Double-blade cutting machine

A cutting machine and blade technology, which is applied in the field of clothing manufacturing machinery, can solve the problems of not being able to guarantee a good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

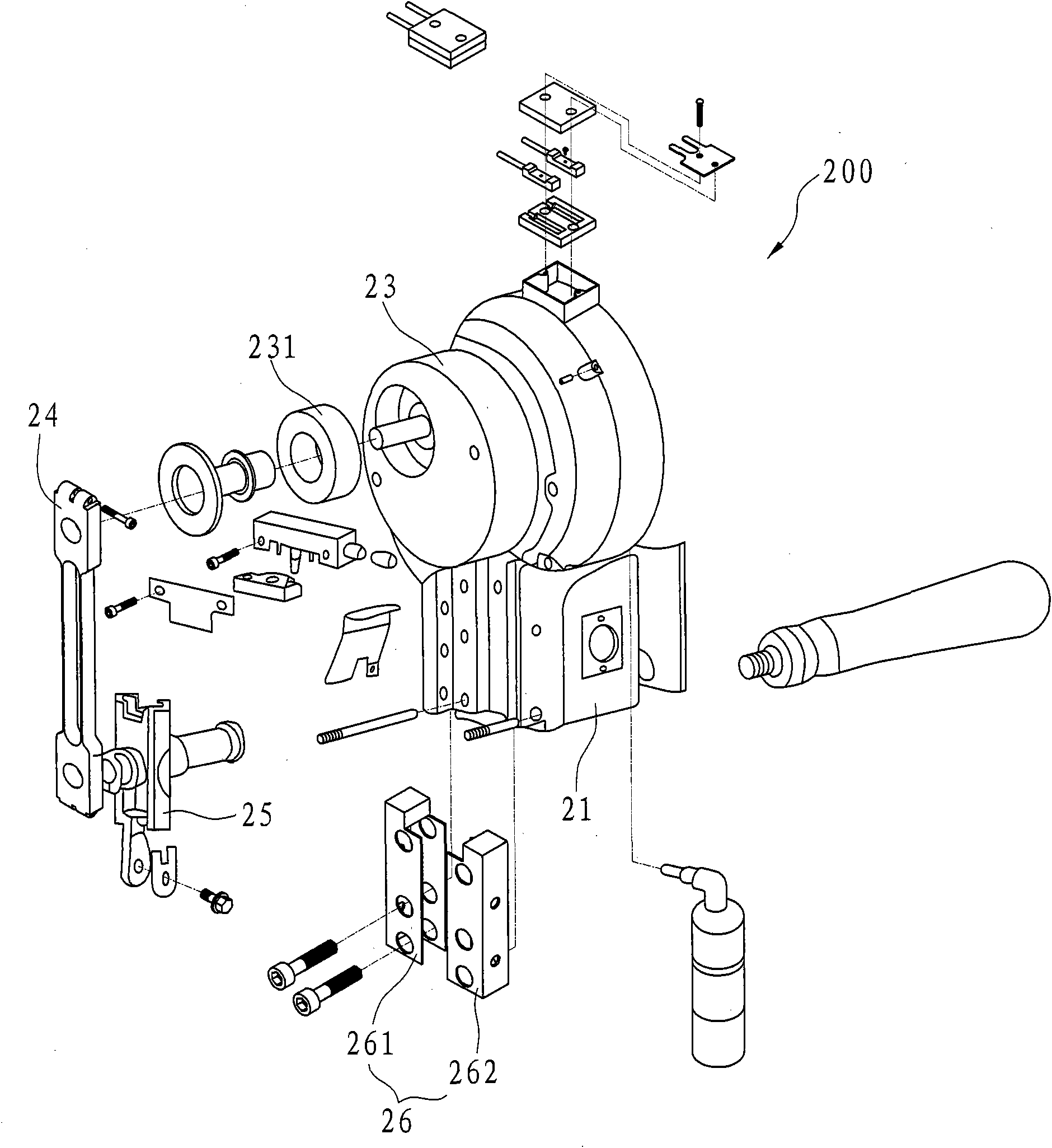

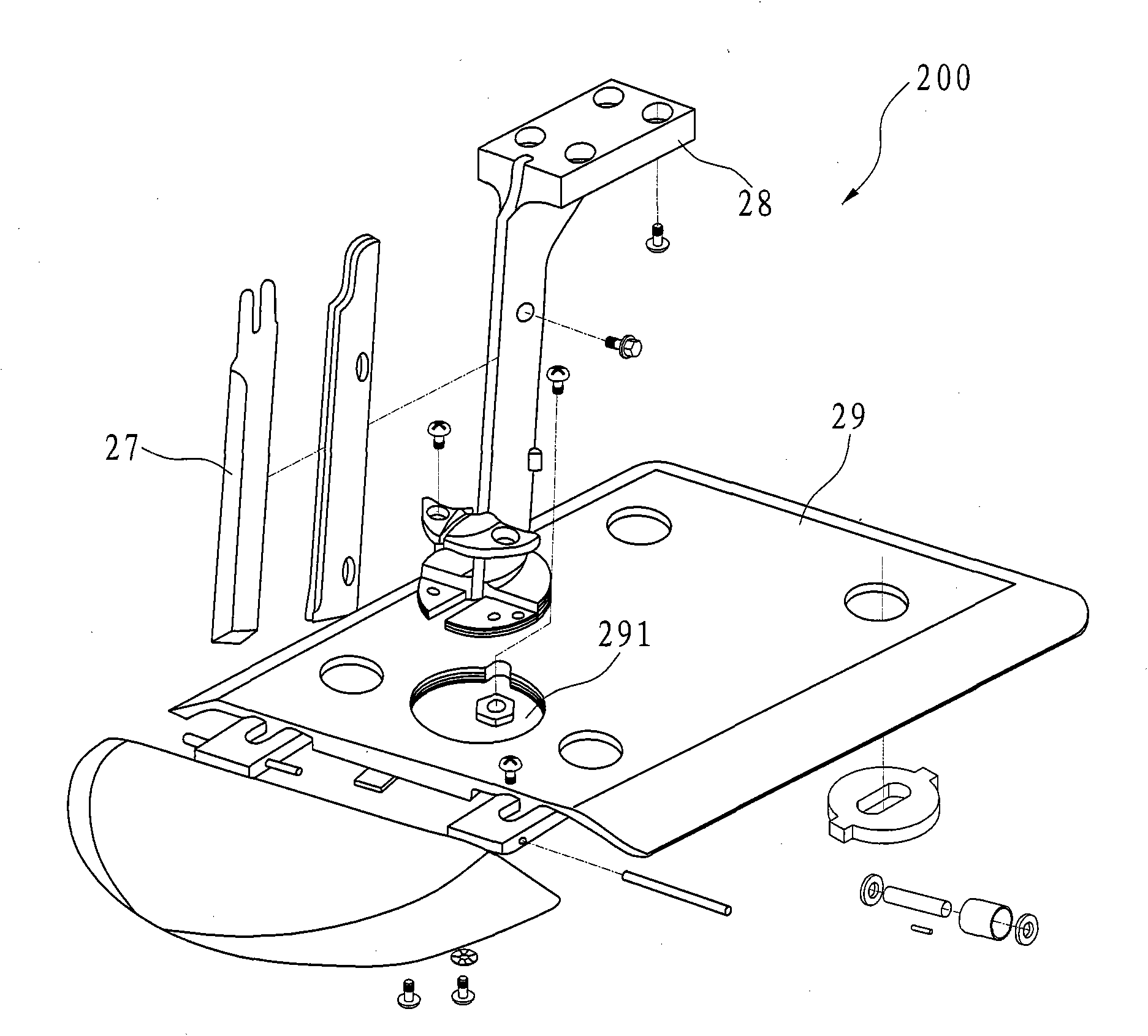

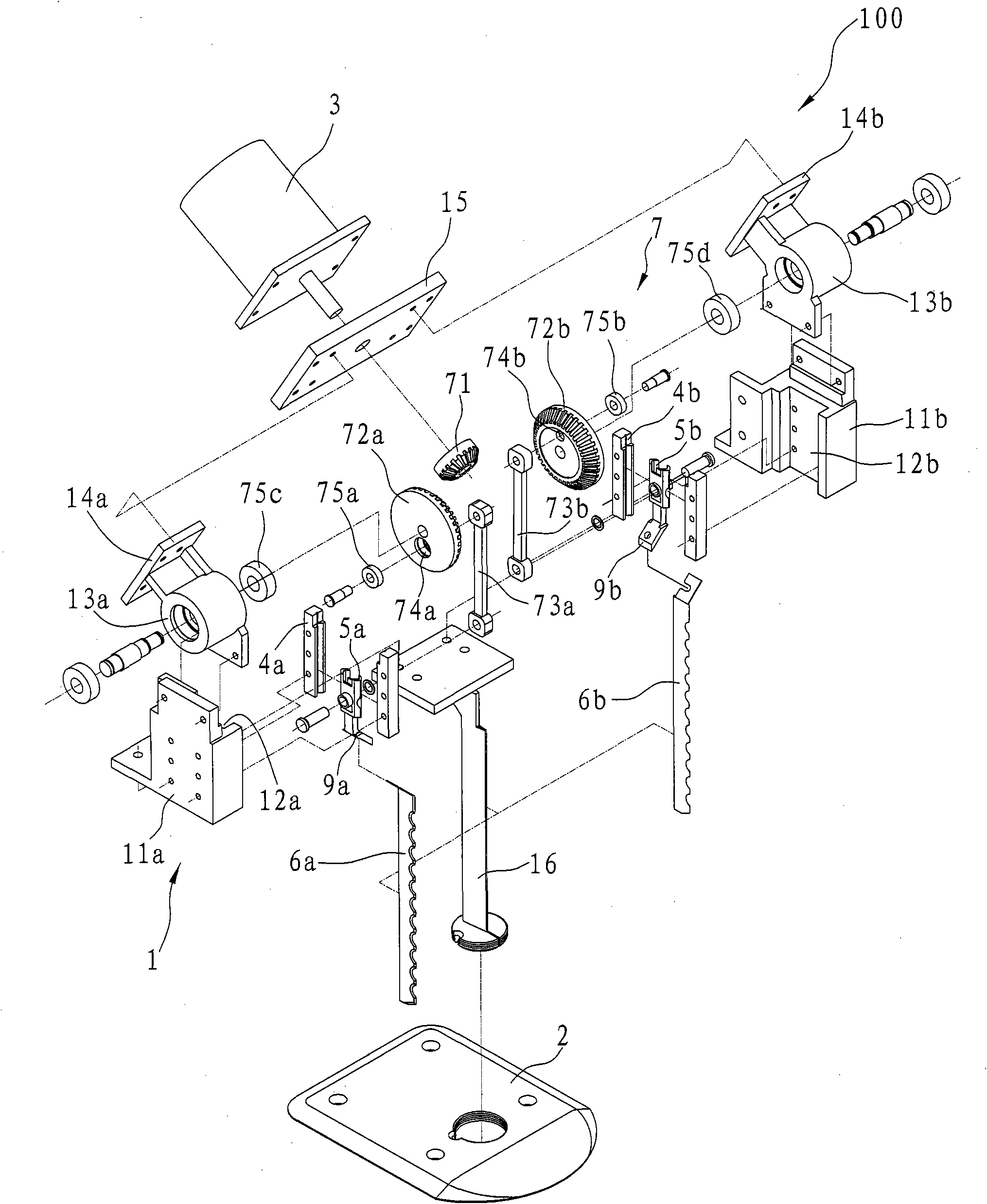

[0058] Such as Figure 3 to Figure 5 As shown, what it shows is a kind of double-knife cutting machine 100 related to the present invention, which includes a frame 1, a chassis 2 and a motor 3 arranged on the frame 1, and the frame 1 is used as the double-knife cutting machine of the present invention The carrying body of 100, the chassis 2 is completely consistent with the chassis 2 in the prior art, and it is also used for the cloth to be arranged on it for the cutting machine to cut, and the motor 3 plays the role of providing power, of course it is the same 3. Other power devices with equivalent functions should also belong to the protection scope of this case. In addition, the double-knife cutting machine 100 can also include a knife magazine 16 to play the functions of knife storage and knife exchange. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com