Machining and detecting device and method for large-aperture aspheric contour

A contour processing and aspheric technology, which is used in metal processing equipment, manufacturing tools, control of workpiece feed movement, etc., can solve the problem of difficult to adapt to the measurement requirements of large-diameter aspheric components, and does not fully utilize the compensability of spatial reference motion errors. , processing efficiency, low handling risks, etc., to achieve the effects of small deformation, short movement range, and improved processing efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as figure 1 As shown, the large-diameter aspheric element contour processing detection method, the detection processing steps are as follows:

[0048] The aspherical element 10 is placed on the precision air-floating rotary table 3, and the sensing and measuring system 5 is fixed on the horizontal measuring arm 9 connected with the bushing 8 of the precision linear air-floating guide rail system 2, and can be used as a joint with the bushing 8. During the measurement process, it is necessary to ensure that the sensing and measuring system 5 is perpendicular to the motion direction of the precision linear air-floating guide rail system 2, and the sensing and measuring system 5 performs a one-dimensional linear motion along the generatrix direction 15 of the aspheric element 10 to complete a One-dimensional scanning measurement.

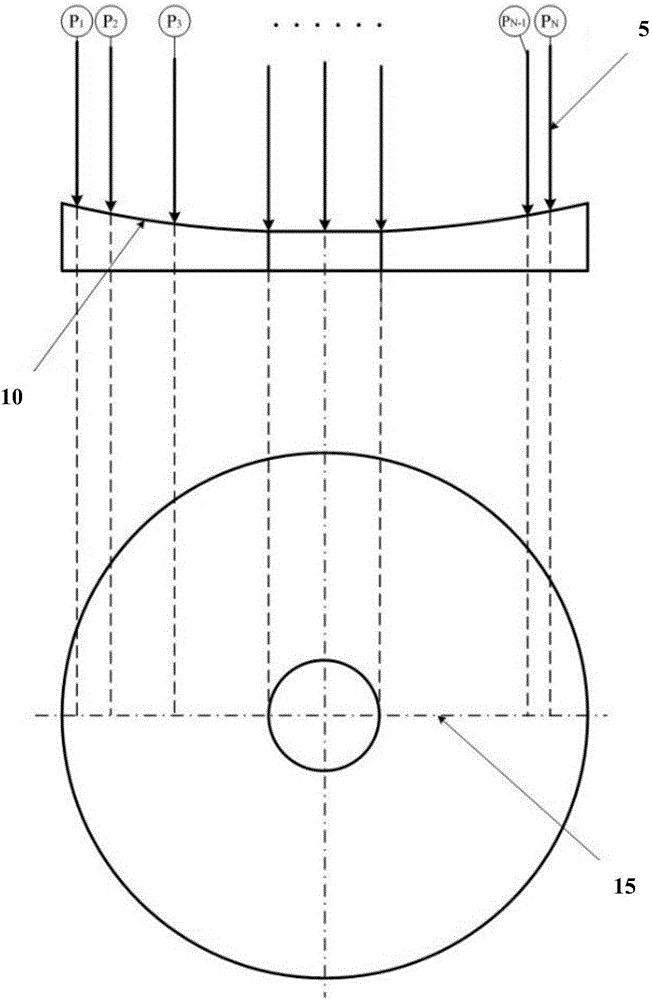

[0049] Such as figure 2 As shown, along the generatrix direction 15, the aspheric element 10 is scanned and measured by the sensing and...

