Modified epoxy resin adhesive and application thereof in hard mica plate

An epoxy resin glue, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of low cutting accuracy, brittle mica board, and many debris, and improve the adhesion. The effect of knot strength, increased wettability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

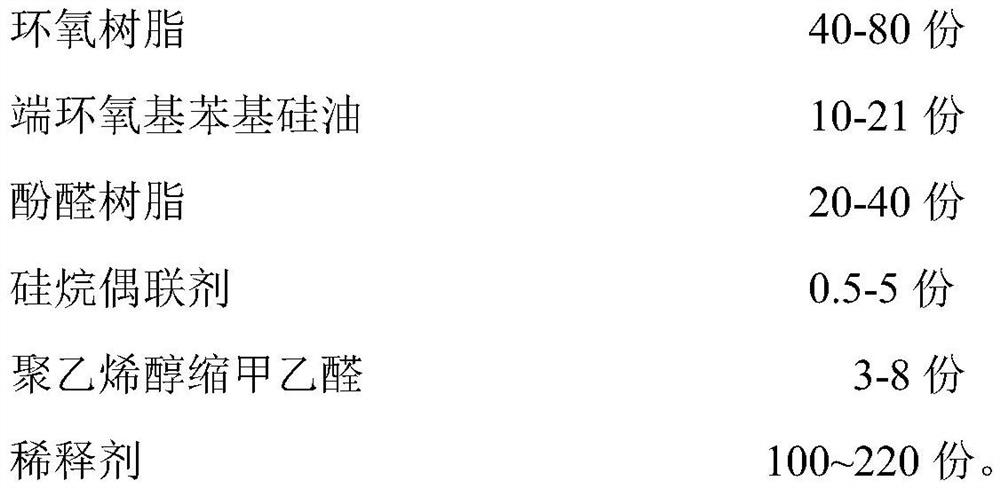

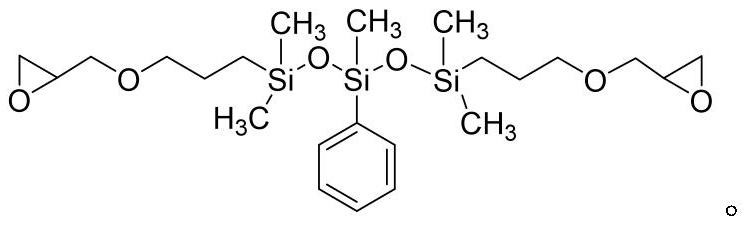

[0026] Put 60kg of epoxy resin, 12kg of epoxy-terminated phenyl silicone oil, 27kg of liquid phenolic resin, 5kg of polyvinyl formal, and 84kg of toluene into the reaction kettle, start stirring and heating, and keep warm at 105°C for 1.5h to make the materials Completely dissolve and mix evenly, turn on the cooling water to cool down the material, when the temperature of the material drops to 27°C±3°C, add 126kg of methanol and 2.5kg of γ-glycidyl etheroxypropyltrimethoxysilane into the reaction kettle, continue stirring for 30min, put The material is modified epoxy resin glue.

Embodiment 2

[0028] Put 55kg of epoxy resin, 16kg of epoxy-terminated phenyl silicone oil, 30kg of liquid phenolic resin, 8kg of polyvinyl formal, and 84kg of toluene into the reaction kettle, start stirring and heating, and keep warm at 105°C for 1.5h to make the materials Completely dissolve and mix evenly, turn on the cooling water to cool down the material, when the temperature of the material drops to 27°C±3°C, add 126kg of methanol and 3kg of β-(3,4 epoxycyclohexyl)ethyltrimethoxysilane to the reaction kettle, continue Stir for 30 minutes, and discharge to obtain the modified epoxy resin glue.

Embodiment 3

[0030] Put 50kg of epoxy resin, 21kg of epoxy-terminated phenyl silicone oil, 30kg of liquid phenolic resin, 7.5kg of polyvinyl formal, and 84kg of toluene into the reaction kettle, start stirring and heating, and keep warm at 105°C for 1.5h. The material is completely dissolved and mixed evenly, and the cooling water is turned on to cool the material. When the temperature of the material drops to 27°C±3°C, add 126kg of methanol and 5kg of glycidoxypropylmethyldiethoxysilane into the reaction kettle, and continue stirring for 30min. The modified epoxy resin glue is obtained by discharging the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com