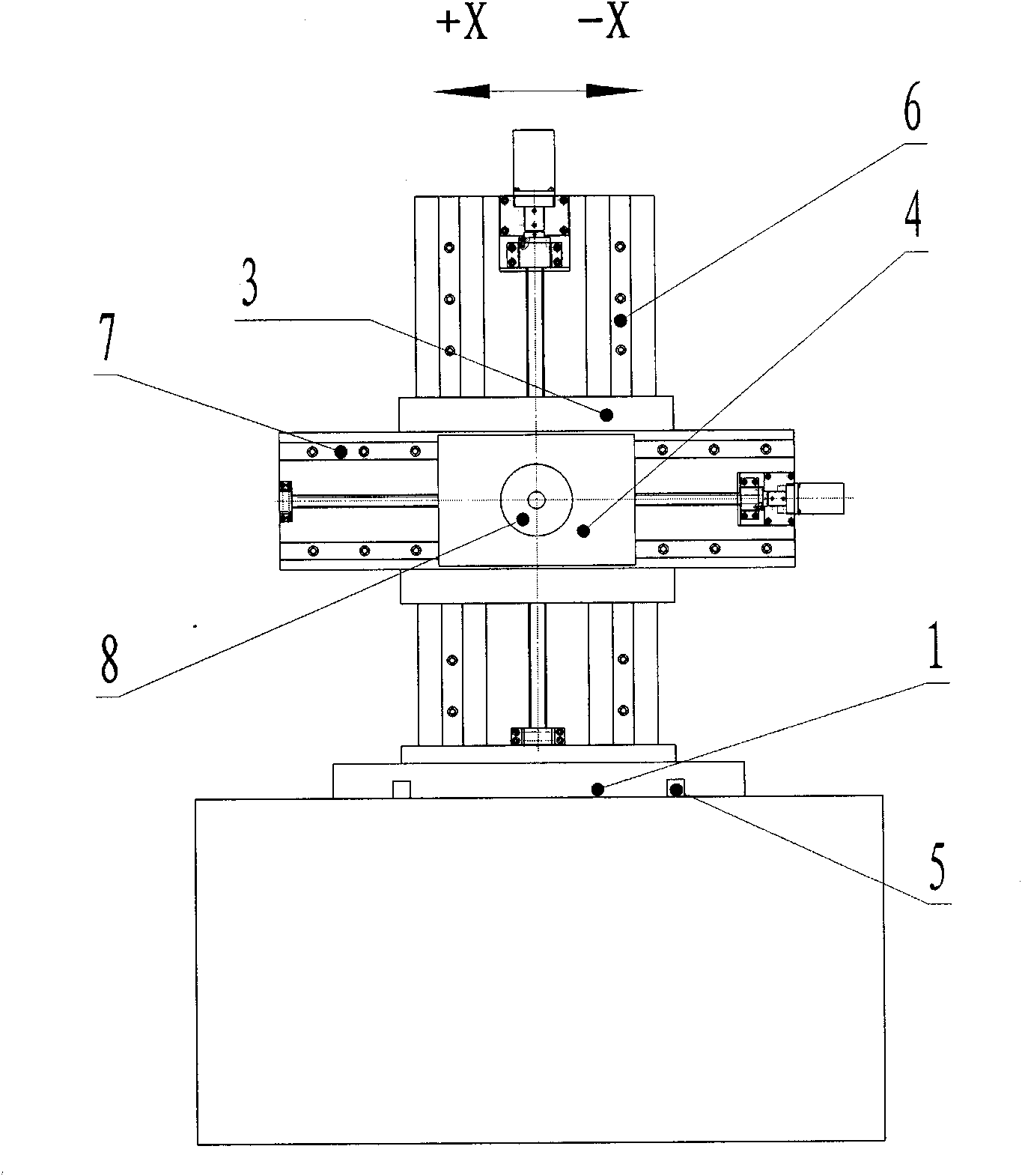

[0016] Now, the working process of the gear left tooth surface profile deviation measurement is taken as an example to illustrate the working process of the present invention: first, the position of the Z-axis during measurement is determined to ensure that it does not move during the entire measurement process; then according to the meshing principle, the C-axis is clockwise. When rotating a pressure angle (ie 20 degrees), the X-axis slider in the negative direction and the Y-axis slider in the negative direction of the three-axis linkage move to the starting position; The rotation angle from the starting measurement position to the final measurement position is simultaneously linked with the positive X axis and the positive Y axis to the final measurement position. The trajectory of the contact point is a tooth profile curve. During the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com