Trimming circle shear for galvanized steel sheet

A technology of galvanized steel sheet and disc shear, applied in shearing device, shearing machine equipment, accessories of shearing machine, etc., can solve the problem of trimming burrs and edge wire defects, and the error between the width of the steel strip and the set width is large. , Unable to adjust the oil drop in the processing state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

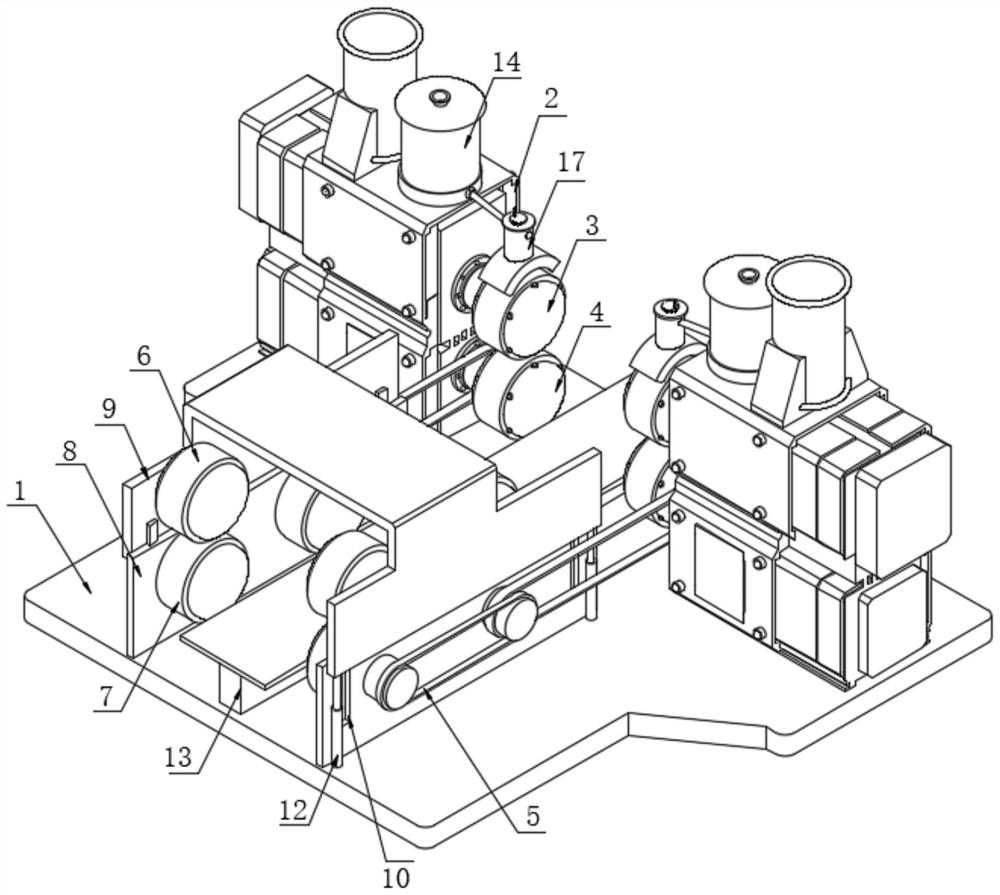

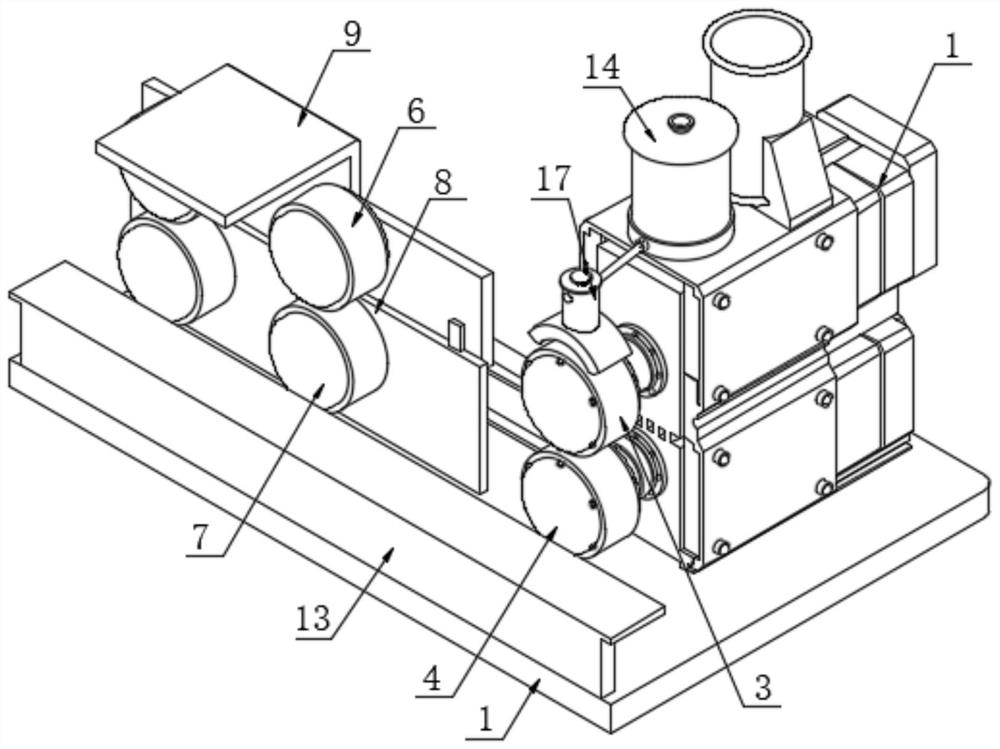

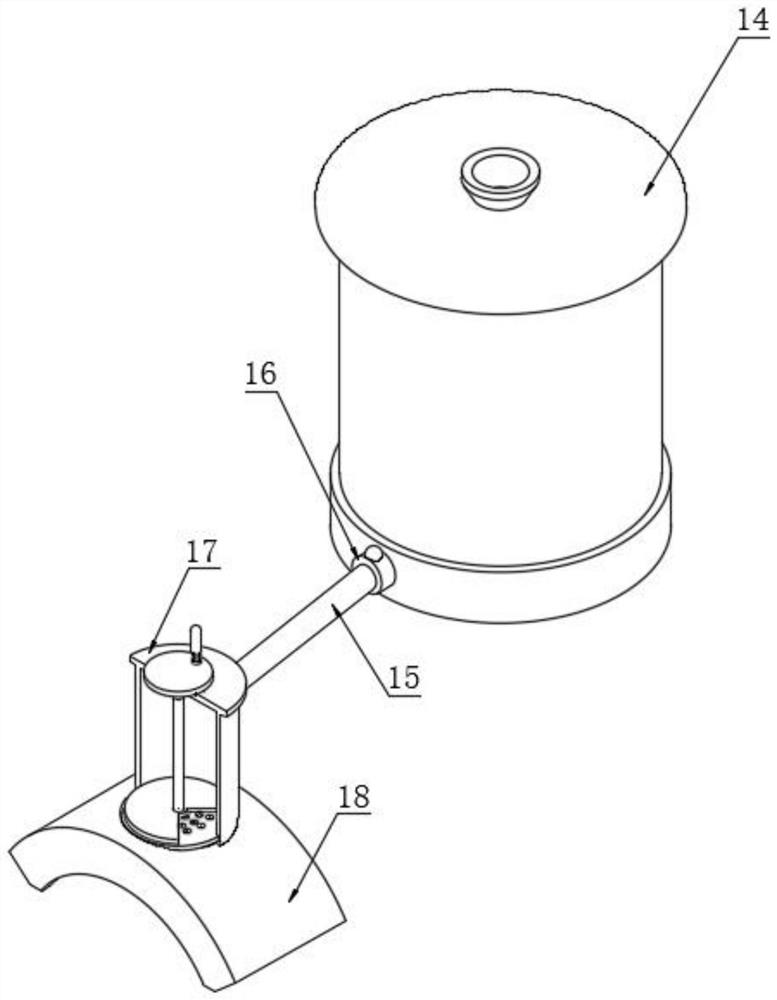

[0032] Such as Figure 1-7 As shown, the present invention provides a kind of technical scheme: a kind of galvanized steel sheet trimming disc shears, including base plate 1, the upper surface of base plate 1 is fixedly connected with the lower surface of disc shears body 2, the inner wall of disc shears body 2 An upper cutterhead 3 and a lower cutterhead 4 are arranged on the left and right sides, the upper surface of the bottom plate 1 is fixedly connected with the lower surfaces of the two baffles 8, and two transmission rollers 7 are arranged on the opposite surfaces of the two baffles 8, The output shafts corresponding to the two transmission rollers 7 and the lower cutterhead 4 are all connected by transmission belt 5. By setting the transmission belt 5, the lower cutterhead 4 is driven to rotate, so that it drives the transmission roller 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com