A scheme for online testing of pantograph-catenary contact force

A technology for online testing and contact force, which is applied in railway vehicle testing, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of increasing the cost of line monitoring, and achieve the effect of avoiding simplified modeling and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

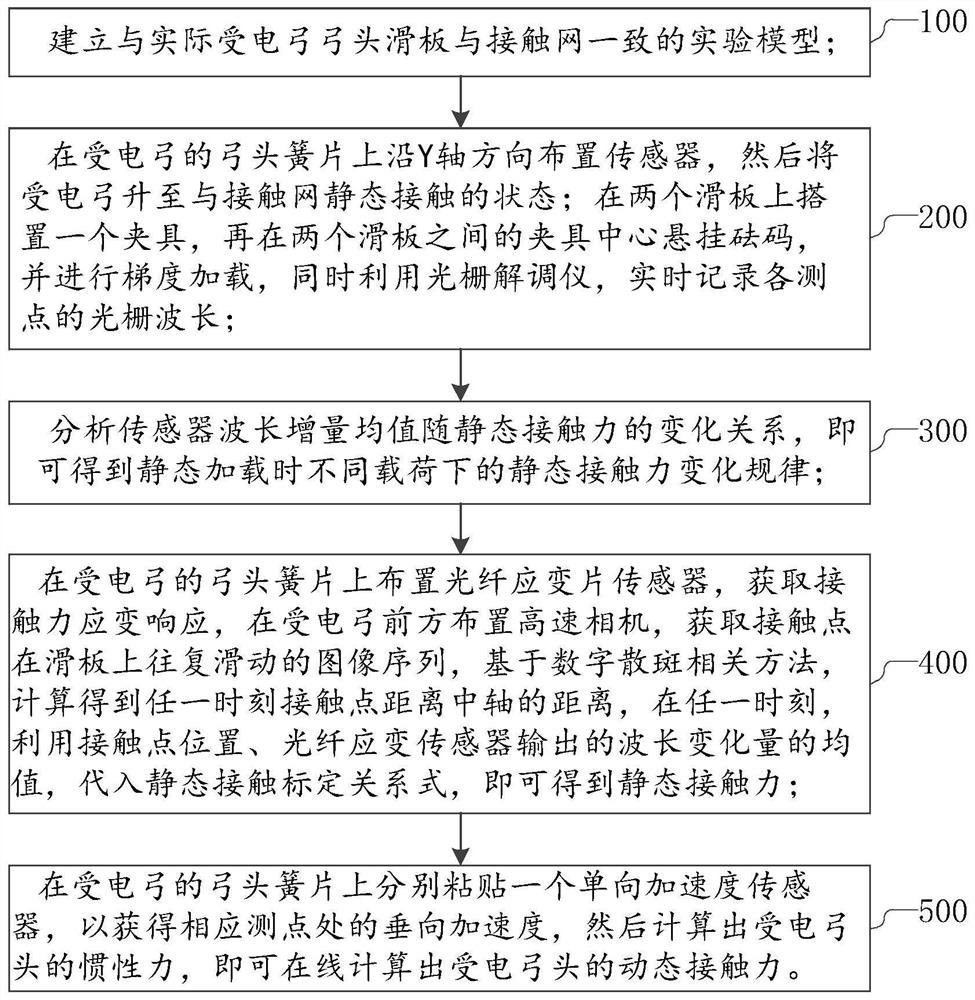

[0018] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

[0019] In one embodiment of the present invention, a solution for online testing of pantograph-catenary contact force is provided.

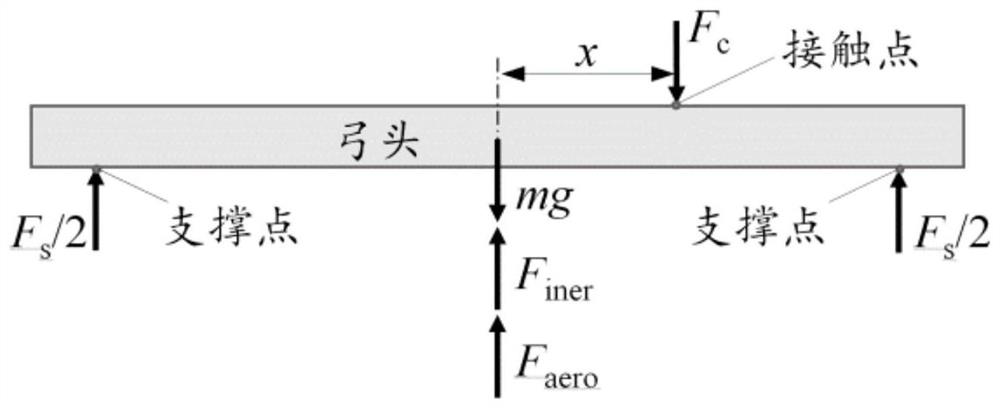

[0020] Such as figure 1 As shown, based on the balance principle of the space force system of the pantograph head, the pantograph-catenary contact force F c =F s -mg +F iner +F aero . In the formula, F s is the sum of the interaction forces between the bow slide and the supporting device, m is the mass of the bow, g is the acceleration of gravity, F iner is the bow inertial force, F aero For aerodynamic force. When the train is stationary, F iner = 0, F aero = 0, then there is a static contact force F c0 =F s -mg. The static contact force is related to factors such as pantograph airbag force and catenary tension. When the train is running, the vibration of the car body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com