Efficient cloth cutting machine for garment production

A cloth breaking machine and high-efficiency technology, which is used in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy movement and wrinkles of the cloth, no cleaning device for the cloth breaking machine, affecting the quality of the cloth, etc., so as to improve work safety performance. , Good shock absorption, firm and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

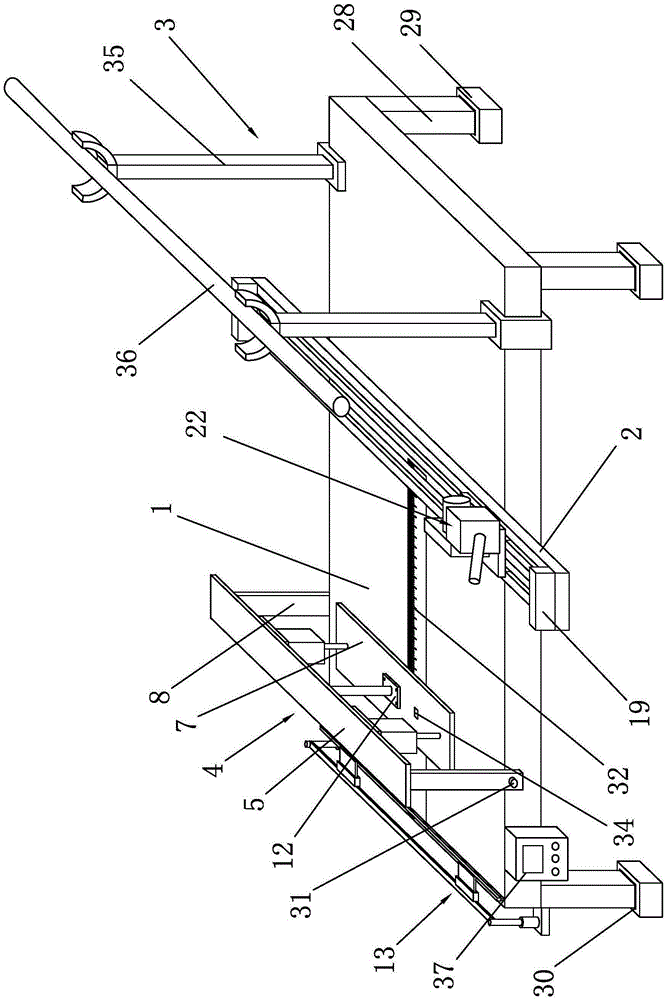

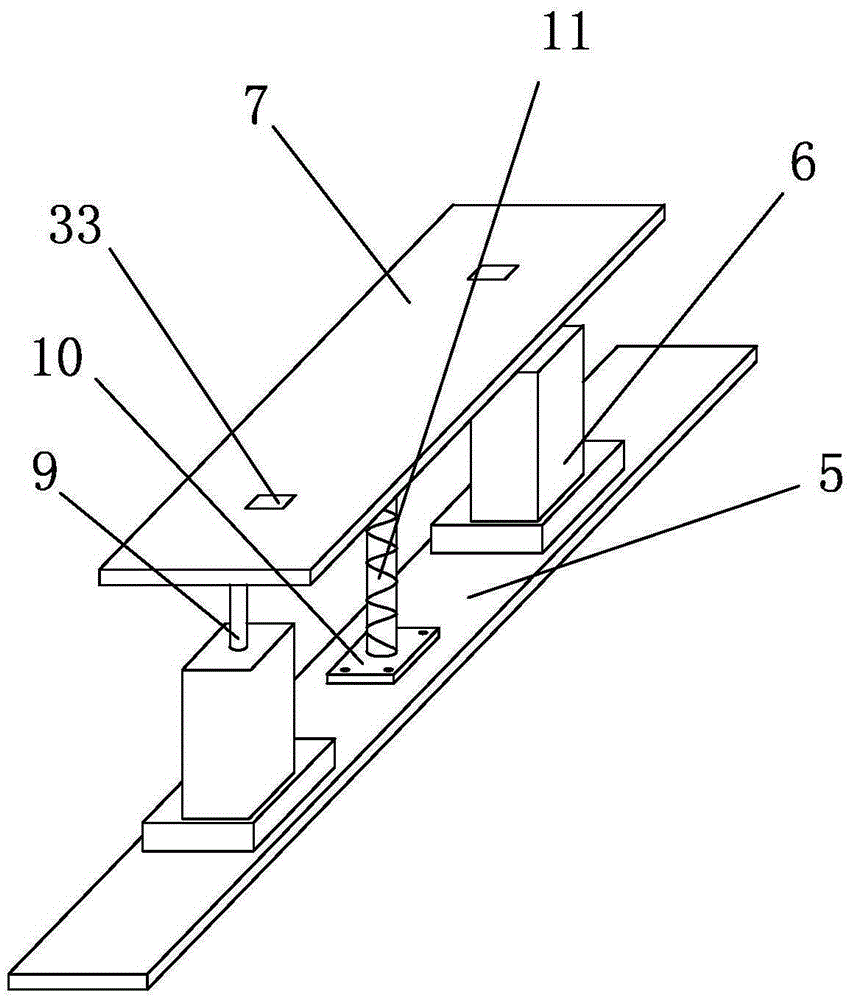

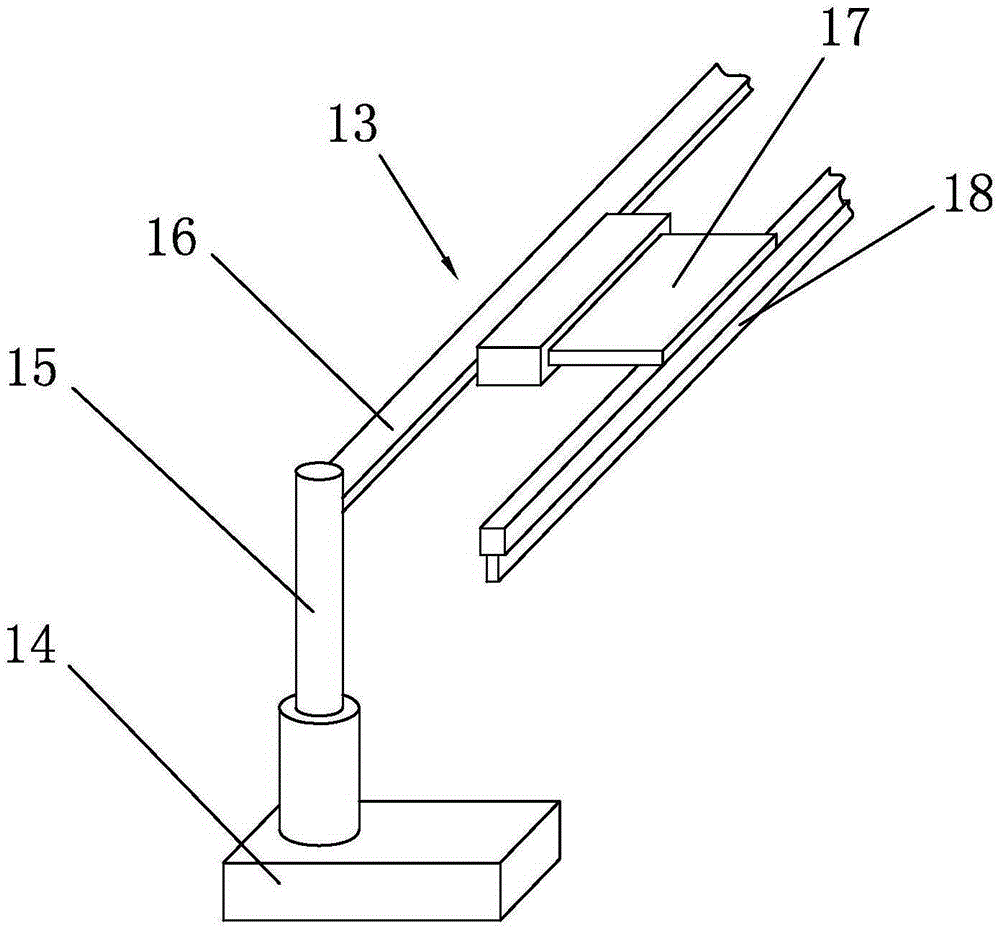

[0030] Such as Figure 1 to Figure 5 As shown, it is a high-efficiency cloth cutting machine for garment production, including a cutting workbench 1, a guide rail 2 and a raw material support 3, an operation box 37 is arranged on the cutting workbench 1, and an operation button is arranged on the operation box 37 , the operation buttons include a cleaning button, a start button and a stop button. The design of the operation box 37 makes the operation of the whole cloth cutting machine more convenient and simple. Press the cleaning button, and the cleaning device 13 starts to work, and the cutting workbench 1 is cleaned. , button start button, and the cloth cutting machine starts to work. When a problem is found, press the stop button and the whole cloth cutting machine stops working, which is convenient and safe. At least four supporting legs 28 are arranged below the cutting workbench 1 to support The bottom of legs 28 is provided with damping device 29, the design of support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com