Cam measuring device and cam measuring method based on laser interference principle

A technology of laser interference and measuring device, applied in the field of precision measurement, can solve the problems of large Abbe error, reduced cam measurement accuracy, inability to apply various cam measurements, etc., and achieves the effect of reducing Abbe error and strong independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

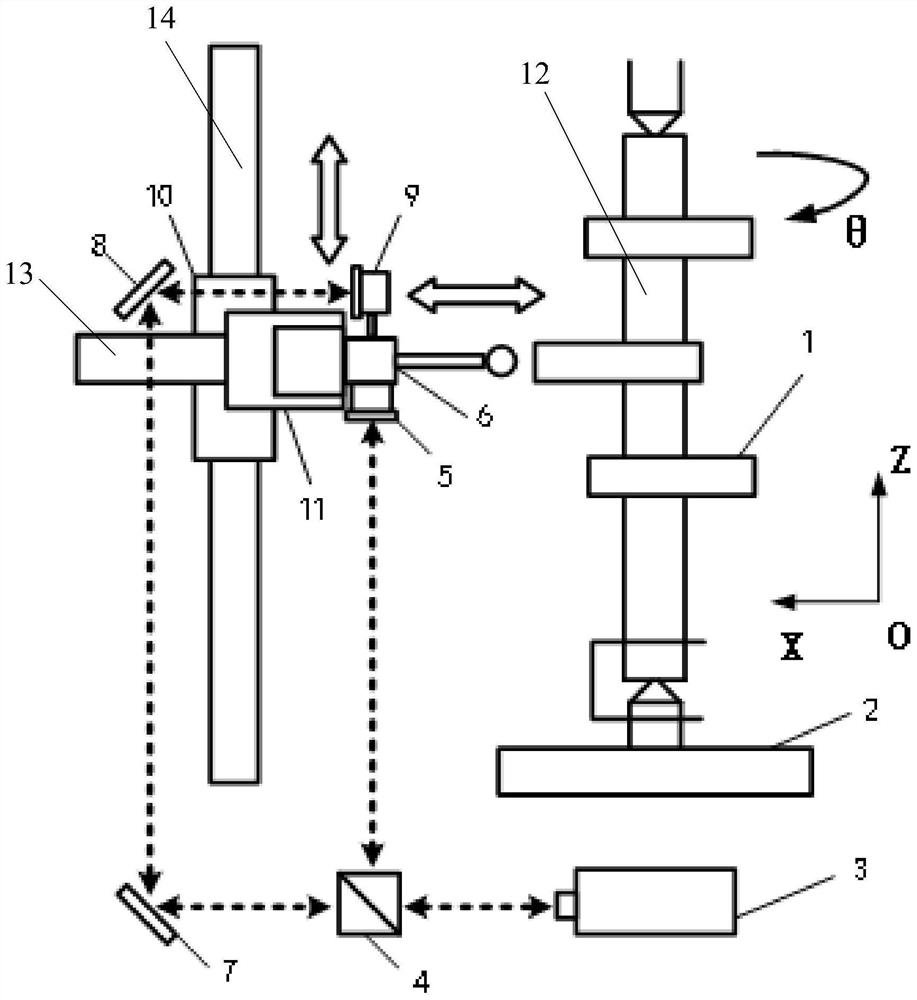

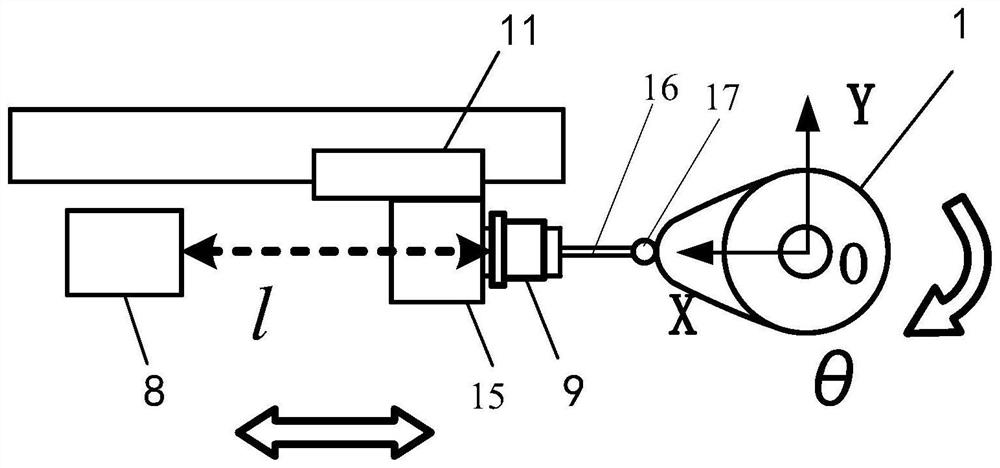

[0035] This embodiment provides the measurement method for disc cam:

