Metal plate less-cutting machining equipment for mechanical part manufacturing

A technology for the manufacture and cutting of mechanical parts, which is applied in the field of metal plate less cutting and processing equipment for the manufacture of mechanical parts, can solve problems such as troubles, and achieve the effect of avoiding repositioning, reasonable design and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

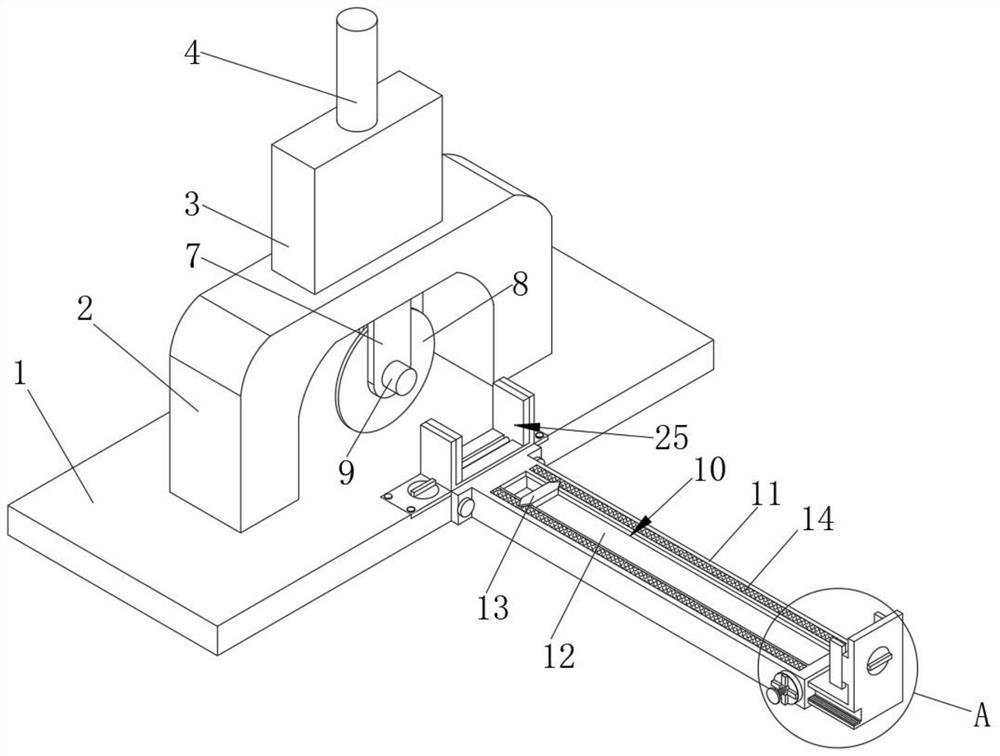

[0024] Embodiment 1: When the sheet metal needs to be clamped, the present invention provides such figure 1 , Figure 4 In the shown metal plate-less cutting processing equipment for the manufacture of mechanical parts, one side of the fixed plate 1 is fixed with a measuring assembly 10 for assisting the measurement and positioning of the metal parts through bolts,

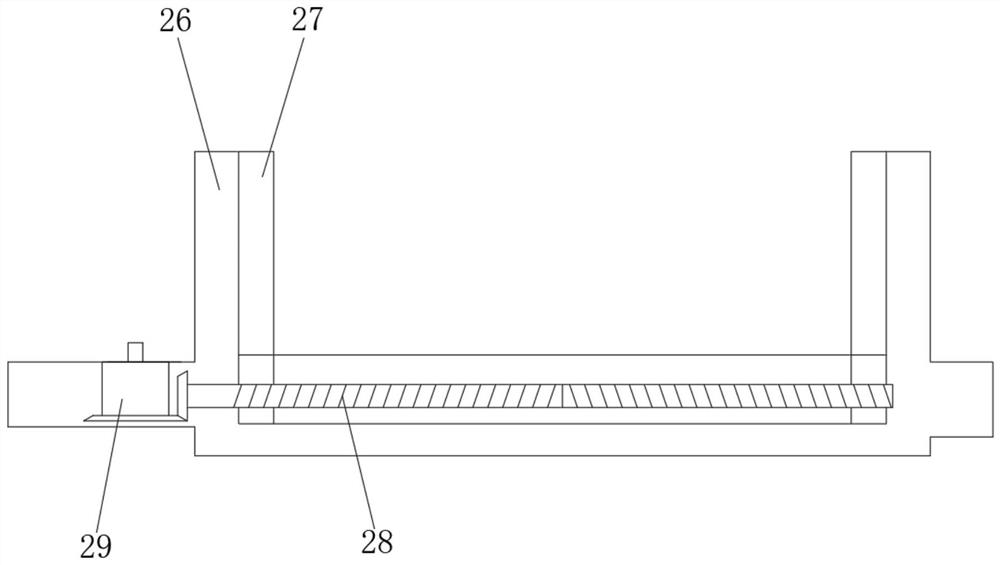

[0025] The measuring assembly 10 includes a fixing box 11 fixed on the side of the fixing plate 1 by bolts and an extending plate 12 installed in the fixing box 11. The measuring assembly 10 can conveniently check the length of the forging during work. For quick and effective cutting and positioning, a protruding plate 15 protrudes from one end of the protruding plate 12 extending out of the fixing box 11 , and a clamping structure 16 is provided on the inner side of the protruding plate 15 .

