A turbocharger axial force measurement system and its testing method

A turbocharger and measurement system technology, applied in the direction of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of increased cost, complex structure, and large difference in the axial force of turbine blades, etc., to achieve reduction The effect of experimental error, fast transient response and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

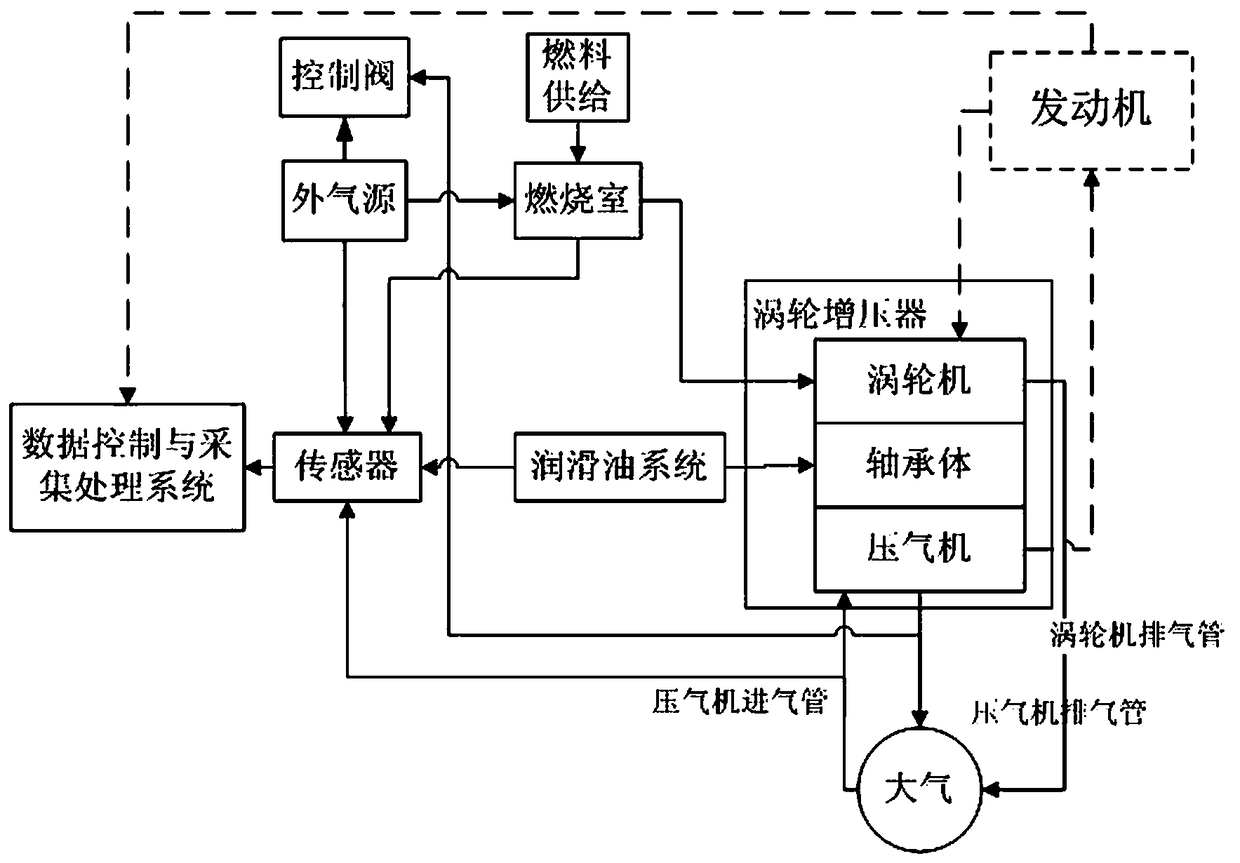

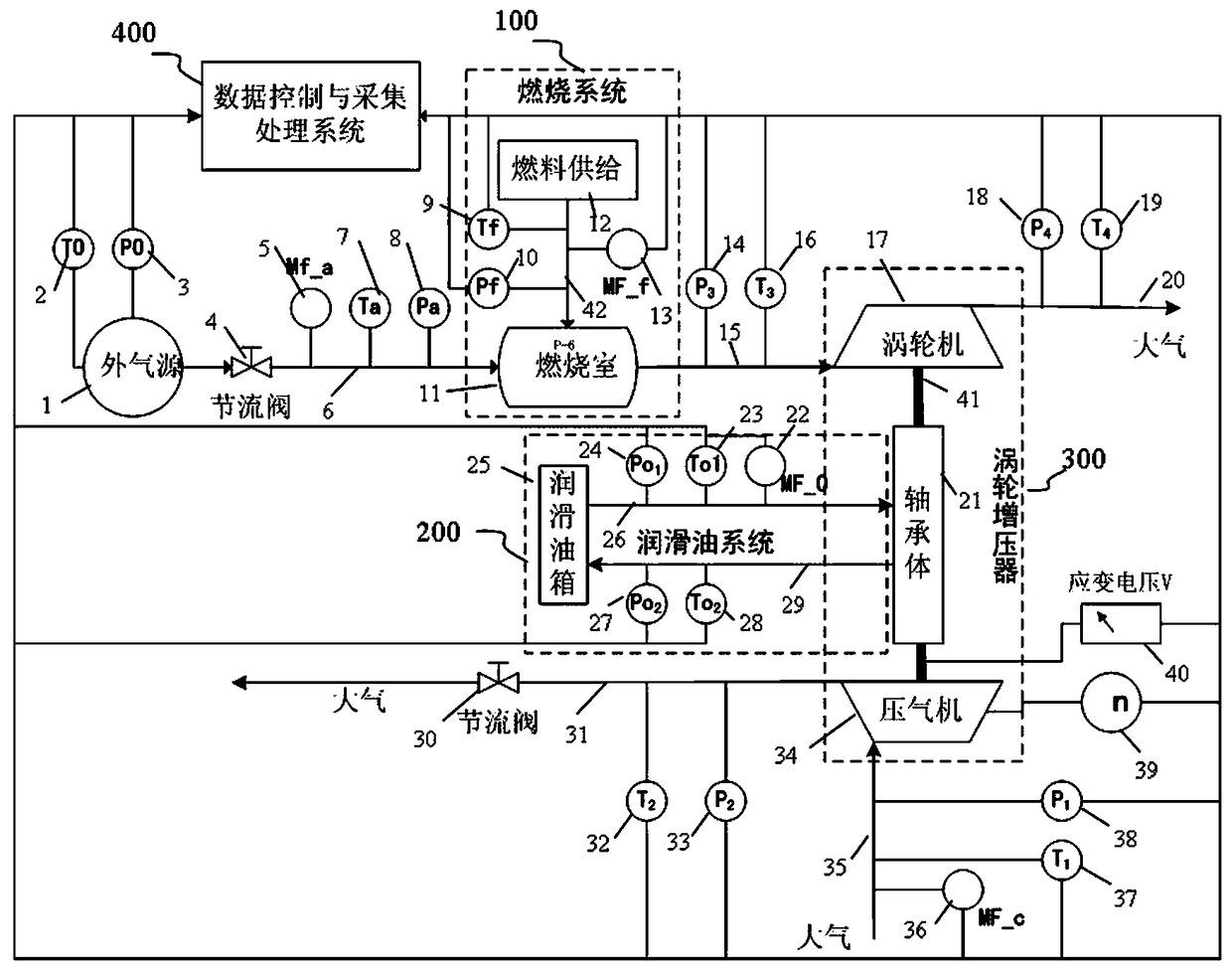

[0054] The detailed device of a turbocharger axial force measurement system of the present invention is as follows: figure 2 As shown, it includes an external air source 1, a combustion system 100, a lubricating oil system 200, a turbocharger 300, a data control and acquisition processing system 400, peripheral pipeline auxiliary systems and sensors.

[0055] The external air source 1 provides compressed air to enter the combustion chamber 11 through the combustion chamber intake pipeline 6, and the fuel supply system 12 in the combustion system 100 provides a corresponding proportion of fuel, which is fully mixed with the compressed air in the combustion chamber 11 to provide The gas that provides the required energy to the turbocharger 300 makes the working state of the turbocharger 300 conform to the actual working state of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com