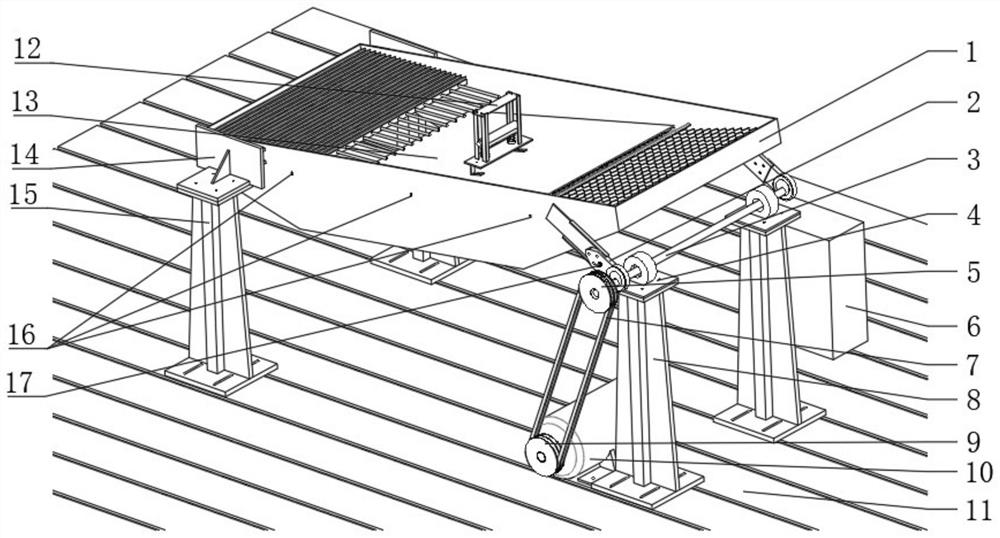

Test bed and test method for quality reliability of cleaning screen box

A test bench, reliable technology, applied in the field of agricultural harvesters, can solve problems such as can not be used to simulate periodic loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] As shown in FIG. 4, the loading mechanism 12 includes a counterweight slider 1202, a loading mechanism main body 1203 and a support frame

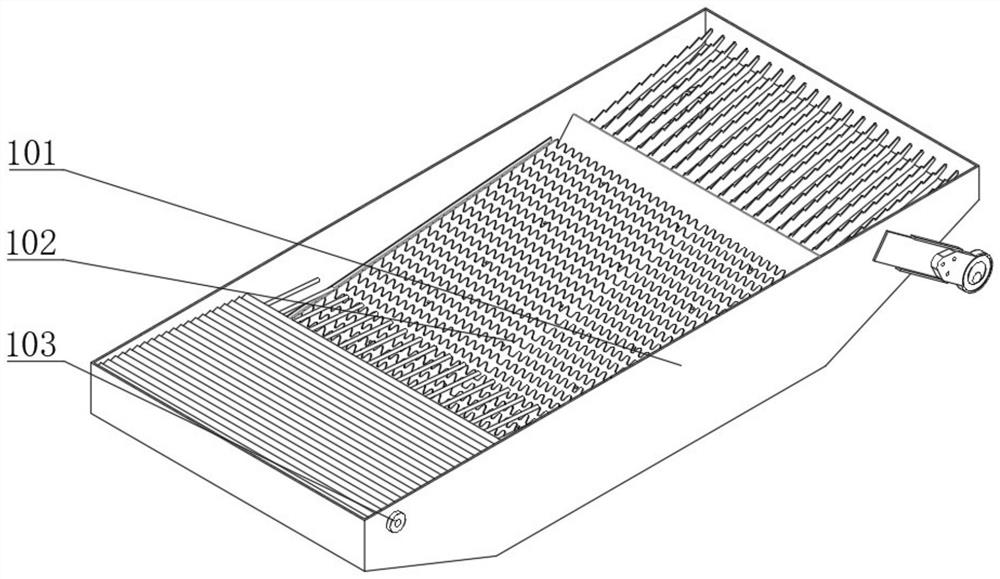

[0048] As shown in Figures 7 and 8, a number of the strain gauge sensors 16 are mounted on the outer surface of the screen box wall 101 for

[0055] It should be understood that although this specification is described in terms of various embodiments, not every embodiment includes only a

[0056] The series of detailed descriptions listed above are only specific descriptions for feasible embodiments of the present invention,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com