Auto heat radiator frame support structure

A technology of support structure and radiator, which is applied in the arrangement of cooling combination of power plant, vehicle components, power plant and other directions, which can solve the problems of difficulty in realization and long distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

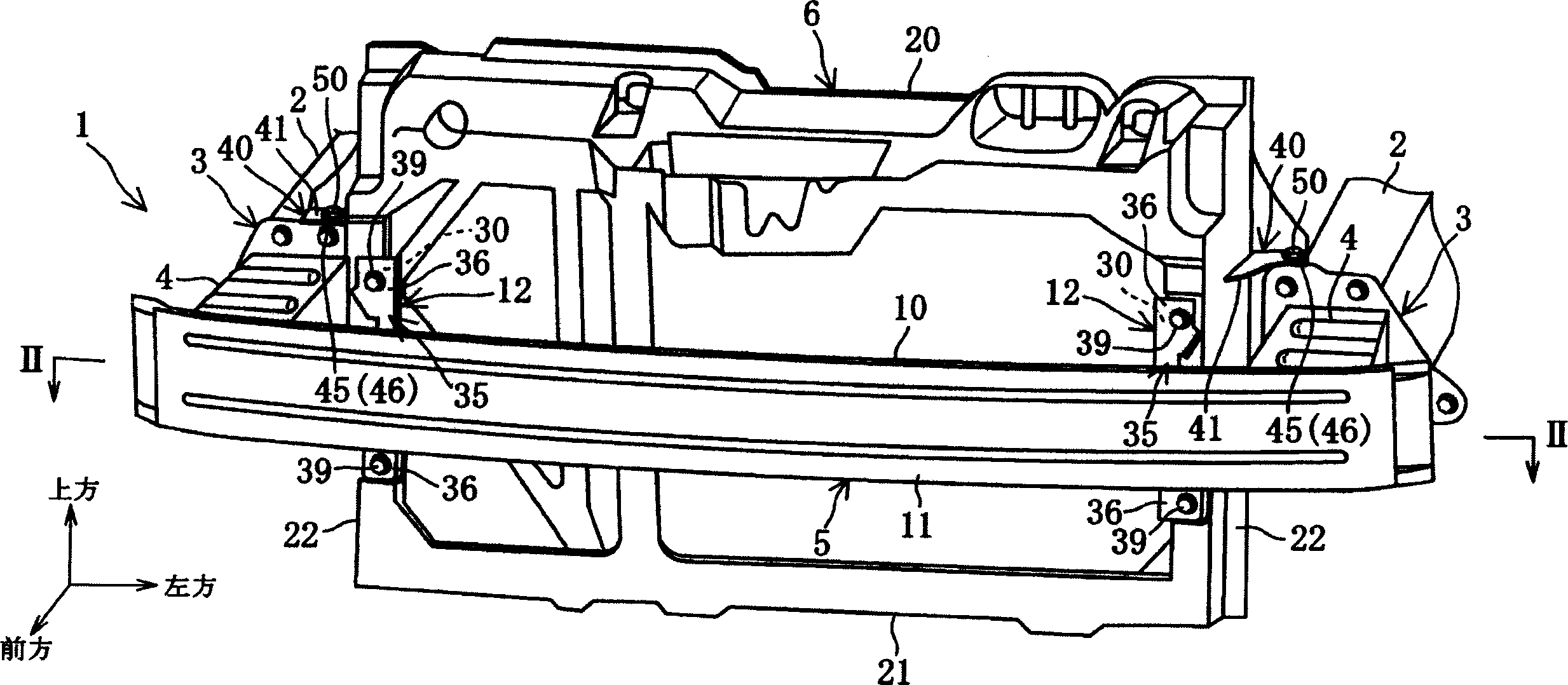

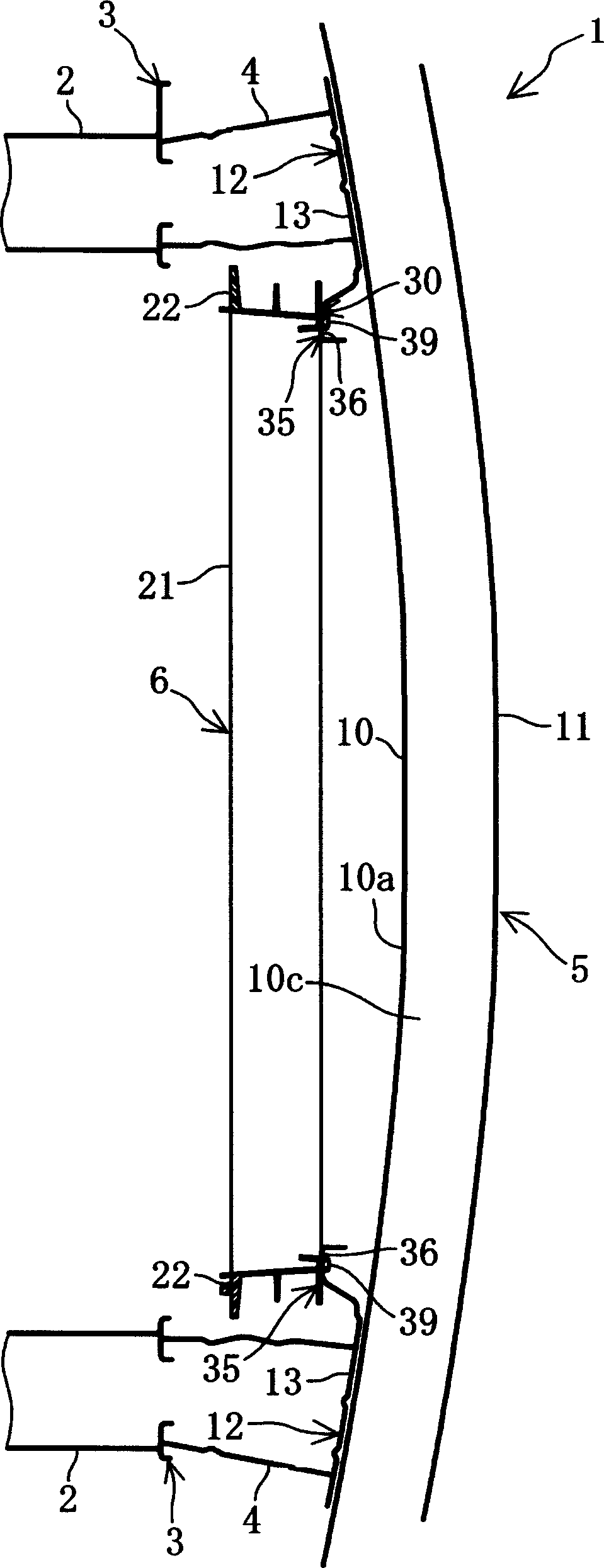

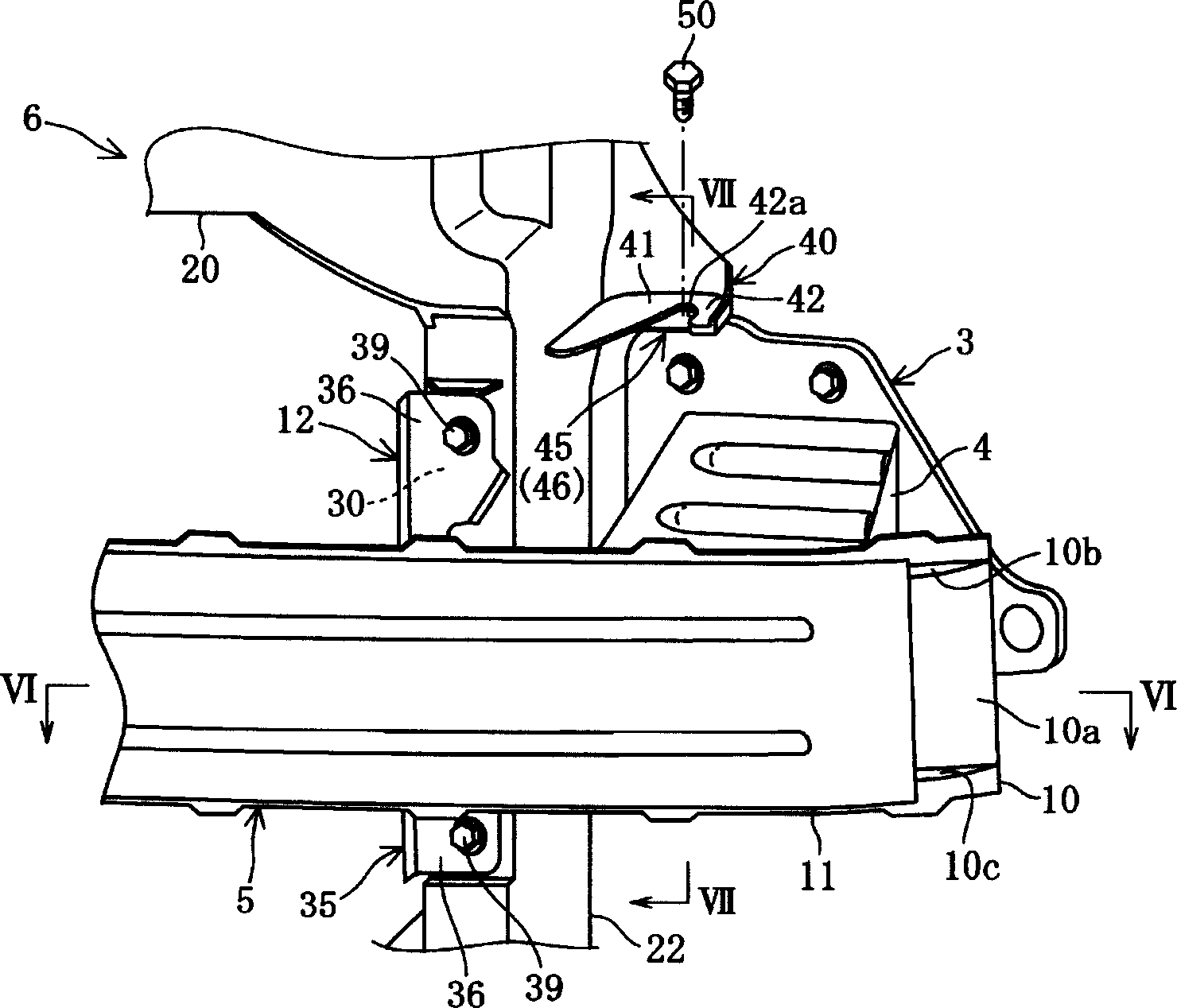

[0047] like figure 1 , figure 2 As shown, the front part 1 of the vehicle body is provided with a left and right pair of front longitudinal beams 2 and 2 extending in the front and rear direction, a left and right pair of crash boxes 4 and a bumper reinforcement 5, wherein the left and right pair of crash boxes 4 are respectively passed through A pair of left and right