Tilting-pad thrust bearing device automatically adjusting oil film thickness

A technology of oil film thickness and thrust bearing, applied in the direction of rotating bearing, bearing assembly, sliding contact bearing, etc., can solve problems such as eccentric load, and achieve the effect of prolonging working life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

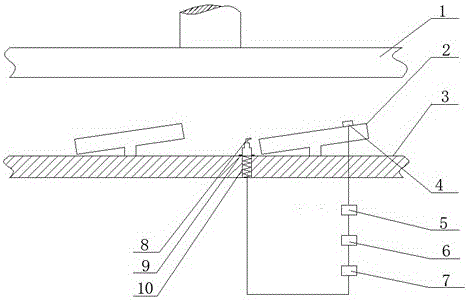

[0014] In order to fully explain the technical solution of the present invention, it will be described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the embodiment of the present invention provides a tilting pad thrust bearing device with automatic adjustment of oil film thickness, and the device includes a tilting pad thrust bearing with automatic adjustment of oil film thickness and a control system.

[0016] The tilting pad thrust bearing whose oil film thickness can be automatically adjusted includes a mirror plate 1, several tiles 2 and a base 3; the several tiles 2 are located between the mirror plate 1 and the base 3; there are several threads on the base 3 Holes 10 are distributed beside several tiles 2 .

[0017] The control system includes several resistance strain gauge sensors 4 pasted on several tiles 2, the resistance strain gauge sensors 4 are connected to the input end of the resistance voltage converter 5, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com