Large gear grinding machine grinding wheel rack rotation device and rotation control method thereof

A technology of slewing device and grinding wheel frame, which is applied in the direction of gear tooth manufacturing device, gear cutting machine, belt/chain/gear, etc. It can solve the problem of difficult to achieve high-precision, high-sensitivity control, reduced support performance of grinding wheel frame, and difficulty in meeting high rigidity requirements and other problems to achieve the effect of stable rotation, small Abbe error, and improved support rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

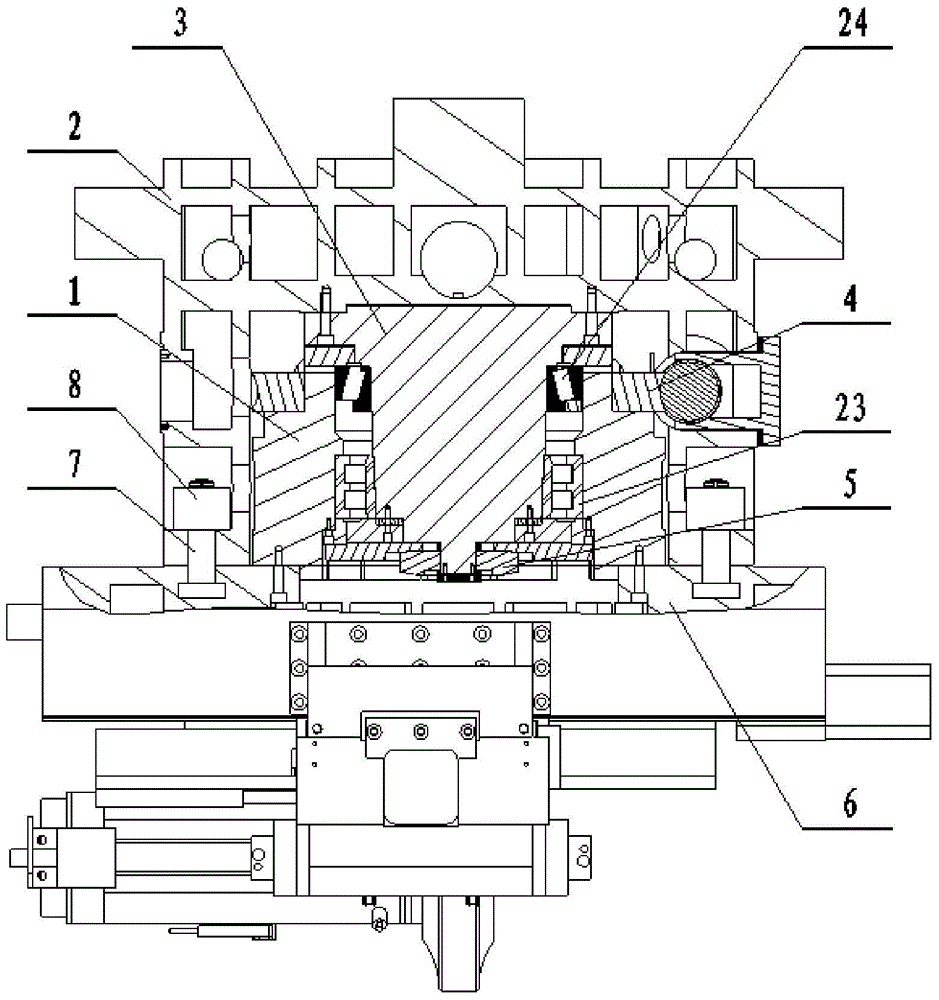

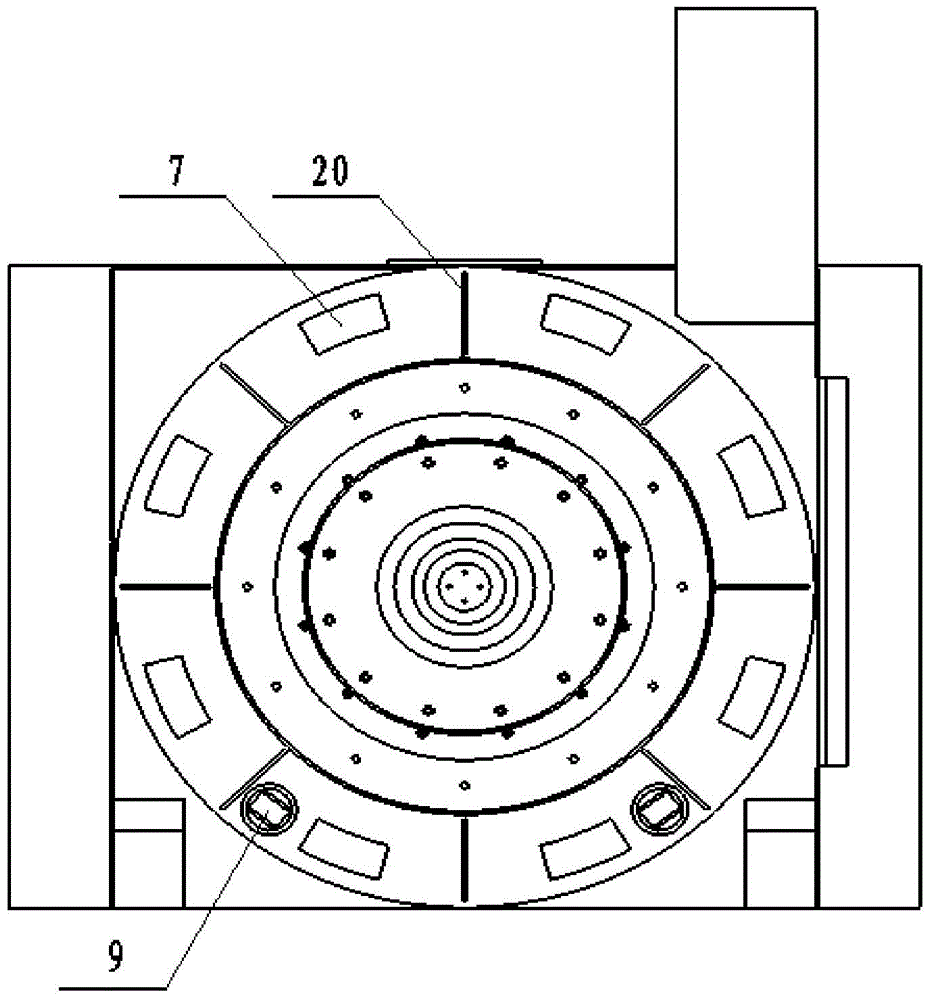

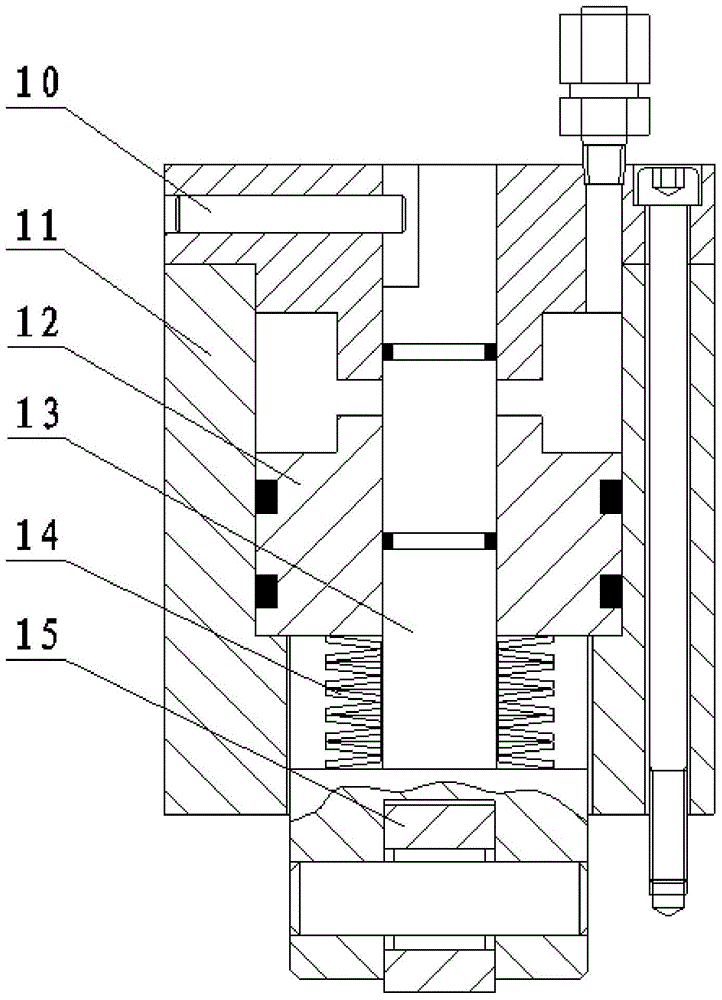

[0041] Such as figure 1 As shown, a grinding wheel frame rotary device for a large gear grinding machine includes a rotary cylinder 1, a rotary seat 2, a main shaft 3, a double-lead anti-backlash worm gear pair 4, a circular grating 5, a grinding wheel frame 6, a clamping mechanism 8 and an unloading mechanism. Dutch agency 9. The main shaft 3 is fastened to the slew seat 2 with bolts (rigid connection). Rotary cylinder 1 is supported on the main shaft 3 through double-row cylindrical roller bearings 23 and tapered roller bearings 24. The grinding wheel frame 6 is directly connected to the rotary drum 1. The rotary drum 1 is driven by the double-lead anti-backlash worm gear pair 4 to realize the grinding wheel frame. Rotation, the rotation position is controlled by the circular grating 5, and can be firmly locked on the rotary base 2 by the clamping mechanism 8. The grinding wheel frame 6 is directly supported by the main shaft 3, which has high rigidity; the main shaft is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com