flange members 3, 3 are connected to the front ends of the front side members 2, 2 and extend forward from the front side members 2, 2; the bumper reinforcement 5 extends along the vehicle width direction and is connected to the crash box 4 at the front end. A radiator frame 6 made of synthetic resin having a "mouth" shape (rectangular frame shape) is supported and attached to the vehicle body front portion 1 described above.

[0048] The pair of front side members 2, 2 described above extend in the front-rear direction and are provided at a predetermined distance in the vehicle width direction, the flange 2a...

no. 2 Embodiment approach

[0073] The radiator frame support structure of the second embodiment is a radiator frame support structure obtained by partially modifying the vehicle body front portion 1 including the radiator frame support structure of the first embodiment. Therefore, the same reference numerals are assigned to the same components as those in the first embodiment, and description thereof will be omitted.

[0074] As shown in Figure 9~ Figure 14 As shown, in the vehicle body front portion 1A of the second embodiment, a flange member 3A is joined (welded) to the rear end portion of a crash box 4A, and the flange 2 a and the flange member 3A are joined by bolts / nuts 3A. The front end portion of the crash box 4A is directly joined to the bumper reinforcement 5 , therefore, an extension portion 4Aa extending forward is formed at the front end portions of the upper and lower walls of the crash box 4A, and the upper and lower extension portions 4Aa, 4Aa are welded to each other. The upper wall 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com