Subframe for vehicle and bush attaching structure

A sub-frame and vehicle technology, applied in the substructure, vehicle components, transportation and packaging, etc., to achieve the effect of increasing the strength of the beam and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

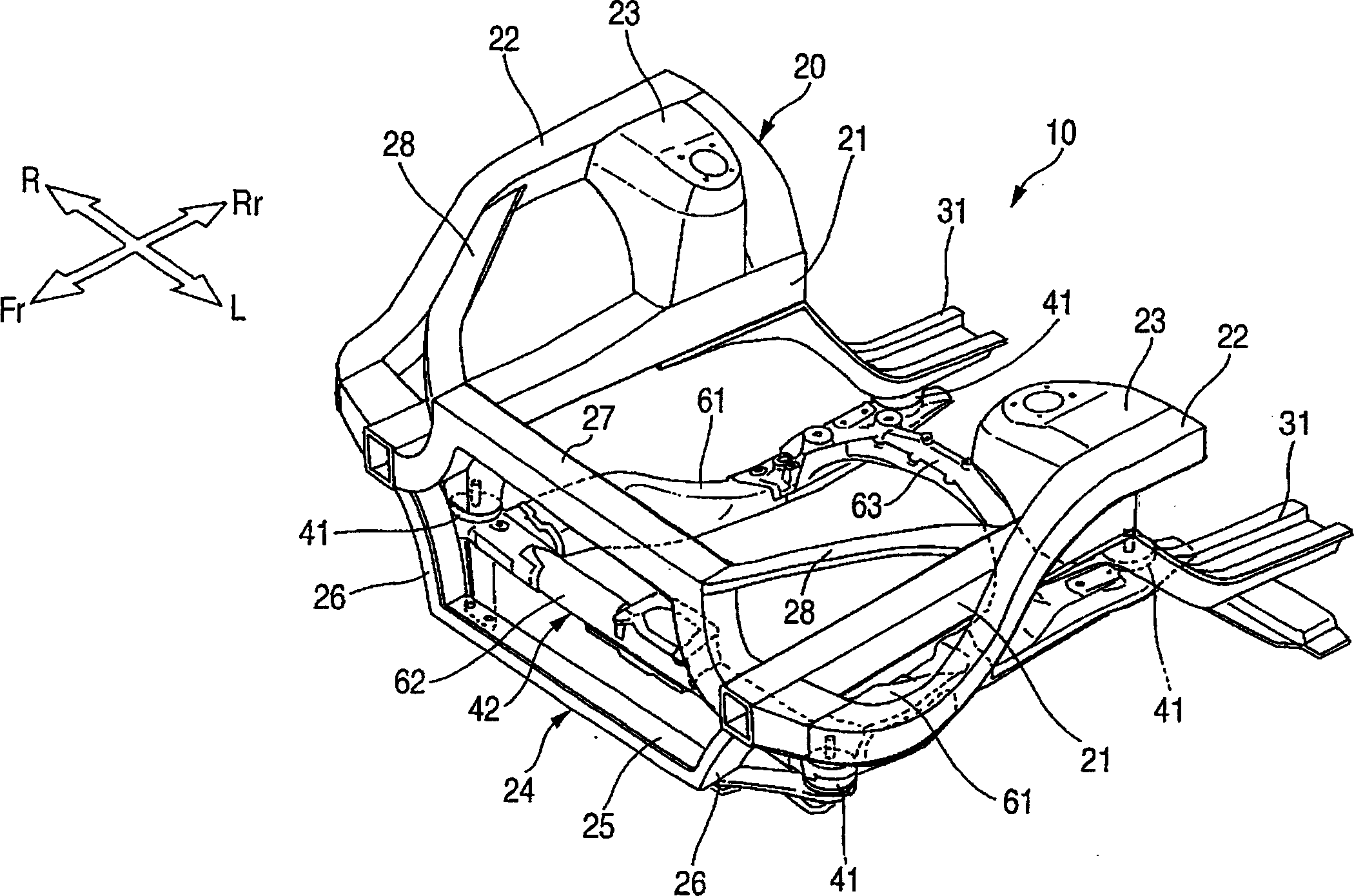

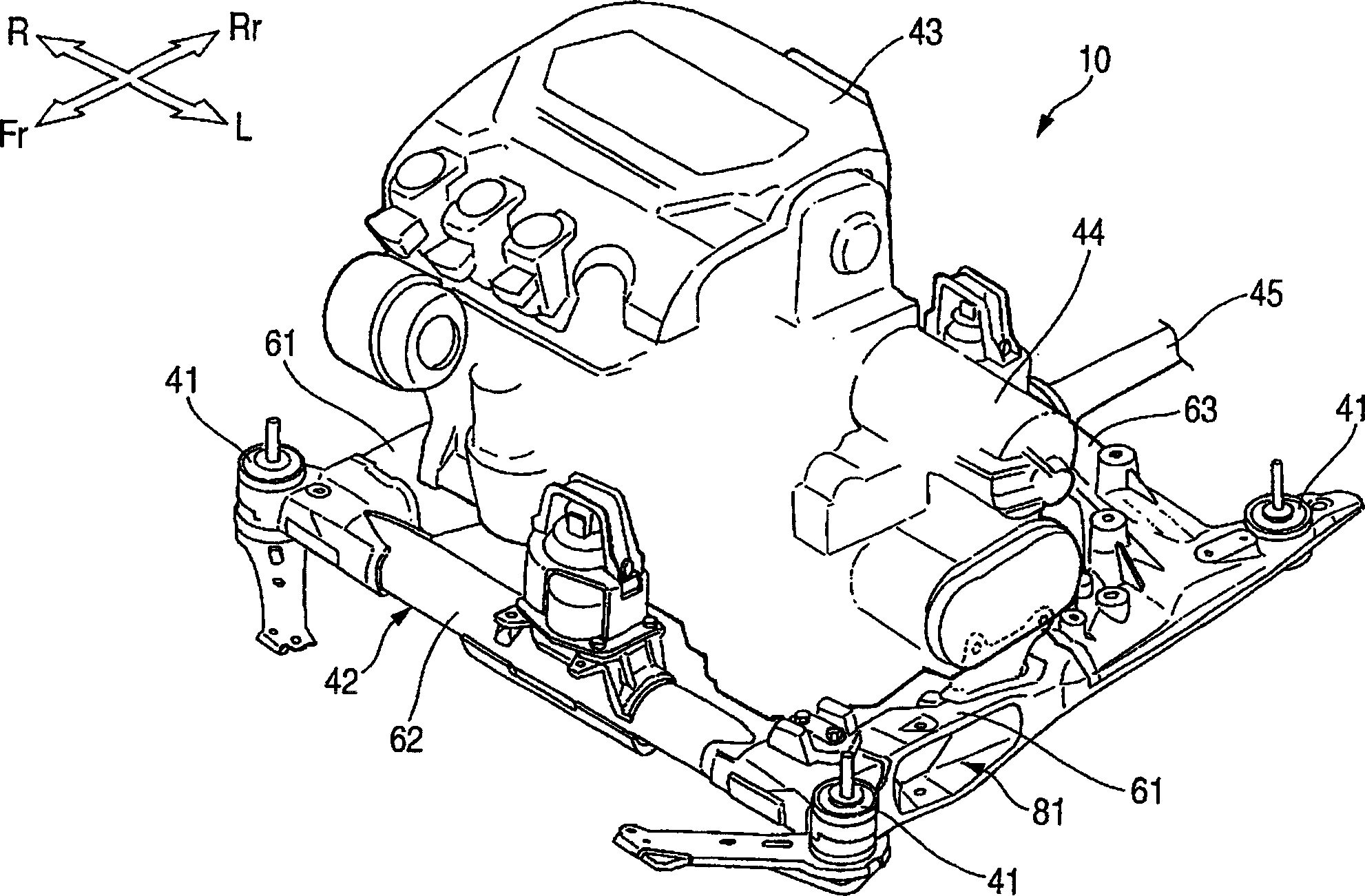

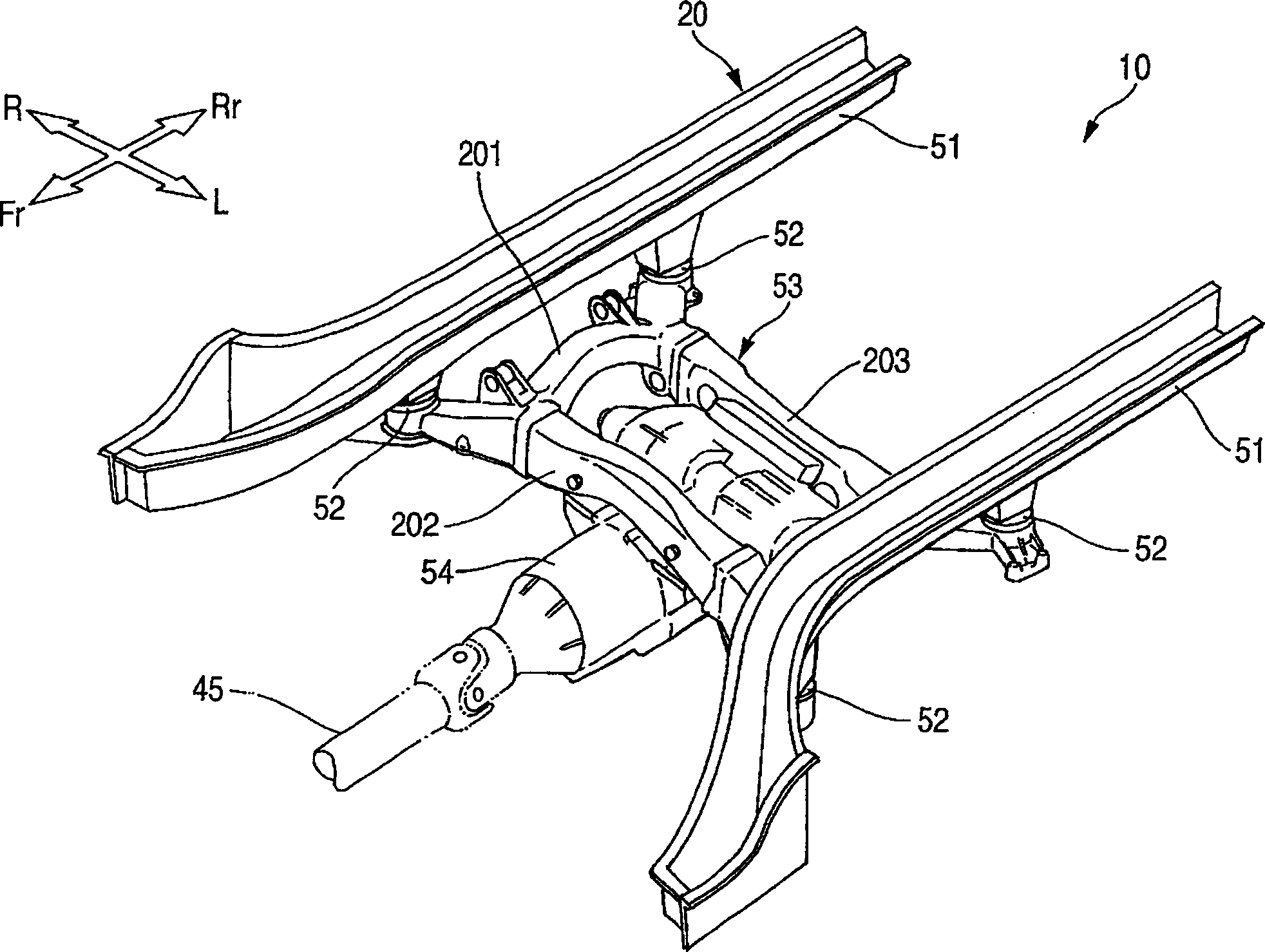

[0051] The best embodiment of the present invention will be described below with reference to the accompanying drawings. "Front", "Rear", "Left", "Right", "Up" and "Down" are the directions viewed by the driver, Fr means the front side, Rr means the rear side, L means the left side, R means the right side, CL represents the center of the vehicle body (the center of the vehicle width).

[0052] First, according to Figure 1 ~ Figure 3 The outline of the vehicle is explained.

[0053] figure 1 It is a perspective view of the front part of the vehicle of this invention. The vehicle frame (body) 20 of the vehicle 10 is a monocoque body, and its front structure mainly includes: left and right front side frames 21, 21 that are positioned at both sides of the front portion of the vehicle body and extend forward and backward to the vehicle body; The left and right upper frames 22,22 extending to the front and rear of the vehicle body on the outside and the top of the vehicle width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com