Ball screw elliptic reverser nut turning and milling clamp

A ball screw pair and reverser technology, applied in the direction of expanding the mandrel, etc., can solve the problems of damaged tool and reverser hole integrity, low processing efficiency, poor workpiece accuracy, etc., to achieve precise positioning and improve processing efficiency. and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

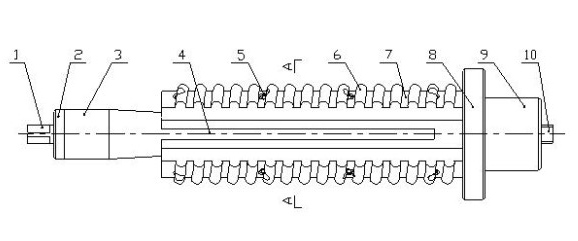

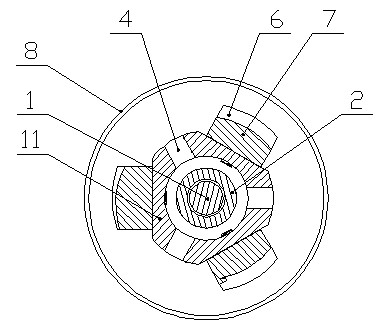

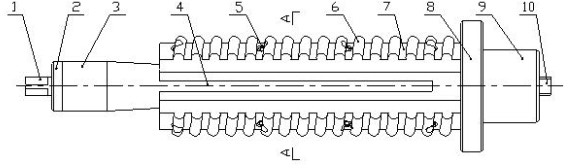

[0012] see figure 1 with figure 2 , the present invention is a ball screw pair elliptical reverser nut turning and milling fixture, including a tensioning sleeve 8, a tensioning mandrel 3 arranged in the tensioning sleeve 8 and a locking mandrel arranged in the tensioning mandrel 3 The shaft 1 and the tensioning sleeve 8 include an end portion 9 with an internally threaded hole and a sleeve body 11 penetrating with the internally threaded hole. The sleeve body 11 is provided with axial grooves 4 uniformly distributed along the circumference; the tensioning mandrel 3 The front end extends into the tensioning sleeve 8, and the contact surface between the tensioning sleeve 8 and the tensioning mandrel 3 is a tapered surface; the front end 10 of the locking shaft passes through the tensioning mandrel 3 and is threadedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com