Embodiment 2

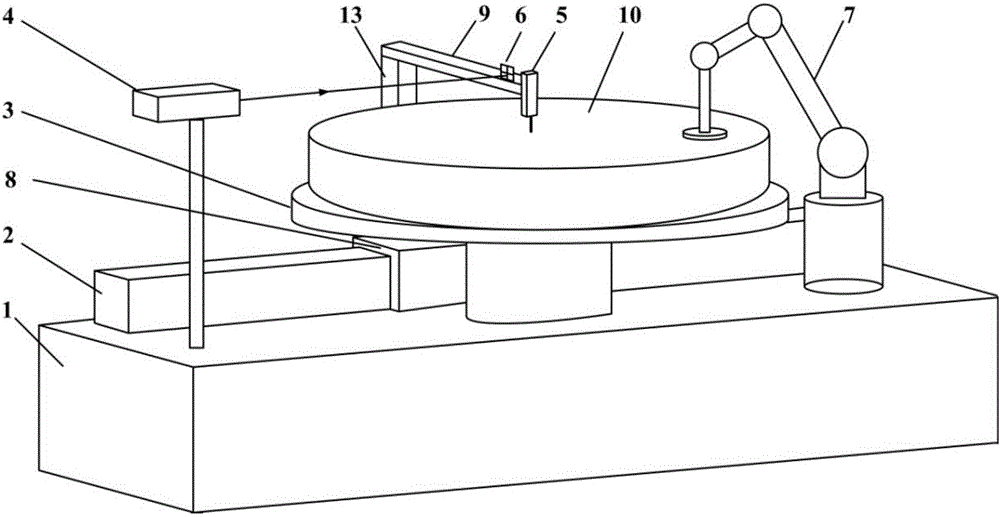

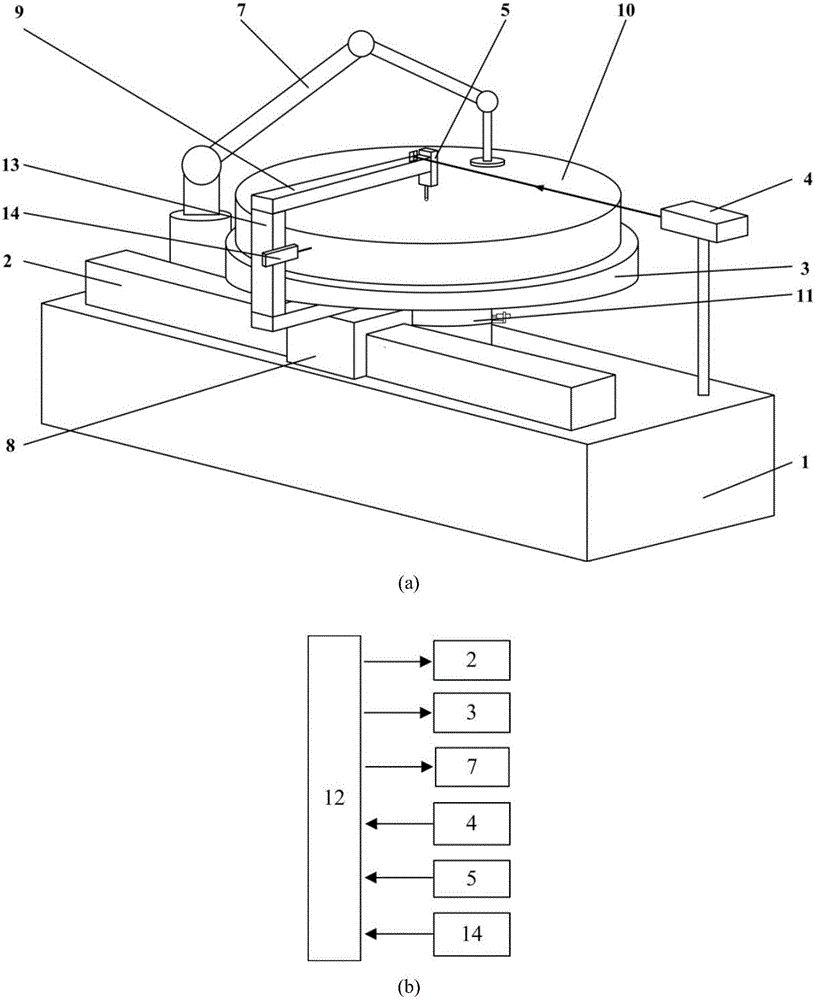

[0054] combine figure 1 with image 3 As shown, the large-diameter aspheric surface processing and testing device is mainly composed of base 1, precision linear air-floating guide rail system 2, precision air-floating rotary table 3, linear air-floating guide rail system motion error laser monitoring system 4, and air-floating table adjustment system 11. Measuring and sensing system 5, grinding and polishing articulated arm 7, computer grinding and polishing measurement control system 12, etc., precision linear air-floating guide rail system 2, linear air-floating guide rail system motion error laser monitoring system 4, grinding and polishing articulated arm 7 distribution Around the precise air-floating rotary table 3, all of them are fixed on the base 1. Among them, the sensing and measuring system 5 is fixed on the transverse measuring arm 9 connected with the shaft sleeve 8 of the precision linear air-floating guide rail system 2, and can perform one-dimensional linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com