[0026] Specifically, the clamping structure 16 includes a clamping block 161 fixed on the protruding plate 15 and a fast...

Embodiment 2

[0029] Embodiment 2: after clamping, the present invention provides such as figure 1 , Figure 4 In the metal plate-less cutting processing equipment shown for the manufacture of mechanical parts, the side of the fixed box 11 close to the protruding plate 15 is provided with a positioning structure 21 that assists in the adjustment of the protruding plate 12 .

[0030] Specifically, a transmission groove is opened on the side of the extending plate 12 close to the positioning structure 21, and an engaging plate 121 is fixed at the bottom of the transmission groove. Wheel 22, the positioning structure 21 can quickly position and fasten the insertion plate 12 after the adjustment of the measuring assembly 10 in the working process, so as to avoid the occurrence of forging movement during cutting. One side of the adjustment wheel 22 A transmission wheel 24 is fixed on the side, and a jacking bolt 23 is installed transversely on the adjustment wheel 22 .

[0031] Specifically, t...

Embodiment 3

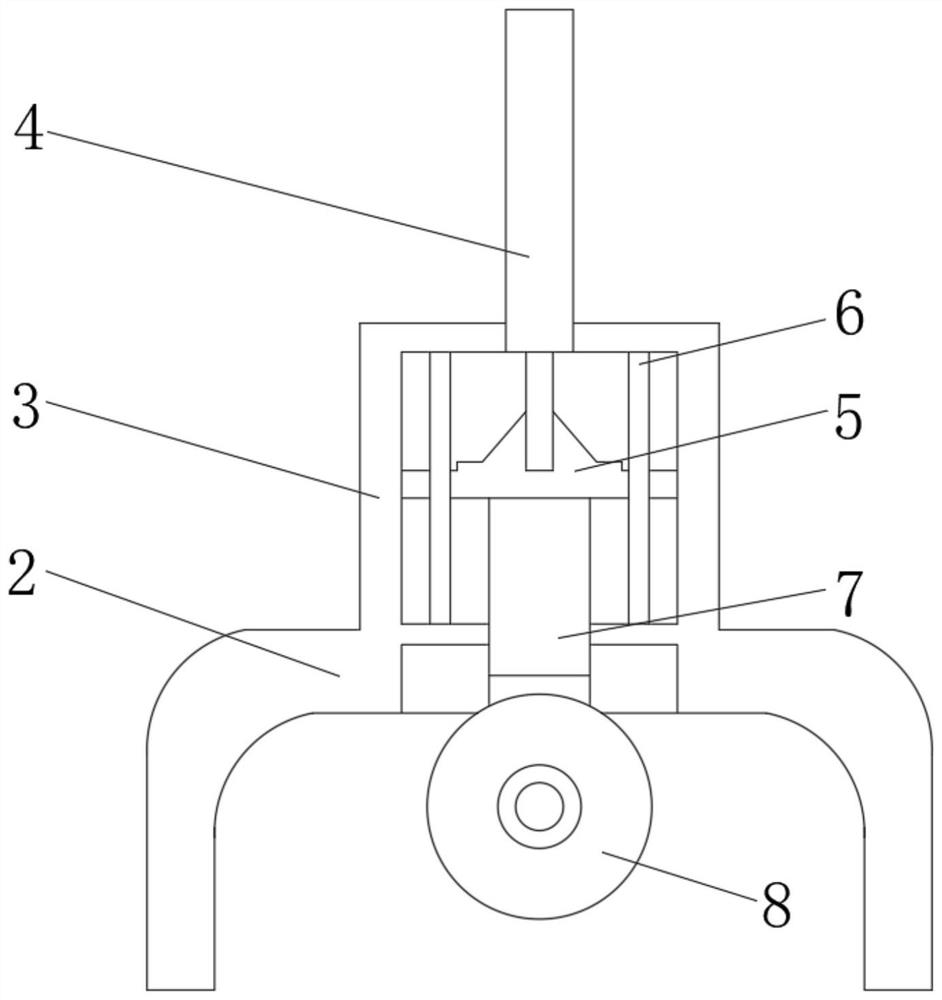

[0035] Embodiment 3: when cutting, the present invention provides as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 The shown metal plate-less cutting processing equipment for the manufacture of mechanical parts includes a fixed plate 1 and an inverted U-shaped support frame 2 installed on the top of the fixed plate 1, and a fixed frame 3 is fixed on the top of the support frame 2. A hydraulic rod 4 is fixed at the top of the fixed frame 3, and the extending end of the hydraulic rod 4 extends into the fixed frame 3, and one end extending into the fixed frame 3 is fixed with a push plate 5, and the inside of the fixed frame 3 is symmetrically fixed with Two guide rods 6, the push plate 5 is installed on the guide rod 6, the guide rod 6 can play an auxiliary guiding role in the working process, and the bottom of the push plate 5 is fixed with a mounting frame for the cutting wheel 8 to install 7. A cutting motor 9 that drives the cutting wheel 8 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com