[0036] Such as Figure 1-2As shown, the camshaft 12 is clamped with the upper and lower centers, the lower center rotary shaft system 2 drives the camshaft 12 to the zero position of the angle, and the micrometer probe 6 moves along the Z axis through the Z axis guide rail 14 to the position of the cam under test. Intermediate section height. After the measurement starts, the laser measurement value in the X-axis direction is cleared, and the X-axis slider 11 on the X-axis guide rail 13 drives the micrometer probe 6 to touch the cam surface, and the micrometer probe 6 to be measured is at the X-axis offset value After reaching the set threshold, the micrometer probe 6 sends a trigger signal to the host computer control system, and the control system collects the current laser length measurement value l 1 and the angle value of the rotary shaft system θ 1 . The micrometer probe 6 keeps in contact with th...

Embodiment 2

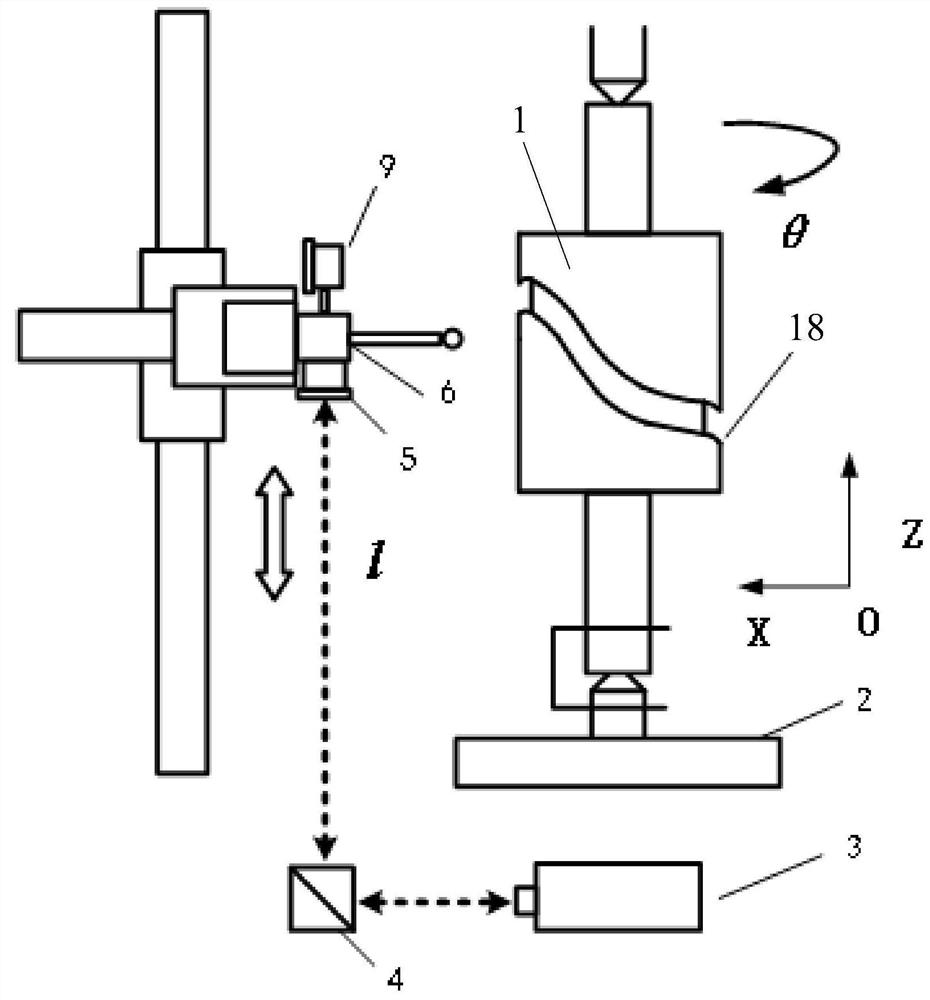

[0038] This embodiment provides the measuring method for cylindrical cam:

[0039] Such as image 3 As shown, the camshaft 12 is clamped with the upper and lower centers, the lower center rotary shaft system 2 drives the camshaft 12 to the zero position of the angle, and the micrometer probe 6 moves along the Z axis through the Z axis guide rail 14 to the cam curve groove 18 Height, and enter the curved groove 18. After the measurement starts, the laser measurement value in the Z-axis direction is cleared, and the Z-axis slider 10 on the Z-axis guide rail 14 drives the micrometer probe 6 to touch the inner bottom surface and the lower end surface of the cam. After the axis offset value reaches the set threshold, the micrometer probe 6 sends a trigger signal to the host computer control system, and the control system collects the current laser length measurement value l 1 and the angle value of the rotary shaft system θ 1 . Then the rotary shaft system 2 starts to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com